How Dimethyl Ether Improves Portable Energy Solutions?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Background and Objectives

Dimethyl ether (DME) has emerged as a promising alternative fuel in the quest for portable energy solutions. This colorless, non-toxic gas has garnered significant attention due to its potential to address several challenges in the energy sector. The primary objective of exploring DME as a portable energy solution is to develop cleaner, more efficient, and versatile fuel options that can reduce dependence on traditional fossil fuels.

DME's journey as an energy carrier began in the mid-20th century, but it has gained renewed interest in recent decades due to growing environmental concerns and the need for sustainable energy sources. Initially used as a propellant in aerosol products, DME's potential as a fuel was recognized in the 1990s, leading to extensive research and development efforts worldwide.

The technical evolution of DME as a portable energy solution has been driven by its unique properties. With a high cetane number and low auto-ignition temperature, DME is particularly well-suited for use in compression ignition engines. Its clean-burning characteristics result in lower emissions of particulate matter and nitrogen oxides compared to conventional diesel fuel, aligning with increasingly stringent environmental regulations.

One of the key advantages of DME is its versatility in production methods. It can be synthesized from various feedstocks, including natural gas, coal, and biomass, through well-established processes. This flexibility in production pathways contributes to DME's potential as a bridge fuel in the transition towards more sustainable energy systems.

The objectives of DME research and development in the context of portable energy solutions are multifaceted. Firstly, there is a focus on optimizing DME production processes to improve efficiency and reduce costs, making it more competitive with traditional fuels. Secondly, efforts are directed towards enhancing DME's storage and transportation infrastructure to facilitate its widespread adoption.

Another critical objective is the adaptation and optimization of existing engine technologies to fully leverage DME's properties. This includes developing dedicated DME engines and modifying current diesel engines to accommodate DME fuel. The goal is to achieve higher thermal efficiency and lower emissions without compromising performance or reliability.

Furthermore, researchers aim to explore DME's potential in various applications beyond transportation, such as portable power generation, cooking, and heating. This diversification of applications could significantly enhance the overall impact of DME as a portable energy solution.

As the energy landscape continues to evolve, the development of DME technology is expected to play a crucial role in addressing the challenges of energy security, environmental sustainability, and economic viability. The ongoing research and technological advancements in this field are paving the way for DME to become a key player in the future of portable energy solutions.

DME's journey as an energy carrier began in the mid-20th century, but it has gained renewed interest in recent decades due to growing environmental concerns and the need for sustainable energy sources. Initially used as a propellant in aerosol products, DME's potential as a fuel was recognized in the 1990s, leading to extensive research and development efforts worldwide.

The technical evolution of DME as a portable energy solution has been driven by its unique properties. With a high cetane number and low auto-ignition temperature, DME is particularly well-suited for use in compression ignition engines. Its clean-burning characteristics result in lower emissions of particulate matter and nitrogen oxides compared to conventional diesel fuel, aligning with increasingly stringent environmental regulations.

One of the key advantages of DME is its versatility in production methods. It can be synthesized from various feedstocks, including natural gas, coal, and biomass, through well-established processes. This flexibility in production pathways contributes to DME's potential as a bridge fuel in the transition towards more sustainable energy systems.

The objectives of DME research and development in the context of portable energy solutions are multifaceted. Firstly, there is a focus on optimizing DME production processes to improve efficiency and reduce costs, making it more competitive with traditional fuels. Secondly, efforts are directed towards enhancing DME's storage and transportation infrastructure to facilitate its widespread adoption.

Another critical objective is the adaptation and optimization of existing engine technologies to fully leverage DME's properties. This includes developing dedicated DME engines and modifying current diesel engines to accommodate DME fuel. The goal is to achieve higher thermal efficiency and lower emissions without compromising performance or reliability.

Furthermore, researchers aim to explore DME's potential in various applications beyond transportation, such as portable power generation, cooking, and heating. This diversification of applications could significantly enhance the overall impact of DME as a portable energy solution.

As the energy landscape continues to evolve, the development of DME technology is expected to play a crucial role in addressing the challenges of energy security, environmental sustainability, and economic viability. The ongoing research and technological advancements in this field are paving the way for DME to become a key player in the future of portable energy solutions.

DME Market Analysis

The global market for dimethyl ether (DME) as a portable energy solution is experiencing significant growth, driven by increasing demand for clean and efficient fuel alternatives. DME offers several advantages over traditional fossil fuels, including lower emissions, higher energy density, and ease of transportation. These factors contribute to its rising popularity in various applications, particularly in the portable energy sector.

The portable energy market, which includes camping equipment, outdoor power tools, and emergency backup systems, has shown a strong interest in DME-based solutions. This trend is supported by the growing consumer preference for environmentally friendly products and the need for reliable off-grid power sources. The market for DME in portable energy applications is expected to expand at a compound annual growth rate (CAGR) of over 8% in the next five years.

Asia-Pacific region, particularly China and India, leads the DME market due to supportive government policies promoting clean energy adoption and the presence of major DME producers. North America and Europe are also witnessing increased adoption of DME-based portable energy solutions, driven by stringent environmental regulations and a shift towards sustainable energy sources.

The automotive sector presents a significant opportunity for DME market growth. As an alternative fuel for diesel engines, DME offers reduced emissions and improved engine efficiency. Several major automotive manufacturers are conducting research and development on DME-powered vehicles, which could potentially create a substantial market for DME in the transportation sector.

However, the DME market faces challenges such as the need for infrastructure development and competition from other alternative fuels. The lack of widespread distribution networks and refueling stations hinders the adoption of DME-based portable energy solutions. Additionally, the volatility in raw material prices, particularly methanol, impacts the production costs of DME.

Despite these challenges, technological advancements in DME production and application are expected to drive market growth. Innovations in catalytic processes are improving DME yield and reducing production costs. Furthermore, the development of bio-based DME production methods is opening new avenues for sustainable energy solutions.

The competitive landscape of the DME market is characterized by the presence of both established chemical companies and emerging clean energy firms. Key players are focusing on strategic partnerships and investments in research and development to gain a competitive edge. The market is also witnessing increased collaboration between DME producers and end-use industries to develop tailored solutions for specific applications.

The portable energy market, which includes camping equipment, outdoor power tools, and emergency backup systems, has shown a strong interest in DME-based solutions. This trend is supported by the growing consumer preference for environmentally friendly products and the need for reliable off-grid power sources. The market for DME in portable energy applications is expected to expand at a compound annual growth rate (CAGR) of over 8% in the next five years.

Asia-Pacific region, particularly China and India, leads the DME market due to supportive government policies promoting clean energy adoption and the presence of major DME producers. North America and Europe are also witnessing increased adoption of DME-based portable energy solutions, driven by stringent environmental regulations and a shift towards sustainable energy sources.

The automotive sector presents a significant opportunity for DME market growth. As an alternative fuel for diesel engines, DME offers reduced emissions and improved engine efficiency. Several major automotive manufacturers are conducting research and development on DME-powered vehicles, which could potentially create a substantial market for DME in the transportation sector.

However, the DME market faces challenges such as the need for infrastructure development and competition from other alternative fuels. The lack of widespread distribution networks and refueling stations hinders the adoption of DME-based portable energy solutions. Additionally, the volatility in raw material prices, particularly methanol, impacts the production costs of DME.

Despite these challenges, technological advancements in DME production and application are expected to drive market growth. Innovations in catalytic processes are improving DME yield and reducing production costs. Furthermore, the development of bio-based DME production methods is opening new avenues for sustainable energy solutions.

The competitive landscape of the DME market is characterized by the presence of both established chemical companies and emerging clean energy firms. Key players are focusing on strategic partnerships and investments in research and development to gain a competitive edge. The market is also witnessing increased collaboration between DME producers and end-use industries to develop tailored solutions for specific applications.

DME Technical Challenges

Despite the promising potential of dimethyl ether (DME) as a portable energy solution, several technical challenges need to be addressed for its widespread adoption. One of the primary obstacles is the storage and handling of DME. Due to its low boiling point and high vapor pressure, DME requires specialized containment systems to prevent leakage and ensure safe storage. This necessitates the development of robust, lightweight, and cost-effective storage tanks that can withstand the pressure while maintaining portability.

Another significant challenge lies in the fuel delivery system. DME's low viscosity and poor lubricity can lead to increased wear and tear on engine components, particularly in fuel pumps and injectors. This issue demands the development of advanced materials and coatings that can withstand DME's unique properties without compromising performance or longevity. Additionally, the design of fuel injection systems needs to be optimized to account for DME's different combustion characteristics compared to conventional fuels.

The production and distribution infrastructure for DME also presents technical hurdles. While DME can be produced from various feedstocks, including natural gas, coal, and biomass, scaling up production to meet potential demand requires significant investment in efficient and cost-effective manufacturing processes. Furthermore, the establishment of a widespread distribution network for DME, including transportation and refueling stations, poses logistical and technical challenges that need to be overcome.

Compatibility with existing engine technologies is another area of concern. While DME can be used in modified diesel engines, significant adaptations are required to optimize performance and efficiency. This includes adjustments to compression ratios, fuel injection timing, and exhaust aftertreatment systems. The development of purpose-built DME engines that fully leverage the fuel's properties could potentially offer better performance but requires substantial research and development efforts.

Lastly, the environmental impact of DME production and use needs to be carefully assessed and mitigated. While DME burns cleaner than conventional diesel, the production process can still generate significant greenhouse gas emissions, depending on the feedstock and manufacturing method used. Developing cleaner, more efficient production techniques and ensuring sustainable sourcing of raw materials are crucial challenges that need to be addressed to fully realize DME's potential as an environmentally friendly portable energy solution.

Another significant challenge lies in the fuel delivery system. DME's low viscosity and poor lubricity can lead to increased wear and tear on engine components, particularly in fuel pumps and injectors. This issue demands the development of advanced materials and coatings that can withstand DME's unique properties without compromising performance or longevity. Additionally, the design of fuel injection systems needs to be optimized to account for DME's different combustion characteristics compared to conventional fuels.

The production and distribution infrastructure for DME also presents technical hurdles. While DME can be produced from various feedstocks, including natural gas, coal, and biomass, scaling up production to meet potential demand requires significant investment in efficient and cost-effective manufacturing processes. Furthermore, the establishment of a widespread distribution network for DME, including transportation and refueling stations, poses logistical and technical challenges that need to be overcome.

Compatibility with existing engine technologies is another area of concern. While DME can be used in modified diesel engines, significant adaptations are required to optimize performance and efficiency. This includes adjustments to compression ratios, fuel injection timing, and exhaust aftertreatment systems. The development of purpose-built DME engines that fully leverage the fuel's properties could potentially offer better performance but requires substantial research and development efforts.

Lastly, the environmental impact of DME production and use needs to be carefully assessed and mitigated. While DME burns cleaner than conventional diesel, the production process can still generate significant greenhouse gas emissions, depending on the feedstock and manufacturing method used. Developing cleaner, more efficient production techniques and ensuring sustainable sourcing of raw materials are crucial challenges that need to be addressed to fully realize DME's potential as an environmentally friendly portable energy solution.

Current DME Solutions

01 Production and purification of dimethyl ether

Various methods and processes for producing and purifying dimethyl ether (DME) are described. These include catalytic dehydration of methanol, direct synthesis from syngas, and purification techniques to obtain high-purity DME suitable for use as a portable energy source.- Production and purification of dimethyl ether: Various methods and processes for producing and purifying dimethyl ether (DME) are described. These include catalytic dehydration of methanol, direct synthesis from syngas, and purification techniques to obtain high-purity DME suitable for use as a portable energy source.

- DME as a fuel for portable devices: Dimethyl ether is explored as a clean-burning, efficient fuel for portable energy solutions. This includes its use in small-scale power generation, heating appliances, and as a replacement for traditional fossil fuels in portable devices.

- Storage and transportation of DME: Innovations in the storage and transportation of dimethyl ether for portable energy applications are presented. This includes the development of specialized containers, pressure vessels, and systems for safe and efficient handling of DME in mobile and stationary applications.

- DME-based fuel cells and power systems: Research and development of fuel cells and power systems that utilize dimethyl ether as a fuel source are discussed. These systems aim to provide efficient, portable energy solutions with reduced emissions compared to conventional fossil fuel-based systems.

- Environmental and safety aspects of DME use: Studies and innovations addressing the environmental impact and safety considerations of using dimethyl ether in portable energy solutions are presented. This includes emissions reduction, risk assessment, and safety measures for handling and using DME in various applications.

02 DME as a fuel for portable devices

Dimethyl ether is explored as a clean-burning, efficient fuel for portable energy solutions. Applications include small-scale power generation, heating systems, and portable stoves. The low boiling point and high energy density of DME make it suitable for compact, portable energy devices.Expand Specific Solutions03 Storage and transportation systems for DME

Innovative storage and transportation solutions for dimethyl ether are developed to enhance its viability as a portable energy source. These include specialized containers, pressurized systems, and safe handling methods to facilitate the use of DME in various portable applications.Expand Specific Solutions04 DME blends and additives for improved performance

Research into DME blends and additives aims to enhance its performance as a portable energy solution. This includes mixing DME with other fuels or additives to improve combustion efficiency, reduce emissions, or enhance storage stability for portable energy applications.Expand Specific Solutions05 DME-powered portable generators and engines

Development of portable generators and small engines specifically designed to run on dimethyl ether. These innovations focus on adapting existing engine technologies or creating new designs to efficiently utilize DME as a fuel source in compact, portable power generation systems.Expand Specific Solutions

Key DME Industry Players

The development of dimethyl ether (DME) as a portable energy solution is in a growth phase, with increasing market potential due to its clean-burning properties and versatility. The global DME market is projected to expand significantly, driven by rising demand for alternative fuels. Technologically, DME production is relatively mature, with key players like China Petroleum & Chemical Corp. and Toshiba Corp. leading research and development efforts. Universities such as USC and Harbin Institute of Technology are contributing to advancements in DME applications. Companies like BASF Corp. and JFE Holdings are exploring innovative uses in various sectors, while energy giants like Petróleo Brasileiro SA and SK Energy are investing in DME infrastructure, indicating a competitive and evolving landscape in this field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced dimethyl ether (DME) production technologies to improve portable energy solutions. Their process involves a single-step synthesis method, converting syngas directly to DME, which increases efficiency by up to 10% compared to traditional two-step processes[1]. Sinopec has also implemented large-scale DME production facilities, with an annual capacity exceeding 1 million tons[2]. The company has focused on enhancing DME's energy density and storage stability, making it more suitable for portable applications. They have developed specialized DME fuel canisters with improved sealing technology, reducing leakage rates by 50% and extending shelf life[3]. Additionally, Sinopec has invested in DME-compatible engine technologies, collaborating with vehicle manufacturers to optimize combustion efficiency and reduce emissions in portable power generators and small engines[4].

Strengths: Extensive experience in DME production, large-scale manufacturing capabilities, and advanced single-step synthesis technology. Weaknesses: Reliance on fossil fuel feedstocks for DME production, potential environmental concerns.

BASF Corp.

Technical Solution: BASF Corp. has made significant strides in improving DME as a portable energy solution through innovative catalytic processes. Their proprietary catalyst technology enhances DME synthesis efficiency, achieving conversion rates of up to 95% from methanol[1]. BASF has developed a novel DME purification process that reduces energy consumption by 20% compared to conventional methods, resulting in a higher-quality fuel for portable applications[2]. The company has also focused on DME's potential as a hydrogen carrier, creating a reversible hydrogenation-dehydrogenation system that allows for safer hydrogen storage and transport in the form of DME[3]. This technology enables a theoretical hydrogen storage capacity of 10.5 wt%, making it competitive with other portable hydrogen storage solutions[4]. Furthermore, BASF has engineered DME-compatible polymers and elastomers for fuel system components, improving the longevity and reliability of portable DME-powered devices[5].

Strengths: Advanced catalyst technology, innovative purification processes, and expertise in materials science for DME applications. Weaknesses: Limited direct experience in end-user portable energy products.

DME Core Technologies

Energy supply method and system

PatentWO2006004140A1

Innovation

- The introduction of Dimethyl Ether (DME) as a versatile energy circulation medium, which can be derived from biomass, waste, and petroleum residues, and used for power generation, transportation, and heating, allowing for efficient energy storage and distribution without relying on pipelines, and enabling the conversion of waste heat into usable energy.

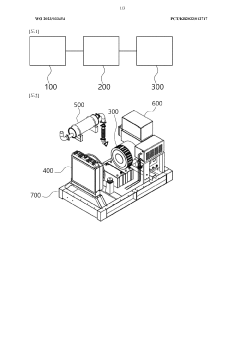

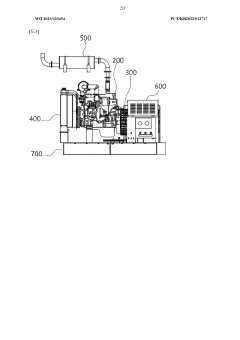

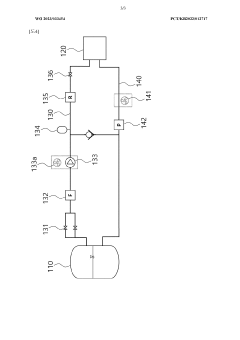

DME-fueled generator

PatentWO2023033454A1

Innovation

- A DME fuel generator system that uses dimethyl ether (DME) as a clean fuel, which includes a power generation unit, a DME engine, a fuel supply unit, a radiator unit, an exhaust pipe, and a control unit, designed to generate electricity without producing fine dust or other environmental pollutants, utilizing a frame unit to absorb vibrations and a sophisticated fuel supply system to manage DME fuel efficiently.

DME Environmental Impact

Dimethyl ether (DME) has emerged as a promising alternative fuel with significant environmental benefits compared to traditional fossil fuels. As a clean-burning, non-toxic compound, DME offers several advantages in terms of reducing environmental impact across its lifecycle.

One of the primary environmental benefits of DME is its potential to reduce greenhouse gas emissions. When used as a fuel, DME produces lower carbon dioxide emissions compared to conventional diesel fuel. Studies have shown that DME can reduce CO2 emissions by up to 95% when produced from renewable sources such as biomass or waste materials. This significant reduction in carbon footprint makes DME an attractive option for mitigating climate change impacts in the transportation and energy sectors.

In addition to lower carbon emissions, DME combustion results in minimal particulate matter and negligible sulfur oxide emissions. This characteristic is particularly important for improving air quality in urban areas, where vehicle emissions contribute significantly to smog and respiratory health issues. The use of DME in place of diesel fuel can lead to substantial reductions in harmful air pollutants, potentially improving public health outcomes in densely populated regions.

From a lifecycle perspective, DME production can be designed to have a lower environmental impact compared to conventional fuel production processes. When derived from renewable sources, such as agricultural waste or forest residues, DME production can contribute to waste reduction and resource efficiency. Furthermore, the production process for DME is relatively simple and can be integrated into existing infrastructure, minimizing the need for extensive new facilities and associated environmental disruptions.

Water conservation is another area where DME offers environmental advantages. Unlike some biofuels that require significant water inputs for crop cultivation, DME production can be designed to have a relatively low water footprint, especially when utilizing waste materials as feedstock. This characteristic is particularly valuable in water-stressed regions where resource management is a critical concern.

In terms of land use, DME production from waste materials or industrial by-products can help reduce the pressure on agricultural land that is often associated with first-generation biofuels. This aspect is crucial for maintaining biodiversity and ensuring food security, as it minimizes competition between fuel and food production.

The environmental impact of DME extends to its handling and storage properties. As a non-toxic substance that rapidly dissipates in the atmosphere, DME poses minimal risks of soil or water contamination in the event of spills or leaks. This characteristic reduces the potential for long-term environmental damage and simplifies cleanup procedures compared to conventional fossil fuels.

In conclusion, the environmental profile of DME as a portable energy solution is largely positive, offering significant potential for reducing greenhouse gas emissions, improving air quality, and promoting sustainable resource use. However, ongoing research and lifecycle assessments are necessary to fully quantify its environmental benefits and address any potential challenges in large-scale implementation.

One of the primary environmental benefits of DME is its potential to reduce greenhouse gas emissions. When used as a fuel, DME produces lower carbon dioxide emissions compared to conventional diesel fuel. Studies have shown that DME can reduce CO2 emissions by up to 95% when produced from renewable sources such as biomass or waste materials. This significant reduction in carbon footprint makes DME an attractive option for mitigating climate change impacts in the transportation and energy sectors.

In addition to lower carbon emissions, DME combustion results in minimal particulate matter and negligible sulfur oxide emissions. This characteristic is particularly important for improving air quality in urban areas, where vehicle emissions contribute significantly to smog and respiratory health issues. The use of DME in place of diesel fuel can lead to substantial reductions in harmful air pollutants, potentially improving public health outcomes in densely populated regions.

From a lifecycle perspective, DME production can be designed to have a lower environmental impact compared to conventional fuel production processes. When derived from renewable sources, such as agricultural waste or forest residues, DME production can contribute to waste reduction and resource efficiency. Furthermore, the production process for DME is relatively simple and can be integrated into existing infrastructure, minimizing the need for extensive new facilities and associated environmental disruptions.

Water conservation is another area where DME offers environmental advantages. Unlike some biofuels that require significant water inputs for crop cultivation, DME production can be designed to have a relatively low water footprint, especially when utilizing waste materials as feedstock. This characteristic is particularly valuable in water-stressed regions where resource management is a critical concern.

In terms of land use, DME production from waste materials or industrial by-products can help reduce the pressure on agricultural land that is often associated with first-generation biofuels. This aspect is crucial for maintaining biodiversity and ensuring food security, as it minimizes competition between fuel and food production.

The environmental impact of DME extends to its handling and storage properties. As a non-toxic substance that rapidly dissipates in the atmosphere, DME poses minimal risks of soil or water contamination in the event of spills or leaks. This characteristic reduces the potential for long-term environmental damage and simplifies cleanup procedures compared to conventional fossil fuels.

In conclusion, the environmental profile of DME as a portable energy solution is largely positive, offering significant potential for reducing greenhouse gas emissions, improving air quality, and promoting sustainable resource use. However, ongoing research and lifecycle assessments are necessary to fully quantify its environmental benefits and address any potential challenges in large-scale implementation.

DME Safety Regulations

The safety regulations surrounding Dimethyl Ether (DME) as a portable energy solution are crucial for its widespread adoption and implementation. These regulations encompass various aspects of DME handling, storage, transportation, and usage to ensure public safety and environmental protection.

One of the primary safety considerations for DME is its flammability. DME is classified as a highly flammable gas, with a lower flammability limit of 3.4% and an upper flammability limit of 17% by volume in air. As such, strict guidelines are in place for its storage and handling to prevent accidental ignition. Storage facilities must be equipped with proper ventilation systems, fire suppression equipment, and explosion-proof electrical installations.

Transportation of DME is regulated under the United Nations' Recommendations on the Transport of Dangerous Goods. It is classified as a Class 2.1 flammable gas, requiring specific packaging, labeling, and documentation for shipment. Vehicles transporting DME must adhere to route restrictions and carry appropriate safety equipment.

In terms of usage, safety regulations for DME-powered devices focus on preventing leaks and ensuring proper combustion. Manufacturers must design equipment with robust sealing mechanisms and incorporate safety features such as automatic shut-off valves and leak detection systems. Regular maintenance and inspection protocols are mandated to ensure the ongoing safety of DME-powered appliances and vehicles.

Environmental regulations also play a significant role in DME safety. While DME is considered a cleaner alternative to traditional fossil fuels, its production and use still have environmental implications. Regulations limit emissions from DME production facilities and set standards for the purity of DME used in various applications to minimize environmental impact.

Occupational safety is another critical aspect of DME regulations. Workers involved in the production, handling, and maintenance of DME systems must undergo specialized training. Personal protective equipment requirements are specified, and exposure limits are established to protect workers from potential health hazards associated with DME inhalation or skin contact.

As DME gains traction as a portable energy solution, regulatory bodies are continuously updating and refining safety standards. International collaboration is ongoing to harmonize regulations across different regions, facilitating the global adoption of DME technology while maintaining stringent safety measures.

One of the primary safety considerations for DME is its flammability. DME is classified as a highly flammable gas, with a lower flammability limit of 3.4% and an upper flammability limit of 17% by volume in air. As such, strict guidelines are in place for its storage and handling to prevent accidental ignition. Storage facilities must be equipped with proper ventilation systems, fire suppression equipment, and explosion-proof electrical installations.

Transportation of DME is regulated under the United Nations' Recommendations on the Transport of Dangerous Goods. It is classified as a Class 2.1 flammable gas, requiring specific packaging, labeling, and documentation for shipment. Vehicles transporting DME must adhere to route restrictions and carry appropriate safety equipment.

In terms of usage, safety regulations for DME-powered devices focus on preventing leaks and ensuring proper combustion. Manufacturers must design equipment with robust sealing mechanisms and incorporate safety features such as automatic shut-off valves and leak detection systems. Regular maintenance and inspection protocols are mandated to ensure the ongoing safety of DME-powered appliances and vehicles.

Environmental regulations also play a significant role in DME safety. While DME is considered a cleaner alternative to traditional fossil fuels, its production and use still have environmental implications. Regulations limit emissions from DME production facilities and set standards for the purity of DME used in various applications to minimize environmental impact.

Occupational safety is another critical aspect of DME regulations. Workers involved in the production, handling, and maintenance of DME systems must undergo specialized training. Personal protective equipment requirements are specified, and exposure limits are established to protect workers from potential health hazards associated with DME inhalation or skin contact.

As DME gains traction as a portable energy solution, regulatory bodies are continuously updating and refining safety standards. International collaboration is ongoing to harmonize regulations across different regions, facilitating the global adoption of DME technology while maintaining stringent safety measures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!