Redefining Energy Parameters with Dimethyl Ether Advancements

JUL 1, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Tech Evolution

The evolution of Dimethyl Ether (DME) technology has been marked by significant advancements and milestones over the past few decades. Initially developed as a propellant for aerosol products, DME has emerged as a promising alternative fuel and chemical feedstock, reshaping energy parameters across various industries.

In the 1990s, researchers began exploring DME's potential as a clean-burning fuel for diesel engines. This period saw the development of early production methods, primarily focused on the dehydration of methanol. The turn of the millennium brought about a surge in DME research, with Japan and China leading the way in large-scale production and utilization experiments.

The mid-2000s witnessed a pivotal shift in DME technology, as direct synthesis methods from syngas gained traction. This breakthrough significantly reduced production costs and improved overall efficiency. Simultaneously, engine manufacturers began developing DME-compatible engines, addressing challenges such as fuel injection systems and sealing materials.

From 2010 onwards, DME technology entered a phase of rapid commercialization. Major energy companies invested in pilot plants and demonstration projects, showcasing DME's viability as a substitute for liquefied petroleum gas (LPG) and diesel fuel. This period also saw the establishment of international standards for DME fuel quality and handling.

Recent years have seen a focus on integrating DME production with renewable energy sources. Innovations in catalysts and process designs have enabled the efficient conversion of biomass and captured CO2 into DME, aligning with global sustainability goals. Additionally, advancements in fuel cell technology have opened new avenues for DME utilization in power generation.

Looking ahead, the DME technology roadmap is poised for further evolution. Research is underway to enhance DME's energy density and storage efficiency, potentially expanding its applications in the transportation sector. Moreover, the integration of artificial intelligence and machine learning in DME production processes promises to optimize yield and reduce energy consumption.

As global efforts to decarbonize intensify, DME is positioned to play a crucial role in the transition to cleaner energy systems. The ongoing development of novel catalysts, process intensification techniques, and hybrid energy systems incorporating DME are expected to drive the next wave of technological advancements in this field.

In the 1990s, researchers began exploring DME's potential as a clean-burning fuel for diesel engines. This period saw the development of early production methods, primarily focused on the dehydration of methanol. The turn of the millennium brought about a surge in DME research, with Japan and China leading the way in large-scale production and utilization experiments.

The mid-2000s witnessed a pivotal shift in DME technology, as direct synthesis methods from syngas gained traction. This breakthrough significantly reduced production costs and improved overall efficiency. Simultaneously, engine manufacturers began developing DME-compatible engines, addressing challenges such as fuel injection systems and sealing materials.

From 2010 onwards, DME technology entered a phase of rapid commercialization. Major energy companies invested in pilot plants and demonstration projects, showcasing DME's viability as a substitute for liquefied petroleum gas (LPG) and diesel fuel. This period also saw the establishment of international standards for DME fuel quality and handling.

Recent years have seen a focus on integrating DME production with renewable energy sources. Innovations in catalysts and process designs have enabled the efficient conversion of biomass and captured CO2 into DME, aligning with global sustainability goals. Additionally, advancements in fuel cell technology have opened new avenues for DME utilization in power generation.

Looking ahead, the DME technology roadmap is poised for further evolution. Research is underway to enhance DME's energy density and storage efficiency, potentially expanding its applications in the transportation sector. Moreover, the integration of artificial intelligence and machine learning in DME production processes promises to optimize yield and reduce energy consumption.

As global efforts to decarbonize intensify, DME is positioned to play a crucial role in the transition to cleaner energy systems. The ongoing development of novel catalysts, process intensification techniques, and hybrid energy systems incorporating DME are expected to drive the next wave of technological advancements in this field.

DME Market Analysis

The global dimethyl ether (DME) market has been experiencing significant growth in recent years, driven by increasing demand for clean and alternative fuels. DME, with its favorable combustion properties and potential as a renewable energy source, has garnered attention across various industries, particularly in the energy and transportation sectors.

The market for DME is primarily segmented into two main applications: fuel and aerosol propellant. As a fuel, DME is gaining traction as a substitute for diesel in heavy-duty vehicles and as a cooking fuel in developing countries. Its use as an aerosol propellant is well-established in the personal care and household products industries.

Asia-Pacific dominates the DME market, with China leading in both production and consumption. The region's rapid industrialization, coupled with stringent environmental regulations, has spurred the adoption of DME as a cleaner alternative to conventional fuels. Europe and North America are also witnessing growing interest in DME, particularly in the transportation sector.

The market is characterized by the presence of several key players, including Akzo Nobel N.V., China Energy Limited, Grillo-Werke AG, and Oberon Fuels. These companies are actively investing in research and development to improve DME production processes and expand its applications.

Recent market trends indicate a shift towards bio-based DME production, aligning with global sustainability goals. This trend is expected to open new opportunities for market growth, especially in regions with abundant biomass resources.

Despite the positive outlook, the DME market faces challenges such as high production costs and limited infrastructure for distribution. However, ongoing technological advancements and supportive government policies are expected to address these barriers in the coming years.

The future of the DME market looks promising, with projections indicating sustained growth. Factors such as increasing environmental concerns, the need for energy security, and the push for cleaner fuel alternatives are likely to drive market expansion. As industries and governments worldwide continue to prioritize sustainable energy solutions, DME is poised to play a significant role in reshaping the global energy landscape.

The market for DME is primarily segmented into two main applications: fuel and aerosol propellant. As a fuel, DME is gaining traction as a substitute for diesel in heavy-duty vehicles and as a cooking fuel in developing countries. Its use as an aerosol propellant is well-established in the personal care and household products industries.

Asia-Pacific dominates the DME market, with China leading in both production and consumption. The region's rapid industrialization, coupled with stringent environmental regulations, has spurred the adoption of DME as a cleaner alternative to conventional fuels. Europe and North America are also witnessing growing interest in DME, particularly in the transportation sector.

The market is characterized by the presence of several key players, including Akzo Nobel N.V., China Energy Limited, Grillo-Werke AG, and Oberon Fuels. These companies are actively investing in research and development to improve DME production processes and expand its applications.

Recent market trends indicate a shift towards bio-based DME production, aligning with global sustainability goals. This trend is expected to open new opportunities for market growth, especially in regions with abundant biomass resources.

Despite the positive outlook, the DME market faces challenges such as high production costs and limited infrastructure for distribution. However, ongoing technological advancements and supportive government policies are expected to address these barriers in the coming years.

The future of the DME market looks promising, with projections indicating sustained growth. Factors such as increasing environmental concerns, the need for energy security, and the push for cleaner fuel alternatives are likely to drive market expansion. As industries and governments worldwide continue to prioritize sustainable energy solutions, DME is poised to play a significant role in reshaping the global energy landscape.

DME Tech Challenges

The development of dimethyl ether (DME) technology faces several significant challenges that need to be addressed to fully realize its potential as a clean and efficient energy source. One of the primary obstacles is the optimization of DME production processes. Current methods, such as direct synthesis from syngas or methanol dehydration, still require improvements in efficiency and cost-effectiveness to compete with traditional fuel production.

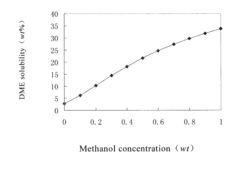

Another major challenge lies in the storage and distribution infrastructure for DME. As a liquefied gas, DME requires specialized handling and storage facilities, which are not as widely available as those for conventional fuels. This limitation hinders the widespread adoption of DME as an alternative fuel source, particularly in regions lacking the necessary infrastructure.

The compatibility of DME with existing engine technologies presents another hurdle. While DME can be used in modified diesel engines, significant adaptations are required to optimize performance and efficiency. These modifications include changes to fuel injection systems, seals, and other engine components to accommodate DME's unique properties.

Furthermore, the long-term durability and reliability of DME-powered engines remain a concern. Extended use of DME in engines may lead to increased wear and tear on certain components due to its lower viscosity compared to conventional diesel fuel. This issue necessitates ongoing research into materials and lubricants that can withstand prolonged exposure to DME.

Environmental considerations also pose challenges in DME technology advancement. While DME combustion produces lower emissions compared to conventional fuels, the production process still contributes to carbon dioxide emissions, particularly when derived from fossil fuel sources. Developing more sustainable production methods, such as utilizing renewable feedstocks or capturing and utilizing CO2, is crucial for enhancing DME's environmental credentials.

Regulatory hurdles and policy frameworks present additional challenges. The lack of standardized regulations for DME as a fuel in many regions creates uncertainty for manufacturers and potential users. Establishing clear guidelines and standards for DME production, distribution, and use is essential for fostering industry growth and consumer confidence.

Lastly, public awareness and acceptance of DME as an alternative fuel remain limited. Overcoming skepticism and educating consumers about the benefits and safety of DME technology is crucial for its widespread adoption. This challenge requires concerted efforts in public outreach, demonstration projects, and collaboration between industry stakeholders and policymakers to build trust and promote the advantages of DME as a clean energy solution.

Another major challenge lies in the storage and distribution infrastructure for DME. As a liquefied gas, DME requires specialized handling and storage facilities, which are not as widely available as those for conventional fuels. This limitation hinders the widespread adoption of DME as an alternative fuel source, particularly in regions lacking the necessary infrastructure.

The compatibility of DME with existing engine technologies presents another hurdle. While DME can be used in modified diesel engines, significant adaptations are required to optimize performance and efficiency. These modifications include changes to fuel injection systems, seals, and other engine components to accommodate DME's unique properties.

Furthermore, the long-term durability and reliability of DME-powered engines remain a concern. Extended use of DME in engines may lead to increased wear and tear on certain components due to its lower viscosity compared to conventional diesel fuel. This issue necessitates ongoing research into materials and lubricants that can withstand prolonged exposure to DME.

Environmental considerations also pose challenges in DME technology advancement. While DME combustion produces lower emissions compared to conventional fuels, the production process still contributes to carbon dioxide emissions, particularly when derived from fossil fuel sources. Developing more sustainable production methods, such as utilizing renewable feedstocks or capturing and utilizing CO2, is crucial for enhancing DME's environmental credentials.

Regulatory hurdles and policy frameworks present additional challenges. The lack of standardized regulations for DME as a fuel in many regions creates uncertainty for manufacturers and potential users. Establishing clear guidelines and standards for DME production, distribution, and use is essential for fostering industry growth and consumer confidence.

Lastly, public awareness and acceptance of DME as an alternative fuel remain limited. Overcoming skepticism and educating consumers about the benefits and safety of DME technology is crucial for its widespread adoption. This challenge requires concerted efforts in public outreach, demonstration projects, and collaboration between industry stakeholders and policymakers to build trust and promote the advantages of DME as a clean energy solution.

Current DME Solutions

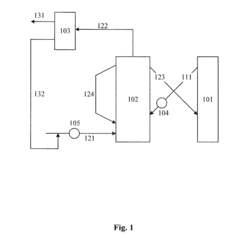

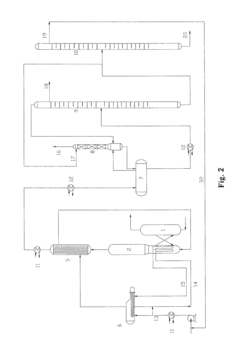

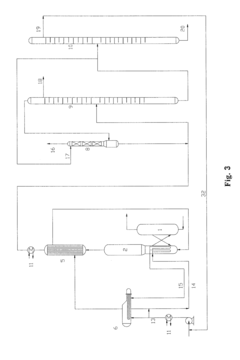

01 Production and purification of dimethyl ether

Various methods and processes for producing and purifying dimethyl ether are described. These include catalytic dehydration of methanol, direct synthesis from syngas, and separation techniques to obtain high-purity dimethyl ether. The processes aim to improve efficiency and yield while reducing energy consumption.- Production and purification of dimethyl ether: Various methods and processes for producing and purifying dimethyl ether are described. These include catalytic dehydration of methanol, direct synthesis from syngas, and purification techniques to obtain high-purity dimethyl ether. The processes aim to improve efficiency and yield while reducing energy consumption.

- Dimethyl ether as an alternative fuel: Dimethyl ether is explored as a potential alternative fuel for various applications, including diesel engines and power generation. Its energy parameters, combustion characteristics, and environmental benefits are investigated. Research focuses on optimizing fuel systems and engine performance for dimethyl ether usage.

- Energy efficiency in dimethyl ether production: Innovations in improving energy efficiency during dimethyl ether production are presented. These include heat integration techniques, advanced catalysts, and optimized reactor designs. The goal is to reduce overall energy consumption and improve the sustainability of the production process.

- Thermodynamic properties and energy parameters of dimethyl ether: Studies on the thermodynamic properties and energy parameters of dimethyl ether are conducted. This includes investigations into its heat capacity, enthalpy of vaporization, and other physical properties relevant to its use as a fuel or chemical feedstock. Understanding these parameters is crucial for optimizing its applications.

- Dimethyl ether in energy storage and transportation: The potential of dimethyl ether in energy storage and transportation systems is explored. This includes its use in fuel cells, as a hydrogen carrier, and in novel energy storage technologies. The energy density and handling characteristics of dimethyl ether make it an attractive option for various energy applications.

02 Dimethyl ether as an alternative fuel

Dimethyl ether is explored as a potential alternative fuel for various applications, including internal combustion engines and fuel cells. Its energy parameters, combustion characteristics, and environmental benefits are investigated. Research focuses on optimizing engine performance and reducing emissions when using dimethyl ether as a fuel.Expand Specific Solutions03 Energy storage and transportation using dimethyl ether

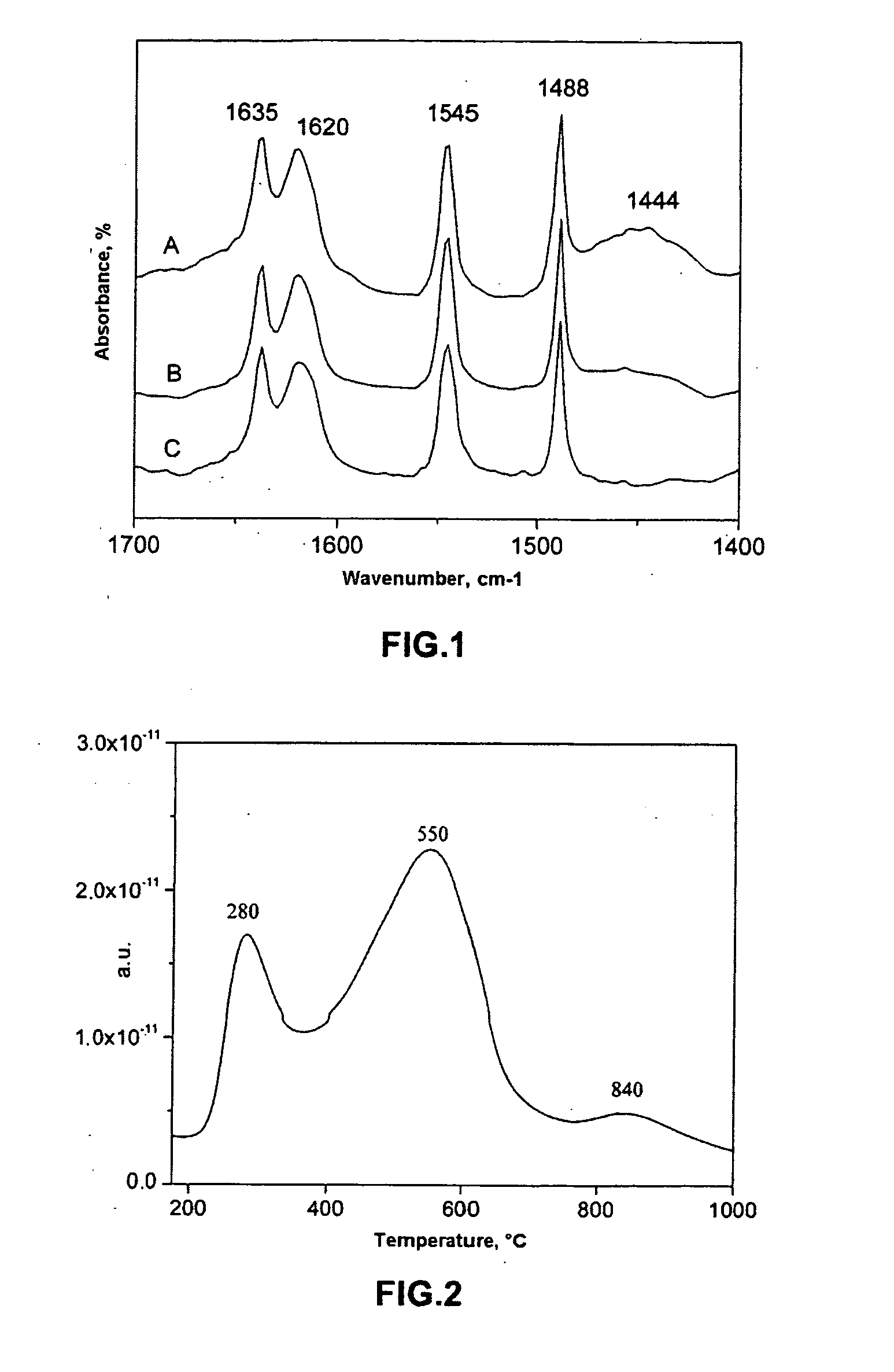

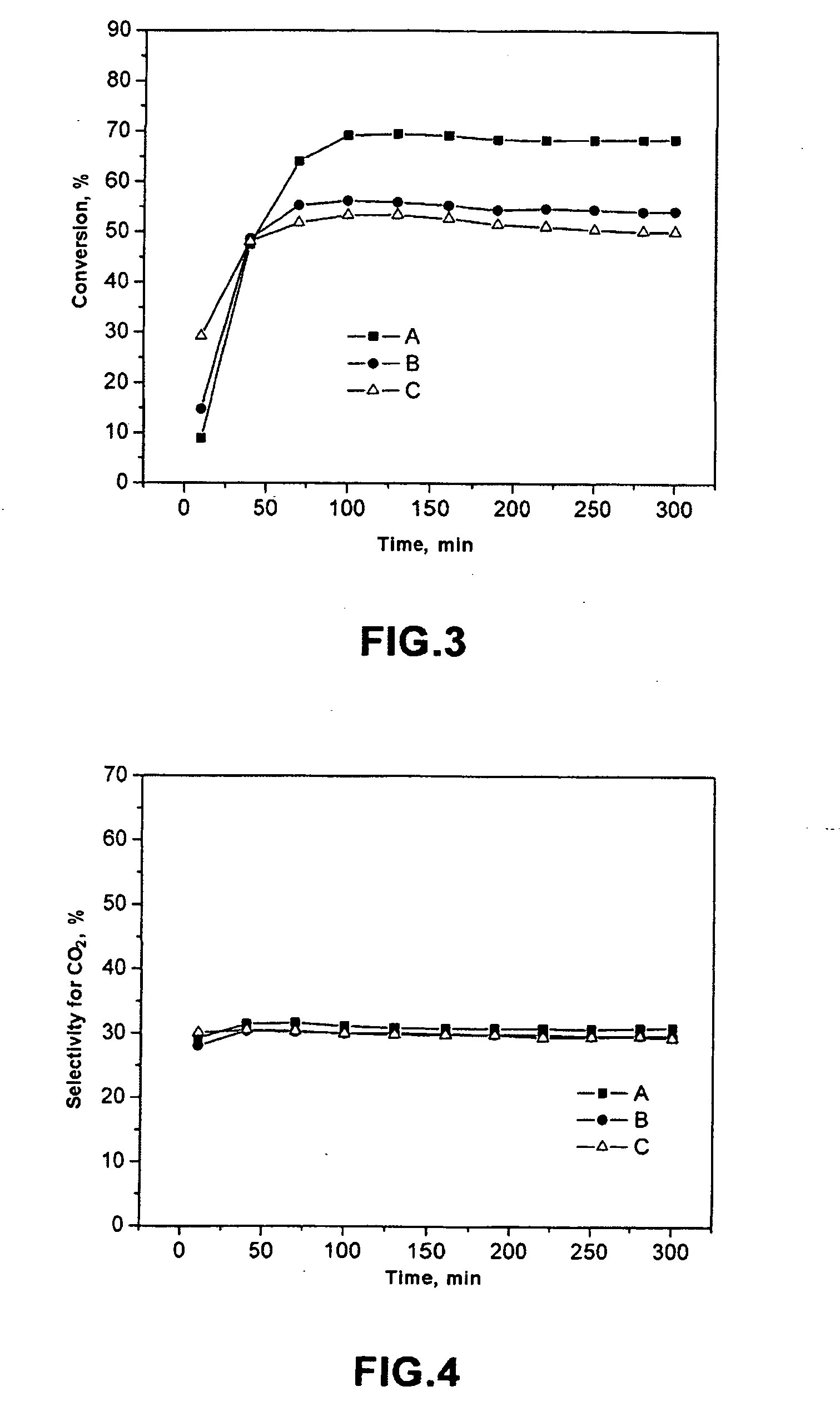

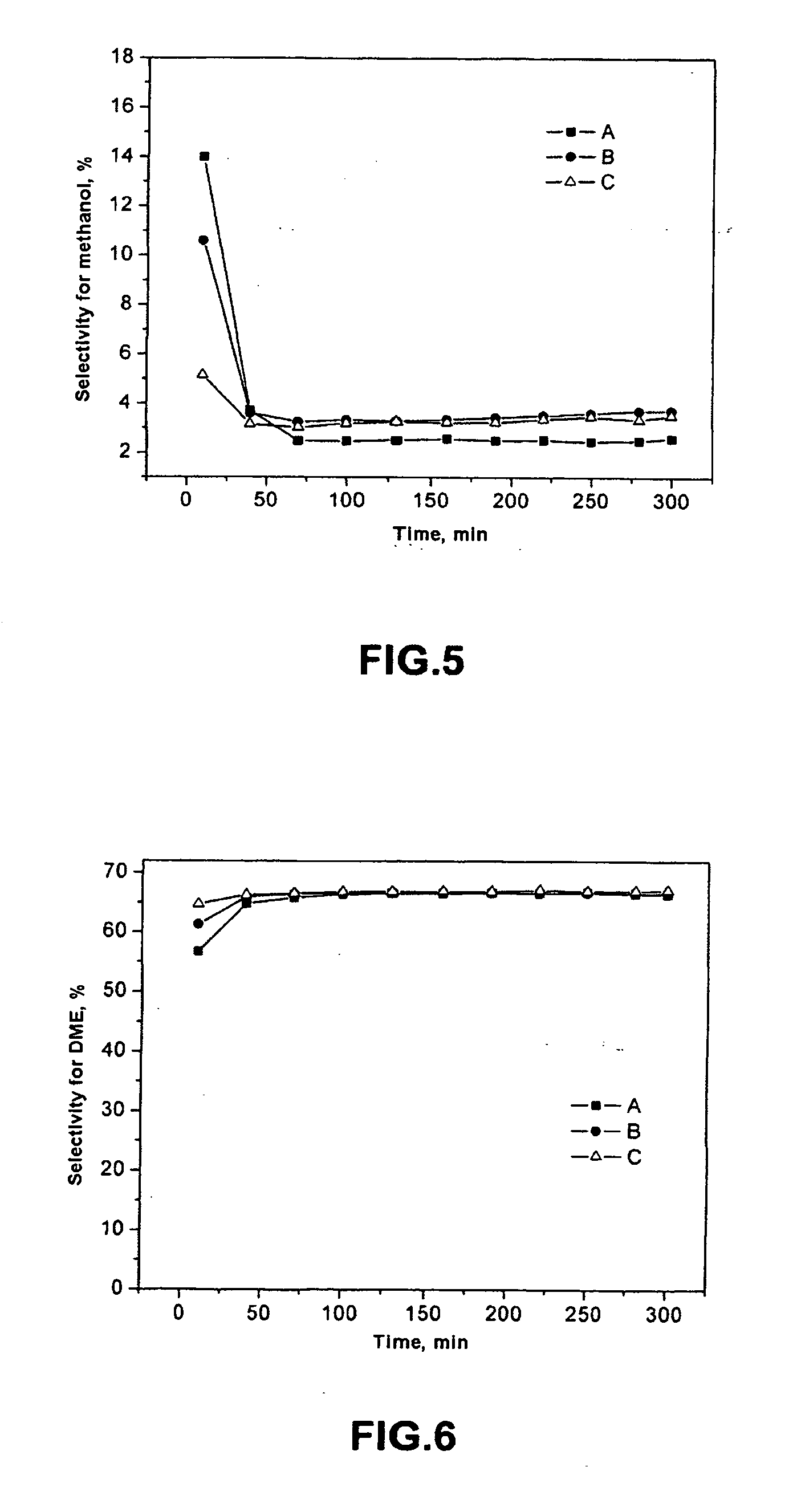

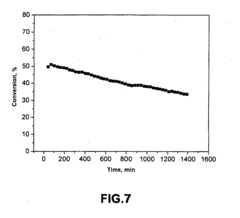

Systems and methods for storing and transporting energy using dimethyl ether are developed. These include innovative storage tanks, transportation containers, and infrastructure designs that take advantage of dimethyl ether's unique properties. The focus is on improving energy density and safety in storage and transportation.Expand Specific Solutions04 Catalysts for dimethyl ether reactions

Research on catalysts for various dimethyl ether reactions, including its synthesis and conversion to other chemicals. The development of novel catalysts aims to enhance reaction rates, selectivity, and energy efficiency in dimethyl ether-related processes.Expand Specific Solutions05 Thermodynamic and kinetic studies of dimethyl ether

Investigations into the thermodynamic properties and reaction kinetics of dimethyl ether under various conditions. These studies provide crucial data for understanding and optimizing dimethyl ether's behavior in different energy-related applications, including combustion and chemical processes.Expand Specific Solutions

DME Industry Players

The development of dimethyl ether (DME) technology is in a growth phase, with increasing market potential and technological advancements. The global DME market is expanding, driven by its applications as a clean-burning fuel and chemical feedstock. Technologically, DME production is maturing, with key players like China Petroleum & Chemical Corp. (Sinopec), BASF, and SK Energy leading research and development efforts. These companies are investing in process improvements and scaling up production capabilities. Universities and research institutes, such as the University of Southern California and Fraunhofer-Gesellschaft, are contributing to fundamental research, potentially unlocking new applications and production methods for DME. The competitive landscape is diverse, with both established petrochemical companies and innovative startups vying for market share in this promising field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant advancements in dimethyl ether (DME) technology. They have developed a proprietary process for large-scale DME production from syngas, which is derived from coal or natural gas. This process involves a single-step synthesis method that directly converts syngas to DME, improving efficiency and reducing production costs[1]. Sinopec has also invested in DME as a clean alternative fuel for vehicles and household cooking, with pilot projects demonstrating its feasibility as a diesel substitute[2]. Their research includes optimizing catalysts for DME synthesis, enhancing conversion rates, and improving the overall energy efficiency of the production process[3].

Strengths: Established infrastructure for large-scale production, extensive R&D capabilities, and integration with existing petroleum operations. Weaknesses: Dependence on fossil fuel feedstocks, potential competition from other alternative fuels.

BASF Corp.

Technical Solution: BASF Corp. has been at the forefront of DME technology development, focusing on innovative catalysts and process improvements. They have developed a novel dual-function catalyst system that combines methanol synthesis and dehydration in a single step, significantly improving DME yield and energy efficiency[4]. BASF's approach includes the use of advanced materials such as zeolites and metal oxides to enhance catalyst performance. Their research also extends to the integration of DME production with carbon capture technologies, aiming to reduce the overall carbon footprint of the process[5]. Additionally, BASF has explored the potential of DME as a chemical feedstock for various industrial applications, expanding its utility beyond fuel use[6].

Strengths: Strong expertise in catalyst development, diverse application research, and integration with other chemical processes. Weaknesses: Less focus on direct fuel applications compared to some competitors.

DME Core Innovations

Catalytic system and process for direct synthesis of dimethyl ether from synthesis gas

PatentInactiveUS20090326281A1

Innovation

- A mixed-bed catalytic system comprising a catalyst for methanol synthesis and acid form zeolite ferrierite, with a silica/alumina ratio of 10 and specific potassium and sodium content, is physically mixed and activated, providing a high concentration of Brønsted acid sites for efficient dehydration without forming unwanted products.

Process for producing dimethyl ether from methanol

PatentActiveUS20110065963A1

Innovation

- A novel process using a fluidized bed reactor that leverages reaction heat for temperature control, regenerates carbon-deposited catalysts, and employs a catalyst composition including Y-zeolite and meso porous zeolites to achieve high methanol conversion and DME selectivity, while reducing energy consumption and by-product formation.

DME Environmental Impact

The environmental impact of dimethyl ether (DME) as an alternative fuel source is a critical aspect to consider in the context of redefining energy parameters. DME offers several environmental advantages over traditional fossil fuels, particularly in terms of reduced emissions and improved air quality.

One of the most significant environmental benefits of DME is its potential to reduce greenhouse gas emissions. When used as a fuel in internal combustion engines or power generation systems, DME produces lower levels of carbon dioxide (CO2) compared to conventional diesel or gasoline. This reduction in CO2 emissions can contribute to mitigating climate change and meeting global carbon reduction targets.

Furthermore, DME combustion results in negligible emissions of particulate matter and sulfur oxides. This characteristic makes it particularly attractive for use in urban areas where air pollution is a major concern. The reduction in particulate matter can lead to improved air quality and potentially reduce the incidence of respiratory diseases associated with air pollution.

Another environmental advantage of DME is its non-toxicity and biodegradability. Unlike some other alternative fuels, DME does not pose significant risks to soil or water resources in the event of spills or leaks. It rapidly decomposes in the atmosphere and does not contribute to the formation of ground-level ozone, a key component of smog.

The production of DME can also have positive environmental implications. When produced from renewable sources such as biomass or waste materials, DME can be considered a carbon-neutral fuel. This renewable production pathway aligns with circular economy principles and can help reduce dependence on fossil fuel resources.

However, it is important to note that the overall environmental impact of DME depends on its production method. While DME produced from renewable sources offers significant environmental benefits, DME derived from natural gas or coal may have a less favorable environmental profile. Life cycle assessments are crucial in determining the true environmental impact of DME across its entire production and use cycle.

In terms of infrastructure and storage, DME's properties allow for easier handling and transportation compared to some other alternative fuels. Its similarity to liquefied petroleum gas (LPG) means that existing LPG infrastructure can be adapted for DME use with minimal modifications, potentially reducing the environmental impact associated with new infrastructure development.

As the world seeks to transition towards cleaner energy sources, the environmental impact of DME positions it as a promising alternative fuel. Its potential to reduce emissions, improve air quality, and integrate with renewable production methods makes it an attractive option for various applications, from transportation to power generation. However, ongoing research and development are necessary to optimize DME production processes and further enhance its environmental benefits.

One of the most significant environmental benefits of DME is its potential to reduce greenhouse gas emissions. When used as a fuel in internal combustion engines or power generation systems, DME produces lower levels of carbon dioxide (CO2) compared to conventional diesel or gasoline. This reduction in CO2 emissions can contribute to mitigating climate change and meeting global carbon reduction targets.

Furthermore, DME combustion results in negligible emissions of particulate matter and sulfur oxides. This characteristic makes it particularly attractive for use in urban areas where air pollution is a major concern. The reduction in particulate matter can lead to improved air quality and potentially reduce the incidence of respiratory diseases associated with air pollution.

Another environmental advantage of DME is its non-toxicity and biodegradability. Unlike some other alternative fuels, DME does not pose significant risks to soil or water resources in the event of spills or leaks. It rapidly decomposes in the atmosphere and does not contribute to the formation of ground-level ozone, a key component of smog.

The production of DME can also have positive environmental implications. When produced from renewable sources such as biomass or waste materials, DME can be considered a carbon-neutral fuel. This renewable production pathway aligns with circular economy principles and can help reduce dependence on fossil fuel resources.

However, it is important to note that the overall environmental impact of DME depends on its production method. While DME produced from renewable sources offers significant environmental benefits, DME derived from natural gas or coal may have a less favorable environmental profile. Life cycle assessments are crucial in determining the true environmental impact of DME across its entire production and use cycle.

In terms of infrastructure and storage, DME's properties allow for easier handling and transportation compared to some other alternative fuels. Its similarity to liquefied petroleum gas (LPG) means that existing LPG infrastructure can be adapted for DME use with minimal modifications, potentially reducing the environmental impact associated with new infrastructure development.

As the world seeks to transition towards cleaner energy sources, the environmental impact of DME positions it as a promising alternative fuel. Its potential to reduce emissions, improve air quality, and integrate with renewable production methods makes it an attractive option for various applications, from transportation to power generation. However, ongoing research and development are necessary to optimize DME production processes and further enhance its environmental benefits.

DME Safety Standards

The safety standards for dimethyl ether (DME) are crucial in ensuring its safe handling, storage, and use as an alternative fuel. These standards are continuously evolving as advancements in DME technology redefine energy parameters. The primary focus of DME safety standards is on preventing accidents, minimizing risks, and protecting both human health and the environment.

One of the key aspects of DME safety standards is the proper classification and labeling of the substance. DME is classified as a flammable gas under most regulatory frameworks, including the Globally Harmonized System of Classification and Labeling of Chemicals (GHS). This classification determines the specific safety measures and handling procedures required for DME throughout its lifecycle.

Storage and transportation of DME are subject to stringent safety regulations. These standards typically mandate the use of pressure vessels designed to withstand the vapor pressure of DME at ambient temperatures. The materials used in storage and transport equipment must be compatible with DME to prevent corrosion or degradation. Regular inspections and maintenance of storage facilities and transportation vehicles are also required to ensure their integrity and compliance with safety standards.

Occupational safety is another critical component of DME safety standards. Workers involved in the production, handling, or use of DME must be provided with appropriate personal protective equipment (PPE) and trained in safe handling procedures. This includes guidelines for proper ventilation in work areas, emergency response protocols, and the use of specialized equipment designed for flammable gases.

Environmental safety standards for DME focus on preventing releases and minimizing the impact of potential spills or leaks. These standards often include requirements for containment systems, leak detection technologies, and emergency shutdown procedures. Additionally, regulations may address the potential environmental impacts of DME production and use, including emissions control and waste management.

As DME technology advances, safety standards are being updated to address new applications and production methods. For instance, the increasing use of DME as a clean-burning fuel for vehicles and power generation has led to the development of specific safety standards for DME fuel systems. These standards cover aspects such as fuel tank design, refueling procedures, and engine compatibility.

International collaboration plays a significant role in the development and harmonization of DME safety standards. Organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) are working to establish globally recognized standards for DME. These efforts aim to facilitate the safe and efficient global trade and use of DME as an energy source.

One of the key aspects of DME safety standards is the proper classification and labeling of the substance. DME is classified as a flammable gas under most regulatory frameworks, including the Globally Harmonized System of Classification and Labeling of Chemicals (GHS). This classification determines the specific safety measures and handling procedures required for DME throughout its lifecycle.

Storage and transportation of DME are subject to stringent safety regulations. These standards typically mandate the use of pressure vessels designed to withstand the vapor pressure of DME at ambient temperatures. The materials used in storage and transport equipment must be compatible with DME to prevent corrosion or degradation. Regular inspections and maintenance of storage facilities and transportation vehicles are also required to ensure their integrity and compliance with safety standards.

Occupational safety is another critical component of DME safety standards. Workers involved in the production, handling, or use of DME must be provided with appropriate personal protective equipment (PPE) and trained in safe handling procedures. This includes guidelines for proper ventilation in work areas, emergency response protocols, and the use of specialized equipment designed for flammable gases.

Environmental safety standards for DME focus on preventing releases and minimizing the impact of potential spills or leaks. These standards often include requirements for containment systems, leak detection technologies, and emergency shutdown procedures. Additionally, regulations may address the potential environmental impacts of DME production and use, including emissions control and waste management.

As DME technology advances, safety standards are being updated to address new applications and production methods. For instance, the increasing use of DME as a clean-burning fuel for vehicles and power generation has led to the development of specific safety standards for DME fuel systems. These standards cover aspects such as fuel tank design, refueling procedures, and engine compatibility.

International collaboration plays a significant role in the development and harmonization of DME safety standards. Organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) are working to establish globally recognized standards for DME. These efforts aim to facilitate the safe and efficient global trade and use of DME as an energy source.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!