How Dimethyl Ether Fuels Green Economy Expansion?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Technology Evolution

Dimethyl ether (DME) has undergone significant technological evolution since its initial discovery in the late 19th century. The journey of DME as a potential green fuel began in earnest during the 1990s when researchers recognized its potential as a clean-burning alternative to conventional fossil fuels.

In the early stages of DME technology development, the focus was primarily on production methods. The traditional approach involved a two-step process: first, synthesizing methanol from syngas, and then dehydrating methanol to produce DME. This method, while effective, was energy-intensive and costly. The late 1990s and early 2000s saw a breakthrough with the development of single-step DME synthesis, which significantly improved production efficiency and reduced costs.

The mid-2000s marked a pivotal point in DME technology evolution with the emergence of bio-based DME production. This innovation aligned DME more closely with green economy goals by utilizing renewable feedstocks such as biomass and waste materials. The ability to produce DME from sustainable sources greatly enhanced its appeal as a green fuel alternative.

Parallel to production advancements, engine technology for DME utilization also progressed. Initially, DME was considered primarily for use in modified diesel engines. However, as research intensified, dedicated DME engines were developed, optimizing performance and efficiency. These engines addressed challenges such as fuel injection systems and sealing materials compatible with DME's unique properties.

The late 2000s and early 2010s saw increased focus on DME as a potential replacement for liquefied petroleum gas (LPG) in household and industrial applications. This diversification of DME usage opened new avenues for green economy expansion, particularly in regions with limited access to traditional energy sources.

Recent years have witnessed advancements in DME purification and storage technologies. Enhanced purification methods have resulted in higher-quality DME, suitable for a broader range of applications. Innovations in storage and transportation infrastructure have also played a crucial role in making DME more viable as a widespread fuel option.

The most recent phase of DME technology evolution has centered on integration with other renewable energy systems. Research into combining DME production with carbon capture technologies and utilizing excess renewable electricity for DME synthesis has shown promising results. These developments position DME as a potential energy storage medium, addressing intermittency issues associated with renewable energy sources like wind and solar.

In the early stages of DME technology development, the focus was primarily on production methods. The traditional approach involved a two-step process: first, synthesizing methanol from syngas, and then dehydrating methanol to produce DME. This method, while effective, was energy-intensive and costly. The late 1990s and early 2000s saw a breakthrough with the development of single-step DME synthesis, which significantly improved production efficiency and reduced costs.

The mid-2000s marked a pivotal point in DME technology evolution with the emergence of bio-based DME production. This innovation aligned DME more closely with green economy goals by utilizing renewable feedstocks such as biomass and waste materials. The ability to produce DME from sustainable sources greatly enhanced its appeal as a green fuel alternative.

Parallel to production advancements, engine technology for DME utilization also progressed. Initially, DME was considered primarily for use in modified diesel engines. However, as research intensified, dedicated DME engines were developed, optimizing performance and efficiency. These engines addressed challenges such as fuel injection systems and sealing materials compatible with DME's unique properties.

The late 2000s and early 2010s saw increased focus on DME as a potential replacement for liquefied petroleum gas (LPG) in household and industrial applications. This diversification of DME usage opened new avenues for green economy expansion, particularly in regions with limited access to traditional energy sources.

Recent years have witnessed advancements in DME purification and storage technologies. Enhanced purification methods have resulted in higher-quality DME, suitable for a broader range of applications. Innovations in storage and transportation infrastructure have also played a crucial role in making DME more viable as a widespread fuel option.

The most recent phase of DME technology evolution has centered on integration with other renewable energy systems. Research into combining DME production with carbon capture technologies and utilizing excess renewable electricity for DME synthesis has shown promising results. These developments position DME as a potential energy storage medium, addressing intermittency issues associated with renewable energy sources like wind and solar.

Green Economy Market Demand

The green economy market demand for dimethyl ether (DME) as a clean fuel alternative is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable energy solutions. DME, with its clean-burning properties and potential to be produced from renewable sources, is positioning itself as a key player in the transition towards a greener economy.

In the transportation sector, DME is gaining traction as a substitute for diesel fuel in heavy-duty vehicles and marine applications. The demand for DME in this sector is expected to rise as governments worldwide implement stricter emissions regulations. Fleet operators and logistics companies are showing increased interest in DME-powered vehicles due to their lower carbon footprint and potential cost savings over the long term.

The industrial sector is another area where DME is seeing growing demand. As a propellant and aerosol propellant replacement, DME offers a more environmentally friendly alternative to traditional hydrofluorocarbons (HFCs). This shift is driven by international agreements such as the Kigali Amendment to the Montreal Protocol, which aims to phase down the use of HFCs.

In the power generation sector, DME is emerging as a promising fuel for gas turbines and combined heat and power (CHP) systems. Its clean-burning characteristics make it an attractive option for regions looking to reduce their reliance on coal and other high-emission fuels. The flexibility of DME production from various feedstocks, including renewable sources, aligns well with the green economy's goals of circular resource utilization.

The residential and commercial heating markets are also showing increased demand for DME as a replacement for liquefied petroleum gas (LPG) and heating oil. DME's compatibility with existing LPG infrastructure makes it an attractive option for regions looking to decarbonize their heating systems without significant infrastructure overhauls.

As countries set more ambitious climate targets and implement supportive policies, the market demand for DME is expected to accelerate. Incentives for clean fuel adoption, carbon pricing mechanisms, and renewable fuel standards are creating a favorable environment for DME market expansion. Additionally, the growing consumer preference for eco-friendly products and services is driving businesses to seek greener fuel alternatives, further boosting DME demand.

The Asia-Pacific region, particularly China and India, is anticipated to be a major growth driver for DME in the green economy. These countries are actively pursuing cleaner air initiatives and energy diversification strategies, creating substantial opportunities for DME adoption across various sectors.

In the transportation sector, DME is gaining traction as a substitute for diesel fuel in heavy-duty vehicles and marine applications. The demand for DME in this sector is expected to rise as governments worldwide implement stricter emissions regulations. Fleet operators and logistics companies are showing increased interest in DME-powered vehicles due to their lower carbon footprint and potential cost savings over the long term.

The industrial sector is another area where DME is seeing growing demand. As a propellant and aerosol propellant replacement, DME offers a more environmentally friendly alternative to traditional hydrofluorocarbons (HFCs). This shift is driven by international agreements such as the Kigali Amendment to the Montreal Protocol, which aims to phase down the use of HFCs.

In the power generation sector, DME is emerging as a promising fuel for gas turbines and combined heat and power (CHP) systems. Its clean-burning characteristics make it an attractive option for regions looking to reduce their reliance on coal and other high-emission fuels. The flexibility of DME production from various feedstocks, including renewable sources, aligns well with the green economy's goals of circular resource utilization.

The residential and commercial heating markets are also showing increased demand for DME as a replacement for liquefied petroleum gas (LPG) and heating oil. DME's compatibility with existing LPG infrastructure makes it an attractive option for regions looking to decarbonize their heating systems without significant infrastructure overhauls.

As countries set more ambitious climate targets and implement supportive policies, the market demand for DME is expected to accelerate. Incentives for clean fuel adoption, carbon pricing mechanisms, and renewable fuel standards are creating a favorable environment for DME market expansion. Additionally, the growing consumer preference for eco-friendly products and services is driving businesses to seek greener fuel alternatives, further boosting DME demand.

The Asia-Pacific region, particularly China and India, is anticipated to be a major growth driver for DME in the green economy. These countries are actively pursuing cleaner air initiatives and energy diversification strategies, creating substantial opportunities for DME adoption across various sectors.

DME Production Challenges

The production of dimethyl ether (DME) faces several significant challenges that need to be addressed to facilitate its widespread adoption as a green fuel. One of the primary hurdles is the high cost of production, which currently makes DME less competitive compared to conventional fossil fuels. The production process, typically involving methanol dehydration or direct synthesis from syngas, requires substantial energy input and expensive catalysts, contributing to the overall cost.

Raw material availability and sustainability also pose challenges. While DME can be produced from various feedstocks, including natural gas, coal, and biomass, ensuring a stable and sustainable supply chain for these raw materials is crucial. The use of renewable feedstocks, such as biomass, is preferable for green economy expansion but presents its own set of challenges in terms of collection, transportation, and processing.

Technical difficulties in the production process further complicate DME manufacturing. The synthesis of DME often involves complex chemical reactions and requires precise control of temperature, pressure, and catalyst performance. Achieving high conversion rates and selectivity while minimizing byproduct formation remains a significant challenge for researchers and engineers in the field.

Scaling up production to meet potential demand is another hurdle. As DME gains traction as an alternative fuel, the industry must develop efficient large-scale production facilities. This scaling process involves overcoming engineering challenges related to reactor design, heat management, and process integration, all of which can impact the overall efficiency and cost-effectiveness of DME production.

Environmental concerns also need to be addressed in DME production. While DME itself is considered a clean-burning fuel, its production process can still generate greenhouse gas emissions, particularly when derived from fossil feedstocks. Developing and implementing carbon capture and utilization technologies in DME production facilities is essential to minimize the carbon footprint and align with green economy goals.

Infrastructure limitations present additional challenges. The lack of widespread distribution networks and storage facilities for DME hampers its adoption as a fuel. Developing the necessary infrastructure for DME handling, transportation, and dispensing requires significant investment and coordination among various stakeholders in the energy sector.

Lastly, regulatory hurdles and policy uncertainties can impede the growth of DME production. Clear and supportive regulatory frameworks are needed to encourage investment in DME technology and production facilities. Harmonizing standards for DME quality, safety, and use across different regions is crucial for creating a stable market environment and fostering innovation in the DME industry.

Raw material availability and sustainability also pose challenges. While DME can be produced from various feedstocks, including natural gas, coal, and biomass, ensuring a stable and sustainable supply chain for these raw materials is crucial. The use of renewable feedstocks, such as biomass, is preferable for green economy expansion but presents its own set of challenges in terms of collection, transportation, and processing.

Technical difficulties in the production process further complicate DME manufacturing. The synthesis of DME often involves complex chemical reactions and requires precise control of temperature, pressure, and catalyst performance. Achieving high conversion rates and selectivity while minimizing byproduct formation remains a significant challenge for researchers and engineers in the field.

Scaling up production to meet potential demand is another hurdle. As DME gains traction as an alternative fuel, the industry must develop efficient large-scale production facilities. This scaling process involves overcoming engineering challenges related to reactor design, heat management, and process integration, all of which can impact the overall efficiency and cost-effectiveness of DME production.

Environmental concerns also need to be addressed in DME production. While DME itself is considered a clean-burning fuel, its production process can still generate greenhouse gas emissions, particularly when derived from fossil feedstocks. Developing and implementing carbon capture and utilization technologies in DME production facilities is essential to minimize the carbon footprint and align with green economy goals.

Infrastructure limitations present additional challenges. The lack of widespread distribution networks and storage facilities for DME hampers its adoption as a fuel. Developing the necessary infrastructure for DME handling, transportation, and dispensing requires significant investment and coordination among various stakeholders in the energy sector.

Lastly, regulatory hurdles and policy uncertainties can impede the growth of DME production. Clear and supportive regulatory frameworks are needed to encourage investment in DME technology and production facilities. Harmonizing standards for DME quality, safety, and use across different regions is crucial for creating a stable market environment and fostering innovation in the DME industry.

Current DME Fuel Solutions

01 Production of dimethyl ether from synthesis gas

Methods for producing dimethyl ether from synthesis gas, which is a mixture of carbon monoxide and hydrogen. This process often involves catalytic conversion and can be an important step in utilizing various feedstocks, including biomass and natural gas, to produce a clean-burning fuel.- Production of dimethyl ether from synthesis gas: Methods for producing dimethyl ether from synthesis gas, which is a mixture of carbon monoxide and hydrogen. This process often involves catalytic conversion and can be an important step in utilizing various feedstocks for green fuel production.

- Catalysts for dimethyl ether synthesis: Development of novel catalysts to improve the efficiency and selectivity of dimethyl ether production. These catalysts often involve metal oxides or zeolites and play a crucial role in the economic viability of dimethyl ether as a green fuel alternative.

- Dimethyl ether as a clean fuel substitute: Exploration of dimethyl ether as a cleaner alternative to conventional fuels, particularly in diesel engines. This includes studies on its combustion properties, emissions reduction potential, and necessary engine modifications for optimal use.

- Integration of dimethyl ether production with other processes: Methods for integrating dimethyl ether production with other industrial processes, such as methanol synthesis or biomass gasification. This integration can improve overall efficiency and reduce costs, making dimethyl ether more competitive in the green economy.

- Environmental impact and lifecycle assessment of dimethyl ether: Studies and methodologies for assessing the environmental impact and lifecycle of dimethyl ether production and use. This includes analysis of greenhouse gas emissions, energy efficiency, and overall sustainability compared to other fuel options.

02 Catalysts for dimethyl ether synthesis

Development of novel catalysts to improve the efficiency and selectivity of dimethyl ether production. These catalysts often involve metal oxides or zeolites and play a crucial role in the conversion of methanol or synthesis gas to dimethyl ether.Expand Specific Solutions03 Dimethyl ether as a green fuel alternative

Exploration of dimethyl ether as a cleaner alternative to conventional fossil fuels, particularly in diesel engines and power generation. This includes studies on its combustion properties, emissions reduction potential, and adaptations needed for existing infrastructure.Expand Specific Solutions04 Integration of dimethyl ether production with other processes

Methods for integrating dimethyl ether production with other industrial processes to improve overall efficiency and reduce environmental impact. This may include co-production with methanol, utilization of waste heat, or incorporation into biorefinery concepts.Expand Specific Solutions05 Purification and handling of dimethyl ether

Techniques for purifying dimethyl ether to meet fuel or chemical grade specifications, as well as methods for safe handling, storage, and transportation. This includes separation processes, contaminant removal, and development of appropriate materials for DME-compatible equipment.Expand Specific Solutions

Key DME Industry Players

The dimethyl ether (DME) fuel market is in a growth phase, driven by increasing demand for cleaner energy alternatives. The global market size is projected to expand significantly in the coming years, with key players like China Petroleum & Chemical Corp., SK Energy, and Indian Oil Corp. leading the way. These companies are investing heavily in research and development to improve DME production efficiency and expand its applications. The technology is maturing rapidly, with universities such as Zhejiang University and Tsinghua University collaborating with industry partners to advance DME fuel technology. While still not as widespread as traditional fuels, DME is gaining traction in various sectors, particularly in transportation and power generation, due to its lower emissions and potential as a renewable energy source.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive dimethyl ether (DME) production and utilization strategy to support green economy expansion. Their approach includes large-scale DME production from coal and natural gas, as well as innovative catalytic processes for DME synthesis[1]. Sinopec has implemented a closed-loop DME production system, integrating carbon capture and utilization to reduce overall emissions[2]. They have also developed DME-powered vehicles and established fueling infrastructure to promote DME as a clean alternative fuel[3]. Sinopec's research focuses on improving DME production efficiency and exploring new applications in power generation and chemical manufacturing[4].

Strengths: Vertically integrated production and utilization chain, large-scale production capacity, established infrastructure. Weaknesses: Dependence on fossil fuel feedstocks, potential competition from other alternative fuels.

SK Energy Co., Ltd.

Technical Solution: SK Energy has pioneered the development of DME as a clean fuel alternative in South Korea. Their technology focuses on producing DME from various feedstocks, including natural gas, coal, and biomass[1]. SK Energy has developed a proprietary catalytic process that improves DME yield and reduces energy consumption during production[2]. They have also invested in DME distribution infrastructure and partnered with vehicle manufacturers to promote DME-powered trucks and buses[3]. SK Energy's research extends to using DME as a hydrogen carrier for fuel cell applications, potentially expanding its role in the green economy[4].

Strengths: Advanced catalytic technology, diverse feedstock capabilities, strong partnerships in transportation sector. Weaknesses: Limited global market presence, competition from established LPG infrastructure.

DME Fuel Innovations

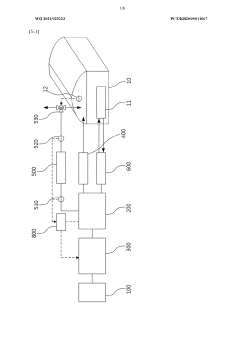

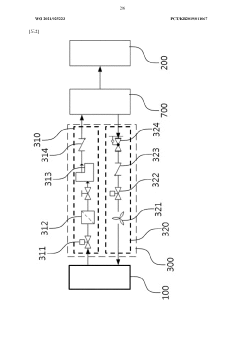

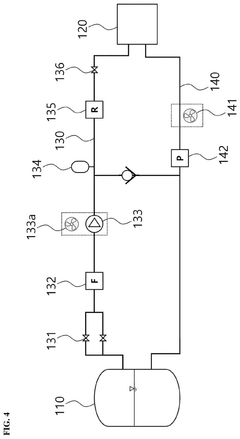

Trigeneration system using dme

PatentWO2021025223A1

Innovation

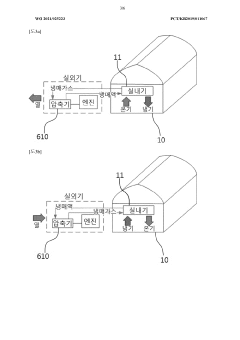

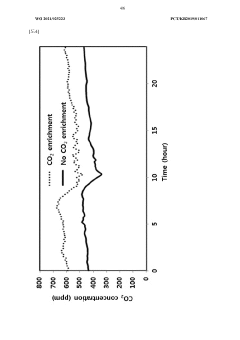

- A DME Trigen system that includes a DME tank, engine, fuel supply unit, processing unit for exhaust gases, power generation unit, and a cooling/heating unit, which uses DME as a clean fuel to produce electricity, control temperature, and supply carbon dioxide for increased photosynthesis, thereby enhancing fruit and vegetable growth.

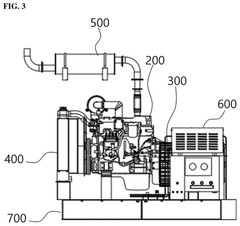

DME-fueled generator

PatentActiveUS20240352887A1

Innovation

- A DME-fueled generator system that utilizes dimethyl ether (DME) as a clean fuel, comprising a power generation unit, a DME engine for burning DME to generate driving force, and a DME supply unit for fueling the engine, which includes a radiator, exhaust pipe, and a controller to manage the power generation process, ensuring no fine dust is emitted in the exhaust gas.

Environmental Impact

Dimethyl ether (DME) has emerged as a promising alternative fuel with significant potential to contribute to green economy expansion. Its environmental impact is a crucial aspect to consider when evaluating its role in sustainable development.

DME combustion produces significantly lower emissions of particulate matter, nitrogen oxides, and sulfur oxides compared to conventional diesel fuel. This reduction in harmful pollutants can lead to improved air quality, particularly in urban areas where vehicle emissions are a major concern. The lower emissions profile of DME aligns well with increasingly stringent environmental regulations and air quality standards worldwide.

From a greenhouse gas perspective, DME offers notable advantages. When produced from renewable sources such as biomass or captured carbon dioxide, DME can achieve near-carbon neutrality or even negative carbon emissions. This characteristic positions DME as a valuable tool in the fight against climate change and supports global efforts to reduce carbon footprints across various sectors.

The production of DME can be integrated into existing industrial processes, potentially reducing waste and improving overall resource efficiency. For instance, DME can be synthesized from syngas derived from biomass gasification or industrial waste streams, turning potential pollutants into valuable fuel products. This circular economy approach contributes to waste reduction and resource conservation.

In the context of land use and biodiversity, DME's impact is generally favorable when compared to some biofuels. Unlike crops grown specifically for biofuel production, which can lead to land-use changes and competition with food crops, DME can be produced from a variety of feedstocks, including waste materials. This flexibility reduces pressure on land resources and helps mitigate concerns about indirect land-use change.

Water consumption and pollution are also important environmental considerations. DME production typically requires less water compared to some other alternative fuel production processes. Additionally, the clean-burning nature of DME reduces the risk of water pollution from fuel spills or leaks, as it quickly evaporates at ambient conditions.

The lifecycle environmental impact of DME depends heavily on its production pathway. While DME derived from fossil fuels still contributes to carbon emissions, the potential for renewable DME production offers a pathway to significant environmental benefits. As production technologies advance and renewable energy sources become more prevalent, the environmental footprint of DME is expected to improve further.

In conclusion, DME's environmental impact is largely positive, particularly when produced from renewable sources. Its potential to reduce air pollution, lower greenhouse gas emissions, and contribute to circular economy practices makes it a valuable component in the transition towards a greener economy. However, ongoing research and development are crucial to optimize production processes and maximize the environmental benefits of DME across its entire lifecycle.

DME combustion produces significantly lower emissions of particulate matter, nitrogen oxides, and sulfur oxides compared to conventional diesel fuel. This reduction in harmful pollutants can lead to improved air quality, particularly in urban areas where vehicle emissions are a major concern. The lower emissions profile of DME aligns well with increasingly stringent environmental regulations and air quality standards worldwide.

From a greenhouse gas perspective, DME offers notable advantages. When produced from renewable sources such as biomass or captured carbon dioxide, DME can achieve near-carbon neutrality or even negative carbon emissions. This characteristic positions DME as a valuable tool in the fight against climate change and supports global efforts to reduce carbon footprints across various sectors.

The production of DME can be integrated into existing industrial processes, potentially reducing waste and improving overall resource efficiency. For instance, DME can be synthesized from syngas derived from biomass gasification or industrial waste streams, turning potential pollutants into valuable fuel products. This circular economy approach contributes to waste reduction and resource conservation.

In the context of land use and biodiversity, DME's impact is generally favorable when compared to some biofuels. Unlike crops grown specifically for biofuel production, which can lead to land-use changes and competition with food crops, DME can be produced from a variety of feedstocks, including waste materials. This flexibility reduces pressure on land resources and helps mitigate concerns about indirect land-use change.

Water consumption and pollution are also important environmental considerations. DME production typically requires less water compared to some other alternative fuel production processes. Additionally, the clean-burning nature of DME reduces the risk of water pollution from fuel spills or leaks, as it quickly evaporates at ambient conditions.

The lifecycle environmental impact of DME depends heavily on its production pathway. While DME derived from fossil fuels still contributes to carbon emissions, the potential for renewable DME production offers a pathway to significant environmental benefits. As production technologies advance and renewable energy sources become more prevalent, the environmental footprint of DME is expected to improve further.

In conclusion, DME's environmental impact is largely positive, particularly when produced from renewable sources. Its potential to reduce air pollution, lower greenhouse gas emissions, and contribute to circular economy practices makes it a valuable component in the transition towards a greener economy. However, ongoing research and development are crucial to optimize production processes and maximize the environmental benefits of DME across its entire lifecycle.

Policy Support for DME

Policy support plays a crucial role in promoting the adoption and expansion of dimethyl ether (DME) as a green fuel alternative. Governments worldwide are implementing various measures to encourage the production and use of DME, recognizing its potential to contribute to a more sustainable economy.

One of the primary policy instruments is the provision of financial incentives. Many countries offer tax credits, grants, and subsidies to companies investing in DME production facilities or developing DME-compatible engines and infrastructure. These incentives help offset the initial capital costs associated with transitioning to DME technology, making it more economically viable for businesses to adopt.

Regulatory frameworks are also being adapted to facilitate DME integration into existing energy systems. This includes updating fuel standards to include DME specifications, streamlining permitting processes for DME production plants, and modifying transportation regulations to accommodate DME as a fuel. Such policy adjustments create a more favorable environment for DME market growth.

Research and development support is another key aspect of policy backing for DME. Governments are allocating funds for academic institutions and private sector entities to conduct studies on DME production efficiency, engine optimization, and environmental impact assessments. This support accelerates technological advancements and helps address technical challenges in DME implementation.

Public-private partnerships are being fostered to drive DME adoption. These collaborations often involve government agencies, energy companies, and vehicle manufacturers working together to develop pilot projects and demonstration programs. Such initiatives help build confidence in DME technology and create real-world examples of its benefits.

Environmental policies, such as carbon pricing mechanisms and emissions reduction targets, indirectly support DME by creating market conditions that favor cleaner fuel alternatives. As DME produces lower greenhouse gas emissions compared to conventional fuels, it becomes more attractive under stringent environmental regulations.

Education and awareness campaigns, backed by government resources, are also essential in promoting DME. These efforts aim to inform industries and the public about the benefits of DME, addressing concerns and misconceptions that may hinder its adoption.

International cooperation is emerging as a significant aspect of DME policy support. Countries are sharing best practices, harmonizing standards, and collaborating on research to create a more cohesive global approach to DME implementation. This cooperation helps create economies of scale and facilitates the development of a robust international DME market.

One of the primary policy instruments is the provision of financial incentives. Many countries offer tax credits, grants, and subsidies to companies investing in DME production facilities or developing DME-compatible engines and infrastructure. These incentives help offset the initial capital costs associated with transitioning to DME technology, making it more economically viable for businesses to adopt.

Regulatory frameworks are also being adapted to facilitate DME integration into existing energy systems. This includes updating fuel standards to include DME specifications, streamlining permitting processes for DME production plants, and modifying transportation regulations to accommodate DME as a fuel. Such policy adjustments create a more favorable environment for DME market growth.

Research and development support is another key aspect of policy backing for DME. Governments are allocating funds for academic institutions and private sector entities to conduct studies on DME production efficiency, engine optimization, and environmental impact assessments. This support accelerates technological advancements and helps address technical challenges in DME implementation.

Public-private partnerships are being fostered to drive DME adoption. These collaborations often involve government agencies, energy companies, and vehicle manufacturers working together to develop pilot projects and demonstration programs. Such initiatives help build confidence in DME technology and create real-world examples of its benefits.

Environmental policies, such as carbon pricing mechanisms and emissions reduction targets, indirectly support DME by creating market conditions that favor cleaner fuel alternatives. As DME produces lower greenhouse gas emissions compared to conventional fuels, it becomes more attractive under stringent environmental regulations.

Education and awareness campaigns, backed by government resources, are also essential in promoting DME. These efforts aim to inform industries and the public about the benefits of DME, addressing concerns and misconceptions that may hinder its adoption.

International cooperation is emerging as a significant aspect of DME policy support. Countries are sharing best practices, harmonizing standards, and collaborating on research to create a more cohesive global approach to DME implementation. This cooperation helps create economies of scale and facilitates the development of a robust international DME market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!