How Dimethyl Ether Powers New Modes of Energy Governance?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Technology Evolution and Objectives

Dimethyl ether (DME) has emerged as a promising alternative fuel, marking a significant evolution in energy technology. The journey of DME as an energy source began in the late 20th century, with initial research focusing on its potential as a clean-burning fuel for diesel engines. As environmental concerns grew, DME gained attention for its low emissions and ability to be produced from various feedstocks, including natural gas, coal, and biomass.

The technology surrounding DME has progressed rapidly over the past two decades. Early developments centered on improving production processes, particularly through the dehydration of methanol. As the technology matured, direct synthesis methods from syngas were developed, offering more efficient and cost-effective production routes. This evolution has been driven by the increasing need for cleaner energy alternatives and the push towards reducing greenhouse gas emissions.

The objectives of DME technology development have shifted and expanded over time. Initially, the focus was on establishing DME as a viable alternative to conventional diesel fuel. This goal has broadened to encompass a range of applications, including use as a cooking fuel, a propellant in aerosol products, and a potential hydrogen carrier for fuel cells. The versatility of DME has opened up new avenues for energy governance, as it offers a flexible solution that can be integrated into existing energy infrastructures.

Current technological objectives for DME are multifaceted. There is a strong emphasis on scaling up production to make DME economically competitive with traditional fuels. This involves optimizing production processes, reducing costs, and developing more efficient catalysts. Another key objective is to enhance the infrastructure for DME distribution and use, including the development of specialized storage and handling equipment.

Looking forward, the evolution of DME technology is expected to play a crucial role in the transition to a more sustainable energy landscape. Objectives include further reducing the carbon footprint of DME production, particularly through the use of renewable feedstocks and carbon capture technologies. There is also a growing focus on integrating DME into smart energy systems, where it can serve as a flexible energy carrier and storage medium.

The evolution of DME technology and its objectives reflect a broader shift in energy governance. As a versatile and relatively clean fuel, DME offers policymakers and energy planners new tools for addressing energy security, environmental concerns, and economic development. The technology's progression demonstrates the potential for alternative fuels to reshape energy systems and governance structures, moving towards more sustainable and flexible models of energy production and consumption.

The technology surrounding DME has progressed rapidly over the past two decades. Early developments centered on improving production processes, particularly through the dehydration of methanol. As the technology matured, direct synthesis methods from syngas were developed, offering more efficient and cost-effective production routes. This evolution has been driven by the increasing need for cleaner energy alternatives and the push towards reducing greenhouse gas emissions.

The objectives of DME technology development have shifted and expanded over time. Initially, the focus was on establishing DME as a viable alternative to conventional diesel fuel. This goal has broadened to encompass a range of applications, including use as a cooking fuel, a propellant in aerosol products, and a potential hydrogen carrier for fuel cells. The versatility of DME has opened up new avenues for energy governance, as it offers a flexible solution that can be integrated into existing energy infrastructures.

Current technological objectives for DME are multifaceted. There is a strong emphasis on scaling up production to make DME economically competitive with traditional fuels. This involves optimizing production processes, reducing costs, and developing more efficient catalysts. Another key objective is to enhance the infrastructure for DME distribution and use, including the development of specialized storage and handling equipment.

Looking forward, the evolution of DME technology is expected to play a crucial role in the transition to a more sustainable energy landscape. Objectives include further reducing the carbon footprint of DME production, particularly through the use of renewable feedstocks and carbon capture technologies. There is also a growing focus on integrating DME into smart energy systems, where it can serve as a flexible energy carrier and storage medium.

The evolution of DME technology and its objectives reflect a broader shift in energy governance. As a versatile and relatively clean fuel, DME offers policymakers and energy planners new tools for addressing energy security, environmental concerns, and economic development. The technology's progression demonstrates the potential for alternative fuels to reshape energy systems and governance structures, moving towards more sustainable and flexible models of energy production and consumption.

Market Demand Analysis for DME

The market demand for dimethyl ether (DME) has been steadily growing, driven by its potential as a clean-burning alternative fuel and its versatility in various applications. As a renewable and environmentally friendly energy source, DME has garnered significant attention in recent years, particularly in the context of energy governance and sustainable development.

In the transportation sector, DME has shown promise as a substitute for diesel fuel in heavy-duty vehicles and marine applications. Its high cetane number and low particulate emissions make it an attractive option for reducing air pollution and meeting stringent environmental regulations. Several countries, including China, Japan, and Sweden, have conducted pilot projects and trials to assess the feasibility of DME as a transportation fuel, demonstrating its potential to disrupt traditional energy markets.

The industrial sector represents another key area of demand for DME. Its use as a propellant in aerosol products has been well-established, and there is growing interest in its application as a refrigerant and in the production of olefins. The chemical industry has also recognized DME's potential as a feedstock for various chemical processes, potentially opening up new markets and applications.

In the residential and commercial sectors, DME has gained traction as a clean-burning cooking and heating fuel, particularly in developing countries. Its properties make it a suitable replacement for liquefied petroleum gas (LPG) and other traditional fuels, offering improved indoor air quality and reduced greenhouse gas emissions. This market segment has shown significant growth potential, especially in regions with limited access to conventional energy infrastructure.

The power generation sector has also begun exploring DME as a fuel for gas turbines and combined cycle power plants. Its low emissions profile and compatibility with existing infrastructure make it an attractive option for utilities seeking to reduce their carbon footprint while maintaining operational flexibility.

From a regional perspective, Asia-Pacific has emerged as the largest market for DME, with China leading in production and consumption. Europe and North America are also showing increased interest, driven by stringent environmental regulations and the push for renewable energy sources. Developing economies in Africa and South America represent potential growth markets, particularly for DME's use in cooking and transportation applications.

The market demand for DME is closely tied to energy governance policies and sustainability goals. As governments worldwide implement stricter emissions standards and promote alternative energy sources, DME's role in the energy mix is expected to expand. This shift in energy governance models creates opportunities for DME to establish itself as a key player in the transition to a more sustainable and diversified energy landscape.

In the transportation sector, DME has shown promise as a substitute for diesel fuel in heavy-duty vehicles and marine applications. Its high cetane number and low particulate emissions make it an attractive option for reducing air pollution and meeting stringent environmental regulations. Several countries, including China, Japan, and Sweden, have conducted pilot projects and trials to assess the feasibility of DME as a transportation fuel, demonstrating its potential to disrupt traditional energy markets.

The industrial sector represents another key area of demand for DME. Its use as a propellant in aerosol products has been well-established, and there is growing interest in its application as a refrigerant and in the production of olefins. The chemical industry has also recognized DME's potential as a feedstock for various chemical processes, potentially opening up new markets and applications.

In the residential and commercial sectors, DME has gained traction as a clean-burning cooking and heating fuel, particularly in developing countries. Its properties make it a suitable replacement for liquefied petroleum gas (LPG) and other traditional fuels, offering improved indoor air quality and reduced greenhouse gas emissions. This market segment has shown significant growth potential, especially in regions with limited access to conventional energy infrastructure.

The power generation sector has also begun exploring DME as a fuel for gas turbines and combined cycle power plants. Its low emissions profile and compatibility with existing infrastructure make it an attractive option for utilities seeking to reduce their carbon footprint while maintaining operational flexibility.

From a regional perspective, Asia-Pacific has emerged as the largest market for DME, with China leading in production and consumption. Europe and North America are also showing increased interest, driven by stringent environmental regulations and the push for renewable energy sources. Developing economies in Africa and South America represent potential growth markets, particularly for DME's use in cooking and transportation applications.

The market demand for DME is closely tied to energy governance policies and sustainability goals. As governments worldwide implement stricter emissions standards and promote alternative energy sources, DME's role in the energy mix is expected to expand. This shift in energy governance models creates opportunities for DME to establish itself as a key player in the transition to a more sustainable and diversified energy landscape.

Current DME Tech Challenges

Despite the promising potential of dimethyl ether (DME) as an alternative fuel, several technical challenges currently hinder its widespread adoption and implementation in energy governance systems. One of the primary obstacles is the lack of dedicated infrastructure for DME production, storage, and distribution. Unlike conventional fuels, DME requires specialized handling equipment and storage facilities due to its unique physical properties, which increases the overall cost of implementation.

Another significant challenge lies in the production process of DME. While it can be synthesized from various feedstocks, including natural gas, coal, and biomass, the efficiency and cost-effectiveness of these production methods still need improvement. The current production processes often involve multiple steps, leading to energy losses and increased production costs. Developing more efficient and economical production techniques remains a critical area of research.

The compatibility of DME with existing engine technologies also presents a hurdle. Although DME can be used in modified diesel engines, widespread adoption would require significant modifications to current engine designs or the development of new, DME-specific engines. This adaptation process involves substantial investment and research efforts from automotive manufacturers and engine developers.

Furthermore, the energy density of DME is lower compared to conventional diesel fuel, which impacts vehicle range and performance. This limitation necessitates larger fuel tanks or more frequent refueling, potentially affecting the practicality of DME-powered vehicles for long-distance transportation. Addressing this issue through improved engine efficiency or innovative storage solutions is crucial for enhancing DME's competitiveness.

Environmental concerns, while generally favorable for DME compared to traditional fuels, still present some challenges. Although DME produces lower emissions of particulate matter and nitrogen oxides, there are ongoing debates about its overall lifecycle emissions, particularly when produced from fossil fuel sources. Ensuring a sustainable and environmentally friendly production chain for DME is essential for its long-term viability as a clean energy solution.

Lastly, the regulatory framework surrounding DME usage in energy systems is still evolving. The lack of standardized regulations and policies across different regions creates uncertainty for investors and slows down the development of DME-based energy solutions. Establishing clear, consistent, and supportive regulatory environments is crucial for fostering innovation and investment in DME technologies.

Another significant challenge lies in the production process of DME. While it can be synthesized from various feedstocks, including natural gas, coal, and biomass, the efficiency and cost-effectiveness of these production methods still need improvement. The current production processes often involve multiple steps, leading to energy losses and increased production costs. Developing more efficient and economical production techniques remains a critical area of research.

The compatibility of DME with existing engine technologies also presents a hurdle. Although DME can be used in modified diesel engines, widespread adoption would require significant modifications to current engine designs or the development of new, DME-specific engines. This adaptation process involves substantial investment and research efforts from automotive manufacturers and engine developers.

Furthermore, the energy density of DME is lower compared to conventional diesel fuel, which impacts vehicle range and performance. This limitation necessitates larger fuel tanks or more frequent refueling, potentially affecting the practicality of DME-powered vehicles for long-distance transportation. Addressing this issue through improved engine efficiency or innovative storage solutions is crucial for enhancing DME's competitiveness.

Environmental concerns, while generally favorable for DME compared to traditional fuels, still present some challenges. Although DME produces lower emissions of particulate matter and nitrogen oxides, there are ongoing debates about its overall lifecycle emissions, particularly when produced from fossil fuel sources. Ensuring a sustainable and environmentally friendly production chain for DME is essential for its long-term viability as a clean energy solution.

Lastly, the regulatory framework surrounding DME usage in energy systems is still evolving. The lack of standardized regulations and policies across different regions creates uncertainty for investors and slows down the development of DME-based energy solutions. Establishing clear, consistent, and supportive regulatory environments is crucial for fostering innovation and investment in DME technologies.

Existing DME Energy Solutions

01 Production of dimethyl ether

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.- Production of dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

- Catalysts for dimethyl ether synthesis: Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.

- Applications of dimethyl ether: Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as a potential alternative fuel for diesel engines due to its clean-burning properties and high cetane number.

- Purification and separation of dimethyl ether: Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes often involve distillation, adsorption, or membrane separation techniques to achieve high-purity dimethyl ether for various applications.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and storage requirements to ensure safe and sustainable utilization of dimethyl ether in various applications.

02 Catalysts for dimethyl ether synthesis

Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice and preparation of catalysts significantly influence the efficiency and selectivity of the dimethyl ether synthesis process.Expand Specific Solutions03 Applications of dimethyl ether

Dimethyl ether has various applications, including use as a fuel additive, propellant, refrigerant, and chemical intermediate. Its properties make it suitable for use in diesel engines, aerosol products, and as a potential alternative to liquefied petroleum gas.Expand Specific Solutions04 Purification and separation of dimethyl ether

Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes often involve distillation, adsorption, or membrane separation techniques to obtain high-purity dimethyl ether.Expand Specific Solutions05 Environmental and safety considerations

Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and potential hazards associated with its storage and transportation.Expand Specific Solutions

Key DME Industry Players

The development of dimethyl ether (DME) as an alternative energy source is in a transitional phase, moving from research and pilot projects to early commercial applications. The global DME market size is projected to grow significantly, driven by increasing demand for clean-burning fuels. Technologically, DME production is relatively mature, with companies like China Petroleum & Chemical Corp. (Sinopec) and SK Energy leading commercial-scale production. Research institutions such as the University of Southern California and Harbin Institute of Technology are advancing DME applications, while companies like Toshiba and Linde are developing innovative DME-based energy solutions. The involvement of major oil and gas players alongside specialized research institutes indicates a growing recognition of DME's potential in reshaping energy governance.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been at the forefront of dimethyl ether (DME) research and development. They have developed a proprietary technology for large-scale DME production from syngas, which is derived from coal or natural gas. Their process involves a single-step synthesis method that directly converts syngas to DME, improving efficiency and reducing production costs[1]. Sinopec has also invested in DME distribution infrastructure, including dedicated filling stations for DME-powered vehicles. They have successfully implemented pilot projects demonstrating DME as a clean alternative fuel for heavy-duty trucks and buses, reducing emissions and improving air quality in urban areas[2]. Furthermore, Sinopec has been exploring the use of DME in power generation, particularly in remote areas where traditional energy sources are less accessible[3].

Strengths: Established infrastructure, large-scale production capability, and extensive R&D resources. Weaknesses: Dependence on fossil fuel feedstocks for DME production, which may limit long-term sustainability.

Sinopec Research Institute of Petroleum Processing

Technical Solution: The Sinopec Research Institute of Petroleum Processing has been instrumental in advancing DME technology. They have developed a novel catalyst system for DME synthesis that significantly improves conversion rates and selectivity. This catalyst, based on a copper-zinc-aluminum oxide formulation, allows for lower operating temperatures and pressures, reducing energy consumption in the production process[4]. The institute has also pioneered a bi-reforming process that combines CO2 reforming and steam reforming of methane to produce syngas for DME synthesis, effectively utilizing CO2 and contributing to carbon capture efforts[5]. Additionally, they have made strides in DME purification techniques, developing membrane separation technology that achieves high-purity DME suitable for various applications, including as a propellant in aerosol products[6].

Strengths: Cutting-edge catalyst and process innovations, strong focus on sustainability. Weaknesses: May face challenges in scaling up new technologies for commercial production.

DME Core Innovations

Energy supply method and system

PatentWO2006004140A1

Innovation

- The introduction of Dimethyl Ether (DME) as a versatile energy circulation medium, which can be derived from biomass, waste, and petroleum residues, and used for power generation, transportation, and heating, allowing for efficient energy storage and distribution without relying on pipelines, and enabling the conversion of waste heat into usable energy.

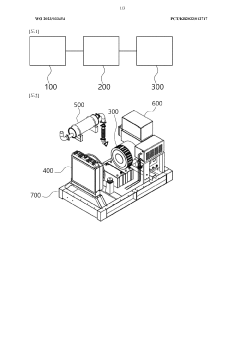

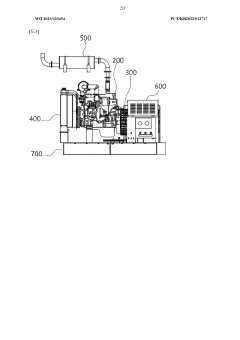

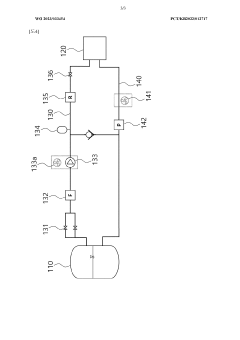

DME-fueled generator

PatentWO2023033454A1

Innovation

- A DME fuel generator system that uses dimethyl ether (DME) as a clean fuel, which includes a power generation unit, a DME engine, a fuel supply unit, a radiator unit, an exhaust pipe, and a control unit, designed to generate electricity without producing fine dust or other environmental pollutants, utilizing a frame unit to absorb vibrations and a sophisticated fuel supply system to manage DME fuel efficiently.

DME Policy and Regulations

The regulatory landscape for dimethyl ether (DME) is evolving as governments recognize its potential as a clean alternative fuel. Many countries are implementing policies to promote DME production and usage, aiming to reduce greenhouse gas emissions and diversify energy sources.

In the United States, the Environmental Protection Agency (EPA) has approved DME as a renewable fuel under the Renewable Fuel Standard program. This classification allows DME producers to generate Renewable Identification Numbers (RINs), providing economic incentives for production. Additionally, several states have introduced legislation to include DME in their clean fuel programs, offering tax credits and other benefits to encourage adoption.

The European Union has incorporated DME into its Renewable Energy Directive (RED II), recognizing it as a renewable fuel when produced from biomass. This inclusion enables DME to contribute to the EU's renewable energy targets and benefit from associated support mechanisms. Some European countries, such as Sweden and Denmark, have gone further by implementing specific DME-friendly policies, including reduced fuel taxes and infrastructure development support.

In Asia, China has been at the forefront of DME policy development. The government has included DME in its national energy strategy, providing subsidies for production facilities and mandating its use in certain sectors. Japan and South Korea have also shown interest, with both countries funding research and development projects related to DME technology and applications.

Globally, international organizations are playing a crucial role in shaping DME regulations. The International Maritime Organization (IMO) is considering DME as a potential marine fuel to meet stricter emissions standards. This could lead to the development of new regulations and standards for DME use in the shipping industry.

However, challenges remain in harmonizing DME regulations across different jurisdictions. Inconsistencies in fuel quality standards, safety regulations, and tax treatments can hinder the global adoption of DME. Efforts are underway to develop international standards, with organizations like the International Organization for Standardization (ISO) working on specifications for DME as a fuel.

As DME gains traction, policymakers are also addressing infrastructure needs. Some countries are implementing regulations to support the development of DME distribution networks, including storage facilities and fueling stations. These policies often involve public-private partnerships and targeted incentives to overcome initial market barriers.

In the United States, the Environmental Protection Agency (EPA) has approved DME as a renewable fuel under the Renewable Fuel Standard program. This classification allows DME producers to generate Renewable Identification Numbers (RINs), providing economic incentives for production. Additionally, several states have introduced legislation to include DME in their clean fuel programs, offering tax credits and other benefits to encourage adoption.

The European Union has incorporated DME into its Renewable Energy Directive (RED II), recognizing it as a renewable fuel when produced from biomass. This inclusion enables DME to contribute to the EU's renewable energy targets and benefit from associated support mechanisms. Some European countries, such as Sweden and Denmark, have gone further by implementing specific DME-friendly policies, including reduced fuel taxes and infrastructure development support.

In Asia, China has been at the forefront of DME policy development. The government has included DME in its national energy strategy, providing subsidies for production facilities and mandating its use in certain sectors. Japan and South Korea have also shown interest, with both countries funding research and development projects related to DME technology and applications.

Globally, international organizations are playing a crucial role in shaping DME regulations. The International Maritime Organization (IMO) is considering DME as a potential marine fuel to meet stricter emissions standards. This could lead to the development of new regulations and standards for DME use in the shipping industry.

However, challenges remain in harmonizing DME regulations across different jurisdictions. Inconsistencies in fuel quality standards, safety regulations, and tax treatments can hinder the global adoption of DME. Efforts are underway to develop international standards, with organizations like the International Organization for Standardization (ISO) working on specifications for DME as a fuel.

As DME gains traction, policymakers are also addressing infrastructure needs. Some countries are implementing regulations to support the development of DME distribution networks, including storage facilities and fueling stations. These policies often involve public-private partnerships and targeted incentives to overcome initial market barriers.

Environmental Impact of DME

The environmental impact of Dimethyl Ether (DME) as an alternative fuel source is a critical consideration in the context of energy governance. DME offers several environmental advantages compared to traditional fossil fuels, particularly in terms of reduced emissions and improved air quality.

One of the primary environmental benefits of DME is its lower carbon footprint. When used as a fuel, DME produces significantly fewer greenhouse gas emissions compared to conventional diesel or gasoline. This reduction in carbon dioxide emissions contributes to mitigating climate change and aligns with global efforts to transition towards cleaner energy sources.

Furthermore, DME combustion results in minimal particulate matter and sulfur oxide emissions. This characteristic is particularly beneficial for urban areas struggling with air pollution, as it can lead to improved air quality and reduced health risks associated with respiratory issues. The reduction in harmful emissions also helps in meeting increasingly stringent environmental regulations imposed by governments worldwide.

DME's production process can be designed to be environmentally friendly, especially when derived from renewable sources such as biomass or captured carbon dioxide. This circular approach to fuel production aligns with principles of sustainable resource management and waste reduction, further enhancing its environmental credentials.

However, it is important to note that the environmental impact of DME is not entirely without concerns. The production of DME, particularly from fossil fuel sources, still involves energy-intensive processes that can contribute to environmental degradation. Additionally, the large-scale adoption of DME would require significant infrastructure changes, which could have short-term environmental impacts during implementation.

The use of DME in energy systems also raises questions about land use, especially if biomass feedstocks are extensively utilized for DME production. Balancing the need for fuel production with food security and biodiversity conservation becomes a crucial consideration in DME governance strategies.

In terms of energy governance, the environmental profile of DME presents both opportunities and challenges. Policymakers must weigh the potential for reduced emissions and improved air quality against the complexities of transitioning energy infrastructure and managing resource allocation. This balancing act requires careful consideration of long-term environmental goals, economic feasibility, and social impacts.

One of the primary environmental benefits of DME is its lower carbon footprint. When used as a fuel, DME produces significantly fewer greenhouse gas emissions compared to conventional diesel or gasoline. This reduction in carbon dioxide emissions contributes to mitigating climate change and aligns with global efforts to transition towards cleaner energy sources.

Furthermore, DME combustion results in minimal particulate matter and sulfur oxide emissions. This characteristic is particularly beneficial for urban areas struggling with air pollution, as it can lead to improved air quality and reduced health risks associated with respiratory issues. The reduction in harmful emissions also helps in meeting increasingly stringent environmental regulations imposed by governments worldwide.

DME's production process can be designed to be environmentally friendly, especially when derived from renewable sources such as biomass or captured carbon dioxide. This circular approach to fuel production aligns with principles of sustainable resource management and waste reduction, further enhancing its environmental credentials.

However, it is important to note that the environmental impact of DME is not entirely without concerns. The production of DME, particularly from fossil fuel sources, still involves energy-intensive processes that can contribute to environmental degradation. Additionally, the large-scale adoption of DME would require significant infrastructure changes, which could have short-term environmental impacts during implementation.

The use of DME in energy systems also raises questions about land use, especially if biomass feedstocks are extensively utilized for DME production. Balancing the need for fuel production with food security and biodiversity conservation becomes a crucial consideration in DME governance strategies.

In terms of energy governance, the environmental profile of DME presents both opportunities and challenges. Policymakers must weigh the potential for reduced emissions and improved air quality against the complexities of transitioning energy infrastructure and managing resource allocation. This balancing act requires careful consideration of long-term environmental goals, economic feasibility, and social impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!