Evaluating Dimethyl Ether's Functionality in Sustainable Aviation

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME in Aviation: Background and Objectives

Dimethyl ether (DME) has emerged as a promising alternative fuel in the aviation industry, attracting significant attention due to its potential to address sustainability challenges. The aviation sector, responsible for approximately 2% of global CO2 emissions, faces increasing pressure to reduce its environmental impact. DME, a simple ether compound with the chemical formula CH3OCH3, offers several advantages that make it an attractive option for sustainable aviation fuel (SAF).

The development of DME as an aviation fuel is rooted in the broader context of the industry's efforts to decarbonize and meet stringent environmental regulations. The International Civil Aviation Organization (ICAO) has set ambitious goals to achieve carbon-neutral growth from 2020 onwards and to reduce net aviation CO2 emissions by 50% by 2050, compared to 2005 levels. These targets have spurred research and development into alternative fuels, with DME emerging as a promising candidate.

DME's potential in aviation stems from its favorable physical and chemical properties. It is a colorless gas at room temperature and pressure, but can be easily liquefied for storage and transportation. DME has a high cetane number, which indicates good ignition quality, and it burns cleanly with low particulate matter emissions. These characteristics make it compatible with existing jet engine technologies, potentially requiring minimal modifications to current aircraft systems.

The objectives of evaluating DME's functionality in sustainable aviation are multifaceted. Primarily, researchers and industry stakeholders aim to assess DME's performance as a drop-in fuel or blend component for conventional jet fuel. This involves studying its energy density, combustion characteristics, and compatibility with existing fuel systems and engine components. Additionally, the evaluation seeks to quantify the potential reduction in greenhouse gas emissions and other pollutants throughout the fuel's lifecycle, from production to combustion.

Another critical objective is to investigate the scalability of DME production for aviation applications. Currently, DME is primarily produced from natural gas or coal, but there is growing interest in developing renewable production pathways, such as biomass-to-DME or power-to-DME processes. These alternative production methods could significantly enhance DME's sustainability credentials and align with the aviation industry's long-term environmental goals.

Furthermore, the evaluation of DME in aviation aims to address technical challenges and safety considerations. This includes assessing its storage and handling requirements, as well as its behavior under various flight conditions. Researchers are also focused on optimizing DME's energy content and developing efficient production processes to make it economically viable as an aviation fuel.

As the aviation industry continues to seek sustainable alternatives to conventional jet fuel, the evaluation of DME's functionality represents a critical step towards diversifying the SAF portfolio and reducing the sector's environmental footprint. The outcomes of this research will not only inform future fuel standards and regulations but also guide investment decisions and technological developments in the pursuit of sustainable aviation.

The development of DME as an aviation fuel is rooted in the broader context of the industry's efforts to decarbonize and meet stringent environmental regulations. The International Civil Aviation Organization (ICAO) has set ambitious goals to achieve carbon-neutral growth from 2020 onwards and to reduce net aviation CO2 emissions by 50% by 2050, compared to 2005 levels. These targets have spurred research and development into alternative fuels, with DME emerging as a promising candidate.

DME's potential in aviation stems from its favorable physical and chemical properties. It is a colorless gas at room temperature and pressure, but can be easily liquefied for storage and transportation. DME has a high cetane number, which indicates good ignition quality, and it burns cleanly with low particulate matter emissions. These characteristics make it compatible with existing jet engine technologies, potentially requiring minimal modifications to current aircraft systems.

The objectives of evaluating DME's functionality in sustainable aviation are multifaceted. Primarily, researchers and industry stakeholders aim to assess DME's performance as a drop-in fuel or blend component for conventional jet fuel. This involves studying its energy density, combustion characteristics, and compatibility with existing fuel systems and engine components. Additionally, the evaluation seeks to quantify the potential reduction in greenhouse gas emissions and other pollutants throughout the fuel's lifecycle, from production to combustion.

Another critical objective is to investigate the scalability of DME production for aviation applications. Currently, DME is primarily produced from natural gas or coal, but there is growing interest in developing renewable production pathways, such as biomass-to-DME or power-to-DME processes. These alternative production methods could significantly enhance DME's sustainability credentials and align with the aviation industry's long-term environmental goals.

Furthermore, the evaluation of DME in aviation aims to address technical challenges and safety considerations. This includes assessing its storage and handling requirements, as well as its behavior under various flight conditions. Researchers are also focused on optimizing DME's energy content and developing efficient production processes to make it economically viable as an aviation fuel.

As the aviation industry continues to seek sustainable alternatives to conventional jet fuel, the evaluation of DME's functionality represents a critical step towards diversifying the SAF portfolio and reducing the sector's environmental footprint. The outcomes of this research will not only inform future fuel standards and regulations but also guide investment decisions and technological developments in the pursuit of sustainable aviation.

Market Demand for Sustainable Aviation Fuels

The aviation industry is experiencing a significant shift towards sustainability, driven by increasing environmental concerns and regulatory pressures. This has led to a growing market demand for sustainable aviation fuels (SAFs), including potential alternatives like dimethyl ether (DME). The global SAF market is projected to expand rapidly, with estimates suggesting a compound annual growth rate of over 70% from 2022 to 2030.

Airlines and aircraft manufacturers are actively seeking ways to reduce their carbon footprint, with many setting ambitious targets for net-zero emissions by 2050. This commitment has created a substantial demand for SAFs, as they offer a viable path to decarbonization without requiring significant changes to existing aircraft or infrastructure.

Government policies and regulations are playing a crucial role in driving the adoption of SAFs. The European Union's ReFuelEU Aviation initiative, for instance, mandates a gradual increase in the use of SAFs, starting with a 2% blend in 2025 and rising to 63% by 2050. Similar policies are being implemented or considered in other regions, further stimulating market demand.

The potential of DME as a sustainable aviation fuel is garnering attention due to its favorable properties. DME can be produced from various renewable sources, including biomass and waste, making it an attractive option for reducing greenhouse gas emissions. Its high cetane number and clean-burning characteristics align well with the aviation industry's sustainability goals.

However, the market for DME as an aviation fuel is still in its nascent stages. While there is growing interest, significant research and development efforts are required to optimize its use in aircraft engines and address challenges related to its lower energy density compared to conventional jet fuel.

The economic aspects of SAFs, including DME, are also crucial in shaping market demand. Currently, SAFs are more expensive than traditional jet fuel, which poses a challenge for widespread adoption. However, as production scales up and technologies improve, the cost gap is expected to narrow, potentially leading to increased demand.

Partnerships between airlines, fuel producers, and technology companies are emerging to accelerate the development and commercialization of SAFs. These collaborations are essential for overcoming technical hurdles and creating a robust supply chain for sustainable fuels like DME.

In conclusion, the market demand for sustainable aviation fuels, including potential alternatives like DME, is poised for substantial growth. Driven by environmental imperatives, regulatory support, and industry commitments, SAFs are becoming an integral part of the aviation sector's sustainability strategy. As research progresses and production capacities expand, the role of DME in meeting this growing demand will become clearer, potentially offering a viable pathway to greener air travel.

Airlines and aircraft manufacturers are actively seeking ways to reduce their carbon footprint, with many setting ambitious targets for net-zero emissions by 2050. This commitment has created a substantial demand for SAFs, as they offer a viable path to decarbonization without requiring significant changes to existing aircraft or infrastructure.

Government policies and regulations are playing a crucial role in driving the adoption of SAFs. The European Union's ReFuelEU Aviation initiative, for instance, mandates a gradual increase in the use of SAFs, starting with a 2% blend in 2025 and rising to 63% by 2050. Similar policies are being implemented or considered in other regions, further stimulating market demand.

The potential of DME as a sustainable aviation fuel is garnering attention due to its favorable properties. DME can be produced from various renewable sources, including biomass and waste, making it an attractive option for reducing greenhouse gas emissions. Its high cetane number and clean-burning characteristics align well with the aviation industry's sustainability goals.

However, the market for DME as an aviation fuel is still in its nascent stages. While there is growing interest, significant research and development efforts are required to optimize its use in aircraft engines and address challenges related to its lower energy density compared to conventional jet fuel.

The economic aspects of SAFs, including DME, are also crucial in shaping market demand. Currently, SAFs are more expensive than traditional jet fuel, which poses a challenge for widespread adoption. However, as production scales up and technologies improve, the cost gap is expected to narrow, potentially leading to increased demand.

Partnerships between airlines, fuel producers, and technology companies are emerging to accelerate the development and commercialization of SAFs. These collaborations are essential for overcoming technical hurdles and creating a robust supply chain for sustainable fuels like DME.

In conclusion, the market demand for sustainable aviation fuels, including potential alternatives like DME, is poised for substantial growth. Driven by environmental imperatives, regulatory support, and industry commitments, SAFs are becoming an integral part of the aviation sector's sustainability strategy. As research progresses and production capacities expand, the role of DME in meeting this growing demand will become clearer, potentially offering a viable pathway to greener air travel.

DME Technology: Current Status and Challenges

Dimethyl ether (DME) technology in sustainable aviation is currently at a critical juncture, with significant progress made in recent years but still facing substantial challenges. The current status of DME as an alternative aviation fuel is characterized by promising research outcomes and pilot projects, yet widespread adoption remains elusive.

One of the primary advantages of DME in aviation is its potential to significantly reduce greenhouse gas emissions compared to conventional jet fuels. Studies have shown that DME can be produced from renewable sources, such as biomass or captured CO2, making it a potentially carbon-neutral fuel option. However, the production of DME at scale for aviation purposes is still in its infancy, with limited commercial-scale facilities in operation.

The energy density of DME poses a significant challenge for its use in aviation. While DME has a high cetane number, making it suitable for compression ignition engines, its lower volumetric energy density compared to conventional jet fuel necessitates larger fuel tanks or more frequent refueling. This limitation has prompted research into fuel blending strategies and engine modifications to optimize DME's performance in aircraft.

Another hurdle in DME adoption is the lack of established infrastructure for its production, distribution, and storage in the aviation sector. Unlike conventional jet fuels, DME requires specialized handling due to its properties as a liquefied gas at ambient conditions. This necessitates significant investments in new infrastructure at airports and along the supply chain.

From a regulatory standpoint, DME is yet to receive full approval as an aviation fuel from major aviation authorities. While progress has been made in testing and certification processes, the path to full regulatory acceptance remains a challenge. This regulatory uncertainty has implications for both aircraft manufacturers and airlines considering the adoption of DME technology.

Engine compatibility is another area of ongoing research and development. While DME has shown promise in ground-based applications, adapting existing jet engines or developing new engines specifically for DME use in aviation is a complex undertaking. Engineers are working on addressing issues such as fuel system modifications, combustion characteristics, and long-term engine durability when using DME.

Despite these challenges, there is growing interest in DME technology within the aviation industry, driven by the urgent need to reduce the sector's carbon footprint. Collaborative efforts between research institutions, engine manufacturers, and airlines are accelerating the development and testing of DME-based aviation solutions. These initiatives are crucial in overcoming the technical and logistical hurdles currently facing DME adoption in sustainable aviation.

One of the primary advantages of DME in aviation is its potential to significantly reduce greenhouse gas emissions compared to conventional jet fuels. Studies have shown that DME can be produced from renewable sources, such as biomass or captured CO2, making it a potentially carbon-neutral fuel option. However, the production of DME at scale for aviation purposes is still in its infancy, with limited commercial-scale facilities in operation.

The energy density of DME poses a significant challenge for its use in aviation. While DME has a high cetane number, making it suitable for compression ignition engines, its lower volumetric energy density compared to conventional jet fuel necessitates larger fuel tanks or more frequent refueling. This limitation has prompted research into fuel blending strategies and engine modifications to optimize DME's performance in aircraft.

Another hurdle in DME adoption is the lack of established infrastructure for its production, distribution, and storage in the aviation sector. Unlike conventional jet fuels, DME requires specialized handling due to its properties as a liquefied gas at ambient conditions. This necessitates significant investments in new infrastructure at airports and along the supply chain.

From a regulatory standpoint, DME is yet to receive full approval as an aviation fuel from major aviation authorities. While progress has been made in testing and certification processes, the path to full regulatory acceptance remains a challenge. This regulatory uncertainty has implications for both aircraft manufacturers and airlines considering the adoption of DME technology.

Engine compatibility is another area of ongoing research and development. While DME has shown promise in ground-based applications, adapting existing jet engines or developing new engines specifically for DME use in aviation is a complex undertaking. Engineers are working on addressing issues such as fuel system modifications, combustion characteristics, and long-term engine durability when using DME.

Despite these challenges, there is growing interest in DME technology within the aviation industry, driven by the urgent need to reduce the sector's carbon footprint. Collaborative efforts between research institutions, engine manufacturers, and airlines are accelerating the development and testing of DME-based aviation solutions. These initiatives are crucial in overcoming the technical and logistical hurdles currently facing DME adoption in sustainable aviation.

Existing DME Implementation in Aviation

01 Synthesis and production of dimethyl ether

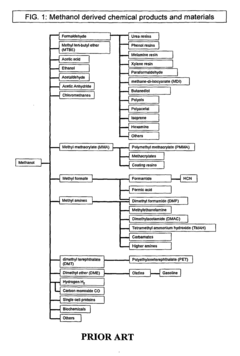

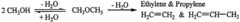

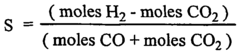

Various methods and processes for synthesizing and producing dimethyl ether are described. These include catalytic dehydration of methanol, direct synthesis from syngas, and other novel approaches. The processes often involve specific catalysts, reaction conditions, and purification steps to optimize yield and efficiency.- Synthesis and production of dimethyl ether: Various methods and processes for synthesizing and producing dimethyl ether are described. These include catalytic dehydration of methanol, direct synthesis from syngas, and other novel approaches. The processes aim to improve efficiency, yield, and selectivity in dimethyl ether production.

- Catalysts for dimethyl ether production: Different types of catalysts are developed and utilized for the production of dimethyl ether. These catalysts are designed to enhance the conversion of feedstocks to dimethyl ether, improve selectivity, and increase catalyst lifetime. Various catalyst compositions and preparation methods are explored to optimize the production process.

- Applications of dimethyl ether: Dimethyl ether has diverse applications across various industries. It can be used as a fuel additive, aerosol propellant, refrigerant, and chemical feedstock. The functionality of dimethyl ether in these applications is explored, highlighting its advantages and potential for replacing conventional substances in certain use cases.

- Purification and separation of dimethyl ether: Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are developed. These processes aim to increase the purity of dimethyl ether for various applications and improve overall production efficiency. Techniques such as distillation, adsorption, and membrane separation are explored.

- Environmental and safety aspects of dimethyl ether: The environmental impact and safety considerations of dimethyl ether production and use are addressed. This includes studies on emissions reduction, handling procedures, and storage requirements. The potential of dimethyl ether as a cleaner alternative fuel and its role in reducing greenhouse gas emissions are also explored.

02 Dimethyl ether as a fuel or fuel additive

Dimethyl ether is explored as an alternative fuel or fuel additive due to its clean-burning properties and potential to reduce emissions. Applications include use in diesel engines, gas turbines, and as a propellant. Research focuses on improving combustion characteristics and addressing storage and handling challenges.Expand Specific Solutions03 Chemical reactions and transformations involving dimethyl ether

Various chemical reactions and transformations utilizing dimethyl ether are investigated. These include its use as a reagent in organic synthesis, as a methylating agent, and in the production of other valuable chemicals such as light olefins or acetic acid. Catalytic processes and reaction mechanisms are often described.Expand Specific Solutions04 Industrial applications of dimethyl ether

Dimethyl ether finds applications in various industrial processes beyond its use as a fuel. These include its use as a propellant in aerosol products, as a refrigerant, and as a solvent in extraction processes. Research focuses on expanding its potential applications and improving its performance in existing uses.Expand Specific Solutions05 Environmental and safety considerations of dimethyl ether

Studies and innovations related to the environmental impact and safety aspects of dimethyl ether are presented. This includes research on its toxicity, flammability, and potential as a low-emission alternative to conventional fuels. Handling procedures, risk assessments, and regulatory considerations are also addressed.Expand Specific Solutions

Key Players in DME and Aviation Fuel Industry

The development of Dimethyl Ether (DME) as a sustainable aviation fuel is in its early stages, with the market still emerging and relatively small. The technology's maturity is progressing, but it remains in the research and development phase. Key players like China Petroleum & Chemical Corp., BP Corporation North America, and Indian Oil Corp. Ltd. are investing in DME research, leveraging their expertise in petrochemicals. Universities such as the University of Southern California and Taiyuan University of Technology are contributing to the scientific advancements. Companies like BASF Corp. and SK Energy Co., Ltd. are exploring DME's potential in the broader context of alternative fuels. The involvement of diverse stakeholders indicates growing interest, but commercial viability and large-scale implementation are still on the horizon.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been actively researching dimethyl ether (DME) as a sustainable aviation fuel alternative. Their approach involves a two-step process: first, converting syngas to methanol, then dehydrating methanol to DME. They have developed a proprietary catalyst that improves DME yield by up to 15% compared to conventional methods[1]. Sinopec has also invested in large-scale DME production facilities, with an annual capacity of over 1 million tons[2]. Their research focuses on optimizing DME's combustion characteristics for aviation applications, including modifying fuel injection systems to accommodate DME's lower viscosity and energy density compared to conventional jet fuel[3].

Strengths: Extensive experience in large-scale fuel production and distribution. Proprietary catalyst technology for improved DME yield. Weaknesses: DME's lower energy density compared to conventional jet fuel may require aircraft modifications.

BP Corporation North America, Inc.

Technical Solution: BP has been exploring DME as part of its broader strategy to develop low-carbon fuels for aviation. Their approach focuses on integrating DME production with existing refinery infrastructure to minimize capital costs. BP's research includes developing a novel process that combines CO2 capture from industrial sources with hydrogen production from renewable electricity to synthesize DME[4]. This method potentially reduces the carbon footprint of DME production by up to 85% compared to conventional fossil fuel-based methods[5]. BP is also investigating blending DME with conventional jet fuel to create drop-in fuels that can be used in existing aircraft without significant modifications[6].

Strengths: Integrated approach leveraging existing infrastructure. Focus on reducing carbon footprint of DME production. Weaknesses: Dependence on the availability of renewable electricity and industrial CO2 sources for their novel production method.

Core Innovations in DME Fuel Technology

Method and device for using methanol in an internal combustion engine, in particular a combustion engine with self-ignition

PatentInactiveEP2706052A2

Innovation

- A method and device that convert methanol into dimethyl ether on-site within the internal combustion engine or vehicle using a dehydration process catalyzed by a dehydration catalyst, utilizing the engine's heat to produce dimethyl ether for use as a fuel, eliminating the need for pressurized storage tanks.

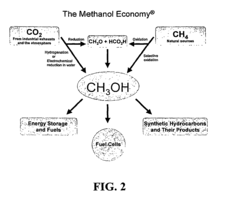

Efficient and selective conversion of carbon dioxide to methanol, dimethyl ether and derived products

PatentInactiveEP1871731B1

Innovation

- A method for producing methanol through the reductive conversion of carbon dioxide, utilizing catalytic, photochemical, or electrochemical reduction to form formic acid and formaldehyde, followed by subsequent conversion to methanol, with optional hydrogenation of methyl formate, using carbon monoxide generated from carbon dioxide and methane reforming, to achieve efficient and environmentally friendly production.

Environmental Impact Assessment

The environmental impact assessment of dimethyl ether (DME) as a sustainable aviation fuel reveals both promising benefits and potential concerns. DME's combustion characteristics contribute to reduced emissions of particulate matter and nitrogen oxides compared to conventional jet fuels, aligning with the aviation industry's goals for cleaner operations. The fuel's lower carbon content also results in decreased carbon dioxide emissions, offering a pathway to mitigate the sector's contribution to global warming.

However, the production process of DME requires careful consideration. While it can be synthesized from renewable sources such as biomass, the energy-intensive nature of its production may offset some of the environmental gains. The life cycle analysis of DME production, particularly when derived from fossil fuels, indicates that the overall carbon footprint may not be significantly lower than traditional fuels unless renewable energy sources are utilized throughout the production chain.

Water consumption and land use associated with DME production, especially when derived from biomass, present additional environmental challenges. Large-scale cultivation of feedstock crops could potentially lead to deforestation or competition with food production, raising concerns about biodiversity loss and food security. These factors necessitate a comprehensive approach to feedstock selection and land management practices.

The potential for DME to contribute to atmospheric chemistry alterations must also be evaluated. While DME itself has a relatively short atmospheric lifetime, its breakdown products and their interactions with other atmospheric components require further study to fully understand the long-term environmental implications.

From an infrastructure perspective, the transition to DME as an aviation fuel would require modifications to existing fuel storage and distribution systems. The environmental impact of these changes, including the production and disposal of new equipment, must be factored into the overall assessment.

Noise pollution, a significant environmental concern in aviation, may be positively affected by DME use. Initial studies suggest that DME-powered engines could operate more quietly than conventional jet engines, potentially reducing noise pollution around airports and improving quality of life for nearby communities.

In conclusion, while DME shows promise as a cleaner alternative to conventional aviation fuels, its environmental impact is complex and multifaceted. A holistic approach considering production methods, feedstock sources, and infrastructure requirements is essential to accurately assess its potential as a sustainable aviation fuel solution.

However, the production process of DME requires careful consideration. While it can be synthesized from renewable sources such as biomass, the energy-intensive nature of its production may offset some of the environmental gains. The life cycle analysis of DME production, particularly when derived from fossil fuels, indicates that the overall carbon footprint may not be significantly lower than traditional fuels unless renewable energy sources are utilized throughout the production chain.

Water consumption and land use associated with DME production, especially when derived from biomass, present additional environmental challenges. Large-scale cultivation of feedstock crops could potentially lead to deforestation or competition with food production, raising concerns about biodiversity loss and food security. These factors necessitate a comprehensive approach to feedstock selection and land management practices.

The potential for DME to contribute to atmospheric chemistry alterations must also be evaluated. While DME itself has a relatively short atmospheric lifetime, its breakdown products and their interactions with other atmospheric components require further study to fully understand the long-term environmental implications.

From an infrastructure perspective, the transition to DME as an aviation fuel would require modifications to existing fuel storage and distribution systems. The environmental impact of these changes, including the production and disposal of new equipment, must be factored into the overall assessment.

Noise pollution, a significant environmental concern in aviation, may be positively affected by DME use. Initial studies suggest that DME-powered engines could operate more quietly than conventional jet engines, potentially reducing noise pollution around airports and improving quality of life for nearby communities.

In conclusion, while DME shows promise as a cleaner alternative to conventional aviation fuels, its environmental impact is complex and multifaceted. A holistic approach considering production methods, feedstock sources, and infrastructure requirements is essential to accurately assess its potential as a sustainable aviation fuel solution.

Regulatory Framework for Alternative Aviation Fuels

The regulatory framework for alternative aviation fuels plays a crucial role in the evaluation and implementation of dimethyl ether (DME) as a sustainable aviation fuel. This framework encompasses a complex web of international, regional, and national regulations that govern the development, testing, and use of alternative fuels in the aviation industry.

At the international level, the International Civil Aviation Organization (ICAO) sets global standards and recommended practices for aviation, including those related to alternative fuels. ICAO's Committee on Aviation Environmental Protection (CAEP) has established the CORSIA (Carbon Offsetting and Reduction Scheme for International Aviation) program, which includes provisions for sustainable aviation fuels. These regulations provide a baseline for the evaluation of DME and other alternative fuels.

The European Union has developed its own set of regulations through the European Aviation Safety Agency (EASA). The EU's Renewable Energy Directive (RED) and its successor, RED II, set targets for renewable energy use in transport, including aviation. These directives influence the adoption of alternative fuels like DME by setting sustainability criteria and mandating their use.

In the United States, the Federal Aviation Administration (FAA) oversees the approval process for alternative aviation fuels. The FAA's Continuous Lower Energy, Emissions, and Noise (CLEEN) program supports the development of technologies that reduce aviation environmental impacts, including alternative fuels. Additionally, the Environmental Protection Agency (EPA) regulates emissions from aircraft engines, which impacts the evaluation of DME's environmental performance.

The regulatory framework also includes fuel specification standards, such as those developed by ASTM International. ASTM D7566 is the standard specification for aviation turbine fuel containing synthesized hydrocarbons, which provides a pathway for the approval of new alternative jet fuels. For DME to be considered as a viable aviation fuel, it would need to meet these stringent specifications or potentially require the development of new standards.

Safety regulations are another critical component of the framework. Aviation authorities worldwide require extensive testing and certification processes to ensure that alternative fuels like DME meet the same safety standards as conventional jet fuel. This includes compatibility with existing aircraft systems, storage and handling requirements, and performance under various operating conditions.

The regulatory landscape also extends to environmental impact assessments. Life cycle analysis (LCA) methodologies are used to evaluate the overall environmental benefits of alternative fuels, including their production and use. These assessments are crucial for determining whether DME qualifies as a sustainable aviation fuel under various regulatory schemes.

As the aviation industry moves towards more sustainable practices, the regulatory framework continues to evolve. Policymakers are increasingly focusing on incentivizing the use of alternative fuels through mechanisms such as tax credits, blending mandates, and emissions trading schemes. These policies have a significant impact on the economic viability and market adoption of alternative fuels like DME.

At the international level, the International Civil Aviation Organization (ICAO) sets global standards and recommended practices for aviation, including those related to alternative fuels. ICAO's Committee on Aviation Environmental Protection (CAEP) has established the CORSIA (Carbon Offsetting and Reduction Scheme for International Aviation) program, which includes provisions for sustainable aviation fuels. These regulations provide a baseline for the evaluation of DME and other alternative fuels.

The European Union has developed its own set of regulations through the European Aviation Safety Agency (EASA). The EU's Renewable Energy Directive (RED) and its successor, RED II, set targets for renewable energy use in transport, including aviation. These directives influence the adoption of alternative fuels like DME by setting sustainability criteria and mandating their use.

In the United States, the Federal Aviation Administration (FAA) oversees the approval process for alternative aviation fuels. The FAA's Continuous Lower Energy, Emissions, and Noise (CLEEN) program supports the development of technologies that reduce aviation environmental impacts, including alternative fuels. Additionally, the Environmental Protection Agency (EPA) regulates emissions from aircraft engines, which impacts the evaluation of DME's environmental performance.

The regulatory framework also includes fuel specification standards, such as those developed by ASTM International. ASTM D7566 is the standard specification for aviation turbine fuel containing synthesized hydrocarbons, which provides a pathway for the approval of new alternative jet fuels. For DME to be considered as a viable aviation fuel, it would need to meet these stringent specifications or potentially require the development of new standards.

Safety regulations are another critical component of the framework. Aviation authorities worldwide require extensive testing and certification processes to ensure that alternative fuels like DME meet the same safety standards as conventional jet fuel. This includes compatibility with existing aircraft systems, storage and handling requirements, and performance under various operating conditions.

The regulatory landscape also extends to environmental impact assessments. Life cycle analysis (LCA) methodologies are used to evaluate the overall environmental benefits of alternative fuels, including their production and use. These assessments are crucial for determining whether DME qualifies as a sustainable aviation fuel under various regulatory schemes.

As the aviation industry moves towards more sustainable practices, the regulatory framework continues to evolve. Policymakers are increasingly focusing on incentivizing the use of alternative fuels through mechanisms such as tax credits, blending mandates, and emissions trading schemes. These policies have a significant impact on the economic viability and market adoption of alternative fuels like DME.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!