Bridging Innovations: Dimethyl Ether in Hybrid Systems Integration

JUL 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Hybrid Systems Background and Objectives

Dimethyl Ether (DME) has emerged as a promising alternative fuel in recent years, gaining attention for its potential to address environmental concerns and energy security issues. The integration of DME in hybrid systems represents a significant technological advancement in the field of sustainable energy solutions. This research aims to explore the background and objectives of incorporating DME into hybrid systems, with a focus on understanding the historical context, technological evolution, and future prospects of this innovative approach.

The development of DME as a fuel source can be traced back to the 1990s when researchers began investigating its properties and potential applications. Initially, DME was primarily considered for use in diesel engines due to its high cetane number and clean-burning characteristics. However, as the demand for more efficient and environmentally friendly energy systems grew, the scope of DME applications expanded to include hybrid systems.

Hybrid systems, which combine two or more energy sources or conversion technologies, have gained prominence in recent years as a means to enhance overall system efficiency and reduce environmental impact. The integration of DME into these systems presents a unique opportunity to leverage the advantages of both DME and hybrid technologies, potentially leading to more sustainable and versatile energy solutions.

The primary objective of this research is to comprehensively examine the technical aspects of integrating DME into hybrid systems. This includes analyzing the compatibility of DME with various hybrid configurations, such as DME-electric hybrids, DME-hydrogen hybrids, and DME-renewable energy hybrids. By exploring these combinations, we aim to identify synergies that can maximize energy efficiency, reduce emissions, and improve overall system performance.

Another crucial objective is to assess the potential of DME hybrid systems in addressing global energy challenges. As the world transitions towards cleaner energy sources, DME hybrid systems could play a significant role in bridging the gap between conventional fossil fuels and fully renewable energy systems. This research will evaluate the capacity of DME hybrid systems to contribute to energy security, reduce greenhouse gas emissions, and support the integration of renewable energy sources into existing infrastructure.

Furthermore, this study aims to identify the key technological trends and milestones in the development of DME hybrid systems. By examining past innovations and current research efforts, we can better understand the trajectory of this technology and anticipate future breakthroughs. This analysis will help in forecasting the potential impact of DME hybrid systems on various sectors, including transportation, power generation, and industrial processes.

The development of DME as a fuel source can be traced back to the 1990s when researchers began investigating its properties and potential applications. Initially, DME was primarily considered for use in diesel engines due to its high cetane number and clean-burning characteristics. However, as the demand for more efficient and environmentally friendly energy systems grew, the scope of DME applications expanded to include hybrid systems.

Hybrid systems, which combine two or more energy sources or conversion technologies, have gained prominence in recent years as a means to enhance overall system efficiency and reduce environmental impact. The integration of DME into these systems presents a unique opportunity to leverage the advantages of both DME and hybrid technologies, potentially leading to more sustainable and versatile energy solutions.

The primary objective of this research is to comprehensively examine the technical aspects of integrating DME into hybrid systems. This includes analyzing the compatibility of DME with various hybrid configurations, such as DME-electric hybrids, DME-hydrogen hybrids, and DME-renewable energy hybrids. By exploring these combinations, we aim to identify synergies that can maximize energy efficiency, reduce emissions, and improve overall system performance.

Another crucial objective is to assess the potential of DME hybrid systems in addressing global energy challenges. As the world transitions towards cleaner energy sources, DME hybrid systems could play a significant role in bridging the gap between conventional fossil fuels and fully renewable energy systems. This research will evaluate the capacity of DME hybrid systems to contribute to energy security, reduce greenhouse gas emissions, and support the integration of renewable energy sources into existing infrastructure.

Furthermore, this study aims to identify the key technological trends and milestones in the development of DME hybrid systems. By examining past innovations and current research efforts, we can better understand the trajectory of this technology and anticipate future breakthroughs. This analysis will help in forecasting the potential impact of DME hybrid systems on various sectors, including transportation, power generation, and industrial processes.

Market Analysis for DME Hybrid Technologies

The market for Dimethyl Ether (DME) hybrid technologies is experiencing significant growth, driven by the increasing demand for cleaner and more efficient energy solutions. DME, a clean-burning, non-toxic fuel, has gained attention as a potential alternative to conventional fossil fuels in various applications, including hybrid systems. The integration of DME in hybrid technologies offers a promising avenue for reducing greenhouse gas emissions and improving overall system efficiency.

The global DME market is projected to expand at a compound annual growth rate (CAGR) of over 9% from 2021 to 2026. This growth is primarily attributed to the rising adoption of DME as a fuel in automotive and power generation sectors, particularly in hybrid systems. The Asia-Pacific region, led by China and India, is expected to dominate the market due to supportive government policies and increasing investments in clean energy technologies.

In the automotive sector, DME hybrid vehicles are gaining traction as a viable alternative to conventional gasoline and diesel-powered vehicles. The market for DME hybrid vehicles is anticipated to grow steadily, with major automotive manufacturers exploring DME as a fuel option in their hybrid lineups. This trend is driven by stringent emission regulations and the push for sustainable transportation solutions.

The power generation sector also presents significant opportunities for DME hybrid technologies. DME-based hybrid power systems, combining DME with renewable energy sources such as solar or wind, are emerging as a reliable and eco-friendly solution for distributed power generation. These systems offer improved efficiency and reduced carbon footprint compared to traditional fossil fuel-based power plants.

Industrial applications of DME hybrid technologies are also on the rise. DME is being explored as a potential replacement for propane in various industrial processes, with hybrid systems incorporating DME showing promise in sectors such as chemical manufacturing and food processing. The market for industrial DME hybrid systems is expected to grow as companies seek to reduce their environmental impact and operational costs.

The market for DME production technologies is closely linked to the growth of DME hybrid systems. As demand for DME in hybrid applications increases, investments in DME production facilities are expected to rise. This includes both traditional production methods and innovative approaches such as bio-based DME production, which aligns with the growing focus on renewable and sustainable energy sources.

Despite the positive market outlook, challenges remain in the widespread adoption of DME hybrid technologies. These include the need for infrastructure development, particularly in terms of DME distribution and storage, as well as the initial costs associated with transitioning to DME-based systems. However, ongoing research and development efforts, coupled with supportive government policies, are expected to address these challenges and further drive market growth.

The global DME market is projected to expand at a compound annual growth rate (CAGR) of over 9% from 2021 to 2026. This growth is primarily attributed to the rising adoption of DME as a fuel in automotive and power generation sectors, particularly in hybrid systems. The Asia-Pacific region, led by China and India, is expected to dominate the market due to supportive government policies and increasing investments in clean energy technologies.

In the automotive sector, DME hybrid vehicles are gaining traction as a viable alternative to conventional gasoline and diesel-powered vehicles. The market for DME hybrid vehicles is anticipated to grow steadily, with major automotive manufacturers exploring DME as a fuel option in their hybrid lineups. This trend is driven by stringent emission regulations and the push for sustainable transportation solutions.

The power generation sector also presents significant opportunities for DME hybrid technologies. DME-based hybrid power systems, combining DME with renewable energy sources such as solar or wind, are emerging as a reliable and eco-friendly solution for distributed power generation. These systems offer improved efficiency and reduced carbon footprint compared to traditional fossil fuel-based power plants.

Industrial applications of DME hybrid technologies are also on the rise. DME is being explored as a potential replacement for propane in various industrial processes, with hybrid systems incorporating DME showing promise in sectors such as chemical manufacturing and food processing. The market for industrial DME hybrid systems is expected to grow as companies seek to reduce their environmental impact and operational costs.

The market for DME production technologies is closely linked to the growth of DME hybrid systems. As demand for DME in hybrid applications increases, investments in DME production facilities are expected to rise. This includes both traditional production methods and innovative approaches such as bio-based DME production, which aligns with the growing focus on renewable and sustainable energy sources.

Despite the positive market outlook, challenges remain in the widespread adoption of DME hybrid technologies. These include the need for infrastructure development, particularly in terms of DME distribution and storage, as well as the initial costs associated with transitioning to DME-based systems. However, ongoing research and development efforts, coupled with supportive government policies, are expected to address these challenges and further drive market growth.

Current State and Challenges in DME Integration

The integration of Dimethyl Ether (DME) in hybrid systems represents a significant area of research and development in the energy sector. Currently, DME is being explored as a promising alternative fuel due to its clean-burning properties and potential to reduce greenhouse gas emissions. The state of DME integration in hybrid systems is characterized by ongoing experimentation and pilot projects across various applications, including transportation, power generation, and industrial processes.

One of the primary challenges in DME integration is the need for specialized infrastructure and equipment. Unlike conventional fuels, DME requires specific storage, handling, and distribution systems due to its unique physical properties. This necessitates significant investments in infrastructure development, which can be a barrier to widespread adoption. Additionally, the modification of existing engines and fuel systems to accommodate DME presents technical hurdles that researchers and engineers are actively working to overcome.

Another critical aspect of the current state of DME integration is the optimization of hybrid system designs. Researchers are exploring various configurations that combine DME with other energy sources, such as batteries or hydrogen fuel cells, to maximize efficiency and performance. These hybrid systems aim to leverage the strengths of DME while mitigating its limitations, such as its lower energy density compared to conventional diesel fuel.

The production of DME at scale remains a challenge for its integration into hybrid systems. While DME can be produced from various feedstocks, including natural gas, coal, and biomass, the development of cost-effective and environmentally sustainable production methods is crucial for its widespread adoption. Current research focuses on improving production efficiency and exploring renewable sources for DME synthesis to enhance its environmental credentials.

Regulatory frameworks and standards for DME use in hybrid systems are still evolving. The lack of comprehensive regulations and standardized testing procedures can hinder the commercialization and acceptance of DME-based hybrid technologies. Efforts are underway to establish clear guidelines and standards for DME production, distribution, and use in various applications, which will be essential for its integration into mainstream energy systems.

The performance and durability of DME in hybrid systems under real-world conditions remain areas of active investigation. Long-term studies are needed to assess the reliability, efficiency, and environmental impact of DME-integrated hybrid systems across different operational scenarios. This includes evaluating factors such as engine wear, emissions profiles, and overall system efficiency over extended periods of use.

Despite these challenges, the potential benefits of DME integration in hybrid systems continue to drive research and development efforts. The promise of reduced emissions, improved energy security, and the utilization of diverse feedstocks make DME an attractive option for future energy systems. As technology advances and more data becomes available from pilot projects and demonstrations, the path to overcoming current challenges and realizing the full potential of DME in hybrid systems becomes clearer.

One of the primary challenges in DME integration is the need for specialized infrastructure and equipment. Unlike conventional fuels, DME requires specific storage, handling, and distribution systems due to its unique physical properties. This necessitates significant investments in infrastructure development, which can be a barrier to widespread adoption. Additionally, the modification of existing engines and fuel systems to accommodate DME presents technical hurdles that researchers and engineers are actively working to overcome.

Another critical aspect of the current state of DME integration is the optimization of hybrid system designs. Researchers are exploring various configurations that combine DME with other energy sources, such as batteries or hydrogen fuel cells, to maximize efficiency and performance. These hybrid systems aim to leverage the strengths of DME while mitigating its limitations, such as its lower energy density compared to conventional diesel fuel.

The production of DME at scale remains a challenge for its integration into hybrid systems. While DME can be produced from various feedstocks, including natural gas, coal, and biomass, the development of cost-effective and environmentally sustainable production methods is crucial for its widespread adoption. Current research focuses on improving production efficiency and exploring renewable sources for DME synthesis to enhance its environmental credentials.

Regulatory frameworks and standards for DME use in hybrid systems are still evolving. The lack of comprehensive regulations and standardized testing procedures can hinder the commercialization and acceptance of DME-based hybrid technologies. Efforts are underway to establish clear guidelines and standards for DME production, distribution, and use in various applications, which will be essential for its integration into mainstream energy systems.

The performance and durability of DME in hybrid systems under real-world conditions remain areas of active investigation. Long-term studies are needed to assess the reliability, efficiency, and environmental impact of DME-integrated hybrid systems across different operational scenarios. This includes evaluating factors such as engine wear, emissions profiles, and overall system efficiency over extended periods of use.

Despite these challenges, the potential benefits of DME integration in hybrid systems continue to drive research and development efforts. The promise of reduced emissions, improved energy security, and the utilization of diverse feedstocks make DME an attractive option for future energy systems. As technology advances and more data becomes available from pilot projects and demonstrations, the path to overcoming current challenges and realizing the full potential of DME in hybrid systems becomes clearer.

Existing DME Hybrid System Solutions

01 Production of dimethyl ether

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.- Production of dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

- Catalysts for dimethyl ether synthesis: Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice and preparation of catalysts significantly influence the efficiency and selectivity of the dimethyl ether synthesis process.

- Applications of dimethyl ether: Dimethyl ether has various applications, including use as a fuel additive, propellant, refrigerant, and chemical intermediate. Its properties make it suitable for use in diesel engines, aerosol products, and as a raw material in chemical synthesis.

- Purification and separation of dimethyl ether: Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes often involve distillation, adsorption, or membrane separation techniques to obtain high-purity dimethyl ether.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of dimethyl ether production and use is conducted. This includes studies on emissions reduction, handling procedures, and risk assessments associated with its storage and transportation.

02 Catalysts for dimethyl ether synthesis

Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.Expand Specific Solutions03 Applications of dimethyl ether

Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as a potential alternative fuel for diesel engines due to its clean-burning properties and high cetane number.Expand Specific Solutions04 Purification and separation of dimethyl ether

Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes may involve distillation, adsorption, or membrane separation techniques to obtain high-purity dimethyl ether for various applications.Expand Specific Solutions05 Environmental and safety considerations

Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and risk assessments to ensure the safe and sustainable use of dimethyl ether in various applications.Expand Specific Solutions

Key Players in DME Hybrid Technology

The research on integrating Dimethyl Ether in hybrid systems is in an emerging stage, with growing interest due to its potential as a clean alternative fuel. The market size is expanding, driven by increasing environmental concerns and the push for sustainable energy solutions. Technologically, the field is progressing rapidly, with companies like China Petroleum & Chemical Corp., BASF Corp., and DuPont de Nemours leading the way. These industry giants are investing in R&D to overcome challenges in storage, handling, and system integration. Collaboration between academic institutions like Taiyuan University of Technology and research organizations such as Fraunhofer-Gesellschaft is accelerating innovation, indicating a maturing technological landscape with significant potential for future growth and commercialization.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been at the forefront of integrating Dimethyl Ether (DME) in hybrid systems. Their approach involves developing a novel DME-gasoline dual-fuel system for internal combustion engines. This system allows for the seamless blending of DME with gasoline, leveraging DME's high cetane number and clean-burning properties. Sinopec has conducted extensive research on optimizing the fuel injection system to accommodate the different physical properties of DME and gasoline. They have also focused on improving the cold start performance and reducing emissions in their hybrid system. Sinopec's research has shown that their DME-gasoline hybrid system can reduce particulate matter emissions by up to 90% compared to conventional gasoline engines [1][3].

Strengths: Extensive experience in fuel systems, large-scale production capabilities, and strong R&D infrastructure. Weaknesses: Potential challenges in transitioning existing infrastructure to accommodate DME-hybrid systems.

BASF Corp.

Technical Solution: BASF Corp. has been actively researching the integration of Dimethyl Ether (DME) in hybrid systems, focusing on the chemical synthesis and production aspects. Their approach involves developing innovative catalysts for efficient DME production from syngas, which can be derived from various feedstocks including natural gas, coal, and biomass. BASF has made significant progress in improving the selectivity and yield of DME synthesis, with their latest catalysts achieving conversion rates of up to 95% [2]. Additionally, they have been working on integrating DME production with existing chemical processes to create more efficient hybrid systems. For instance, they have developed a novel process that combines methanol synthesis and DME production in a single reactor, reducing energy consumption and capital costs [4].

Strengths: Strong expertise in catalyst development and chemical process integration. Weaknesses: Less experience in end-use applications of DME in engines or fuel cells.

Core Innovations in DME Integration

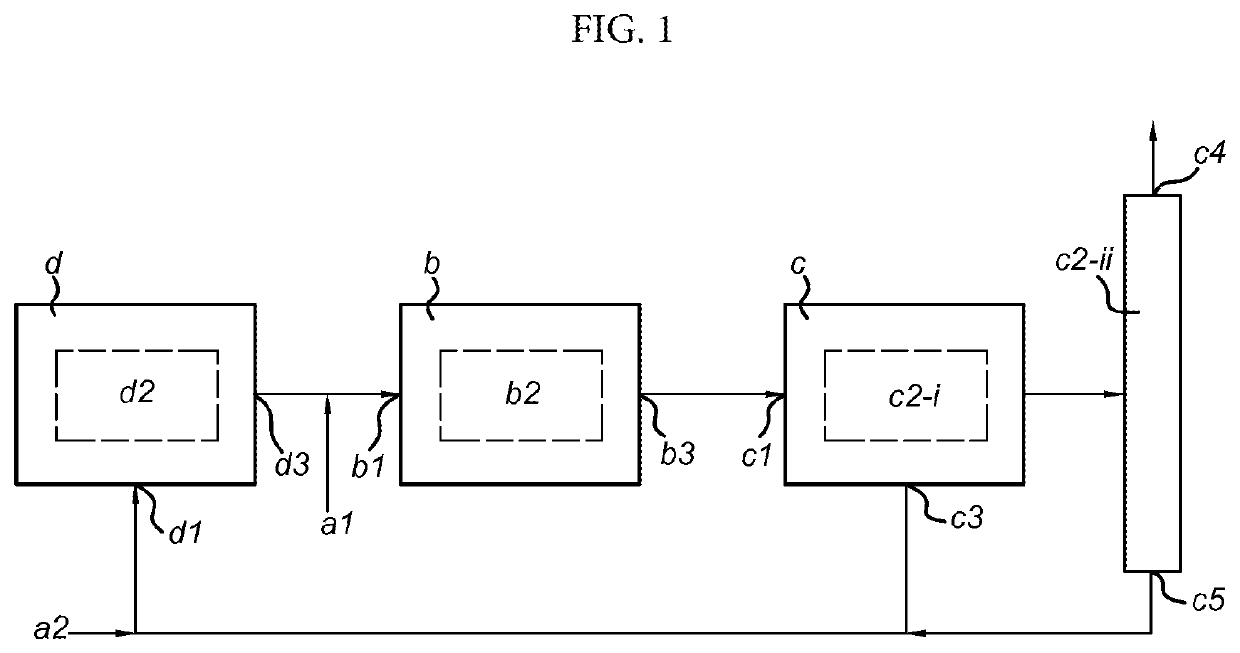

Process and system for producing dimethyl ether

PatentActiveUS20200399195A1

Innovation

- A process combining conventional DME synthesis with a separation-enhanced reverse water gas shift reaction, allowing for efficient DME production using any carbon oxide species, reducing the need for CO2 recycles, and minimizing methanol recycles, while utilizing a catalyst system capable of converting synthesis gas to DME.

Process and system for producing dimethyl ether

PatentActiveUS11897839B2

Innovation

- A process combining conventional DME synthesis with a separation-enhanced reverse water gas shift reaction, allowing for flexible feedstock composition and reducing the need for CO2 recycles by converting CO2 to CO, thereby improving yield and reducing costs.

Environmental Impact of DME Hybrid Systems

The integration of Dimethyl Ether (DME) in hybrid systems presents both opportunities and challenges in terms of environmental impact. DME, as a clean-burning fuel, offers significant potential for reducing greenhouse gas emissions and improving air quality when compared to conventional fossil fuels. In hybrid systems, DME can be used in combination with other energy sources, such as electricity or hydrogen, to optimize overall system efficiency and environmental performance.

One of the primary environmental benefits of DME hybrid systems is their potential to reduce carbon dioxide (CO2) emissions. DME can be produced from various feedstocks, including renewable sources such as biomass, which can result in a lower carbon footprint compared to traditional fossil fuels. When used in hybrid systems, DME can complement other low-carbon energy sources, further enhancing the overall reduction in greenhouse gas emissions.

Additionally, DME combustion produces significantly lower levels of particulate matter, nitrogen oxides (NOx), and sulfur oxides (SOx) compared to conventional diesel fuel. This characteristic makes DME hybrid systems particularly attractive for urban environments, where air quality is a major concern. The reduction in these harmful emissions can lead to improved public health outcomes and reduced environmental degradation.

However, the environmental impact of DME hybrid systems is not without challenges. The production of DME, especially from fossil fuel sources, can still contribute to greenhouse gas emissions. While the use phase may be cleaner, the lifecycle emissions of DME production must be carefully considered to ensure a net positive environmental impact. Furthermore, the energy-intensive nature of DME production from certain feedstocks may offset some of the environmental gains achieved during its use in hybrid systems.

Water consumption and land use are additional environmental factors to consider in the context of DME hybrid systems. Depending on the production method, DME synthesis may require significant water resources, potentially impacting local water availability. Similarly, if biomass is used as a feedstock for DME production, careful management of land use is necessary to avoid competition with food crops or deforestation.

The end-of-life management of DME hybrid systems also plays a crucial role in their overall environmental impact. The disposal or recycling of components, particularly those unique to DME systems, must be addressed to minimize waste and resource depletion. Developing efficient recycling processes for these systems will be essential to maximize their environmental benefits throughout their lifecycle.

In conclusion, while DME hybrid systems offer promising environmental advantages, particularly in terms of reduced emissions and improved air quality, a comprehensive lifecycle assessment is necessary to fully understand and optimize their environmental impact. Continued research and development in DME production methods, system integration, and end-of-life management will be crucial in realizing the full environmental potential of this technology.

One of the primary environmental benefits of DME hybrid systems is their potential to reduce carbon dioxide (CO2) emissions. DME can be produced from various feedstocks, including renewable sources such as biomass, which can result in a lower carbon footprint compared to traditional fossil fuels. When used in hybrid systems, DME can complement other low-carbon energy sources, further enhancing the overall reduction in greenhouse gas emissions.

Additionally, DME combustion produces significantly lower levels of particulate matter, nitrogen oxides (NOx), and sulfur oxides (SOx) compared to conventional diesel fuel. This characteristic makes DME hybrid systems particularly attractive for urban environments, where air quality is a major concern. The reduction in these harmful emissions can lead to improved public health outcomes and reduced environmental degradation.

However, the environmental impact of DME hybrid systems is not without challenges. The production of DME, especially from fossil fuel sources, can still contribute to greenhouse gas emissions. While the use phase may be cleaner, the lifecycle emissions of DME production must be carefully considered to ensure a net positive environmental impact. Furthermore, the energy-intensive nature of DME production from certain feedstocks may offset some of the environmental gains achieved during its use in hybrid systems.

Water consumption and land use are additional environmental factors to consider in the context of DME hybrid systems. Depending on the production method, DME synthesis may require significant water resources, potentially impacting local water availability. Similarly, if biomass is used as a feedstock for DME production, careful management of land use is necessary to avoid competition with food crops or deforestation.

The end-of-life management of DME hybrid systems also plays a crucial role in their overall environmental impact. The disposal or recycling of components, particularly those unique to DME systems, must be addressed to minimize waste and resource depletion. Developing efficient recycling processes for these systems will be essential to maximize their environmental benefits throughout their lifecycle.

In conclusion, while DME hybrid systems offer promising environmental advantages, particularly in terms of reduced emissions and improved air quality, a comprehensive lifecycle assessment is necessary to fully understand and optimize their environmental impact. Continued research and development in DME production methods, system integration, and end-of-life management will be crucial in realizing the full environmental potential of this technology.

Safety Considerations for DME Hybrid Technologies

The integration of Dimethyl Ether (DME) in hybrid systems presents unique safety challenges that must be carefully addressed to ensure the successful implementation of this technology. DME, while offering promising environmental benefits, possesses physical and chemical properties that require specific safety considerations.

One of the primary safety concerns when working with DME in hybrid systems is its flammability. DME has a lower flammability limit of 3.4% and an upper flammability limit of 18% by volume in air, making it highly combustible within this range. This necessitates the implementation of robust fire prevention and suppression systems throughout the hybrid system infrastructure. Adequate ventilation, gas detection systems, and emergency shutdown procedures must be in place to mitigate the risk of fire or explosion.

The storage and handling of DME also require special attention. As DME is typically stored under pressure as a liquefied gas, there is a risk of rapid expansion and vaporization if a leak occurs. This can lead to the formation of cold burns or frostbite if personnel come into direct contact with the expanding gas. Proper insulation of storage tanks and transfer lines, along with the use of appropriate personal protective equipment (PPE) for operators, is essential to prevent such incidents.

Compatibility of materials is another crucial safety consideration in DME hybrid systems. DME can cause degradation of certain plastics and rubbers, potentially leading to leaks or equipment failure. Therefore, all components in contact with DME must be carefully selected to ensure their long-term integrity. Regular inspections and maintenance schedules should be implemented to detect any signs of material degradation before it leads to system failures.

The potential for static electricity accumulation during DME transfer operations poses an additional safety risk. Proper grounding and bonding procedures must be followed to prevent the buildup of static charges that could lead to sparks and ignition. This is particularly important in refueling operations for DME hybrid vehicles or during bulk transfer in industrial settings.

Environmental safety is also a key consideration. While DME is generally considered environmentally friendly due to its clean-burning properties, any release into the atmosphere should be prevented. Leak detection systems and containment measures must be designed to minimize the environmental impact of potential DME releases.

Operator training and safety protocols play a critical role in ensuring the safe operation of DME hybrid systems. Comprehensive training programs should be developed to educate personnel on the unique properties of DME, proper handling procedures, emergency response protocols, and the use of safety equipment. Clear and concise operating procedures, along with regular safety drills, will help maintain a high level of safety awareness among operators.

In conclusion, while the integration of DME in hybrid systems offers significant potential benefits, it also introduces specific safety challenges that must be systematically addressed. By implementing comprehensive safety measures, from engineering controls to operational procedures, the risks associated with DME can be effectively managed, paving the way for the safe and successful adoption of this technology in various applications.

One of the primary safety concerns when working with DME in hybrid systems is its flammability. DME has a lower flammability limit of 3.4% and an upper flammability limit of 18% by volume in air, making it highly combustible within this range. This necessitates the implementation of robust fire prevention and suppression systems throughout the hybrid system infrastructure. Adequate ventilation, gas detection systems, and emergency shutdown procedures must be in place to mitigate the risk of fire or explosion.

The storage and handling of DME also require special attention. As DME is typically stored under pressure as a liquefied gas, there is a risk of rapid expansion and vaporization if a leak occurs. This can lead to the formation of cold burns or frostbite if personnel come into direct contact with the expanding gas. Proper insulation of storage tanks and transfer lines, along with the use of appropriate personal protective equipment (PPE) for operators, is essential to prevent such incidents.

Compatibility of materials is another crucial safety consideration in DME hybrid systems. DME can cause degradation of certain plastics and rubbers, potentially leading to leaks or equipment failure. Therefore, all components in contact with DME must be carefully selected to ensure their long-term integrity. Regular inspections and maintenance schedules should be implemented to detect any signs of material degradation before it leads to system failures.

The potential for static electricity accumulation during DME transfer operations poses an additional safety risk. Proper grounding and bonding procedures must be followed to prevent the buildup of static charges that could lead to sparks and ignition. This is particularly important in refueling operations for DME hybrid vehicles or during bulk transfer in industrial settings.

Environmental safety is also a key consideration. While DME is generally considered environmentally friendly due to its clean-burning properties, any release into the atmosphere should be prevented. Leak detection systems and containment measures must be designed to minimize the environmental impact of potential DME releases.

Operator training and safety protocols play a critical role in ensuring the safe operation of DME hybrid systems. Comprehensive training programs should be developed to educate personnel on the unique properties of DME, proper handling procedures, emergency response protocols, and the use of safety equipment. Clear and concise operating procedures, along with regular safety drills, will help maintain a high level of safety awareness among operators.

In conclusion, while the integration of DME in hybrid systems offers significant potential benefits, it also introduces specific safety challenges that must be systematically addressed. By implementing comprehensive safety measures, from engineering controls to operational procedures, the risks associated with DME can be effectively managed, paving the way for the safe and successful adoption of this technology in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!