How Dimethyl Ether Streamlines New Age Transport Solutions?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Transport Evolution

The evolution of Dimethyl Ether (DME) as a transport solution represents a significant shift in the energy landscape for the automotive and transportation sectors. This evolution can be traced back to the early 2000s when researchers began exploring DME as a potential alternative fuel due to its clean-burning properties and ease of production from various feedstocks.

Initially, DME was primarily considered for use in diesel engines, with early trials focusing on its application in heavy-duty vehicles. The first major milestone in DME transport evolution came in 2009 when Volvo Trucks announced successful tests of DME-powered heavy-duty vehicles, demonstrating the fuel's viability in real-world conditions.

As environmental concerns grew and regulations tightened, the interest in DME as a transport fuel intensified. By the mid-2010s, several countries, including Japan, China, and Sweden, had initiated pilot programs to test DME in various transport applications. These programs not only focused on road transport but also explored the potential of DME in marine and rail sectors.

A significant breakthrough occurred in 2016 when Ford Motor Company, in collaboration with other industry partners, unveiled a passenger car that could run on DME. This development expanded the potential market for DME beyond commercial vehicles to personal transportation, marking a new phase in its evolution.

The late 2010s saw an acceleration in DME transport technology, with advancements in fuel production methods, engine design, and infrastructure development. Companies like Oberon Fuels in the United States made strides in producing renewable DME from waste and biomass, aligning the fuel more closely with sustainability goals.

In recent years, the focus has shifted towards integrating DME into a broader clean energy ecosystem. Research is ongoing to explore synergies between DME and other alternative fuels, such as hydrogen, as well as its potential role in energy storage and grid balancing. The evolution of DME in transport is now closely tied to the development of smart cities and sustainable urban mobility concepts.

Looking ahead, the DME transport evolution is poised to enter a new phase, with increased emphasis on scalability and widespread adoption. Efforts are underway to standardize DME fuel specifications and develop global supply chains. Additionally, there is growing interest in using DME as a platform for further innovation, such as its potential as a hydrogen carrier or as a feedstock for other clean fuels.

As the transport sector continues to seek solutions for decarbonization, the evolution of DME represents a promising pathway. Its journey from a niche alternative to a mainstream option underscores the dynamic nature of energy transitions and the importance of continued innovation in addressing global environmental challenges.

Initially, DME was primarily considered for use in diesel engines, with early trials focusing on its application in heavy-duty vehicles. The first major milestone in DME transport evolution came in 2009 when Volvo Trucks announced successful tests of DME-powered heavy-duty vehicles, demonstrating the fuel's viability in real-world conditions.

As environmental concerns grew and regulations tightened, the interest in DME as a transport fuel intensified. By the mid-2010s, several countries, including Japan, China, and Sweden, had initiated pilot programs to test DME in various transport applications. These programs not only focused on road transport but also explored the potential of DME in marine and rail sectors.

A significant breakthrough occurred in 2016 when Ford Motor Company, in collaboration with other industry partners, unveiled a passenger car that could run on DME. This development expanded the potential market for DME beyond commercial vehicles to personal transportation, marking a new phase in its evolution.

The late 2010s saw an acceleration in DME transport technology, with advancements in fuel production methods, engine design, and infrastructure development. Companies like Oberon Fuels in the United States made strides in producing renewable DME from waste and biomass, aligning the fuel more closely with sustainability goals.

In recent years, the focus has shifted towards integrating DME into a broader clean energy ecosystem. Research is ongoing to explore synergies between DME and other alternative fuels, such as hydrogen, as well as its potential role in energy storage and grid balancing. The evolution of DME in transport is now closely tied to the development of smart cities and sustainable urban mobility concepts.

Looking ahead, the DME transport evolution is poised to enter a new phase, with increased emphasis on scalability and widespread adoption. Efforts are underway to standardize DME fuel specifications and develop global supply chains. Additionally, there is growing interest in using DME as a platform for further innovation, such as its potential as a hydrogen carrier or as a feedstock for other clean fuels.

As the transport sector continues to seek solutions for decarbonization, the evolution of DME represents a promising pathway. Its journey from a niche alternative to a mainstream option underscores the dynamic nature of energy transitions and the importance of continued innovation in addressing global environmental challenges.

DME Market Dynamics

The dimethyl ether (DME) market is experiencing significant growth and transformation, driven by the increasing demand for cleaner and more efficient fuel alternatives in the transportation sector. As governments worldwide implement stricter emissions regulations, DME has emerged as a promising solution for new age transport systems due to its favorable environmental and performance characteristics.

The global DME market is primarily segmented into two main applications: fuel and aerosol propellant. The fuel segment, particularly for transportation, is witnessing rapid expansion as automotive manufacturers and fleet operators seek sustainable alternatives to conventional diesel fuel. This shift is particularly pronounced in heavy-duty vehicles, where DME's high cetane number and clean-burning properties make it an attractive option for reducing particulate matter and NOx emissions.

Geographically, the Asia-Pacific region dominates the DME market, with China leading in both production and consumption. The country's aggressive push towards cleaner energy sources and its well-established DME infrastructure contribute significantly to market growth. Europe and North America are also showing increased interest in DME as a transport fuel, driven by stringent environmental policies and the need to reduce dependency on fossil fuels.

The market dynamics are further influenced by the growing emphasis on circular economy principles. DME can be produced from various feedstocks, including natural gas, coal, and renewable sources such as biomass and waste. This versatility in production pathways not only enhances energy security but also aligns with sustainability goals, making DME an attractive option for countries looking to diversify their energy mix.

Despite the positive outlook, the DME market faces challenges in terms of infrastructure development and competition from other alternative fuels. The lack of widespread fueling stations and the need for engine modifications present barriers to rapid adoption. However, ongoing research and development efforts, coupled with supportive government policies, are addressing these challenges and paving the way for increased market penetration.

The competitive landscape of the DME market is characterized by a mix of established energy companies and innovative startups. Key players are investing in production capacity expansion and technological advancements to improve DME's cost-competitiveness and performance. Strategic partnerships between fuel producers, engine manufacturers, and fleet operators are also shaping the market, accelerating the integration of DME into transport solutions.

As the transportation sector continues to evolve towards more sustainable practices, the DME market is poised for substantial growth. The increasing focus on reducing carbon footprints, coupled with DME's potential to offer a clean and efficient fuel alternative, positions it as a key player in streamlining new age transport solutions.

The global DME market is primarily segmented into two main applications: fuel and aerosol propellant. The fuel segment, particularly for transportation, is witnessing rapid expansion as automotive manufacturers and fleet operators seek sustainable alternatives to conventional diesel fuel. This shift is particularly pronounced in heavy-duty vehicles, where DME's high cetane number and clean-burning properties make it an attractive option for reducing particulate matter and NOx emissions.

Geographically, the Asia-Pacific region dominates the DME market, with China leading in both production and consumption. The country's aggressive push towards cleaner energy sources and its well-established DME infrastructure contribute significantly to market growth. Europe and North America are also showing increased interest in DME as a transport fuel, driven by stringent environmental policies and the need to reduce dependency on fossil fuels.

The market dynamics are further influenced by the growing emphasis on circular economy principles. DME can be produced from various feedstocks, including natural gas, coal, and renewable sources such as biomass and waste. This versatility in production pathways not only enhances energy security but also aligns with sustainability goals, making DME an attractive option for countries looking to diversify their energy mix.

Despite the positive outlook, the DME market faces challenges in terms of infrastructure development and competition from other alternative fuels. The lack of widespread fueling stations and the need for engine modifications present barriers to rapid adoption. However, ongoing research and development efforts, coupled with supportive government policies, are addressing these challenges and paving the way for increased market penetration.

The competitive landscape of the DME market is characterized by a mix of established energy companies and innovative startups. Key players are investing in production capacity expansion and technological advancements to improve DME's cost-competitiveness and performance. Strategic partnerships between fuel producers, engine manufacturers, and fleet operators are also shaping the market, accelerating the integration of DME into transport solutions.

As the transportation sector continues to evolve towards more sustainable practices, the DME market is poised for substantial growth. The increasing focus on reducing carbon footprints, coupled with DME's potential to offer a clean and efficient fuel alternative, positions it as a key player in streamlining new age transport solutions.

DME Tech Challenges

Despite the promising potential of Dimethyl Ether (DME) as a clean alternative fuel for transport solutions, several technical challenges persist in its widespread adoption and implementation. One of the primary obstacles is the need for specialized fuel storage and delivery systems. DME's low boiling point and high vapor pressure require pressurized tanks and modified fuel injection systems, which necessitate significant modifications to existing vehicle designs and fueling infrastructure.

Another challenge lies in the production and distribution of DME at scale. While DME can be synthesized from various feedstocks, including natural gas, coal, and biomass, optimizing production processes for cost-effectiveness and energy efficiency remains an ongoing concern. The development of more efficient catalysts and reactor designs is crucial to enhance DME production yields and reduce overall costs.

Material compatibility issues also pose a significant hurdle in DME implementation. The solvent properties of DME can cause degradation of certain elastomers and plastics commonly used in conventional fuel systems. This necessitates the development and testing of new materials that can withstand long-term exposure to DME without compromising performance or safety.

Engine optimization for DME combustion presents another technical challenge. While DME has favorable combustion characteristics, including high cetane number and low particulate emissions, existing diesel engines require modifications to fully capitalize on these benefits. Adjustments to injection timing, compression ratios, and combustion chamber designs are necessary to maximize efficiency and minimize emissions when using DME as a fuel.

The issue of energy density also needs to be addressed. DME has a lower volumetric energy density compared to conventional diesel fuel, which impacts vehicle range and payload capacity. This challenge necessitates the development of larger fuel tanks or more frequent refueling, potentially affecting the operational efficiency of transport solutions.

Lastly, the lack of standardization in DME fuel quality and specifications across different regions poses a challenge for widespread adoption. Establishing uniform quality standards and regulatory frameworks is essential to ensure consistent performance and compatibility across various DME production methods and applications in the transport sector.

Addressing these technical challenges requires collaborative efforts from researchers, engineers, and policymakers to drive innovation and overcome the barriers to DME implementation in new age transport solutions. As progress is made in these areas, DME's potential as a clean and efficient fuel alternative can be more fully realized, contributing to the development of sustainable transportation systems.

Another challenge lies in the production and distribution of DME at scale. While DME can be synthesized from various feedstocks, including natural gas, coal, and biomass, optimizing production processes for cost-effectiveness and energy efficiency remains an ongoing concern. The development of more efficient catalysts and reactor designs is crucial to enhance DME production yields and reduce overall costs.

Material compatibility issues also pose a significant hurdle in DME implementation. The solvent properties of DME can cause degradation of certain elastomers and plastics commonly used in conventional fuel systems. This necessitates the development and testing of new materials that can withstand long-term exposure to DME without compromising performance or safety.

Engine optimization for DME combustion presents another technical challenge. While DME has favorable combustion characteristics, including high cetane number and low particulate emissions, existing diesel engines require modifications to fully capitalize on these benefits. Adjustments to injection timing, compression ratios, and combustion chamber designs are necessary to maximize efficiency and minimize emissions when using DME as a fuel.

The issue of energy density also needs to be addressed. DME has a lower volumetric energy density compared to conventional diesel fuel, which impacts vehicle range and payload capacity. This challenge necessitates the development of larger fuel tanks or more frequent refueling, potentially affecting the operational efficiency of transport solutions.

Lastly, the lack of standardization in DME fuel quality and specifications across different regions poses a challenge for widespread adoption. Establishing uniform quality standards and regulatory frameworks is essential to ensure consistent performance and compatibility across various DME production methods and applications in the transport sector.

Addressing these technical challenges requires collaborative efforts from researchers, engineers, and policymakers to drive innovation and overcome the barriers to DME implementation in new age transport solutions. As progress is made in these areas, DME's potential as a clean and efficient fuel alternative can be more fully realized, contributing to the development of sustainable transportation systems.

Current DME Solutions

01 Production of dimethyl ether

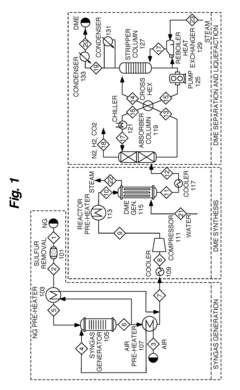

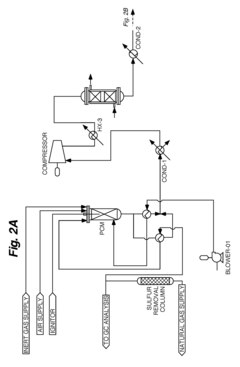

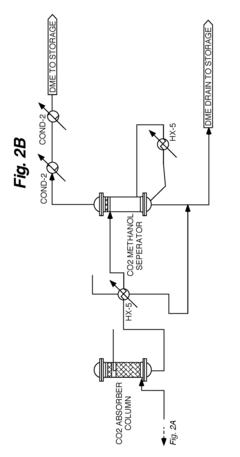

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.- Production of dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

- Catalysts for dimethyl ether synthesis: Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice and preparation of catalysts significantly influence the efficiency and selectivity of the dimethyl ether synthesis process.

- Applications of dimethyl ether: Dimethyl ether has various applications, including use as a fuel substitute, propellant, refrigerant, and chemical intermediate. Its properties make it suitable for use in diesel engines, aerosol products, and as a raw material in chemical synthesis.

- Purification and separation of dimethyl ether: Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes often involve distillation, adsorption, or membrane separation techniques to obtain high-purity dimethyl ether.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of dimethyl ether production and use is conducted. This includes studies on emissions reduction, handling procedures, and risk assessments associated with its use as an alternative fuel or chemical feedstock.

02 Catalysts for dimethyl ether synthesis

Different catalysts are employed in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst affects the reaction efficiency, selectivity, and overall process economics.Expand Specific Solutions03 Applications of dimethyl ether

Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as an alternative clean fuel for diesel engines and power generation due to its favorable combustion properties.Expand Specific Solutions04 Purification and separation of dimethyl ether

Techniques for purifying and separating dimethyl ether from reaction mixtures or other compounds are crucial in its production process. These may include distillation, adsorption, and membrane separation methods to achieve high-purity dimethyl ether.Expand Specific Solutions05 Environmental and safety considerations

Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and storage requirements to ensure safe and sustainable utilization of dimethyl ether.Expand Specific Solutions

DME Industry Leaders

The dimethyl ether (DME) market for transport solutions is in a growth phase, driven by increasing demand for cleaner fuel alternatives. The global market size is projected to expand significantly in the coming years, with Asia-Pacific emerging as a key region. Technologically, DME production and application in transport are advancing, but still require further development for widespread adoption. Key players like China Petroleum & Chemical Corp., BASF, and Linde are investing in research and commercialization efforts. Universities such as USC and Zhejiang University are contributing to technological advancements. While DME shows promise, challenges in infrastructure and engine modifications need to be addressed for broader market penetration.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive dimethyl ether (DME) production and application system. Their technology involves a two-step process: first, synthesizing methanol from syngas, then dehydrating methanol to produce DME. Sinopec has successfully implemented large-scale DME production facilities with capacities exceeding 1 million tons per year [1]. They have also developed DME-powered vehicles and conducted extensive road tests, demonstrating a reduction in particulate matter emissions by up to 90% compared to diesel engines [2]. Sinopec's DME technology includes advanced catalysts that improve conversion efficiency and reduce energy consumption in the production process [3].

Strengths: Integrated production and application system, large-scale production capability, proven emissions reduction in vehicles. Weaknesses: Dependence on fossil fuel-based feedstock, potential competition from other alternative fuels.

BASF Corp.

Technical Solution: BASF Corp. has developed innovative catalysts and process technologies for efficient DME production. Their approach focuses on direct DME synthesis from syngas, bypassing the methanol intermediate step. This one-step process can potentially reduce production costs by up to 20% compared to traditional two-step methods [4]. BASF's proprietary catalysts demonstrate high selectivity and stability, allowing for longer production runs and reduced downtime. The company has also explored the use of bio-based feedstocks for DME production, aligning with sustainability goals [5]. BASF's DME technology is designed to be scalable, suitable for both small-scale distributed production and large centralized facilities.

Strengths: Cost-effective one-step production process, advanced catalyst technology, potential for bio-based DME production. Weaknesses: Less experience in end-use applications compared to some competitors.

DME Core Innovations

Systems and methods for manufacture of dimethyl ether (DME) from natural gas and flare gas feedstock

PatentActiveUS20170174599A1

Innovation

- A mobile system that converts raw natural gas into dimethyl ether (DME), a diesel substitute, using air as a source of oxygen, which can be used for power generation or transportation, without the need for expensive oxygen or steam, and can be easily deployed and redeployed as needed.

Dimethyl ether blended fuel alternative for diesel engines

PatentWO2017184538A1

Innovation

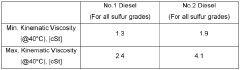

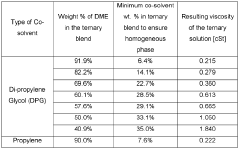

- A blended fuel of DME with di-propylene glycol (DPG) or propylene glycol (PG) and glycerol is developed to increase the viscosity of DME, allowing it to meet ASTM standards for No.1 and No.2 diesel oils, enabling its use in existing diesel engines with minimal modifications.

DME Environmental Impact

Dimethyl Ether (DME) has emerged as a promising alternative fuel with significant environmental benefits in the transport sector. As a clean-burning, non-toxic, and biodegradable fuel, DME offers substantial reductions in greenhouse gas emissions compared to conventional diesel fuel. When produced from renewable sources such as biomass or waste, DME can achieve near-zero or even negative carbon emissions, contributing to climate change mitigation efforts.

The use of DME in transport solutions leads to a marked decrease in particulate matter emissions, a major concern in urban areas. Unlike diesel, DME produces virtually no soot during combustion, resulting in improved air quality and reduced health risks associated with air pollution. This characteristic makes DME particularly attractive for use in densely populated urban environments where air quality is a critical issue.

Furthermore, DME combustion generates lower levels of nitrogen oxides (NOx) compared to diesel fuel. NOx emissions are a significant contributor to smog formation and acid rain, and their reduction through DME use can have far-reaching positive impacts on both human health and ecosystem integrity. The lower NOx emissions also mean that vehicles using DME may require less complex and costly exhaust after-treatment systems.

From a lifecycle perspective, DME production can be designed to have a minimal environmental footprint. When derived from renewable sources or waste streams, the production process can be nearly carbon-neutral. Additionally, DME's potential for carbon capture and utilization in its production phase offers opportunities for further reducing its overall environmental impact.

DME's physical properties also contribute to its environmental benefits. As a gas at ambient conditions, DME vaporizes quickly if spilled, reducing the risk of soil and water contamination compared to liquid fuels. This characteristic enhances the safety profile of DME in transport and storage, minimizing potential environmental hazards associated with fuel handling and distribution.

The adoption of DME in transport solutions aligns with circular economy principles. Its production can utilize various feedstocks, including waste materials and renewable resources, promoting resource efficiency and waste reduction. This versatility in production pathways allows for the development of localized, sustainable fuel supply chains that can reduce the environmental impacts associated with long-distance fuel transportation.

The use of DME in transport solutions leads to a marked decrease in particulate matter emissions, a major concern in urban areas. Unlike diesel, DME produces virtually no soot during combustion, resulting in improved air quality and reduced health risks associated with air pollution. This characteristic makes DME particularly attractive for use in densely populated urban environments where air quality is a critical issue.

Furthermore, DME combustion generates lower levels of nitrogen oxides (NOx) compared to diesel fuel. NOx emissions are a significant contributor to smog formation and acid rain, and their reduction through DME use can have far-reaching positive impacts on both human health and ecosystem integrity. The lower NOx emissions also mean that vehicles using DME may require less complex and costly exhaust after-treatment systems.

From a lifecycle perspective, DME production can be designed to have a minimal environmental footprint. When derived from renewable sources or waste streams, the production process can be nearly carbon-neutral. Additionally, DME's potential for carbon capture and utilization in its production phase offers opportunities for further reducing its overall environmental impact.

DME's physical properties also contribute to its environmental benefits. As a gas at ambient conditions, DME vaporizes quickly if spilled, reducing the risk of soil and water contamination compared to liquid fuels. This characteristic enhances the safety profile of DME in transport and storage, minimizing potential environmental hazards associated with fuel handling and distribution.

The adoption of DME in transport solutions aligns with circular economy principles. Its production can utilize various feedstocks, including waste materials and renewable resources, promoting resource efficiency and waste reduction. This versatility in production pathways allows for the development of localized, sustainable fuel supply chains that can reduce the environmental impacts associated with long-distance fuel transportation.

DME Policy Landscape

The policy landscape surrounding Dimethyl Ether (DME) as a transport fuel is evolving rapidly across the globe, reflecting growing interest in its potential to reduce emissions and diversify energy sources. In the United States, the Environmental Protection Agency (EPA) has approved DME as a renewable fuel under the Renewable Fuel Standard program, paving the way for its increased adoption. This classification allows DME producers to generate Renewable Identification Numbers (RINs), providing economic incentives for production and use.

The European Union has also recognized DME's potential, including it in the Renewable Energy Directive (RED II) as a renewable fuel option. This inclusion supports the EU's goals of reducing greenhouse gas emissions and increasing the share of renewable energy in the transport sector. Several European countries, including Sweden and Denmark, have implemented specific policies to promote DME use in heavy-duty vehicles and public transportation.

In Asia, China has been at the forefront of DME policy development. The Chinese government has included DME in its national energy strategy, offering subsidies and tax incentives for DME production and utilization. Japan has also shown interest, with the Ministry of Economy, Trade and Industry (METI) supporting research and development projects focused on DME as an alternative fuel.

Regulatory frameworks are being adapted to accommodate DME's unique properties. Safety standards and handling protocols are being developed or updated in many jurisdictions to ensure the safe storage, transportation, and use of DME. These efforts are crucial for building public confidence and facilitating widespread adoption.

International collaboration is playing a significant role in shaping DME policies. Organizations such as the International DME Association (IDA) are working with governments and industry stakeholders to harmonize standards and promote best practices. This global approach is helping to create a more consistent regulatory environment for DME across different regions.

However, challenges remain in the policy landscape. The lack of uniform global standards for DME as a transport fuel can create barriers to international trade and technology transfer. Additionally, competing alternative fuel technologies and established fossil fuel interests continue to influence policy decisions, sometimes slowing the progress of DME-specific initiatives.

As awareness of DME's benefits grows, policymakers are increasingly considering its role in achieving climate goals and energy security objectives. This is leading to the integration of DME into broader clean energy and sustainable transport policies. The coming years are likely to see further refinement and expansion of DME-related policies as countries seek to balance environmental concerns with economic and energy security considerations.

The European Union has also recognized DME's potential, including it in the Renewable Energy Directive (RED II) as a renewable fuel option. This inclusion supports the EU's goals of reducing greenhouse gas emissions and increasing the share of renewable energy in the transport sector. Several European countries, including Sweden and Denmark, have implemented specific policies to promote DME use in heavy-duty vehicles and public transportation.

In Asia, China has been at the forefront of DME policy development. The Chinese government has included DME in its national energy strategy, offering subsidies and tax incentives for DME production and utilization. Japan has also shown interest, with the Ministry of Economy, Trade and Industry (METI) supporting research and development projects focused on DME as an alternative fuel.

Regulatory frameworks are being adapted to accommodate DME's unique properties. Safety standards and handling protocols are being developed or updated in many jurisdictions to ensure the safe storage, transportation, and use of DME. These efforts are crucial for building public confidence and facilitating widespread adoption.

International collaboration is playing a significant role in shaping DME policies. Organizations such as the International DME Association (IDA) are working with governments and industry stakeholders to harmonize standards and promote best practices. This global approach is helping to create a more consistent regulatory environment for DME across different regions.

However, challenges remain in the policy landscape. The lack of uniform global standards for DME as a transport fuel can create barriers to international trade and technology transfer. Additionally, competing alternative fuel technologies and established fossil fuel interests continue to influence policy decisions, sometimes slowing the progress of DME-specific initiatives.

As awareness of DME's benefits grows, policymakers are increasingly considering its role in achieving climate goals and energy security objectives. This is leading to the integration of DME into broader clean energy and sustainable transport policies. The coming years are likely to see further refinement and expansion of DME-related policies as countries seek to balance environmental concerns with economic and energy security considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!