How Dimethyl Ether Drives New Innovations in Fuel Efficiency?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Fuel Evolution

The evolution of Dimethyl Ether (DME) as a fuel has been marked by significant milestones and technological advancements. Initially developed as a propellant and refrigerant, DME's potential as a clean-burning alternative fuel was recognized in the late 20th century. This recognition sparked a series of research and development efforts aimed at harnessing its properties for improved fuel efficiency.

In the 1990s, researchers began exploring DME's use as a diesel substitute due to its high cetane number and clean combustion characteristics. This period saw the first successful demonstrations of DME-powered engines, laying the groundwork for future innovations. The early 2000s witnessed a surge in DME fuel research, with major automotive and energy companies investing in pilot projects and feasibility studies.

A significant breakthrough came in the mid-2000s when large-scale DME production from various feedstocks, including natural gas, coal, and biomass, became technically viable. This development addressed concerns about DME's availability and production costs, making it a more attractive option for widespread adoption. Concurrently, engine manufacturers began developing dedicated DME engines, optimizing combustion systems to fully exploit DME's unique properties.

The 2010s marked a period of rapid advancement in DME fuel technology. Improved catalysts and production processes enhanced DME's economic viability, while advancements in engine design led to higher efficiency and lower emissions. During this time, several countries, notably Sweden, China, and Japan, initiated DME fuel programs, conducting road tests and establishing infrastructure for DME distribution.

Recent years have seen a focus on integrating DME into renewable energy systems. The concept of "green DME," produced from renewable sources such as biomass or captured CO2, has gained traction. This approach aligns DME with global efforts to reduce carbon emissions and promote sustainable energy solutions. Additionally, researchers have explored DME's potential in fuel cells and as a hydrogen carrier, expanding its applications beyond traditional combustion engines.

The evolution of DME fuel technology has been characterized by continuous improvements in production efficiency, engine performance, and environmental impact. From its initial recognition as a potential fuel to its current status as a promising alternative in the transition to cleaner energy, DME has undergone significant development. As global efforts to improve fuel efficiency and reduce emissions intensify, DME continues to evolve, driving innovations in engine technology, fuel production, and energy systems integration.

In the 1990s, researchers began exploring DME's use as a diesel substitute due to its high cetane number and clean combustion characteristics. This period saw the first successful demonstrations of DME-powered engines, laying the groundwork for future innovations. The early 2000s witnessed a surge in DME fuel research, with major automotive and energy companies investing in pilot projects and feasibility studies.

A significant breakthrough came in the mid-2000s when large-scale DME production from various feedstocks, including natural gas, coal, and biomass, became technically viable. This development addressed concerns about DME's availability and production costs, making it a more attractive option for widespread adoption. Concurrently, engine manufacturers began developing dedicated DME engines, optimizing combustion systems to fully exploit DME's unique properties.

The 2010s marked a period of rapid advancement in DME fuel technology. Improved catalysts and production processes enhanced DME's economic viability, while advancements in engine design led to higher efficiency and lower emissions. During this time, several countries, notably Sweden, China, and Japan, initiated DME fuel programs, conducting road tests and establishing infrastructure for DME distribution.

Recent years have seen a focus on integrating DME into renewable energy systems. The concept of "green DME," produced from renewable sources such as biomass or captured CO2, has gained traction. This approach aligns DME with global efforts to reduce carbon emissions and promote sustainable energy solutions. Additionally, researchers have explored DME's potential in fuel cells and as a hydrogen carrier, expanding its applications beyond traditional combustion engines.

The evolution of DME fuel technology has been characterized by continuous improvements in production efficiency, engine performance, and environmental impact. From its initial recognition as a potential fuel to its current status as a promising alternative in the transition to cleaner energy, DME has undergone significant development. As global efforts to improve fuel efficiency and reduce emissions intensify, DME continues to evolve, driving innovations in engine technology, fuel production, and energy systems integration.

Market Demand Analysis

The market demand for dimethyl ether (DME) as an alternative fuel is experiencing significant growth, driven by increasing concerns over environmental sustainability and the need for cleaner energy sources. DME's potential to enhance fuel efficiency and reduce emissions has garnered attention from various sectors, particularly in transportation and power generation.

In the automotive industry, DME is emerging as a promising substitute for diesel fuel. Its high cetane number and clean-burning properties make it an attractive option for heavy-duty vehicles, such as trucks and buses. The market for DME-powered vehicles is expected to expand as more countries implement stricter emission regulations and seek to reduce their dependence on conventional fossil fuels.

The power generation sector is another key area driving the demand for DME. As countries strive to transition towards cleaner energy sources, DME's potential as a low-carbon alternative to natural gas in power plants is gaining traction. This shift is particularly evident in regions with limited natural gas infrastructure, where DME can be more easily transported and stored.

In the industrial sector, DME is finding applications as a propellant and refrigerant, further diversifying its market potential. The chemical industry is also exploring DME as a feedstock for various processes, opening up new avenues for market growth.

Geographically, Asia-Pacific is leading the DME market, with China at the forefront of adoption and production. The region's rapid industrialization, coupled with government initiatives to promote cleaner fuels, is driving substantial investments in DME technology and infrastructure.

Europe and North America are also showing increased interest in DME, primarily driven by environmental regulations and the push for sustainable transportation solutions. These regions are focusing on research and development to optimize DME production processes and improve its overall efficiency as a fuel source.

The market demand for DME is closely tied to advancements in production technologies. As more efficient and cost-effective methods for DME synthesis are developed, its competitiveness against traditional fuels is expected to improve, potentially leading to wider adoption across various industries.

However, challenges remain in scaling up DME production and establishing the necessary infrastructure for widespread use. The market's growth will depend on overcoming these hurdles through continued technological innovations and supportive policy frameworks.

Overall, the market demand for DME as a fuel efficiency enhancer is on an upward trajectory, with its potential to address both environmental concerns and energy security issues driving interest across multiple sectors and regions.

In the automotive industry, DME is emerging as a promising substitute for diesel fuel. Its high cetane number and clean-burning properties make it an attractive option for heavy-duty vehicles, such as trucks and buses. The market for DME-powered vehicles is expected to expand as more countries implement stricter emission regulations and seek to reduce their dependence on conventional fossil fuels.

The power generation sector is another key area driving the demand for DME. As countries strive to transition towards cleaner energy sources, DME's potential as a low-carbon alternative to natural gas in power plants is gaining traction. This shift is particularly evident in regions with limited natural gas infrastructure, where DME can be more easily transported and stored.

In the industrial sector, DME is finding applications as a propellant and refrigerant, further diversifying its market potential. The chemical industry is also exploring DME as a feedstock for various processes, opening up new avenues for market growth.

Geographically, Asia-Pacific is leading the DME market, with China at the forefront of adoption and production. The region's rapid industrialization, coupled with government initiatives to promote cleaner fuels, is driving substantial investments in DME technology and infrastructure.

Europe and North America are also showing increased interest in DME, primarily driven by environmental regulations and the push for sustainable transportation solutions. These regions are focusing on research and development to optimize DME production processes and improve its overall efficiency as a fuel source.

The market demand for DME is closely tied to advancements in production technologies. As more efficient and cost-effective methods for DME synthesis are developed, its competitiveness against traditional fuels is expected to improve, potentially leading to wider adoption across various industries.

However, challenges remain in scaling up DME production and establishing the necessary infrastructure for widespread use. The market's growth will depend on overcoming these hurdles through continued technological innovations and supportive policy frameworks.

Overall, the market demand for DME as a fuel efficiency enhancer is on an upward trajectory, with its potential to address both environmental concerns and energy security issues driving interest across multiple sectors and regions.

DME Tech Challenges

Despite the promising potential of dimethyl ether (DME) as a clean and efficient fuel, several technical challenges hinder its widespread adoption and implementation in fuel efficiency innovations. One of the primary obstacles is the lack of dedicated infrastructure for DME production, storage, and distribution. Unlike conventional fuels, DME requires specialized handling and storage facilities due to its unique physical properties, which necessitates significant investments in infrastructure development.

Another major challenge lies in the engine and fuel system modifications required for DME utilization. Existing diesel engines need substantial alterations to accommodate DME's lower viscosity and lubricity compared to conventional diesel fuel. These modifications include redesigning fuel injection systems, adjusting compression ratios, and implementing new sealing technologies to prevent fuel leakage. The cost and complexity of these adaptations pose a significant barrier to widespread adoption, particularly for retrofitting existing vehicle fleets.

DME's lower energy density compared to diesel fuel presents another technical hurdle. This characteristic results in reduced driving range and requires larger fuel tanks to achieve comparable mileage, which can impact vehicle design and payload capacity. Addressing this issue demands innovative solutions in fuel storage technology and engine efficiency optimization to maximize the energy utilization of DME.

The production of DME from renewable sources, while promising for sustainability, faces its own set of challenges. Current production methods, such as biomass gasification or methanol dehydration, are not yet optimized for large-scale, cost-effective production. Improving the efficiency and reducing the costs of these processes is crucial for making renewable DME economically viable and competitive with conventional fuels.

Furthermore, the long-term effects of DME usage on engine components and emissions control systems are not yet fully understood. Extensive research and long-duration testing are necessary to ensure the durability and reliability of DME-powered engines over their operational lifetime. This includes studying the potential impacts on engine wear, exhaust aftertreatment systems, and overall vehicle performance under various operating conditions.

Lastly, the regulatory landscape surrounding DME as a fuel alternative remains complex and varied across different regions. Establishing consistent standards for DME fuel quality, safety regulations, and emissions compliance is essential for fostering industry confidence and facilitating global adoption. Overcoming these regulatory challenges requires coordinated efforts between industry stakeholders, policymakers, and environmental agencies to create a supportive framework for DME implementation.

Another major challenge lies in the engine and fuel system modifications required for DME utilization. Existing diesel engines need substantial alterations to accommodate DME's lower viscosity and lubricity compared to conventional diesel fuel. These modifications include redesigning fuel injection systems, adjusting compression ratios, and implementing new sealing technologies to prevent fuel leakage. The cost and complexity of these adaptations pose a significant barrier to widespread adoption, particularly for retrofitting existing vehicle fleets.

DME's lower energy density compared to diesel fuel presents another technical hurdle. This characteristic results in reduced driving range and requires larger fuel tanks to achieve comparable mileage, which can impact vehicle design and payload capacity. Addressing this issue demands innovative solutions in fuel storage technology and engine efficiency optimization to maximize the energy utilization of DME.

The production of DME from renewable sources, while promising for sustainability, faces its own set of challenges. Current production methods, such as biomass gasification or methanol dehydration, are not yet optimized for large-scale, cost-effective production. Improving the efficiency and reducing the costs of these processes is crucial for making renewable DME economically viable and competitive with conventional fuels.

Furthermore, the long-term effects of DME usage on engine components and emissions control systems are not yet fully understood. Extensive research and long-duration testing are necessary to ensure the durability and reliability of DME-powered engines over their operational lifetime. This includes studying the potential impacts on engine wear, exhaust aftertreatment systems, and overall vehicle performance under various operating conditions.

Lastly, the regulatory landscape surrounding DME as a fuel alternative remains complex and varied across different regions. Establishing consistent standards for DME fuel quality, safety regulations, and emissions compliance is essential for fostering industry confidence and facilitating global adoption. Overcoming these regulatory challenges requires coordinated efforts between industry stakeholders, policymakers, and environmental agencies to create a supportive framework for DME implementation.

Current DME Solutions

01 Dimethyl ether as an alternative fuel

Dimethyl ether (DME) is being explored as an alternative fuel for internal combustion engines due to its high cetane number and clean-burning properties. It can be used in diesel engines with minimal modifications, offering improved fuel efficiency and reduced emissions compared to conventional diesel fuel.- Dimethyl ether as an alternative fuel: Dimethyl ether (DME) is being explored as an alternative fuel for internal combustion engines due to its high cetane number and clean-burning properties. It can be used in diesel engines with minimal modifications, offering improved fuel efficiency and reduced emissions compared to conventional diesel fuel.

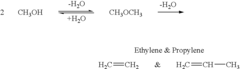

- Production methods for dimethyl ether: Various methods for producing dimethyl ether are being developed to improve efficiency and reduce costs. These include direct synthesis from syngas, dehydration of methanol, and catalytic conversion of biomass or natural gas. Improved production methods can lead to increased availability and lower costs for DME as a fuel.

- Fuel blends incorporating dimethyl ether: Researchers are investigating fuel blends that incorporate dimethyl ether with other fuels to optimize performance and efficiency. These blends can combine the benefits of DME with those of traditional fuels, potentially offering improved combustion characteristics and reduced emissions in various engine types.

- Engine and fuel system modifications for DME use: To fully utilize the potential of dimethyl ether as a fuel, modifications to engine components and fuel systems are being developed. These adaptations aim to address the unique properties of DME, such as its lower viscosity and lubricity compared to diesel, ensuring optimal performance and efficiency in DME-powered vehicles.

- Catalysts for improving DME fuel efficiency: Research is ongoing into the development of advanced catalysts to enhance the efficiency of dimethyl ether production and utilization as a fuel. These catalysts aim to improve conversion rates, reduce byproduct formation, and optimize the overall energy efficiency of DME-based fuel systems.

02 Production methods for dimethyl ether

Various production methods for dimethyl ether are being developed to improve efficiency and reduce costs. These include direct synthesis from syngas, dehydration of methanol, and catalytic conversion of biomass or natural gas. Improved production methods can lead to increased availability and cost-effectiveness of DME as a fuel.Expand Specific Solutions03 Fuel blends incorporating dimethyl ether

Researchers are investigating fuel blends that incorporate dimethyl ether with other fuels or additives to optimize performance and efficiency. These blends can potentially enhance combustion characteristics, improve cold-start performance, and reduce emissions in various engine types.Expand Specific Solutions04 Engine and fuel system modifications for DME use

To fully utilize the benefits of dimethyl ether as a fuel, modifications to engine components and fuel systems are being developed. These include specialized fuel injectors, fuel pumps, and engine control systems designed to optimize DME combustion and improve overall fuel efficiency.Expand Specific Solutions05 Environmental and efficiency benefits of DME fuel

Studies are focusing on the environmental and efficiency benefits of using dimethyl ether as a fuel. DME combustion produces lower particulate matter, NOx, and CO2 emissions compared to conventional fuels. Additionally, its high cetane number and oxygen content contribute to improved fuel efficiency in properly optimized engines.Expand Specific Solutions

Key DME Fuel Players

The development of dimethyl ether (DME) as an alternative fuel is gaining momentum, driven by increasing demand for cleaner and more efficient energy solutions. The market is in its growth phase, with significant potential for expansion as environmental regulations tighten globally. Key players in this field include major oil and gas companies like China Petroleum & Chemical Corp. and Petróleo Brasileiro SA, as well as automotive manufacturers such as Ford Motor Co., Isuzu Motors Ltd., and Volvo Lastvagnar AB. Research institutions like the University of Southern California and Xi'an Jiaotong University are also contributing to technological advancements. The technology is approaching maturity, with ongoing efforts to improve production processes and engine compatibility, indicating a competitive landscape poised for further innovation and market penetration.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been at the forefront of dimethyl ether (DME) research and development for fuel efficiency. They have developed a proprietary DME production process using coal and natural gas as feedstocks[1]. Their technology allows for the direct synthesis of DME from syngas, improving overall efficiency. Sinopec has also invested in DME fueling stations and conducted large-scale vehicle trials[2]. They've successfully demonstrated DME's potential as a clean-burning alternative fuel in modified diesel engines, achieving lower emissions and comparable performance to conventional diesel[3].

Strengths: Vertically integrated production and distribution capabilities, extensive R&D resources, and large-scale trial experience. Weaknesses: Dependence on fossil fuel feedstocks may limit long-term sustainability.

Ford Motor Co.

Technical Solution: Ford Motor Co. has been exploring DME as a potential alternative fuel for its diesel engines. They have developed and tested DME-compatible fuel systems and engine modifications to optimize performance and efficiency[4]. Ford's research focuses on leveraging DME's high cetane number and clean-burning properties to achieve lower emissions without sacrificing engine power. They have conducted extensive durability tests and emissions analyses on DME-fueled engines, demonstrating significant reductions in particulate matter and NOx emissions compared to conventional diesel[5]. Ford has also collaborated with fuel suppliers to address infrastructure challenges for DME distribution.

Strengths: Extensive experience in engine design and optimization, global reach for potential implementation. Weaknesses: Limited control over fuel production and distribution infrastructure.

DME Fuel Innovations

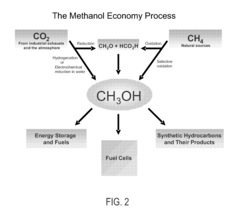

Conversion of carbon dioxide to methanol and/or dimethyl ether using bi-reforming of methane or natural gas

PatentActiveUS7906559B2

Innovation

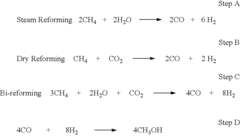

- A bi-reforming process combining steam and dry reforming of methane to achieve a specific CO/H2 molar ratio of 1:2, allowing for the efficient conversion of carbon dioxide and methane to methanol and dimethyl ether without producing CO2 or other by-products, using a catalyst such as V2O5 and NiO on a silica carrier.

Conversion of carbon dioxide to dimethyl ether using bi-reforming of methane or natural gas

PatentActiveUS8133926B2

Innovation

- The BI-REFORMING™ process combines steam and dry reforming of methane to produce a mixture of hydrogen and carbon monoxide with a 2:1 molar ratio, allowing for the conversion to methanol and dimethyl ether without releasing CO2 into the atmosphere and without using external hydrogen, using catalysts like Nafion-H for dehydration and recycling water to form dimethyl ether.

Environmental Impact

Dimethyl ether (DME) has emerged as a promising alternative fuel with significant potential to drive innovations in fuel efficiency while offering substantial environmental benefits. As a clean-burning, non-toxic fuel, DME presents a compelling case for reducing harmful emissions and mitigating the environmental impact of traditional fossil fuels.

One of the primary environmental advantages of DME is its low carbon footprint. When produced from renewable sources such as biomass or waste materials, DME can achieve near-carbon neutrality. This characteristic positions DME as a valuable tool in the global effort to combat climate change and reduce greenhouse gas emissions from the transportation and industrial sectors.

DME combustion produces significantly lower levels of particulate matter, nitrogen oxides, and sulfur oxides compared to conventional diesel fuel. This reduction in harmful emissions translates to improved air quality, particularly in urban areas where vehicle emissions are a major contributor to smog and respiratory health issues. The cleaner burn of DME also means reduced strain on emission control systems, potentially extending the lifespan of these components and reducing waste.

In terms of its impact on water resources, DME offers advantages over some other alternative fuels. Unlike ethanol production, which can be water-intensive, DME production generally requires less water. Additionally, DME is non-toxic and biodegradable, minimizing the risk of environmental contamination in case of spills or leaks during transportation and storage.

The production of DME can be integrated into existing waste management systems, offering an opportunity to reduce landfill waste and methane emissions. By utilizing organic waste, agricultural residues, or even captured carbon dioxide as feedstock, DME production can contribute to a more circular economy and help address multiple environmental challenges simultaneously.

However, it is important to note that the environmental impact of DME is heavily dependent on its production method. While DME produced from renewable sources offers significant environmental benefits, DME derived from fossil fuels may have a less favorable environmental profile. As such, the push towards renewable DME production is crucial for maximizing its positive environmental impact.

The adoption of DME as a fuel also has implications for land use. While it can be produced from waste materials, large-scale production from dedicated biomass crops could potentially compete with food production or lead to land-use changes. Careful management and sustainable sourcing practices are essential to mitigate these risks and ensure that DME production does not inadvertently cause environmental harm in other areas.

One of the primary environmental advantages of DME is its low carbon footprint. When produced from renewable sources such as biomass or waste materials, DME can achieve near-carbon neutrality. This characteristic positions DME as a valuable tool in the global effort to combat climate change and reduce greenhouse gas emissions from the transportation and industrial sectors.

DME combustion produces significantly lower levels of particulate matter, nitrogen oxides, and sulfur oxides compared to conventional diesel fuel. This reduction in harmful emissions translates to improved air quality, particularly in urban areas where vehicle emissions are a major contributor to smog and respiratory health issues. The cleaner burn of DME also means reduced strain on emission control systems, potentially extending the lifespan of these components and reducing waste.

In terms of its impact on water resources, DME offers advantages over some other alternative fuels. Unlike ethanol production, which can be water-intensive, DME production generally requires less water. Additionally, DME is non-toxic and biodegradable, minimizing the risk of environmental contamination in case of spills or leaks during transportation and storage.

The production of DME can be integrated into existing waste management systems, offering an opportunity to reduce landfill waste and methane emissions. By utilizing organic waste, agricultural residues, or even captured carbon dioxide as feedstock, DME production can contribute to a more circular economy and help address multiple environmental challenges simultaneously.

However, it is important to note that the environmental impact of DME is heavily dependent on its production method. While DME produced from renewable sources offers significant environmental benefits, DME derived from fossil fuels may have a less favorable environmental profile. As such, the push towards renewable DME production is crucial for maximizing its positive environmental impact.

The adoption of DME as a fuel also has implications for land use. While it can be produced from waste materials, large-scale production from dedicated biomass crops could potentially compete with food production or lead to land-use changes. Careful management and sustainable sourcing practices are essential to mitigate these risks and ensure that DME production does not inadvertently cause environmental harm in other areas.

DME Infrastructure

The development of a robust infrastructure is crucial for the widespread adoption and utilization of Dimethyl Ether (DME) as an alternative fuel. The DME infrastructure encompasses production facilities, storage systems, transportation networks, and distribution channels necessary to support the fuel's lifecycle from manufacture to end-use.

Production facilities for DME are currently limited but expanding. These plants typically use natural gas, coal, or biomass as feedstock to produce DME through various processes, including direct synthesis or methanol dehydration. As demand for DME grows, there is a need for increased investment in production capacity to ensure a stable supply chain.

Storage of DME requires specialized equipment due to its physical properties. At ambient temperature and moderate pressure, DME is a gas, but it can be easily liquefied for storage and transportation. This characteristic necessitates the development of pressurized storage tanks and handling systems similar to those used for liquefied petroleum gas (LPG).

Transportation of DME can leverage existing LPG infrastructure to some extent, which provides a significant advantage in terms of cost and implementation speed. However, modifications to pipelines, tanker trucks, and rail cars may be necessary to accommodate DME's specific properties and ensure safe handling.

Distribution networks for DME are still in their infancy in most regions. The establishment of fueling stations equipped to handle DME is a critical component of the infrastructure. These stations require specialized pumps, storage tanks, and safety systems to dispense DME to vehicles and other end-users effectively.

The development of DME infrastructure faces several challenges, including high initial investment costs, regulatory hurdles, and the need for standardization across the industry. However, the potential benefits of DME as a clean-burning, high-efficiency fuel are driving continued investment and innovation in this area.

Governments and industry stakeholders are collaborating to address these challenges and accelerate the development of DME infrastructure. Initiatives include funding for research and development, pilot projects for DME production and distribution, and the creation of regulatory frameworks to support the safe and efficient use of DME as a fuel.

As the DME infrastructure continues to evolve, it is expected to play a crucial role in enhancing fuel efficiency and reducing emissions in various sectors, including transportation, power generation, and industrial applications. The successful implementation of a comprehensive DME infrastructure will be a key factor in realizing the full potential of this innovative fuel technology.

Production facilities for DME are currently limited but expanding. These plants typically use natural gas, coal, or biomass as feedstock to produce DME through various processes, including direct synthesis or methanol dehydration. As demand for DME grows, there is a need for increased investment in production capacity to ensure a stable supply chain.

Storage of DME requires specialized equipment due to its physical properties. At ambient temperature and moderate pressure, DME is a gas, but it can be easily liquefied for storage and transportation. This characteristic necessitates the development of pressurized storage tanks and handling systems similar to those used for liquefied petroleum gas (LPG).

Transportation of DME can leverage existing LPG infrastructure to some extent, which provides a significant advantage in terms of cost and implementation speed. However, modifications to pipelines, tanker trucks, and rail cars may be necessary to accommodate DME's specific properties and ensure safe handling.

Distribution networks for DME are still in their infancy in most regions. The establishment of fueling stations equipped to handle DME is a critical component of the infrastructure. These stations require specialized pumps, storage tanks, and safety systems to dispense DME to vehicles and other end-users effectively.

The development of DME infrastructure faces several challenges, including high initial investment costs, regulatory hurdles, and the need for standardization across the industry. However, the potential benefits of DME as a clean-burning, high-efficiency fuel are driving continued investment and innovation in this area.

Governments and industry stakeholders are collaborating to address these challenges and accelerate the development of DME infrastructure. Initiatives include funding for research and development, pilot projects for DME production and distribution, and the creation of regulatory frameworks to support the safe and efficient use of DME as a fuel.

As the DME infrastructure continues to evolve, it is expected to play a crucial role in enhancing fuel efficiency and reducing emissions in various sectors, including transportation, power generation, and industrial applications. The successful implementation of a comprehensive DME infrastructure will be a key factor in realizing the full potential of this innovative fuel technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!