How Dimethyl Ether Influences Advanced Microgrid Design?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME in Microgrids: Background and Objectives

Dimethyl ether (DME) has emerged as a promising alternative fuel in the context of advanced microgrid design, offering a unique set of properties that align with the evolving needs of sustainable energy systems. The integration of DME into microgrids represents a convergence of two significant technological trends: the push for cleaner, more efficient energy sources and the development of decentralized power systems.

Historically, microgrids have relied primarily on conventional fossil fuels or renewable energy sources such as solar and wind. However, the intermittent nature of renewables and the environmental concerns associated with fossil fuels have driven the search for more versatile and sustainable energy carriers. DME, with its clean-burning characteristics and potential for renewable production, has attracted attention as a complementary fuel in this landscape.

The primary objective of incorporating DME into microgrid design is to enhance system flexibility, reliability, and environmental performance. DME can be used in various applications within a microgrid, including power generation, combined heat and power systems, and as a storage medium for excess renewable energy. Its compatibility with existing infrastructure for liquefied petroleum gas (LPG) also presents opportunities for rapid adoption in certain contexts.

From a technical perspective, the integration of DME into microgrids aims to address several key challenges. These include improving energy density for storage applications, reducing emissions from power generation, and providing a stable backup power source to complement intermittent renewables. The versatility of DME as both a fuel and a potential energy storage medium aligns well with the multi-faceted requirements of modern microgrid systems.

The evolution of DME technology in the context of microgrids is closely tied to advancements in production methods, particularly those focused on renewable pathways. Bio-based DME production and power-to-DME processes using excess renewable electricity are areas of active research and development. These innovations are crucial for positioning DME as a sustainable component of future energy systems.

As microgrid designs become more sophisticated, incorporating smart grid technologies and advanced control systems, the role of DME is expected to expand. The ability to rapidly adjust output and serve multiple functions within the microgrid ecosystem makes DME an attractive option for system operators seeking to optimize performance and resilience.

Historically, microgrids have relied primarily on conventional fossil fuels or renewable energy sources such as solar and wind. However, the intermittent nature of renewables and the environmental concerns associated with fossil fuels have driven the search for more versatile and sustainable energy carriers. DME, with its clean-burning characteristics and potential for renewable production, has attracted attention as a complementary fuel in this landscape.

The primary objective of incorporating DME into microgrid design is to enhance system flexibility, reliability, and environmental performance. DME can be used in various applications within a microgrid, including power generation, combined heat and power systems, and as a storage medium for excess renewable energy. Its compatibility with existing infrastructure for liquefied petroleum gas (LPG) also presents opportunities for rapid adoption in certain contexts.

From a technical perspective, the integration of DME into microgrids aims to address several key challenges. These include improving energy density for storage applications, reducing emissions from power generation, and providing a stable backup power source to complement intermittent renewables. The versatility of DME as both a fuel and a potential energy storage medium aligns well with the multi-faceted requirements of modern microgrid systems.

The evolution of DME technology in the context of microgrids is closely tied to advancements in production methods, particularly those focused on renewable pathways. Bio-based DME production and power-to-DME processes using excess renewable electricity are areas of active research and development. These innovations are crucial for positioning DME as a sustainable component of future energy systems.

As microgrid designs become more sophisticated, incorporating smart grid technologies and advanced control systems, the role of DME is expected to expand. The ability to rapidly adjust output and serve multiple functions within the microgrid ecosystem makes DME an attractive option for system operators seeking to optimize performance and resilience.

Market Analysis for DME-based Microgrids

The market for DME-based microgrids is experiencing significant growth potential due to the increasing demand for clean and efficient energy solutions. Dimethyl ether (DME) has emerged as a promising alternative fuel for microgrid applications, offering several advantages over traditional fossil fuels. The global microgrid market is projected to expand rapidly in the coming years, with DME-based systems poised to capture a substantial share.

DME's versatility as a fuel source makes it particularly attractive for microgrid applications. It can be produced from various feedstocks, including natural gas, coal, and biomass, providing flexibility in sourcing and production. This adaptability aligns well with the diverse energy needs of different regions and industries, potentially expanding the market reach of DME-based microgrids.

The environmental benefits of DME are driving its adoption in microgrid systems. As a clean-burning fuel with low emissions of particulate matter and nitrogen oxides, DME aligns with increasingly stringent environmental regulations and sustainability goals. This positions DME-based microgrids favorably in markets prioritizing green energy solutions, particularly in developed economies with strict emission standards.

In the industrial sector, DME-based microgrids are gaining traction due to their ability to provide reliable and efficient power for manufacturing processes. Industries with high energy demands, such as chemical plants and food processing facilities, are showing increased interest in DME as a fuel source for their microgrid systems. This trend is expected to contribute significantly to market growth in the coming years.

The remote and off-grid power generation segment presents a substantial opportunity for DME-based microgrids. In regions with limited access to centralized power grids, such as rural areas in developing countries or remote industrial sites, DME-based systems offer a viable solution for reliable and sustainable energy production. This market segment is anticipated to be a key driver of growth for DME microgrid technology.

However, the market for DME-based microgrids also faces challenges. The initial infrastructure costs associated with DME production and distribution can be significant, potentially limiting adoption in some regions. Additionally, competition from other alternative fuels and energy storage technologies may impact market penetration rates.

Despite these challenges, the overall market outlook for DME-based microgrids remains positive. As technology advances and economies of scale are achieved, the cost-effectiveness of these systems is expected to improve. Furthermore, ongoing research and development efforts are likely to enhance the efficiency and performance of DME-based microgrids, further boosting their market appeal.

DME's versatility as a fuel source makes it particularly attractive for microgrid applications. It can be produced from various feedstocks, including natural gas, coal, and biomass, providing flexibility in sourcing and production. This adaptability aligns well with the diverse energy needs of different regions and industries, potentially expanding the market reach of DME-based microgrids.

The environmental benefits of DME are driving its adoption in microgrid systems. As a clean-burning fuel with low emissions of particulate matter and nitrogen oxides, DME aligns with increasingly stringent environmental regulations and sustainability goals. This positions DME-based microgrids favorably in markets prioritizing green energy solutions, particularly in developed economies with strict emission standards.

In the industrial sector, DME-based microgrids are gaining traction due to their ability to provide reliable and efficient power for manufacturing processes. Industries with high energy demands, such as chemical plants and food processing facilities, are showing increased interest in DME as a fuel source for their microgrid systems. This trend is expected to contribute significantly to market growth in the coming years.

The remote and off-grid power generation segment presents a substantial opportunity for DME-based microgrids. In regions with limited access to centralized power grids, such as rural areas in developing countries or remote industrial sites, DME-based systems offer a viable solution for reliable and sustainable energy production. This market segment is anticipated to be a key driver of growth for DME microgrid technology.

However, the market for DME-based microgrids also faces challenges. The initial infrastructure costs associated with DME production and distribution can be significant, potentially limiting adoption in some regions. Additionally, competition from other alternative fuels and energy storage technologies may impact market penetration rates.

Despite these challenges, the overall market outlook for DME-based microgrids remains positive. As technology advances and economies of scale are achieved, the cost-effectiveness of these systems is expected to improve. Furthermore, ongoing research and development efforts are likely to enhance the efficiency and performance of DME-based microgrids, further boosting their market appeal.

Current Challenges in DME Integration

The integration of Dimethyl Ether (DME) into advanced microgrid designs presents several significant challenges that need to be addressed for successful implementation. One of the primary obstacles is the lack of widespread infrastructure for DME distribution and storage. Unlike traditional fuels, DME requires specialized handling and storage facilities, which are not readily available in many areas where microgrids are being deployed.

Another critical challenge is the need for specialized equipment and technologies to effectively utilize DME in power generation systems. Existing generators and engines often require modifications or replacements to accommodate DME as a fuel source. This adaptation process can be both costly and time-consuming, potentially slowing down the adoption of DME in microgrid applications.

The variability in DME quality and composition poses additional challenges for microgrid designers. DME can be produced from various feedstocks, resulting in slight variations in its properties. These variations can affect combustion efficiency and emissions, requiring sophisticated control systems to maintain optimal performance across different DME sources.

Safety concerns also present a significant hurdle in DME integration. While DME is generally considered safer than some conventional fuels, its flammability and potential for rapid vaporization necessitate stringent safety protocols and equipment. Microgrid operators must implement comprehensive safety measures and train personnel accordingly, adding complexity to system design and operation.

Environmental considerations further complicate DME integration. Although DME is often touted as a cleaner alternative to diesel, its production process can still have environmental impacts. Microgrid designers must carefully assess the lifecycle emissions and environmental footprint of DME use, particularly in comparison to other renewable energy sources that may be available for integration.

The regulatory landscape surrounding DME use in power generation is still evolving, creating uncertainty for microgrid developers. Compliance with existing and potential future regulations adds another layer of complexity to system design and may require ongoing adjustments as regulatory frameworks mature.

Lastly, the economic viability of DME integration remains a significant challenge. The cost of DME production, transportation, and storage, coupled with the expenses associated with adapting existing infrastructure, can impact the overall cost-effectiveness of DME-based microgrids. Designers must carefully balance these costs against potential benefits to ensure the long-term sustainability of DME-powered systems.

Another critical challenge is the need for specialized equipment and technologies to effectively utilize DME in power generation systems. Existing generators and engines often require modifications or replacements to accommodate DME as a fuel source. This adaptation process can be both costly and time-consuming, potentially slowing down the adoption of DME in microgrid applications.

The variability in DME quality and composition poses additional challenges for microgrid designers. DME can be produced from various feedstocks, resulting in slight variations in its properties. These variations can affect combustion efficiency and emissions, requiring sophisticated control systems to maintain optimal performance across different DME sources.

Safety concerns also present a significant hurdle in DME integration. While DME is generally considered safer than some conventional fuels, its flammability and potential for rapid vaporization necessitate stringent safety protocols and equipment. Microgrid operators must implement comprehensive safety measures and train personnel accordingly, adding complexity to system design and operation.

Environmental considerations further complicate DME integration. Although DME is often touted as a cleaner alternative to diesel, its production process can still have environmental impacts. Microgrid designers must carefully assess the lifecycle emissions and environmental footprint of DME use, particularly in comparison to other renewable energy sources that may be available for integration.

The regulatory landscape surrounding DME use in power generation is still evolving, creating uncertainty for microgrid developers. Compliance with existing and potential future regulations adds another layer of complexity to system design and may require ongoing adjustments as regulatory frameworks mature.

Lastly, the economic viability of DME integration remains a significant challenge. The cost of DME production, transportation, and storage, coupled with the expenses associated with adapting existing infrastructure, can impact the overall cost-effectiveness of DME-based microgrids. Designers must carefully balance these costs against potential benefits to ensure the long-term sustainability of DME-powered systems.

Existing DME Solutions for Microgrids

01 Production of dimethyl ether

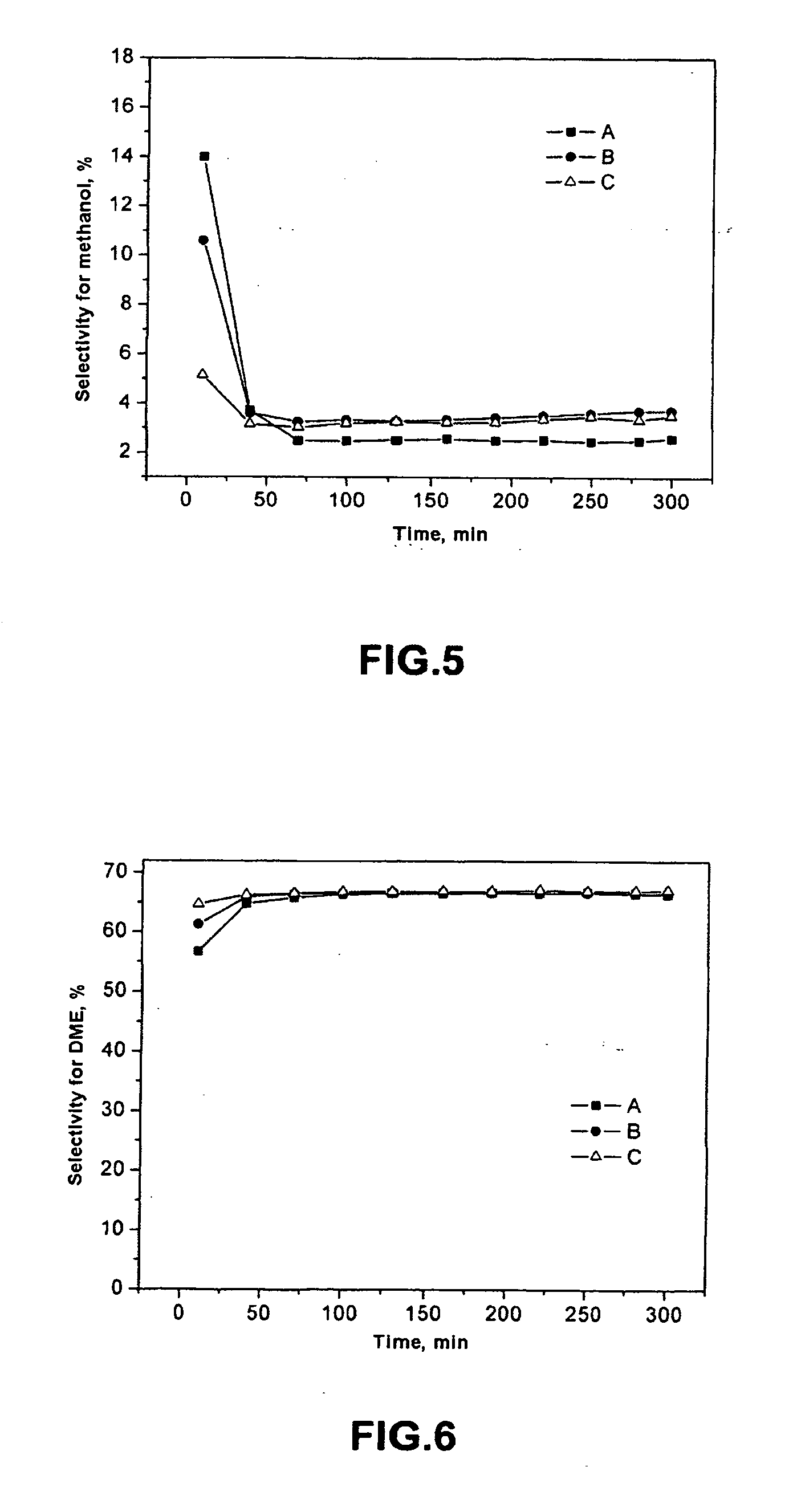

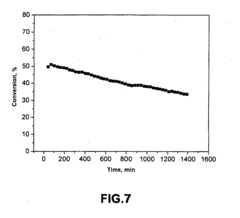

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.- Production of dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

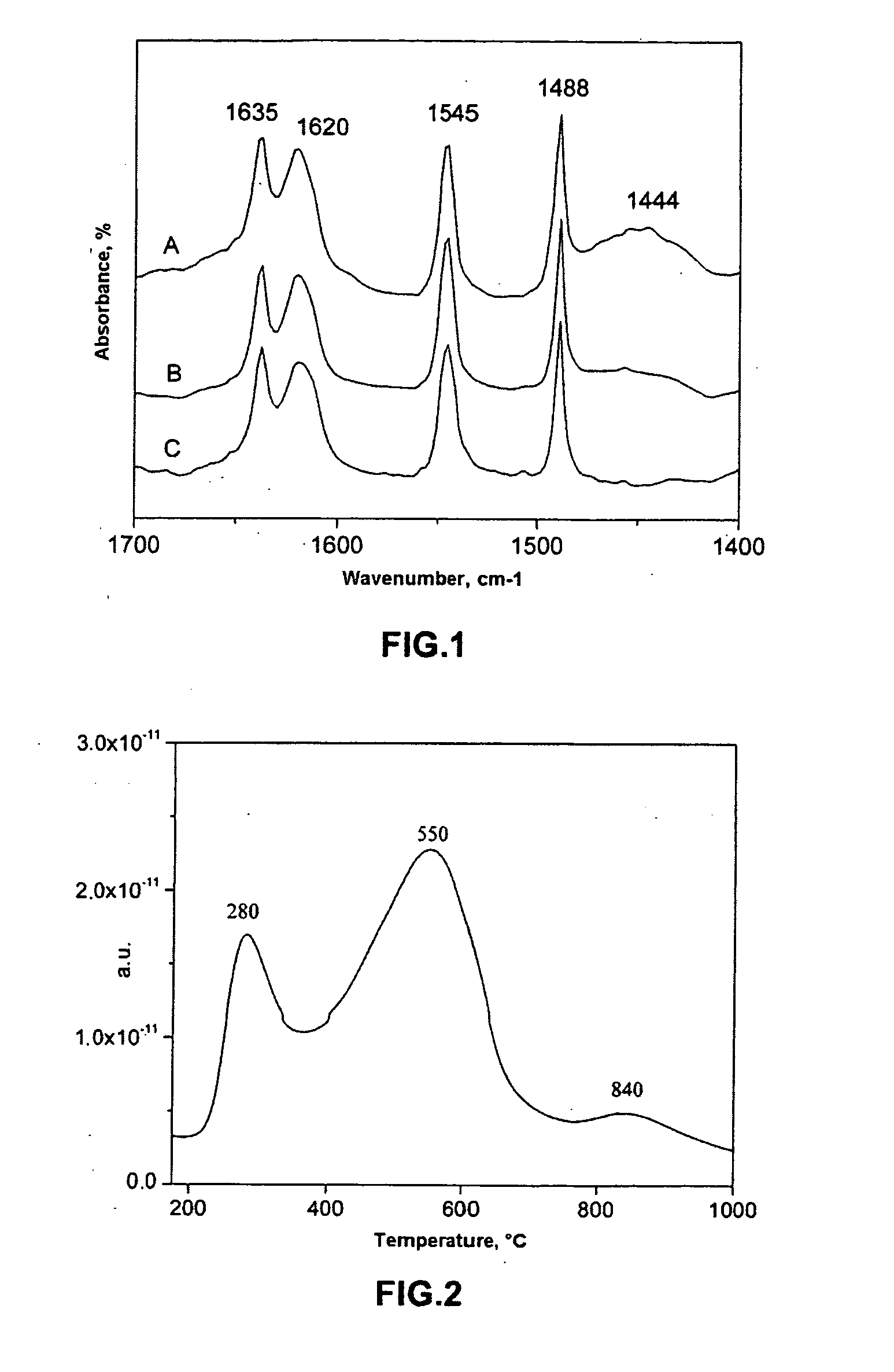

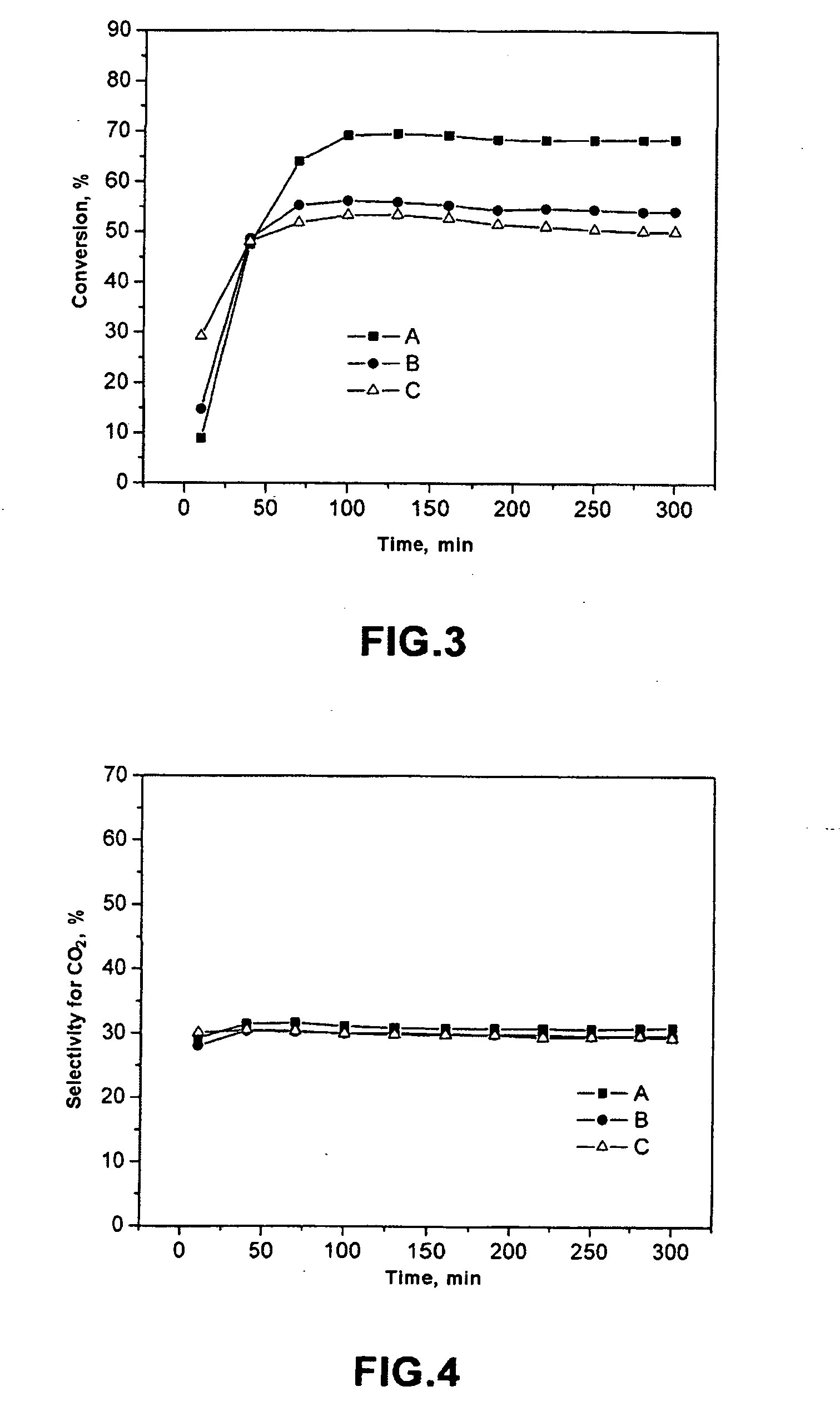

- Catalysts for dimethyl ether synthesis: Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.

- Applications of dimethyl ether: Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as an alternative fuel for diesel engines and as a feedstock for other chemical processes.

- Purification and separation of dimethyl ether: Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes often involve distillation, adsorption, or membrane separation techniques to achieve high-purity dimethyl ether.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and risk assessments associated with its use as a fuel or chemical intermediate.

02 Catalysts for dimethyl ether synthesis

Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.Expand Specific Solutions03 Applications of dimethyl ether

Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as a potential alternative fuel for diesel engines due to its clean-burning properties and high cetane number.Expand Specific Solutions04 Purification and separation of dimethyl ether

Techniques for purifying and separating dimethyl ether from reaction mixtures or other compounds are crucial in its production process. These may include distillation, adsorption, and membrane separation methods to achieve high-purity dimethyl ether.Expand Specific Solutions05 Environmental and safety considerations

Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and storage requirements to ensure safe and sustainable utilization of dimethyl ether.Expand Specific Solutions

Key Players in DME and Microgrid Industries

The development of dimethyl ether (DME) technology for advanced microgrid design is in an early growth stage, with increasing market potential as the demand for clean energy solutions rises. The global DME market size is projected to expand significantly in the coming years, driven by its applications in power generation and energy storage. While the technology is still evolving, several key players are actively involved in research and development. Companies like China Petroleum & Chemical Corp., BASF Corp., and Linde GmbH are at the forefront of DME production and application technologies. Academic institutions such as the University of Southern California and Zhejiang University are contributing to fundamental research. The involvement of diverse stakeholders indicates growing interest and investment in DME's potential for microgrid applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced microgrid designs incorporating dimethyl ether (DME) as a clean alternative fuel. Their approach integrates DME production facilities with renewable energy sources to create self-sustaining energy systems. The company has implemented pilot projects using DME in microgrids for remote industrial sites, demonstrating up to 30% reduction in carbon emissions compared to traditional diesel generators [1]. Sinopec's microgrid design incorporates smart grid technologies to optimize DME usage, balancing it with solar and wind power inputs. They have also developed specialized DME storage and distribution systems within the microgrid to ensure consistent fuel supply [3].

Strengths: Extensive experience in fuel production and distribution; large-scale implementation capability. Weaknesses: Potential dependency on fossil fuel-based DME production; adaptation challenges for existing infrastructure.

BASF Corp.

Technical Solution: BASF Corp. has pioneered the integration of DME into advanced microgrid designs through their innovative catalytic conversion technology. Their approach focuses on producing DME from renewable sources such as biomass and captured CO2, making it a carbon-neutral fuel option for microgrids. BASF's microgrid solution incorporates a modular DME production unit that can be scaled according to energy demands. The company has developed high-efficiency DME-compatible generators that achieve up to 45% electrical efficiency [2]. Additionally, BASF's advanced control systems optimize the interplay between DME generation, renewable energy sources, and energy storage within the microgrid, ensuring stable power supply and maximizing overall system efficiency [4].

Strengths: Advanced catalytic technology for DME production; expertise in chemical process integration. Weaknesses: Limited experience in power distribution systems; potential high initial costs for implementation.

Innovative DME Technologies for Microgrids

Catalytic system and process for direct synthesis of dimethyl ether from synthesis gas

PatentInactiveUS20090326281A1

Innovation

- A mixed-bed catalytic system comprising a catalyst for methanol synthesis and acid form zeolite ferrierite, with a silica/alumina ratio of 10 and specific potassium and sodium content, is physically mixed and activated, providing a high concentration of Brønsted acid sites for efficient dehydration without forming unwanted products.

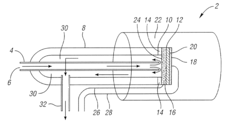

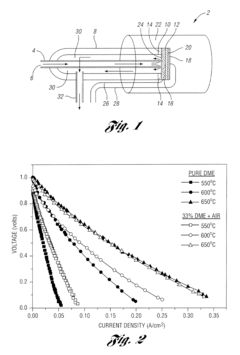

Direct operation of low temperature solid oxide fuel cells using oxygenated fuel

PatentInactiveUS20050106427A1

Innovation

- A method involving the formation of a mixture of molecular oxygen and a methyl ether compound, heated to produce carbon monoxide and hydrogen, which is then used to power a solid oxide fuel cell, preferably with a nickel-containing anode, at temperatures between 550°C to 650°C, optimizing the molar ratio of oxygen to methyl ether to minimize water and carbon dioxide production.

Environmental Impact of DME in Microgrids

The environmental impact of Dimethyl Ether (DME) in microgrids is a crucial consideration for advanced microgrid design. DME, as a clean-burning synthetic fuel, offers several environmental advantages when integrated into microgrid systems. Primarily, DME combustion produces significantly lower emissions of particulate matter, sulfur oxides, and nitrogen oxides compared to conventional diesel fuel. This reduction in harmful emissions contributes to improved air quality and reduced environmental pollution in areas where microgrids are deployed.

Furthermore, DME can be produced from various renewable sources, including biomass and waste materials, making it a potentially carbon-neutral fuel option. When derived from renewable feedstocks, DME can help reduce the overall carbon footprint of microgrid operations, aligning with global efforts to mitigate climate change. The ability to produce DME locally from renewable resources also promotes energy independence and reduces the environmental impact associated with fuel transportation.

In microgrid applications, DME can serve as a versatile energy carrier, capable of powering generators, fuel cells, and other energy conversion devices. This flexibility allows for the integration of DME into hybrid microgrid systems, potentially increasing the overall efficiency and reducing the environmental impact of energy generation. The use of DME in microgrids can also facilitate the integration of intermittent renewable energy sources, such as solar and wind, by providing a reliable and clean backup power source.

However, it is essential to consider the full lifecycle environmental impact of DME production and use in microgrids. While DME combustion is cleaner than many alternatives, the production process may have environmental implications depending on the feedstock and production methods used. Life cycle assessments are necessary to accurately evaluate the net environmental benefit of incorporating DME into microgrid designs.

Additionally, the implementation of DME in microgrids may require modifications to existing infrastructure and equipment. The environmental impact of these changes, including the production and disposal of new components, should be factored into the overall environmental assessment. Proper handling and storage of DME are also critical to prevent leaks or spills that could have localized environmental effects.

In conclusion, the integration of DME into advanced microgrid designs offers promising environmental benefits, particularly in terms of reduced emissions and the potential for carbon-neutral operation. However, a comprehensive approach to environmental impact assessment is necessary to ensure that the adoption of DME in microgrids truly contributes to sustainable energy solutions.

Furthermore, DME can be produced from various renewable sources, including biomass and waste materials, making it a potentially carbon-neutral fuel option. When derived from renewable feedstocks, DME can help reduce the overall carbon footprint of microgrid operations, aligning with global efforts to mitigate climate change. The ability to produce DME locally from renewable resources also promotes energy independence and reduces the environmental impact associated with fuel transportation.

In microgrid applications, DME can serve as a versatile energy carrier, capable of powering generators, fuel cells, and other energy conversion devices. This flexibility allows for the integration of DME into hybrid microgrid systems, potentially increasing the overall efficiency and reducing the environmental impact of energy generation. The use of DME in microgrids can also facilitate the integration of intermittent renewable energy sources, such as solar and wind, by providing a reliable and clean backup power source.

However, it is essential to consider the full lifecycle environmental impact of DME production and use in microgrids. While DME combustion is cleaner than many alternatives, the production process may have environmental implications depending on the feedstock and production methods used. Life cycle assessments are necessary to accurately evaluate the net environmental benefit of incorporating DME into microgrid designs.

Additionally, the implementation of DME in microgrids may require modifications to existing infrastructure and equipment. The environmental impact of these changes, including the production and disposal of new components, should be factored into the overall environmental assessment. Proper handling and storage of DME are also critical to prevent leaks or spills that could have localized environmental effects.

In conclusion, the integration of DME into advanced microgrid designs offers promising environmental benefits, particularly in terms of reduced emissions and the potential for carbon-neutral operation. However, a comprehensive approach to environmental impact assessment is necessary to ensure that the adoption of DME in microgrids truly contributes to sustainable energy solutions.

Regulatory Framework for DME-based Microgrids

The regulatory framework for DME-based microgrids is a complex and evolving landscape that significantly impacts the design and implementation of advanced microgrid systems. As dimethyl ether (DME) gains traction as an alternative fuel source, policymakers and regulatory bodies are working to establish guidelines that ensure safety, efficiency, and environmental compliance.

At the federal level, the Federal Energy Regulatory Commission (FERC) plays a crucial role in overseeing the integration of DME-based microgrids into the broader energy infrastructure. FERC has issued several orders and guidelines addressing the interconnection of distributed energy resources, including those utilizing DME. These regulations aim to streamline the process of connecting microgrids to the main grid while maintaining system reliability and stability.

State-level regulations vary considerably, with some states taking a proactive approach to encourage DME-based microgrid development. For instance, California has implemented policies that incentivize the use of alternative fuels in microgrids, including DME, as part of its efforts to reduce greenhouse gas emissions and enhance grid resilience. Other states are following suit, developing their own regulatory frameworks to address the unique challenges and opportunities presented by DME-based microgrids.

Environmental regulations also play a significant role in shaping the design of DME-based microgrids. The Environmental Protection Agency (EPA) has established emissions standards that apply to stationary power generation sources, including those using DME. Microgrid designers must ensure compliance with these standards, which may influence the choice of equipment and operational strategies.

Safety regulations are another critical aspect of the regulatory framework. The Occupational Safety and Health Administration (OSHA) has set guidelines for the handling and storage of DME, which must be incorporated into microgrid design and operational procedures. Additionally, local fire codes and building regulations may impose specific requirements on DME storage and distribution systems within microgrid installations.

The regulatory landscape also addresses the economic aspects of DME-based microgrids. Many jurisdictions have implemented net metering policies and tariff structures that impact the financial viability of microgrid projects. These regulations determine how excess energy generated by microgrids can be sold back to the grid and how costs are allocated between microgrid operators and utility companies.

As the technology continues to evolve, regulatory bodies are working to keep pace with innovations in DME-based microgrid design. This includes developing standards for advanced control systems, cybersecurity protocols, and grid integration technologies specific to DME applications. The National Institute of Standards and Technology (NIST) has been instrumental in developing these standards, which are crucial for ensuring interoperability and reliability across different microgrid implementations.

At the federal level, the Federal Energy Regulatory Commission (FERC) plays a crucial role in overseeing the integration of DME-based microgrids into the broader energy infrastructure. FERC has issued several orders and guidelines addressing the interconnection of distributed energy resources, including those utilizing DME. These regulations aim to streamline the process of connecting microgrids to the main grid while maintaining system reliability and stability.

State-level regulations vary considerably, with some states taking a proactive approach to encourage DME-based microgrid development. For instance, California has implemented policies that incentivize the use of alternative fuels in microgrids, including DME, as part of its efforts to reduce greenhouse gas emissions and enhance grid resilience. Other states are following suit, developing their own regulatory frameworks to address the unique challenges and opportunities presented by DME-based microgrids.

Environmental regulations also play a significant role in shaping the design of DME-based microgrids. The Environmental Protection Agency (EPA) has established emissions standards that apply to stationary power generation sources, including those using DME. Microgrid designers must ensure compliance with these standards, which may influence the choice of equipment and operational strategies.

Safety regulations are another critical aspect of the regulatory framework. The Occupational Safety and Health Administration (OSHA) has set guidelines for the handling and storage of DME, which must be incorporated into microgrid design and operational procedures. Additionally, local fire codes and building regulations may impose specific requirements on DME storage and distribution systems within microgrid installations.

The regulatory landscape also addresses the economic aspects of DME-based microgrids. Many jurisdictions have implemented net metering policies and tariff structures that impact the financial viability of microgrid projects. These regulations determine how excess energy generated by microgrids can be sold back to the grid and how costs are allocated between microgrid operators and utility companies.

As the technology continues to evolve, regulatory bodies are working to keep pace with innovations in DME-based microgrid design. This includes developing standards for advanced control systems, cybersecurity protocols, and grid integration technologies specific to DME applications. The National Institute of Standards and Technology (NIST) has been instrumental in developing these standards, which are crucial for ensuring interoperability and reliability across different microgrid implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!