How to Adapt Dimethyl Ether for Smart Metering Processes?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Smart Metering Background and Objectives

Dimethyl ether (DME) has emerged as a promising alternative fuel and chemical feedstock, gaining attention in various industries due to its clean-burning properties and versatile applications. The adaptation of DME for smart metering processes represents a significant technological advancement in the energy sector, aiming to enhance efficiency, accuracy, and sustainability in fuel consumption measurement and management.

The evolution of DME technology can be traced back to the early 1990s when it was first considered as a potential fuel substitute. Since then, research and development efforts have focused on improving its production methods, storage capabilities, and end-use applications. The current trend in DME technology is moving towards its integration with smart metering systems, which aligns with the global push for more intelligent and sustainable energy solutions.

The primary objective of adapting DME for smart metering processes is to create a seamless and efficient system for measuring, monitoring, and managing DME consumption in various applications. This integration aims to provide real-time data on fuel usage, enable predictive maintenance, and optimize energy efficiency across industrial, commercial, and residential sectors.

Key technological goals include developing DME-compatible smart meters that can accurately measure flow rates and volumes under varying pressure and temperature conditions. These meters must also be capable of transmitting data securely and reliably to centralized management systems, allowing for remote monitoring and analysis.

Another critical objective is to enhance the overall safety of DME handling and distribution through smart metering. This involves implementing advanced leak detection systems, pressure monitoring, and automated shut-off mechanisms to prevent accidents and ensure compliance with safety regulations.

The adaptation of DME for smart metering also seeks to address environmental concerns by enabling more precise control over emissions and promoting efficient fuel utilization. By providing detailed consumption data, smart metering can help identify opportunities for reducing waste and optimizing DME usage, thereby minimizing the carbon footprint associated with its use.

Furthermore, the integration of DME with smart metering technology aims to facilitate the broader adoption of this alternative fuel by providing a robust infrastructure for its measurement and management. This, in turn, could accelerate the transition towards cleaner energy sources and support global efforts to reduce dependence on traditional fossil fuels.

As the technology continues to evolve, researchers and industry professionals are focusing on overcoming challenges such as meter accuracy in extreme conditions, compatibility with existing infrastructure, and the development of standardized protocols for DME smart metering. The successful adaptation of DME for smart metering processes has the potential to revolutionize energy management practices and contribute significantly to the advancement of sustainable energy solutions.

The evolution of DME technology can be traced back to the early 1990s when it was first considered as a potential fuel substitute. Since then, research and development efforts have focused on improving its production methods, storage capabilities, and end-use applications. The current trend in DME technology is moving towards its integration with smart metering systems, which aligns with the global push for more intelligent and sustainable energy solutions.

The primary objective of adapting DME for smart metering processes is to create a seamless and efficient system for measuring, monitoring, and managing DME consumption in various applications. This integration aims to provide real-time data on fuel usage, enable predictive maintenance, and optimize energy efficiency across industrial, commercial, and residential sectors.

Key technological goals include developing DME-compatible smart meters that can accurately measure flow rates and volumes under varying pressure and temperature conditions. These meters must also be capable of transmitting data securely and reliably to centralized management systems, allowing for remote monitoring and analysis.

Another critical objective is to enhance the overall safety of DME handling and distribution through smart metering. This involves implementing advanced leak detection systems, pressure monitoring, and automated shut-off mechanisms to prevent accidents and ensure compliance with safety regulations.

The adaptation of DME for smart metering also seeks to address environmental concerns by enabling more precise control over emissions and promoting efficient fuel utilization. By providing detailed consumption data, smart metering can help identify opportunities for reducing waste and optimizing DME usage, thereby minimizing the carbon footprint associated with its use.

Furthermore, the integration of DME with smart metering technology aims to facilitate the broader adoption of this alternative fuel by providing a robust infrastructure for its measurement and management. This, in turn, could accelerate the transition towards cleaner energy sources and support global efforts to reduce dependence on traditional fossil fuels.

As the technology continues to evolve, researchers and industry professionals are focusing on overcoming challenges such as meter accuracy in extreme conditions, compatibility with existing infrastructure, and the development of standardized protocols for DME smart metering. The successful adaptation of DME for smart metering processes has the potential to revolutionize energy management practices and contribute significantly to the advancement of sustainable energy solutions.

Market Analysis for DME Smart Metering Solutions

The market for Dimethyl Ether (DME) smart metering solutions is experiencing significant growth, driven by the increasing demand for efficient and environmentally friendly energy solutions. DME, a clean-burning synthetic fuel, has gained attention as a potential alternative to traditional fossil fuels in various applications, including smart metering processes.

The global smart meter market is projected to expand rapidly in the coming years, with a particular focus on gas and energy metering. This growth is fueled by government initiatives promoting energy efficiency, the need for accurate billing, and the desire for real-time consumption data. As DME gains traction as a fuel source, the demand for compatible smart metering solutions is expected to rise in parallel.

Several key factors are driving the market for DME smart metering solutions. Firstly, the environmental benefits of DME, including lower emissions and reduced carbon footprint, align well with global sustainability goals. This makes DME an attractive option for energy companies and consumers alike, potentially leading to increased adoption of DME-compatible smart meters.

Secondly, the versatility of DME as a fuel source opens up new opportunities in the smart metering market. DME can be used in various applications, from household heating to industrial processes, creating a diverse range of potential use cases for smart metering solutions.

The market for DME smart metering solutions is also influenced by technological advancements in sensor technology and data analytics. These innovations enable more accurate measurement of DME consumption and provide valuable insights for both consumers and utility companies.

However, the market faces certain challenges. The infrastructure for DME distribution is still developing in many regions, which may slow the adoption of DME-specific smart metering solutions. Additionally, the initial costs associated with implementing new metering systems could be a barrier for some utility companies.

Despite these challenges, the long-term outlook for the DME smart metering market remains positive. As awareness of DME's benefits grows and infrastructure improves, the demand for compatible smart metering solutions is expected to increase. This presents significant opportunities for companies specializing in smart meter technology and DME-related products.

In conclusion, the market for DME smart metering solutions shows promising growth potential, driven by environmental concerns, technological advancements, and the increasing adoption of DME as an alternative fuel source. Companies that can develop innovative, cost-effective, and reliable smart metering solutions for DME applications are likely to find success in this emerging market.

The global smart meter market is projected to expand rapidly in the coming years, with a particular focus on gas and energy metering. This growth is fueled by government initiatives promoting energy efficiency, the need for accurate billing, and the desire for real-time consumption data. As DME gains traction as a fuel source, the demand for compatible smart metering solutions is expected to rise in parallel.

Several key factors are driving the market for DME smart metering solutions. Firstly, the environmental benefits of DME, including lower emissions and reduced carbon footprint, align well with global sustainability goals. This makes DME an attractive option for energy companies and consumers alike, potentially leading to increased adoption of DME-compatible smart meters.

Secondly, the versatility of DME as a fuel source opens up new opportunities in the smart metering market. DME can be used in various applications, from household heating to industrial processes, creating a diverse range of potential use cases for smart metering solutions.

The market for DME smart metering solutions is also influenced by technological advancements in sensor technology and data analytics. These innovations enable more accurate measurement of DME consumption and provide valuable insights for both consumers and utility companies.

However, the market faces certain challenges. The infrastructure for DME distribution is still developing in many regions, which may slow the adoption of DME-specific smart metering solutions. Additionally, the initial costs associated with implementing new metering systems could be a barrier for some utility companies.

Despite these challenges, the long-term outlook for the DME smart metering market remains positive. As awareness of DME's benefits grows and infrastructure improves, the demand for compatible smart metering solutions is expected to increase. This presents significant opportunities for companies specializing in smart meter technology and DME-related products.

In conclusion, the market for DME smart metering solutions shows promising growth potential, driven by environmental concerns, technological advancements, and the increasing adoption of DME as an alternative fuel source. Companies that can develop innovative, cost-effective, and reliable smart metering solutions for DME applications are likely to find success in this emerging market.

Technical Challenges in DME Smart Metering

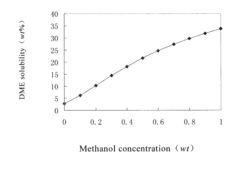

The adaptation of Dimethyl Ether (DME) for smart metering processes presents several significant technical challenges. One of the primary obstacles is the unique physical properties of DME, which differ substantially from traditional fuels. DME's low viscosity and high volatility make it difficult to accurately measure and control flow rates using conventional metering technologies.

The low boiling point of DME (-25°C at atmospheric pressure) poses challenges for maintaining the fuel in a liquid state during metering. This necessitates the development of specialized pressure-maintaining systems to prevent vaporization, which can lead to inaccurate measurements and potential safety hazards. Additionally, DME's propensity to absorb moisture from the atmosphere can cause corrosion and degradation of metering components, requiring the use of specialized materials and sealing technologies.

Another significant challenge lies in the development of precise and reliable flow measurement techniques for DME. Traditional volumetric and mass flow meters may not provide the necessary accuracy due to DME's unique fluid dynamics and thermodynamic properties. This has led to the need for innovative sensing technologies, such as Coriolis meters or ultrasonic flow meters, which must be adapted and calibrated specifically for DME applications.

The integration of smart metering technologies with DME systems presents additional complexities. Real-time monitoring and data transmission require the development of sensors and communication protocols that can operate reliably in the presence of DME's electromagnetic properties and potential interference. Furthermore, ensuring the long-term stability and accuracy of these smart metering systems in DME environments remains a significant technical hurdle.

Safety considerations also play a crucial role in the technical challenges of DME smart metering. The flammability and explosive potential of DME necessitate the development of intrinsically safe metering systems and robust leak detection mechanisms. This includes the design of explosion-proof enclosures and the implementation of advanced safety protocols to prevent accidents during metering operations.

Lastly, the lack of standardized testing and calibration procedures for DME metering systems poses challenges for ensuring consistency and reliability across different applications and geographical regions. The development of internationally recognized standards and certification processes for DME smart metering equipment is essential for widespread adoption and interoperability of these systems.

The low boiling point of DME (-25°C at atmospheric pressure) poses challenges for maintaining the fuel in a liquid state during metering. This necessitates the development of specialized pressure-maintaining systems to prevent vaporization, which can lead to inaccurate measurements and potential safety hazards. Additionally, DME's propensity to absorb moisture from the atmosphere can cause corrosion and degradation of metering components, requiring the use of specialized materials and sealing technologies.

Another significant challenge lies in the development of precise and reliable flow measurement techniques for DME. Traditional volumetric and mass flow meters may not provide the necessary accuracy due to DME's unique fluid dynamics and thermodynamic properties. This has led to the need for innovative sensing technologies, such as Coriolis meters or ultrasonic flow meters, which must be adapted and calibrated specifically for DME applications.

The integration of smart metering technologies with DME systems presents additional complexities. Real-time monitoring and data transmission require the development of sensors and communication protocols that can operate reliably in the presence of DME's electromagnetic properties and potential interference. Furthermore, ensuring the long-term stability and accuracy of these smart metering systems in DME environments remains a significant technical hurdle.

Safety considerations also play a crucial role in the technical challenges of DME smart metering. The flammability and explosive potential of DME necessitate the development of intrinsically safe metering systems and robust leak detection mechanisms. This includes the design of explosion-proof enclosures and the implementation of advanced safety protocols to prevent accidents during metering operations.

Lastly, the lack of standardized testing and calibration procedures for DME metering systems poses challenges for ensuring consistency and reliability across different applications and geographical regions. The development of internationally recognized standards and certification processes for DME smart metering equipment is essential for widespread adoption and interoperability of these systems.

Current DME Smart Metering Solutions

01 Production of dimethyl ether

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other feedstocks. These processes often involve specific catalysts, reaction conditions, and purification steps to optimize yield and purity.- Production of dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

- Catalysts for dimethyl ether synthesis: Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.

- Applications of dimethyl ether: Dimethyl ether has various applications, including use as a fuel substitute, aerosol propellant, and chemical intermediate. Its properties make it suitable for use in diesel engines, household products, and as a feedstock for other chemical processes.

- Purification and separation of dimethyl ether: Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes may involve distillation, adsorption, or membrane separation techniques to obtain high-purity dimethyl ether.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and risk assessments associated with its storage and transportation.

02 Catalysts for dimethyl ether synthesis

Different catalysts are employed in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst affects reaction efficiency, selectivity, and product yield. Research focuses on developing novel catalysts with improved performance and stability.Expand Specific Solutions03 Applications of dimethyl ether

Dimethyl ether has various applications, including use as a fuel substitute, propellant, refrigerant, and chemical intermediate. Its properties make it suitable for use in diesel engines, aerosol products, and as a building block for other chemicals. Research explores new potential applications and improvements in existing uses.Expand Specific Solutions04 Purification and handling of dimethyl ether

Techniques for purifying and handling dimethyl ether are crucial for its production and use. This includes separation methods, storage solutions, and safety measures. Innovations in these areas aim to improve product quality, reduce costs, and enhance safety in industrial and commercial settings.Expand Specific Solutions05 Environmental and economic aspects of dimethyl ether

Research on dimethyl ether production and use considers environmental impacts and economic feasibility. This includes studies on emissions reduction, energy efficiency, and cost-effective production methods. The potential of dimethyl ether as a cleaner alternative fuel is a key focus area.Expand Specific Solutions

Key Players in DME Smart Metering Industry

The adaptation of dimethyl ether (DME) for smart metering processes is in an early development stage, with a growing market potential due to increasing demand for cleaner energy alternatives. The technology's maturity is still evolving, with key players like China Petroleum & Chemical Corp., Zhejiang University, and Sinopec Research Institute of Petroleum Processing leading research efforts. Other significant contributors include Air Liquide, BASF, and Linde GmbH, focusing on process optimization and application development. The competitive landscape is characterized by collaborations between academic institutions and industry leaders, aiming to overcome technical challenges and improve DME's viability in smart metering applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach for adapting dimethyl ether (DME) to smart metering processes. Their technology involves a two-stage conversion process: first, synthesizing DME from syngas, then utilizing advanced catalysts to convert DME into value-added products[1]. For smart metering, they've implemented a high-precision flow measurement system that accounts for DME's unique properties, such as its low viscosity and high vapor pressure[2]. This system incorporates temperature and pressure compensation algorithms to ensure accurate readings across various operating conditions[3]. Additionally, Sinopec has developed corrosion-resistant materials for meter components to withstand DME's potential corrosive effects, enhancing the longevity and reliability of smart meters in DME applications[4].

Strengths: Comprehensive DME production and utilization expertise, advanced catalyst technology, and tailored metering solutions. Weaknesses: Potential high implementation costs and the need for specialized infrastructure adaptations.

Sinopec Research Institute of Petroleum Processing

Technical Solution: The Sinopec Research Institute of Petroleum Processing has pioneered a cutting-edge approach to adapt dimethyl ether (DME) for smart metering processes. Their method focuses on enhancing the accuracy of DME flow measurement through the development of a multi-parameter compensation algorithm[1]. This algorithm takes into account DME's unique thermodynamic properties, including its high compressibility and low boiling point, to provide real-time adjustments to flow calculations[2]. The institute has also developed a novel sensor array that combines ultrasonic and Coriolis flow measurement technologies, specifically calibrated for DME's physical characteristics[3]. To address the challenges of DME's low viscosity, they've implemented a micro-channel design in their smart meters, which improves flow stability and measurement precision[4]. Furthermore, the institute has created a predictive maintenance system using machine learning algorithms to detect potential issues in DME metering equipment before they affect accuracy[5].

Strengths: Highly specialized DME measurement technology, advanced algorithm development, and integrated predictive maintenance. Weaknesses: Potentially limited applicability to other fluids and higher initial investment costs for implementation.

Core Innovations in DME Metering Technology

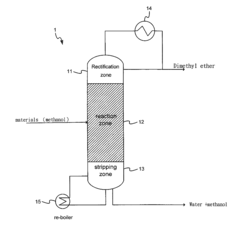

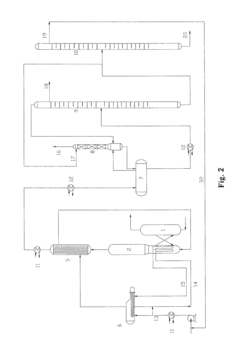

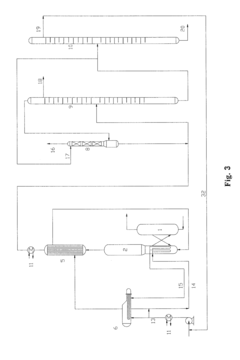

Method for Making Dimethyl Ether by Reactive-Distillation

PatentInactiveUS20120232311A1

Innovation

- A reactive distillation tower with defined zones, operated at specific temperature and pressure conditions, using a catalyst-filled reaction zone and incorporating a condenser and re-boiler to enhance conversion efficiency and reduce energy consumption, allowing for a single, smaller, and less expensive equipment setup.

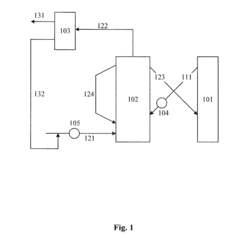

Process for producing dimethyl ether from methanol

PatentActiveUS20110065963A1

Innovation

- A novel process using a fluidized bed reactor that leverages reaction heat for temperature control, regenerates carbon-deposited catalysts, and employs a catalyst composition including Y-zeolite and meso porous zeolites to achieve high methanol conversion and DME selectivity, while reducing energy consumption and by-product formation.

Regulatory Framework for DME Metering

The regulatory framework for Dimethyl Ether (DME) metering is a critical aspect of adapting this alternative fuel for smart metering processes. As DME gains traction as a potential replacement for traditional fossil fuels, it is essential to establish comprehensive regulations that ensure accurate measurement, safety, and environmental compliance.

At the international level, organizations such as the International Organization of Legal Metrology (OIML) play a crucial role in developing guidelines for DME metering. The OIML Recommendation R 117, which covers dynamic measuring systems for liquids other than water, provides a foundation for DME metering regulations. However, specific adaptations may be necessary to address the unique properties of DME.

National regulatory bodies, such as the National Institute of Standards and Technology (NIST) in the United States and the European Committee for Standardization (CEN) in Europe, are responsible for developing and implementing standards for DME metering. These standards typically cover aspects such as meter accuracy, calibration procedures, and data security in smart metering systems.

One of the key challenges in regulating DME metering is addressing the fuel's physical properties. DME has a lower viscosity and density compared to conventional diesel fuel, which can affect metering accuracy. Regulatory frameworks must account for these differences and specify appropriate calibration methods and correction factors to ensure precise measurements.

Safety considerations are paramount in DME metering regulations. Given DME's flammability and potential for leakage, regulatory frameworks must include stringent safety standards for metering equipment, installation procedures, and maintenance protocols. This may involve requirements for explosion-proof designs, leak detection systems, and regular safety inspections.

Environmental regulations also play a significant role in shaping the framework for DME metering. As DME is promoted as a cleaner alternative to conventional fuels, regulatory bodies must establish guidelines for monitoring and reporting emissions associated with DME use. This may include requirements for integrating emissions monitoring capabilities into smart metering systems.

The regulatory framework must also address the integration of DME metering with smart grid technologies. This involves establishing standards for data communication protocols, cybersecurity measures, and interoperability with existing energy management systems. Regulations may specify requirements for real-time data transmission, remote meter reading capabilities, and data encryption to protect consumer privacy.

As the adoption of DME as a fuel source expands, regulatory frameworks will need to evolve to address emerging challenges and technological advancements. This may involve regular reviews and updates to metering standards, as well as collaboration between industry stakeholders, regulatory bodies, and research institutions to ensure that regulations keep pace with technological innovations in DME metering and smart grid integration.

At the international level, organizations such as the International Organization of Legal Metrology (OIML) play a crucial role in developing guidelines for DME metering. The OIML Recommendation R 117, which covers dynamic measuring systems for liquids other than water, provides a foundation for DME metering regulations. However, specific adaptations may be necessary to address the unique properties of DME.

National regulatory bodies, such as the National Institute of Standards and Technology (NIST) in the United States and the European Committee for Standardization (CEN) in Europe, are responsible for developing and implementing standards for DME metering. These standards typically cover aspects such as meter accuracy, calibration procedures, and data security in smart metering systems.

One of the key challenges in regulating DME metering is addressing the fuel's physical properties. DME has a lower viscosity and density compared to conventional diesel fuel, which can affect metering accuracy. Regulatory frameworks must account for these differences and specify appropriate calibration methods and correction factors to ensure precise measurements.

Safety considerations are paramount in DME metering regulations. Given DME's flammability and potential for leakage, regulatory frameworks must include stringent safety standards for metering equipment, installation procedures, and maintenance protocols. This may involve requirements for explosion-proof designs, leak detection systems, and regular safety inspections.

Environmental regulations also play a significant role in shaping the framework for DME metering. As DME is promoted as a cleaner alternative to conventional fuels, regulatory bodies must establish guidelines for monitoring and reporting emissions associated with DME use. This may include requirements for integrating emissions monitoring capabilities into smart metering systems.

The regulatory framework must also address the integration of DME metering with smart grid technologies. This involves establishing standards for data communication protocols, cybersecurity measures, and interoperability with existing energy management systems. Regulations may specify requirements for real-time data transmission, remote meter reading capabilities, and data encryption to protect consumer privacy.

As the adoption of DME as a fuel source expands, regulatory frameworks will need to evolve to address emerging challenges and technological advancements. This may involve regular reviews and updates to metering standards, as well as collaboration between industry stakeholders, regulatory bodies, and research institutions to ensure that regulations keep pace with technological innovations in DME metering and smart grid integration.

Environmental Impact of DME Smart Metering

The implementation of Dimethyl Ether (DME) in smart metering processes presents both opportunities and challenges from an environmental perspective. DME, as a clean-burning fuel with lower carbon emissions compared to traditional fossil fuels, offers potential benefits in reducing greenhouse gas emissions when used in smart metering systems. However, its environmental impact must be carefully considered across the entire lifecycle of smart metering applications.

One of the primary environmental advantages of DME smart metering is the potential reduction in energy consumption. Smart meters equipped with DME technology can provide more accurate and real-time data on energy usage, enabling consumers and utility companies to optimize energy consumption patterns. This increased efficiency can lead to a decrease in overall energy demand, subsequently reducing the environmental footprint associated with energy production and distribution.

Furthermore, DME's chemical properties make it less harmful to the environment in case of leaks or spills compared to conventional fuels. It has a lower global warming potential and does not contribute to ozone depletion. This characteristic is particularly important in smart metering applications where the fuel may be stored or transported in various locations.

However, the production of DME for smart metering purposes must be scrutinized. While DME can be produced from renewable sources such as biomass, its current production primarily relies on natural gas or coal, which can offset some of its environmental benefits. The environmental impact of DME production, including water usage, land use changes, and emissions from manufacturing processes, needs to be carefully assessed and mitigated.

The disposal and recycling of DME-based smart metering equipment at the end of its lifecycle also present environmental considerations. Proper recycling and waste management protocols must be established to prevent the release of harmful substances into the environment and to maximize the recovery of valuable materials.

Additionally, the integration of DME into existing smart metering infrastructure may require modifications or replacements of current systems. The environmental cost of these changes, including the production and disposal of new equipment, should be weighed against the long-term environmental benefits of DME implementation.

Lastly, the potential for DME to contribute to air quality improvements in urban areas where smart metering systems are widely deployed should not be overlooked. Its clean-burning properties can help reduce local air pollutants, potentially leading to improved public health outcomes and reduced environmental degradation in densely populated areas.

In conclusion, while DME smart metering offers promising environmental benefits, a comprehensive lifecycle assessment is crucial to fully understand and optimize its environmental impact. Balancing the advantages of reduced emissions and increased energy efficiency against the challenges of production and end-of-life management will be key to ensuring that DME smart metering contributes positively to environmental sustainability goals.

One of the primary environmental advantages of DME smart metering is the potential reduction in energy consumption. Smart meters equipped with DME technology can provide more accurate and real-time data on energy usage, enabling consumers and utility companies to optimize energy consumption patterns. This increased efficiency can lead to a decrease in overall energy demand, subsequently reducing the environmental footprint associated with energy production and distribution.

Furthermore, DME's chemical properties make it less harmful to the environment in case of leaks or spills compared to conventional fuels. It has a lower global warming potential and does not contribute to ozone depletion. This characteristic is particularly important in smart metering applications where the fuel may be stored or transported in various locations.

However, the production of DME for smart metering purposes must be scrutinized. While DME can be produced from renewable sources such as biomass, its current production primarily relies on natural gas or coal, which can offset some of its environmental benefits. The environmental impact of DME production, including water usage, land use changes, and emissions from manufacturing processes, needs to be carefully assessed and mitigated.

The disposal and recycling of DME-based smart metering equipment at the end of its lifecycle also present environmental considerations. Proper recycling and waste management protocols must be established to prevent the release of harmful substances into the environment and to maximize the recovery of valuable materials.

Additionally, the integration of DME into existing smart metering infrastructure may require modifications or replacements of current systems. The environmental cost of these changes, including the production and disposal of new equipment, should be weighed against the long-term environmental benefits of DME implementation.

Lastly, the potential for DME to contribute to air quality improvements in urban areas where smart metering systems are widely deployed should not be overlooked. Its clean-burning properties can help reduce local air pollutants, potentially leading to improved public health outcomes and reduced environmental degradation in densely populated areas.

In conclusion, while DME smart metering offers promising environmental benefits, a comprehensive lifecycle assessment is crucial to fully understand and optimize its environmental impact. Balancing the advantages of reduced emissions and increased energy efficiency against the challenges of production and end-of-life management will be key to ensuring that DME smart metering contributes positively to environmental sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!