Dimethyl Ether Across Global Energy Policy Frameworks

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Energy Policy Background and Objectives

Dimethyl ether (DME) has emerged as a promising alternative fuel in global energy policy frameworks, driven by the urgent need for cleaner and more sustainable energy sources. The background of DME in energy policy is rooted in the growing concerns over climate change, air pollution, and energy security. As nations worldwide seek to reduce their carbon footprint and transition away from fossil fuels, DME has gained attention for its potential to address these challenges.

The development of DME as an energy solution can be traced back to the late 20th century, with initial research focusing on its use as a propellant and aerosol. However, it was not until the early 2000s that DME began to be seriously considered as a viable alternative fuel for transportation and power generation. This shift in focus was largely driven by the increasing stringency of environmental regulations and the need for cleaner-burning fuels.

One of the primary objectives of incorporating DME into global energy policy frameworks is to reduce greenhouse gas emissions. DME produces significantly lower carbon dioxide emissions compared to conventional fossil fuels, making it an attractive option for countries striving to meet their climate change mitigation targets. Additionally, DME combustion results in minimal particulate matter and sulfur oxide emissions, addressing air quality concerns in urban areas.

Another key objective is to enhance energy security by diversifying fuel sources. DME can be produced from a variety of feedstocks, including natural gas, coal, and biomass, allowing countries to leverage their domestic resources and reduce dependence on imported oil. This flexibility in production aligns with the goals of many nations to achieve greater energy independence and resilience.

The integration of DME into energy policies also aims to promote technological innovation and economic growth in the clean energy sector. By encouraging research, development, and deployment of DME technologies, policymakers seek to create new job opportunities and stimulate economic activity in related industries.

Furthermore, DME policies often target the improvement of rural economies and waste management practices. The potential for DME production from agricultural and forestry residues offers a pathway for rural communities to participate in the energy transition while addressing waste disposal challenges.

As global energy policies continue to evolve, the objectives surrounding DME are expanding to include its role in sector coupling and energy storage. The ability of DME to act as an energy carrier, capable of being used in both transportation and power generation, makes it a valuable component in integrated energy systems and the broader transition to a low-carbon economy.

The development of DME as an energy solution can be traced back to the late 20th century, with initial research focusing on its use as a propellant and aerosol. However, it was not until the early 2000s that DME began to be seriously considered as a viable alternative fuel for transportation and power generation. This shift in focus was largely driven by the increasing stringency of environmental regulations and the need for cleaner-burning fuels.

One of the primary objectives of incorporating DME into global energy policy frameworks is to reduce greenhouse gas emissions. DME produces significantly lower carbon dioxide emissions compared to conventional fossil fuels, making it an attractive option for countries striving to meet their climate change mitigation targets. Additionally, DME combustion results in minimal particulate matter and sulfur oxide emissions, addressing air quality concerns in urban areas.

Another key objective is to enhance energy security by diversifying fuel sources. DME can be produced from a variety of feedstocks, including natural gas, coal, and biomass, allowing countries to leverage their domestic resources and reduce dependence on imported oil. This flexibility in production aligns with the goals of many nations to achieve greater energy independence and resilience.

The integration of DME into energy policies also aims to promote technological innovation and economic growth in the clean energy sector. By encouraging research, development, and deployment of DME technologies, policymakers seek to create new job opportunities and stimulate economic activity in related industries.

Furthermore, DME policies often target the improvement of rural economies and waste management practices. The potential for DME production from agricultural and forestry residues offers a pathway for rural communities to participate in the energy transition while addressing waste disposal challenges.

As global energy policies continue to evolve, the objectives surrounding DME are expanding to include its role in sector coupling and energy storage. The ability of DME to act as an energy carrier, capable of being used in both transportation and power generation, makes it a valuable component in integrated energy systems and the broader transition to a low-carbon economy.

Global Market Demand for DME as Alternative Fuel

The global market demand for Dimethyl Ether (DME) as an alternative fuel has been steadily growing, driven by increasing environmental concerns and the need for cleaner energy sources. DME, a colorless gas at ambient conditions, has gained attention as a potential substitute for conventional fossil fuels, particularly in the transportation and power generation sectors.

In the transportation industry, DME has shown promise as a replacement for diesel fuel in heavy-duty vehicles. Its high cetane number and clean-burning properties make it an attractive option for reducing emissions and improving air quality in urban areas. Several countries, including China, Japan, and Sweden, have conducted extensive trials and pilot projects to evaluate the feasibility of DME-powered vehicles.

The power generation sector has also expressed interest in DME as a fuel for gas turbines and combined cycle power plants. Its low emissions profile and compatibility with existing natural gas infrastructure make it an appealing option for utilities seeking to reduce their carbon footprint while maintaining operational flexibility.

In the residential and commercial sectors, DME has found applications as a cooking fuel and heating source, particularly in regions with limited access to natural gas networks. Its ease of liquefaction and transportation has made it a viable alternative to liquefied petroleum gas (LPG) in some markets.

The Asia-Pacific region, led by China, has emerged as the largest market for DME, driven by government initiatives to promote cleaner fuels and reduce dependence on imported oil. Europe and North America have also shown growing interest in DME, with several pilot projects and research initiatives underway to assess its potential in various applications.

Despite the promising outlook, the global market demand for DME as an alternative fuel faces several challenges. These include the need for significant infrastructure investments, competition from other alternative fuels such as biodiesel and electric vehicles, and the current reliance on methanol as the primary feedstock for DME production.

To address these challenges and stimulate market growth, policymakers and industry stakeholders are exploring various strategies. These include developing more efficient and cost-effective production methods, establishing supportive regulatory frameworks, and promoting public-private partnerships to accelerate the adoption of DME technologies.

In the transportation industry, DME has shown promise as a replacement for diesel fuel in heavy-duty vehicles. Its high cetane number and clean-burning properties make it an attractive option for reducing emissions and improving air quality in urban areas. Several countries, including China, Japan, and Sweden, have conducted extensive trials and pilot projects to evaluate the feasibility of DME-powered vehicles.

The power generation sector has also expressed interest in DME as a fuel for gas turbines and combined cycle power plants. Its low emissions profile and compatibility with existing natural gas infrastructure make it an appealing option for utilities seeking to reduce their carbon footprint while maintaining operational flexibility.

In the residential and commercial sectors, DME has found applications as a cooking fuel and heating source, particularly in regions with limited access to natural gas networks. Its ease of liquefaction and transportation has made it a viable alternative to liquefied petroleum gas (LPG) in some markets.

The Asia-Pacific region, led by China, has emerged as the largest market for DME, driven by government initiatives to promote cleaner fuels and reduce dependence on imported oil. Europe and North America have also shown growing interest in DME, with several pilot projects and research initiatives underway to assess its potential in various applications.

Despite the promising outlook, the global market demand for DME as an alternative fuel faces several challenges. These include the need for significant infrastructure investments, competition from other alternative fuels such as biodiesel and electric vehicles, and the current reliance on methanol as the primary feedstock for DME production.

To address these challenges and stimulate market growth, policymakers and industry stakeholders are exploring various strategies. These include developing more efficient and cost-effective production methods, establishing supportive regulatory frameworks, and promoting public-private partnerships to accelerate the adoption of DME technologies.

Current Status and Challenges in DME Adoption

The global adoption of Dimethyl Ether (DME) as an alternative fuel faces several challenges despite its potential as a clean-burning, low-carbon energy source. Currently, DME production and utilization are limited to a few countries, with China leading in both production capacity and consumption. The primary use of DME is as a substitute for liquefied petroleum gas (LPG) in household and industrial applications, while its use as a transportation fuel remains in the early stages of development.

One of the main challenges in DME adoption is the lack of widespread infrastructure for production, distribution, and end-use applications. Unlike conventional fuels, DME requires specialized handling and storage facilities, which are not readily available in most regions. This infrastructure gap significantly hinders the expansion of DME use beyond localized areas where production and consumption are already established.

Another significant hurdle is the economic viability of DME production and use compared to conventional fuels. While DME can be produced from various feedstocks, including natural gas, coal, and biomass, the production costs are often higher than those of traditional fuels. This cost differential makes it challenging for DME to compete in the energy market without substantial policy support or incentives.

Regulatory frameworks and policy support for DME vary widely across different countries and regions. While some nations, particularly in Asia, have implemented policies to promote DME use, many others lack clear regulatory guidelines or incentives for its adoption. This inconsistency in policy approaches creates uncertainty for potential investors and slows down the development of a global DME market.

Technical challenges also persist in the widespread adoption of DME. For instance, when used as a transportation fuel, DME requires modifications to existing diesel engines and fuel systems. While these modifications are technically feasible, they represent an additional barrier to adoption, particularly in the automotive sector where standardization and cost-effectiveness are crucial.

Furthermore, public awareness and acceptance of DME as an alternative fuel remain limited. Many consumers and businesses are unfamiliar with DME and its potential benefits, which hampers market demand and slows the transition from conventional fuels.

Despite these challenges, ongoing research and development efforts are addressing many of these issues. Improvements in production technologies are gradually reducing costs, while pilot projects in various countries are demonstrating the feasibility of DME use in different applications. However, overcoming these challenges will require coordinated efforts from policymakers, industry stakeholders, and researchers to create a supportive environment for DME adoption on a global scale.

One of the main challenges in DME adoption is the lack of widespread infrastructure for production, distribution, and end-use applications. Unlike conventional fuels, DME requires specialized handling and storage facilities, which are not readily available in most regions. This infrastructure gap significantly hinders the expansion of DME use beyond localized areas where production and consumption are already established.

Another significant hurdle is the economic viability of DME production and use compared to conventional fuels. While DME can be produced from various feedstocks, including natural gas, coal, and biomass, the production costs are often higher than those of traditional fuels. This cost differential makes it challenging for DME to compete in the energy market without substantial policy support or incentives.

Regulatory frameworks and policy support for DME vary widely across different countries and regions. While some nations, particularly in Asia, have implemented policies to promote DME use, many others lack clear regulatory guidelines or incentives for its adoption. This inconsistency in policy approaches creates uncertainty for potential investors and slows down the development of a global DME market.

Technical challenges also persist in the widespread adoption of DME. For instance, when used as a transportation fuel, DME requires modifications to existing diesel engines and fuel systems. While these modifications are technically feasible, they represent an additional barrier to adoption, particularly in the automotive sector where standardization and cost-effectiveness are crucial.

Furthermore, public awareness and acceptance of DME as an alternative fuel remain limited. Many consumers and businesses are unfamiliar with DME and its potential benefits, which hampers market demand and slows the transition from conventional fuels.

Despite these challenges, ongoing research and development efforts are addressing many of these issues. Improvements in production technologies are gradually reducing costs, while pilot projects in various countries are demonstrating the feasibility of DME use in different applications. However, overcoming these challenges will require coordinated efforts from policymakers, industry stakeholders, and researchers to create a supportive environment for DME adoption on a global scale.

Existing DME Production and Utilization Methods

01 Production of dimethyl ether

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.- Production of dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

- Catalysts for dimethyl ether synthesis: Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.

- Applications of dimethyl ether: Dimethyl ether has various applications, including use as a fuel substitute, propellant, refrigerant, and chemical intermediate. Its properties make it suitable for use in diesel engines, aerosol products, and as a building block for other chemicals.

- Purification and separation of dimethyl ether: Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes may involve distillation, adsorption, or membrane separation techniques to obtain high-purity dimethyl ether.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of dimethyl ether production and use is presented. This includes studies on emissions reduction, handling procedures, and risk assessments associated with its use as an alternative fuel or chemical feedstock.

02 Catalysts for dimethyl ether synthesis

Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice and preparation of catalysts significantly influence the efficiency and selectivity of the dimethyl ether synthesis process.Expand Specific Solutions03 Applications of dimethyl ether

Dimethyl ether has various applications, including use as a fuel additive, propellant, refrigerant, and chemical intermediate. Its properties make it suitable for use in diesel engines, aerosol products, and as a building block for other chemicals.Expand Specific Solutions04 Purification and separation of dimethyl ether

Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes often involve distillation, adsorption, or membrane separation techniques to obtain high-purity dimethyl ether.Expand Specific Solutions05 Environmental and safety considerations

Research on the environmental impact and safety aspects of dimethyl ether production and use is conducted. This includes studies on emissions reduction, handling procedures, and risk assessments associated with its use as an alternative fuel or chemical feedstock.Expand Specific Solutions

Key Stakeholders in DME Industry

The global dimethyl ether (DME) market is in a growth phase, driven by increasing focus on clean energy alternatives. The market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, DME production is relatively mature, but ongoing research aims to improve efficiency and reduce costs. Key players like China Petroleum & Chemical Corp., SK Energy, and BP Corporation North America are investing in DME technology development and production capacity. Academic institutions such as the University of Southern California and East China Normal University are contributing to research advancements. The involvement of diverse stakeholders, including energy companies, research institutes, and chemical manufacturers, indicates a competitive and evolving landscape for DME across global energy policy frameworks.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been at the forefront of dimethyl ether (DME) research and development. They have developed a proprietary process for large-scale DME production from syngas, which is derived from coal or natural gas. This process involves a single-step synthesis method that combines methanol synthesis and dehydration, improving efficiency and reducing costs[1]. Sinopec has also invested in DME as a clean alternative fuel for vehicles and household cooking, aligning with China's energy transition goals. They have established pilot projects for DME production and utilization, including a 100,000 tons/year DME plant in Shanxi province[2]. Furthermore, Sinopec has been actively involved in policy discussions to promote DME as part of China's energy mix, advocating for supportive regulatory frameworks and standards[3].

Strengths: Established infrastructure, large-scale production capability, and integration with existing energy systems. Weaknesses: Dependence on fossil fuel feedstocks, which may conflict with long-term decarbonization goals.

BP Corporation North America, Inc.

Technical Solution: BP has been exploring DME as part of its broader strategy to diversify its energy portfolio and reduce carbon emissions. The company has invested in research and development of DME production technologies, particularly focusing on bio-based feedstocks to create a more sustainable production pathway. BP's approach involves a two-step process: first, producing bio-methanol from biomass or waste, and then dehydrating it to form DME[4]. This method allows for the utilization of renewable resources, potentially reducing the carbon footprint of DME production. BP has also been involved in collaborative projects to assess the feasibility of DME as a marine fuel, recognizing its potential to help decarbonize the shipping industry[5]. Additionally, the company has been engaging with policymakers to advocate for the inclusion of DME in renewable fuel standards and incentive programs across various jurisdictions[6].

Strengths: Focus on renewable feedstocks, potential for carbon-neutral DME production. Weaknesses: Higher production costs compared to fossil fuel-based methods, limited existing infrastructure for bio-based DME.

Innovative DME Technologies and Patents

Energy supply method and system

PatentWO2006004140A1

Innovation

- The introduction of Dimethyl Ether (DME) as a versatile energy circulation medium, which can be derived from biomass, waste, and petroleum residues, and used for power generation, transportation, and heating, allowing for efficient energy storage and distribution without relying on pipelines, and enabling the conversion of waste heat into usable energy.

Dimethyl ether blended fuel alternative for diesel engines

PatentWO2017184538A1

Innovation

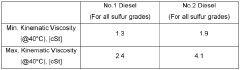

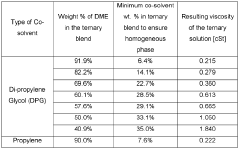

- A blended fuel of DME with di-propylene glycol (DPG) or propylene glycol (PG) and glycerol is developed to increase the viscosity of DME, allowing it to meet ASTM standards for No.1 and No.2 diesel oils, enabling its use in existing diesel engines with minimal modifications.

Environmental Impact of DME Usage

The environmental impact of Dimethyl Ether (DME) usage is a critical consideration in global energy policy frameworks. DME, as a clean-burning alternative fuel, offers several environmental advantages over traditional fossil fuels. Its combustion produces significantly lower levels of particulate matter, sulfur oxides, and nitrogen oxides compared to diesel fuel, contributing to improved air quality in urban areas and reduced smog formation.

One of the key environmental benefits of DME is its potential to reduce greenhouse gas emissions. When produced from renewable sources such as biomass or waste materials, DME can achieve near-zero or even negative carbon footprints. This characteristic aligns with global efforts to mitigate climate change and transition towards low-carbon energy systems. However, the environmental impact of DME production varies depending on the feedstock and production methods used, necessitating a comprehensive life cycle assessment for accurate evaluation.

DME's physical properties also contribute to its environmental profile. As a gas at ambient conditions, DME does not pose the same risks of soil and water contamination associated with liquid fuel spills. This reduces the potential for environmental damage in the event of accidents during transportation or storage. Additionally, DME's high cetane number and clean combustion characteristics enable more efficient engine operation, potentially leading to reduced fuel consumption and lower overall emissions.

In the context of air quality management, DME usage can play a significant role in reducing urban pollution. Its low particulate matter emissions make it particularly suitable for use in heavy-duty vehicles and industrial applications in densely populated areas. This can contribute to meeting increasingly stringent air quality standards and improving public health outcomes in cities struggling with air pollution.

The adoption of DME as an energy carrier also has implications for land use and biodiversity. When produced from sustainable biomass sources, DME can provide an additional revenue stream for agricultural and forestry sectors, potentially reducing pressure on natural habitats. However, careful management is required to ensure that DME production does not lead to deforestation or competition with food crops.

As global energy policies increasingly focus on sustainability and environmental protection, the environmental impact of DME usage is likely to be a key factor in determining its role in future energy systems. Policymakers and industry stakeholders must carefully consider the full lifecycle environmental impacts of DME, from production to end-use, to ensure its deployment aligns with broader environmental goals and contributes positively to global sustainability efforts.

One of the key environmental benefits of DME is its potential to reduce greenhouse gas emissions. When produced from renewable sources such as biomass or waste materials, DME can achieve near-zero or even negative carbon footprints. This characteristic aligns with global efforts to mitigate climate change and transition towards low-carbon energy systems. However, the environmental impact of DME production varies depending on the feedstock and production methods used, necessitating a comprehensive life cycle assessment for accurate evaluation.

DME's physical properties also contribute to its environmental profile. As a gas at ambient conditions, DME does not pose the same risks of soil and water contamination associated with liquid fuel spills. This reduces the potential for environmental damage in the event of accidents during transportation or storage. Additionally, DME's high cetane number and clean combustion characteristics enable more efficient engine operation, potentially leading to reduced fuel consumption and lower overall emissions.

In the context of air quality management, DME usage can play a significant role in reducing urban pollution. Its low particulate matter emissions make it particularly suitable for use in heavy-duty vehicles and industrial applications in densely populated areas. This can contribute to meeting increasingly stringent air quality standards and improving public health outcomes in cities struggling with air pollution.

The adoption of DME as an energy carrier also has implications for land use and biodiversity. When produced from sustainable biomass sources, DME can provide an additional revenue stream for agricultural and forestry sectors, potentially reducing pressure on natural habitats. However, careful management is required to ensure that DME production does not lead to deforestation or competition with food crops.

As global energy policies increasingly focus on sustainability and environmental protection, the environmental impact of DME usage is likely to be a key factor in determining its role in future energy systems. Policymakers and industry stakeholders must carefully consider the full lifecycle environmental impacts of DME, from production to end-use, to ensure its deployment aligns with broader environmental goals and contributes positively to global sustainability efforts.

Regulatory Frameworks for DME Implementation

The implementation of Dimethyl Ether (DME) as an alternative fuel source is subject to various regulatory frameworks across different countries and regions. These frameworks play a crucial role in shaping the adoption and utilization of DME in the global energy landscape.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for the use of DME as a transportation fuel. The EPA's Renewable Fuel Standard (RFS) program includes DME as an eligible renewable fuel, providing incentives for its production and use. Additionally, the Department of Energy (DOE) has supported research and development initiatives to promote DME as a clean alternative fuel.

The European Union has implemented the Renewable Energy Directive (RED II), which sets targets for renewable energy consumption in the transport sector. DME derived from renewable sources is recognized as a viable option to meet these targets. The directive also establishes sustainability criteria for biofuels, including DME, to ensure environmental benefits and reduce greenhouse gas emissions.

In Asia, countries like China and Japan have taken proactive steps to incorporate DME into their energy policies. China has included DME in its national energy strategy, promoting its use in industrial applications and as a substitute for liquefied petroleum gas (LPG). Japan has established technical standards for DME fuel and vehicles, facilitating its integration into the transportation sector.

Regulatory frameworks for DME implementation often address safety standards, fuel quality specifications, and infrastructure requirements. For instance, the International Organization for Standardization (ISO) has developed standards for DME fuel quality (ISO 16861) and DME fuel systems for vehicles (ISO 21087), providing a foundation for consistent global implementation.

Many countries have introduced tax incentives and subsidies to encourage DME adoption. These financial mechanisms aim to offset the initial costs associated with DME production and infrastructure development, making it more competitive with conventional fuels.

Environmental regulations, such as emissions standards and carbon pricing schemes, indirectly support DME implementation by creating a favorable market for cleaner alternative fuels. As DME produces lower emissions compared to conventional diesel, it aligns well with increasingly stringent environmental policies.

However, regulatory challenges persist in some regions due to the lack of specific frameworks for DME. This regulatory gap can hinder investment and slow down market penetration. Harmonization of standards and regulations across different jurisdictions remains a key challenge for the global adoption of DME as an energy solution.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for the use of DME as a transportation fuel. The EPA's Renewable Fuel Standard (RFS) program includes DME as an eligible renewable fuel, providing incentives for its production and use. Additionally, the Department of Energy (DOE) has supported research and development initiatives to promote DME as a clean alternative fuel.

The European Union has implemented the Renewable Energy Directive (RED II), which sets targets for renewable energy consumption in the transport sector. DME derived from renewable sources is recognized as a viable option to meet these targets. The directive also establishes sustainability criteria for biofuels, including DME, to ensure environmental benefits and reduce greenhouse gas emissions.

In Asia, countries like China and Japan have taken proactive steps to incorporate DME into their energy policies. China has included DME in its national energy strategy, promoting its use in industrial applications and as a substitute for liquefied petroleum gas (LPG). Japan has established technical standards for DME fuel and vehicles, facilitating its integration into the transportation sector.

Regulatory frameworks for DME implementation often address safety standards, fuel quality specifications, and infrastructure requirements. For instance, the International Organization for Standardization (ISO) has developed standards for DME fuel quality (ISO 16861) and DME fuel systems for vehicles (ISO 21087), providing a foundation for consistent global implementation.

Many countries have introduced tax incentives and subsidies to encourage DME adoption. These financial mechanisms aim to offset the initial costs associated with DME production and infrastructure development, making it more competitive with conventional fuels.

Environmental regulations, such as emissions standards and carbon pricing schemes, indirectly support DME implementation by creating a favorable market for cleaner alternative fuels. As DME produces lower emissions compared to conventional diesel, it aligns well with increasingly stringent environmental policies.

However, regulatory challenges persist in some regions due to the lack of specific frameworks for DME. This regulatory gap can hinder investment and slow down market penetration. Harmonization of standards and regulations across different jurisdictions remains a key challenge for the global adoption of DME as an energy solution.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!