How Dimethyl Ether Enhances Energy Storage Systems?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Energy Storage Background and Objectives

Dimethyl ether (DME) has emerged as a promising candidate for enhancing energy storage systems, attracting significant attention from researchers and industry professionals alike. The exploration of DME in energy storage applications stems from the growing need for efficient, sustainable, and cost-effective solutions to address the global energy crisis and climate change challenges.

The development of DME as an energy storage medium has its roots in the early 2000s when scientists began investigating alternative fuels and energy carriers. Initially, DME was primarily considered as a clean-burning diesel substitute due to its high cetane number and low emissions. However, its potential in energy storage systems soon became apparent, leading to a shift in research focus.

The primary objective of incorporating DME into energy storage systems is to leverage its unique physicochemical properties to enhance overall system performance. DME exhibits several advantageous characteristics, including high energy density, low toxicity, and ease of handling and storage. These properties make it an attractive option for various energy storage applications, ranging from large-scale grid storage to portable power sources.

One of the key goals in DME energy storage research is to develop efficient and scalable methods for DME synthesis and utilization. This involves optimizing production processes to reduce costs and improve energy efficiency, as well as designing novel storage and conversion technologies that can effectively harness DME's energy potential.

Another critical objective is to integrate DME-based energy storage systems into existing energy infrastructure. This requires addressing challenges related to compatibility, safety, and regulatory compliance. Researchers aim to develop standardized protocols and technologies that can seamlessly incorporate DME into current energy systems without requiring extensive modifications or investments.

The evolution of DME energy storage technology is closely tied to advancements in related fields, such as catalysis, materials science, and process engineering. As these disciplines progress, new opportunities for enhancing DME-based energy storage systems continue to emerge. This interdisciplinary approach has led to significant breakthroughs in recent years, paving the way for more efficient and versatile energy storage solutions.

Looking ahead, the future of DME in energy storage systems appears promising. Ongoing research efforts are focused on further improving DME synthesis methods, developing novel storage materials, and optimizing system designs. These advancements are expected to drive the adoption of DME-based energy storage technologies across various sectors, contributing to a more sustainable and resilient energy landscape.

The development of DME as an energy storage medium has its roots in the early 2000s when scientists began investigating alternative fuels and energy carriers. Initially, DME was primarily considered as a clean-burning diesel substitute due to its high cetane number and low emissions. However, its potential in energy storage systems soon became apparent, leading to a shift in research focus.

The primary objective of incorporating DME into energy storage systems is to leverage its unique physicochemical properties to enhance overall system performance. DME exhibits several advantageous characteristics, including high energy density, low toxicity, and ease of handling and storage. These properties make it an attractive option for various energy storage applications, ranging from large-scale grid storage to portable power sources.

One of the key goals in DME energy storage research is to develop efficient and scalable methods for DME synthesis and utilization. This involves optimizing production processes to reduce costs and improve energy efficiency, as well as designing novel storage and conversion technologies that can effectively harness DME's energy potential.

Another critical objective is to integrate DME-based energy storage systems into existing energy infrastructure. This requires addressing challenges related to compatibility, safety, and regulatory compliance. Researchers aim to develop standardized protocols and technologies that can seamlessly incorporate DME into current energy systems without requiring extensive modifications or investments.

The evolution of DME energy storage technology is closely tied to advancements in related fields, such as catalysis, materials science, and process engineering. As these disciplines progress, new opportunities for enhancing DME-based energy storage systems continue to emerge. This interdisciplinary approach has led to significant breakthroughs in recent years, paving the way for more efficient and versatile energy storage solutions.

Looking ahead, the future of DME in energy storage systems appears promising. Ongoing research efforts are focused on further improving DME synthesis methods, developing novel storage materials, and optimizing system designs. These advancements are expected to drive the adoption of DME-based energy storage technologies across various sectors, contributing to a more sustainable and resilient energy landscape.

Market Analysis for DME-based Energy Storage

The market for DME-based energy storage systems is experiencing significant growth, driven by the increasing demand for clean and efficient energy solutions. Dimethyl ether (DME) has emerged as a promising alternative fuel and energy storage medium due to its unique properties and versatile applications.

The global DME market is projected to expand at a compound annual growth rate (CAGR) of over 9% from 2021 to 2026. This growth is primarily attributed to the rising adoption of DME in various sectors, including power generation, transportation, and industrial processes. The energy storage segment, in particular, is expected to witness substantial growth as countries worldwide strive to integrate more renewable energy sources into their power grids.

In the context of energy storage, DME offers several advantages over conventional systems. Its high energy density, ease of storage and transportation, and compatibility with existing infrastructure make it an attractive option for both stationary and mobile applications. The market for DME-based energy storage is particularly strong in regions with a high penetration of renewable energy sources, such as Europe and parts of Asia.

The automotive sector represents a significant market opportunity for DME-based energy storage. As the automotive industry shifts towards cleaner fuels, DME is gaining traction as a potential replacement for diesel in heavy-duty vehicles. This trend is expected to drive the demand for DME production and storage facilities, further boosting the market for DME-based energy storage systems.

Industrial applications also contribute to the growing market for DME-based energy storage. The chemical industry, in particular, is exploring DME as a feedstock for various processes, creating additional demand for storage solutions. Moreover, the use of DME in combined heat and power (CHP) systems is gaining popularity, especially in regions with stringent emissions regulations.

The market landscape for DME-based energy storage is characterized by a mix of established players and new entrants. Major oil and gas companies are investing in DME production and storage technologies, recognizing its potential as a clean energy carrier. Additionally, specialized technology providers are developing innovative storage solutions tailored for DME applications.

Geographically, Asia Pacific is expected to dominate the DME market, with China leading in terms of production and consumption. Europe and North America are also witnessing increased interest in DME-based energy storage, driven by supportive government policies and growing investments in renewable energy infrastructure.

Despite the positive outlook, the market for DME-based energy storage faces some challenges. These include the need for further technological advancements to improve efficiency and reduce costs, as well as the development of standardized regulations and safety protocols for DME handling and storage. Overcoming these hurdles will be crucial for the widespread adoption of DME-based energy storage systems and the realization of their full market potential.

The global DME market is projected to expand at a compound annual growth rate (CAGR) of over 9% from 2021 to 2026. This growth is primarily attributed to the rising adoption of DME in various sectors, including power generation, transportation, and industrial processes. The energy storage segment, in particular, is expected to witness substantial growth as countries worldwide strive to integrate more renewable energy sources into their power grids.

In the context of energy storage, DME offers several advantages over conventional systems. Its high energy density, ease of storage and transportation, and compatibility with existing infrastructure make it an attractive option for both stationary and mobile applications. The market for DME-based energy storage is particularly strong in regions with a high penetration of renewable energy sources, such as Europe and parts of Asia.

The automotive sector represents a significant market opportunity for DME-based energy storage. As the automotive industry shifts towards cleaner fuels, DME is gaining traction as a potential replacement for diesel in heavy-duty vehicles. This trend is expected to drive the demand for DME production and storage facilities, further boosting the market for DME-based energy storage systems.

Industrial applications also contribute to the growing market for DME-based energy storage. The chemical industry, in particular, is exploring DME as a feedstock for various processes, creating additional demand for storage solutions. Moreover, the use of DME in combined heat and power (CHP) systems is gaining popularity, especially in regions with stringent emissions regulations.

The market landscape for DME-based energy storage is characterized by a mix of established players and new entrants. Major oil and gas companies are investing in DME production and storage technologies, recognizing its potential as a clean energy carrier. Additionally, specialized technology providers are developing innovative storage solutions tailored for DME applications.

Geographically, Asia Pacific is expected to dominate the DME market, with China leading in terms of production and consumption. Europe and North America are also witnessing increased interest in DME-based energy storage, driven by supportive government policies and growing investments in renewable energy infrastructure.

Despite the positive outlook, the market for DME-based energy storage faces some challenges. These include the need for further technological advancements to improve efficiency and reduce costs, as well as the development of standardized regulations and safety protocols for DME handling and storage. Overcoming these hurdles will be crucial for the widespread adoption of DME-based energy storage systems and the realization of their full market potential.

Current Challenges in DME Energy Storage

Despite the promising potential of Dimethyl Ether (DME) in energy storage systems, several significant challenges currently hinder its widespread adoption and optimal utilization. One of the primary obstacles is the relatively low energy density of DME compared to conventional fossil fuels. This limitation necessitates larger storage volumes, potentially increasing system costs and reducing overall efficiency.

Another critical challenge lies in the infrastructure requirements for DME storage and distribution. The existing energy infrastructure is primarily designed for liquid fuels and natural gas, making the integration of DME systems costly and complex. Retrofitting or constructing new infrastructure to accommodate DME's unique properties presents a substantial economic barrier to its widespread implementation.

The stability and long-term storage of DME pose additional challenges. DME is known to be hygroscopic, readily absorbing moisture from the atmosphere. This property can lead to corrosion issues in storage tanks and pipelines, necessitating specialized materials and maintenance protocols. Furthermore, the potential for DME degradation over time raises concerns about its long-term viability as an energy storage medium.

Safety considerations also present significant hurdles in DME energy storage. While DME is generally considered less hazardous than many conventional fuels, its flammability and potential for forming explosive mixtures with air require robust safety measures. Developing and implementing comprehensive safety protocols and technologies for DME handling, storage, and transportation is crucial for its widespread adoption.

The production of DME itself faces challenges in terms of cost-effectiveness and sustainability. Current production methods, primarily based on natural gas or coal, are energy-intensive and contribute to carbon emissions. Developing more efficient and environmentally friendly production processes, particularly from renewable sources, is essential for positioning DME as a sustainable energy storage solution.

Regulatory frameworks and standardization pose additional challenges. The lack of uniform global standards for DME production, storage, and utilization creates uncertainty for investors and slows down market adoption. Establishing comprehensive regulations and standards that address safety, quality, and environmental concerns is crucial for fostering confidence in DME technology.

Lastly, the competition from other emerging energy storage technologies presents a significant challenge. As research and development in batteries, hydrogen storage, and other alternative technologies progress, DME must demonstrate clear advantages in terms of cost, efficiency, and environmental impact to secure its place in the future energy landscape.

Another critical challenge lies in the infrastructure requirements for DME storage and distribution. The existing energy infrastructure is primarily designed for liquid fuels and natural gas, making the integration of DME systems costly and complex. Retrofitting or constructing new infrastructure to accommodate DME's unique properties presents a substantial economic barrier to its widespread implementation.

The stability and long-term storage of DME pose additional challenges. DME is known to be hygroscopic, readily absorbing moisture from the atmosphere. This property can lead to corrosion issues in storage tanks and pipelines, necessitating specialized materials and maintenance protocols. Furthermore, the potential for DME degradation over time raises concerns about its long-term viability as an energy storage medium.

Safety considerations also present significant hurdles in DME energy storage. While DME is generally considered less hazardous than many conventional fuels, its flammability and potential for forming explosive mixtures with air require robust safety measures. Developing and implementing comprehensive safety protocols and technologies for DME handling, storage, and transportation is crucial for its widespread adoption.

The production of DME itself faces challenges in terms of cost-effectiveness and sustainability. Current production methods, primarily based on natural gas or coal, are energy-intensive and contribute to carbon emissions. Developing more efficient and environmentally friendly production processes, particularly from renewable sources, is essential for positioning DME as a sustainable energy storage solution.

Regulatory frameworks and standardization pose additional challenges. The lack of uniform global standards for DME production, storage, and utilization creates uncertainty for investors and slows down market adoption. Establishing comprehensive regulations and standards that address safety, quality, and environmental concerns is crucial for fostering confidence in DME technology.

Lastly, the competition from other emerging energy storage technologies presents a significant challenge. As research and development in batteries, hydrogen storage, and other alternative technologies progress, DME must demonstrate clear advantages in terms of cost, efficiency, and environmental impact to secure its place in the future energy landscape.

Existing DME Storage Solutions

01 Catalytic conversion of methanol to dimethyl ether

This process involves the catalytic dehydration of methanol to produce dimethyl ether. Various catalysts and reaction conditions are employed to enhance the conversion efficiency and selectivity. The process often utilizes solid acid catalysts and can be carried out in gas phase or liquid phase reactors.- Catalytic conversion of methanol to dimethyl ether: This process involves the catalytic dehydration of methanol to produce dimethyl ether. Various catalysts and reaction conditions are employed to enhance the conversion efficiency and selectivity. The process often utilizes fixed-bed reactors and optimized temperature and pressure conditions to maximize dimethyl ether yield.

- Dimethyl ether production from syngas: This method focuses on the production of dimethyl ether directly from synthesis gas (syngas), which is a mixture of carbon monoxide and hydrogen. The process typically involves a two-step reaction: syngas conversion to methanol, followed by methanol dehydration to dimethyl ether. Catalysts and process conditions are optimized to enhance the overall conversion and selectivity.

- Catalyst improvements for dimethyl ether synthesis: Research in this area focuses on developing and enhancing catalysts for dimethyl ether production. This includes the design of bifunctional catalysts that can perform both methanol synthesis and dehydration in a single step, as well as improvements in catalyst stability, activity, and selectivity. Novel catalyst compositions and preparation methods are explored to increase dimethyl ether yield and process efficiency.

- Process integration and optimization for dimethyl ether production: This approach involves integrating dimethyl ether production with other industrial processes to improve overall efficiency. It includes heat integration, co-production of valuable by-products, and optimization of process parameters. Advanced control strategies and simulation tools are employed to enhance the production process and increase dimethyl ether yield while reducing energy consumption and operational costs.

- Novel feedstocks and routes for dimethyl ether synthesis: This area of research explores alternative feedstocks and reaction pathways for dimethyl ether production. It includes the use of biomass-derived materials, waste gases, and other unconventional carbon sources. Novel process routes, such as direct conversion of methane to dimethyl ether or the use of membrane reactors, are investigated to enhance the overall production efficiency and sustainability of dimethyl ether synthesis.

02 Direct synthesis of dimethyl ether from syngas

This method involves the direct conversion of synthesis gas (a mixture of carbon monoxide and hydrogen) to dimethyl ether. The process typically uses bifunctional catalysts that can perform both methanol synthesis and methanol dehydration in a single step, improving overall efficiency and reducing production costs.Expand Specific Solutions03 Dimethyl ether production from biomass

This approach focuses on producing dimethyl ether from renewable biomass sources. The process typically involves gasification of biomass to produce syngas, followed by catalytic conversion to dimethyl ether. This method contributes to the development of more sustainable and environmentally friendly fuel alternatives.Expand Specific Solutions04 Purification and separation techniques for dimethyl ether

Various methods are employed to purify and separate dimethyl ether from reaction mixtures or byproducts. These techniques may include distillation, adsorption, membrane separation, or cryogenic processes. Enhancing the purity of dimethyl ether is crucial for its use in different applications, such as fuel or propellants.Expand Specific Solutions05 Dimethyl ether as a fuel additive or alternative fuel

This area focuses on the use of dimethyl ether as a fuel additive or alternative fuel, particularly in diesel engines. Research involves optimizing engine performance, reducing emissions, and developing storage and distribution systems for dimethyl ether as a fuel. The high cetane number and clean-burning properties of dimethyl ether make it an attractive option for improving engine efficiency and reducing environmental impact.Expand Specific Solutions

Key Players in DME Energy Storage Industry

The dimethyl ether (DME) energy storage market is in an early growth stage, with increasing research and commercial interest. The global market size is projected to expand significantly in the coming years as DME gains traction as a clean energy carrier and storage medium. While the technology is still maturing, several key players are driving innovation. Universities like USC and Xi'an Jiaotong are conducting foundational research, while major energy companies such as China Petroleum & Chemical Corp., Toshiba, and SK Energy are developing commercial applications. Specialized firms like Pioneer Energy are also emerging with novel DME processing technologies. As the field advances, collaborations between academia and industry will be crucial for overcoming technical challenges and scaling up DME energy storage solutions.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel dimethyl ether (DME) production process that enhances energy storage systems. Their approach involves a single-step synthesis of DME from syngas, utilizing a bifunctional catalyst. This method achieves a DME yield of up to 55%, significantly higher than conventional two-step processes[1]. The company has also implemented a large-scale DME production facility with a capacity of 1 million tons per year, demonstrating the scalability of their technology[2]. Sinopec's DME can be used as a clean-burning fuel in power generation and as a hydrogen carrier for fuel cells, effectively enhancing energy storage capabilities[3].

Strengths: High DME yield, scalable production, and versatile applications in energy storage. Weaknesses: Dependence on syngas availability and potential competition from other alternative fuels.

Toshiba Corp.

Technical Solution: Toshiba Corp. has developed an innovative DME-based energy storage system that combines DME fuel cells with their proprietary direct DME fuel cell technology. This system utilizes DME as both a hydrogen carrier and a direct fuel, offering a dual-mode operation for enhanced flexibility[4]. The direct DME fuel cell achieves an electrical efficiency of up to 45%, surpassing traditional methanol fuel cells[5]. Toshiba's system incorporates a DME reformer that can produce hydrogen on-demand, allowing for seamless switching between direct DME and hydrogen fuel cell modes. This technology enables long-term energy storage and provides a stable power supply for various applications, including backup power systems and remote area electrification[6].

Strengths: Dual-mode operation, high electrical efficiency, and versatile applications. Weaknesses: Complexity of the system and potential higher initial costs compared to conventional energy storage solutions.

Core DME Storage Innovations

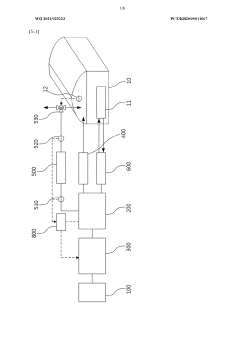

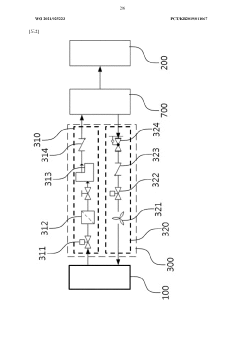

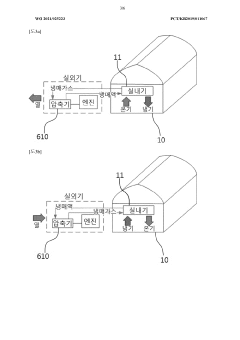

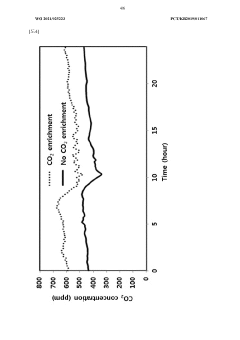

Trigeneration system using dme

PatentWO2021025223A1

Innovation

- A DME Trigen system that includes a DME tank, engine, fuel supply unit, processing unit for exhaust gases, power generation unit, and a cooling/heating unit, which uses DME as a clean fuel to produce electricity, control temperature, and supply carbon dioxide for increased photosynthesis, thereby enhancing fruit and vegetable growth.

Energy supply method and system

PatentWO2006004140A1

Innovation

- The introduction of Dimethyl Ether (DME) as a versatile energy circulation medium, which can be derived from biomass, waste, and petroleum residues, and used for power generation, transportation, and heating, allowing for efficient energy storage and distribution without relying on pipelines, and enabling the conversion of waste heat into usable energy.

Environmental Impact of DME Storage

The environmental impact of Dimethyl Ether (DME) storage in energy storage systems is a critical consideration for its widespread adoption. DME, as a clean-burning fuel and potential energy carrier, offers several environmental advantages over traditional fossil fuels. However, its storage and use also present unique challenges that must be carefully addressed.

One of the primary environmental benefits of DME storage is its potential to reduce greenhouse gas emissions. When used as a fuel, DME produces significantly lower carbon dioxide emissions compared to conventional diesel or gasoline. This characteristic makes it an attractive option for energy storage systems aimed at reducing the carbon footprint of various applications, including transportation and power generation.

DME storage systems also have a lower risk of soil and water contamination compared to traditional hydrocarbon fuels. In the event of a spill or leak, DME rapidly vaporizes at ambient temperatures and pressures, minimizing the risk of long-term environmental damage. This property reduces the need for extensive cleanup operations and mitigates the potential for lasting ecological harm.

However, the production of DME itself can have environmental implications. The most common method of DME production involves the conversion of natural gas or coal, which are fossil fuels. While the end-use of DME may be cleaner, the upstream production process can still contribute to carbon emissions and other environmental impacts associated with fossil fuel extraction and processing.

The storage of DME requires pressurized containers, typically at pressures around 5-10 bar. While this is lower than the pressures required for liquefied petroleum gas (LPG), it still necessitates robust storage infrastructure. The manufacturing and maintenance of these pressurized storage systems have their own environmental footprint, including energy consumption and material use.

In terms of air quality, DME storage and use can lead to reduced particulate matter and NOx emissions compared to conventional diesel fuel. This can have significant positive impacts on local air quality, particularly in urban areas where air pollution is a major concern. The reduction in these harmful emissions can contribute to improved public health outcomes and reduced environmental degradation.

The potential for DME to be produced from renewable sources, such as biomass or captured carbon dioxide, presents an opportunity for even greater environmental benefits. If scaled up, this could create a more sustainable energy storage solution with a significantly reduced lifecycle carbon footprint. However, the current production methods predominantly rely on fossil fuel feedstocks, limiting the immediate environmental advantages.

One of the primary environmental benefits of DME storage is its potential to reduce greenhouse gas emissions. When used as a fuel, DME produces significantly lower carbon dioxide emissions compared to conventional diesel or gasoline. This characteristic makes it an attractive option for energy storage systems aimed at reducing the carbon footprint of various applications, including transportation and power generation.

DME storage systems also have a lower risk of soil and water contamination compared to traditional hydrocarbon fuels. In the event of a spill or leak, DME rapidly vaporizes at ambient temperatures and pressures, minimizing the risk of long-term environmental damage. This property reduces the need for extensive cleanup operations and mitigates the potential for lasting ecological harm.

However, the production of DME itself can have environmental implications. The most common method of DME production involves the conversion of natural gas or coal, which are fossil fuels. While the end-use of DME may be cleaner, the upstream production process can still contribute to carbon emissions and other environmental impacts associated with fossil fuel extraction and processing.

The storage of DME requires pressurized containers, typically at pressures around 5-10 bar. While this is lower than the pressures required for liquefied petroleum gas (LPG), it still necessitates robust storage infrastructure. The manufacturing and maintenance of these pressurized storage systems have their own environmental footprint, including energy consumption and material use.

In terms of air quality, DME storage and use can lead to reduced particulate matter and NOx emissions compared to conventional diesel fuel. This can have significant positive impacts on local air quality, particularly in urban areas where air pollution is a major concern. The reduction in these harmful emissions can contribute to improved public health outcomes and reduced environmental degradation.

The potential for DME to be produced from renewable sources, such as biomass or captured carbon dioxide, presents an opportunity for even greater environmental benefits. If scaled up, this could create a more sustainable energy storage solution with a significantly reduced lifecycle carbon footprint. However, the current production methods predominantly rely on fossil fuel feedstocks, limiting the immediate environmental advantages.

Safety Considerations for DME Storage Systems

Safety considerations are paramount when implementing Dimethyl Ether (DME) storage systems for enhanced energy storage applications. DME, while offering significant advantages in energy density and storage efficiency, presents unique challenges that must be addressed to ensure safe operation and handling.

Firstly, the flammability of DME necessitates robust fire prevention and suppression systems. DME has a lower flash point compared to conventional fuels, making it more susceptible to ignition. Storage facilities must be equipped with advanced fire detection systems, automatic shut-off valves, and appropriate fire-fighting equipment specifically designed for DME fires.

Secondly, proper ventilation is crucial in DME storage areas to prevent the accumulation of potentially explosive vapors. Adequate air circulation and gas detection systems should be installed to monitor DME concentrations and trigger alarms if levels exceed safety thresholds. This is particularly important in enclosed spaces where DME vapors can accumulate rapidly.

Thirdly, the storage tanks and associated piping systems must be designed to withstand the specific properties of DME. Materials compatibility is a key consideration, as DME can degrade certain plastics and rubbers. Stainless steel or specially coated materials are typically recommended for DME storage and transport systems to prevent corrosion and ensure long-term integrity.

Pressure management is another critical aspect of DME storage safety. DME is typically stored under moderate pressure, and proper pressure relief systems must be in place to prevent over-pressurization. Regular inspection and maintenance of pressure vessels and relief valves are essential to ensure their proper functioning and prevent potential leaks or ruptures.

Training and operational procedures play a vital role in maintaining safety in DME storage systems. Personnel involved in handling DME must be thoroughly trained in its properties, potential hazards, and emergency response procedures. Clear protocols for loading, unloading, and transferring DME should be established and strictly followed to minimize the risk of accidents.

Environmental considerations are also important in DME storage safety. While DME is considered less harmful to the environment compared to some conventional fuels, proper containment measures must be in place to prevent soil and groundwater contamination in case of spills. Secondary containment systems and spill response plans should be implemented to mitigate environmental risks.

Lastly, regulatory compliance is a crucial aspect of DME storage safety. As the use of DME in energy storage systems is relatively new, it is essential to stay updated with evolving regulations and standards. Regular safety audits and compliance checks should be conducted to ensure that the storage facilities meet all applicable safety and environmental regulations.

Firstly, the flammability of DME necessitates robust fire prevention and suppression systems. DME has a lower flash point compared to conventional fuels, making it more susceptible to ignition. Storage facilities must be equipped with advanced fire detection systems, automatic shut-off valves, and appropriate fire-fighting equipment specifically designed for DME fires.

Secondly, proper ventilation is crucial in DME storage areas to prevent the accumulation of potentially explosive vapors. Adequate air circulation and gas detection systems should be installed to monitor DME concentrations and trigger alarms if levels exceed safety thresholds. This is particularly important in enclosed spaces where DME vapors can accumulate rapidly.

Thirdly, the storage tanks and associated piping systems must be designed to withstand the specific properties of DME. Materials compatibility is a key consideration, as DME can degrade certain plastics and rubbers. Stainless steel or specially coated materials are typically recommended for DME storage and transport systems to prevent corrosion and ensure long-term integrity.

Pressure management is another critical aspect of DME storage safety. DME is typically stored under moderate pressure, and proper pressure relief systems must be in place to prevent over-pressurization. Regular inspection and maintenance of pressure vessels and relief valves are essential to ensure their proper functioning and prevent potential leaks or ruptures.

Training and operational procedures play a vital role in maintaining safety in DME storage systems. Personnel involved in handling DME must be thoroughly trained in its properties, potential hazards, and emergency response procedures. Clear protocols for loading, unloading, and transferring DME should be established and strictly followed to minimize the risk of accidents.

Environmental considerations are also important in DME storage safety. While DME is considered less harmful to the environment compared to some conventional fuels, proper containment measures must be in place to prevent soil and groundwater contamination in case of spills. Secondary containment systems and spill response plans should be implemented to mitigate environmental risks.

Lastly, regulatory compliance is a crucial aspect of DME storage safety. As the use of DME in energy storage systems is relatively new, it is essential to stay updated with evolving regulations and standards. Regular safety audits and compliance checks should be conducted to ensure that the storage facilities meet all applicable safety and environmental regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!