How Dimethyl Ether Innovates Technology Applications in Deep-water Environments?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME in Deep-water Tech: Background and Objectives

Dimethyl ether (DME) has emerged as a promising innovative technology for deep-water applications, offering unique properties that address several challenges in this demanding environment. The background of DME's potential in deep-water technology stems from its physical and chemical characteristics, which make it particularly suitable for use in extreme conditions found at great depths.

DME is a colorless, non-toxic gas at room temperature and pressure, with a chemical formula of CH3OCH3. Its low boiling point and high vapor pressure allow it to remain in a gaseous state even under the high pressures encountered in deep-water environments. This property is crucial for various applications, including subsea power generation, gas lift operations, and enhanced oil recovery techniques.

The development of DME technology for deep-water applications has been driven by the increasing demand for efficient and environmentally friendly solutions in offshore oil and gas operations. As exploration and production activities move into deeper waters, traditional technologies face limitations due to extreme pressures, low temperatures, and corrosive conditions. DME offers a potential alternative that can withstand these harsh environments while providing improved performance and reduced environmental impact.

The primary objective of innovating with DME in deep-water environments is to overcome the technical challenges associated with conventional methods. These challenges include the need for high-pressure equipment, the risk of hydrate formation, and the difficulties in transporting and storing gases at great depths. By leveraging DME's unique properties, researchers and engineers aim to develop more efficient and cost-effective solutions for deep-water operations.

Another key objective is to enhance the sustainability of deep-water activities. DME can be produced from various renewable sources, including biomass and waste materials, making it a potentially carbon-neutral fuel. This aligns with the growing emphasis on reducing the environmental footprint of offshore operations and transitioning towards cleaner energy solutions.

The innovation of DME technology in deep-water applications also seeks to improve safety standards. Its non-toxic nature and low flammability compared to other hydrocarbons make it a safer alternative for use in confined spaces and high-pressure systems typical of subsea environments. This aspect is particularly important given the inherent risks associated with deep-water operations.

As research and development in this field progress, the ultimate goal is to establish DME as a versatile and reliable technology for a wide range of deep-water applications. This includes its use as a working fluid in subsea power systems, a transport medium for oil and gas, and a key component in enhanced recovery techniques. The successful implementation of DME-based technologies has the potential to revolutionize deep-water operations, offering improved efficiency, reduced costs, and enhanced environmental performance.

DME is a colorless, non-toxic gas at room temperature and pressure, with a chemical formula of CH3OCH3. Its low boiling point and high vapor pressure allow it to remain in a gaseous state even under the high pressures encountered in deep-water environments. This property is crucial for various applications, including subsea power generation, gas lift operations, and enhanced oil recovery techniques.

The development of DME technology for deep-water applications has been driven by the increasing demand for efficient and environmentally friendly solutions in offshore oil and gas operations. As exploration and production activities move into deeper waters, traditional technologies face limitations due to extreme pressures, low temperatures, and corrosive conditions. DME offers a potential alternative that can withstand these harsh environments while providing improved performance and reduced environmental impact.

The primary objective of innovating with DME in deep-water environments is to overcome the technical challenges associated with conventional methods. These challenges include the need for high-pressure equipment, the risk of hydrate formation, and the difficulties in transporting and storing gases at great depths. By leveraging DME's unique properties, researchers and engineers aim to develop more efficient and cost-effective solutions for deep-water operations.

Another key objective is to enhance the sustainability of deep-water activities. DME can be produced from various renewable sources, including biomass and waste materials, making it a potentially carbon-neutral fuel. This aligns with the growing emphasis on reducing the environmental footprint of offshore operations and transitioning towards cleaner energy solutions.

The innovation of DME technology in deep-water applications also seeks to improve safety standards. Its non-toxic nature and low flammability compared to other hydrocarbons make it a safer alternative for use in confined spaces and high-pressure systems typical of subsea environments. This aspect is particularly important given the inherent risks associated with deep-water operations.

As research and development in this field progress, the ultimate goal is to establish DME as a versatile and reliable technology for a wide range of deep-water applications. This includes its use as a working fluid in subsea power systems, a transport medium for oil and gas, and a key component in enhanced recovery techniques. The successful implementation of DME-based technologies has the potential to revolutionize deep-water operations, offering improved efficiency, reduced costs, and enhanced environmental performance.

Market Analysis for DME in Deep-water Applications

The market for Dimethyl Ether (DME) in deep-water applications is experiencing significant growth potential due to its unique properties and versatile applications. As a clean-burning, non-toxic, and easily transportable fuel, DME offers several advantages over traditional fuels in deep-water environments.

The global deep-water market is expanding rapidly, driven by increasing offshore oil and gas exploration activities and the growing demand for renewable energy sources. DME's potential as a fuel for deep-water operations aligns well with the industry's shift towards cleaner and more efficient energy solutions.

In the offshore oil and gas sector, DME shows promise as a substitute for conventional diesel fuel in power generation and equipment operation. Its low emissions profile and high cetane number make it an attractive option for reducing environmental impact while maintaining operational efficiency. This aligns with the industry's increasing focus on sustainability and regulatory compliance.

The renewable energy sector, particularly offshore wind farms, presents another significant market opportunity for DME. As these installations move into deeper waters, the demand for reliable and clean fuel sources for maintenance vessels and power generation increases. DME's properties make it well-suited for these applications, potentially driving market growth in this segment.

The marine transportation industry is also a key market for DME in deep-water applications. With stricter emissions regulations coming into force, ship operators are seeking alternative fuels to comply with these standards. DME's clean-burning characteristics position it as a viable option for powering vessels in deep-water environments, potentially capturing a share of this market.

Geographically, regions with extensive offshore activities, such as the Gulf of Mexico, the North Sea, and Southeast Asia, are expected to be primary markets for DME in deep-water applications. These areas have well-established offshore industries and are likely to be early adopters of innovative fuel solutions.

However, the market faces challenges, including the need for infrastructure development to support DME production, storage, and distribution in deep-water environments. Additionally, competition from other alternative fuels and the current dominance of conventional fuels in the market pose obstacles to widespread adoption.

Despite these challenges, the long-term outlook for DME in deep-water applications remains positive. As technology advances and environmental regulations tighten, the demand for clean and efficient fuel solutions in deep-water operations is expected to grow, potentially driving significant market expansion for DME in this sector.

The global deep-water market is expanding rapidly, driven by increasing offshore oil and gas exploration activities and the growing demand for renewable energy sources. DME's potential as a fuel for deep-water operations aligns well with the industry's shift towards cleaner and more efficient energy solutions.

In the offshore oil and gas sector, DME shows promise as a substitute for conventional diesel fuel in power generation and equipment operation. Its low emissions profile and high cetane number make it an attractive option for reducing environmental impact while maintaining operational efficiency. This aligns with the industry's increasing focus on sustainability and regulatory compliance.

The renewable energy sector, particularly offshore wind farms, presents another significant market opportunity for DME. As these installations move into deeper waters, the demand for reliable and clean fuel sources for maintenance vessels and power generation increases. DME's properties make it well-suited for these applications, potentially driving market growth in this segment.

The marine transportation industry is also a key market for DME in deep-water applications. With stricter emissions regulations coming into force, ship operators are seeking alternative fuels to comply with these standards. DME's clean-burning characteristics position it as a viable option for powering vessels in deep-water environments, potentially capturing a share of this market.

Geographically, regions with extensive offshore activities, such as the Gulf of Mexico, the North Sea, and Southeast Asia, are expected to be primary markets for DME in deep-water applications. These areas have well-established offshore industries and are likely to be early adopters of innovative fuel solutions.

However, the market faces challenges, including the need for infrastructure development to support DME production, storage, and distribution in deep-water environments. Additionally, competition from other alternative fuels and the current dominance of conventional fuels in the market pose obstacles to widespread adoption.

Despite these challenges, the long-term outlook for DME in deep-water applications remains positive. As technology advances and environmental regulations tighten, the demand for clean and efficient fuel solutions in deep-water operations is expected to grow, potentially driving significant market expansion for DME in this sector.

DME Deep-water Tech: Current Status and Challenges

The application of Dimethyl Ether (DME) in deep-water environments represents a frontier in technological innovation, yet it faces significant challenges. Currently, the use of DME in deep-water settings is in its nascent stages, with research and development efforts primarily focused on its potential as an alternative fuel and chemical feedstock in these extreme conditions.

One of the primary challenges in implementing DME technology in deep-water environments is the high pressure and low temperature conditions. These factors significantly affect the physical properties and behavior of DME, necessitating specialized equipment and handling procedures. Engineers and scientists are grappling with the need to design systems that can effectively store, transport, and utilize DME under these demanding circumstances.

Another critical challenge is the corrosive nature of the deep-water environment. The presence of salt water and various dissolved minerals can accelerate the degradation of materials used in DME-based systems. This necessitates the development of corrosion-resistant materials and protective coatings to ensure the longevity and reliability of deep-water DME applications.

The issue of environmental impact also poses a significant challenge. While DME is considered a cleaner alternative to traditional fossil fuels, its potential effects on deep-water ecosystems are not yet fully understood. Researchers are working to assess the ecological implications of DME use in these sensitive environments and develop mitigation strategies to minimize any adverse effects.

Logistical challenges also play a crucial role in the current status of DME technology in deep-water applications. The remote nature of many deep-water operations complicates the supply chain for DME, requiring innovative solutions for production, storage, and transportation. This includes the development of on-site DME synthesis capabilities and efficient distribution systems capable of operating in harsh underwater conditions.

From a regulatory standpoint, the use of DME in deep-water environments is still navigating a complex landscape. The lack of established standards and guidelines specific to deep-water DME applications creates uncertainty for industry players and potential investors. Regulatory bodies are working to develop appropriate frameworks to ensure safety and environmental compliance while fostering innovation in this field.

Despite these challenges, the potential benefits of DME in deep-water applications continue to drive research and development efforts. The technology's promise as a clean-burning fuel for underwater vehicles and equipment, as well as its potential use in enhanced oil recovery techniques, keeps it at the forefront of deep-water innovation. As the industry continues to address these challenges, the coming years are likely to see significant advancements in the practical application of DME technology in deep-water environments.

One of the primary challenges in implementing DME technology in deep-water environments is the high pressure and low temperature conditions. These factors significantly affect the physical properties and behavior of DME, necessitating specialized equipment and handling procedures. Engineers and scientists are grappling with the need to design systems that can effectively store, transport, and utilize DME under these demanding circumstances.

Another critical challenge is the corrosive nature of the deep-water environment. The presence of salt water and various dissolved minerals can accelerate the degradation of materials used in DME-based systems. This necessitates the development of corrosion-resistant materials and protective coatings to ensure the longevity and reliability of deep-water DME applications.

The issue of environmental impact also poses a significant challenge. While DME is considered a cleaner alternative to traditional fossil fuels, its potential effects on deep-water ecosystems are not yet fully understood. Researchers are working to assess the ecological implications of DME use in these sensitive environments and develop mitigation strategies to minimize any adverse effects.

Logistical challenges also play a crucial role in the current status of DME technology in deep-water applications. The remote nature of many deep-water operations complicates the supply chain for DME, requiring innovative solutions for production, storage, and transportation. This includes the development of on-site DME synthesis capabilities and efficient distribution systems capable of operating in harsh underwater conditions.

From a regulatory standpoint, the use of DME in deep-water environments is still navigating a complex landscape. The lack of established standards and guidelines specific to deep-water DME applications creates uncertainty for industry players and potential investors. Regulatory bodies are working to develop appropriate frameworks to ensure safety and environmental compliance while fostering innovation in this field.

Despite these challenges, the potential benefits of DME in deep-water applications continue to drive research and development efforts. The technology's promise as a clean-burning fuel for underwater vehicles and equipment, as well as its potential use in enhanced oil recovery techniques, keeps it at the forefront of deep-water innovation. As the industry continues to address these challenges, the coming years are likely to see significant advancements in the practical application of DME technology in deep-water environments.

Existing DME Solutions for Deep-water Environments

01 Production of dimethyl ether

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.- Production of dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

- Catalysts for dimethyl ether synthesis: Different catalysts are employed in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst affects the reaction efficiency, selectivity, and overall process economics.

- Applications of dimethyl ether: Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as a potential alternative fuel for diesel engines due to its clean-burning properties.

- Purification and separation of dimethyl ether: Techniques for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These methods may involve distillation, adsorption, or membrane separation processes to obtain high-purity dimethyl ether.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and risk assessments associated with its storage and transportation.

02 Catalysts for dimethyl ether synthesis

Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice and preparation of catalysts significantly influence the efficiency and selectivity of the dimethyl ether synthesis process.Expand Specific Solutions03 Applications of dimethyl ether

Dimethyl ether has various applications, including use as a fuel additive, propellant, refrigerant, and chemical intermediate. Its properties make it suitable for use in diesel engines and as a potential alternative to liquefied petroleum gas (LPG).Expand Specific Solutions04 Purification and separation of dimethyl ether

Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes often involve distillation, adsorption, or membrane separation techniques to obtain high-purity dimethyl ether.Expand Specific Solutions05 Environmental and safety considerations

Research on the environmental impact and safety aspects of dimethyl ether production and use is conducted. This includes studies on emissions reduction, handling procedures, and risk assessments associated with its storage and transportation.Expand Specific Solutions

Key Players in DME Deep-water Technology Industry

The development of dimethyl ether (DME) technology for deep-water environments is in its early stages, with significant potential for growth. The market size is expanding as the demand for cleaner alternative fuels increases, particularly in marine applications. The technology's maturity varies among key players, with companies like China Petroleum & Chemical Corp. (Sinopec) and SK Energy Co., Ltd. leading research efforts. Shell Internationale Research Maatschappij BV and Petróleo Brasileiro SA are also making strides in DME applications for deep-water environments. The competitive landscape is characterized by collaborations between energy giants and research institutions, such as the University of Southern California and Nankai University, to advance DME technology for challenging underwater conditions.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed innovative applications of dimethyl ether (DME) in deep-water environments. Their approach involves using DME as a gas hydrate inhibitor and as a drilling fluid additive. In deep-water drilling operations, Sinopec has implemented DME-based solutions to prevent the formation of gas hydrates, which can cause pipeline blockages and equipment damage[1]. The company has also formulated DME-enhanced drilling fluids that improve lubricity and reduce friction in deep-water wells, leading to more efficient drilling processes[2]. Additionally, Sinopec has explored the use of DME as a potential fuel source for subsea equipment, leveraging its clean-burning properties and ease of storage under pressure[3].

Strengths: Effective gas hydrate inhibition, improved drilling efficiency, and potential as a clean fuel source. Weaknesses: May require specialized handling equipment and safety protocols in deep-water environments.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed a novel approach to utilizing dimethyl ether (DME) in deep-water environments, focusing on its application as a multi-functional fluid for enhanced oil recovery (EOR) and well stimulation. Their technology involves injecting DME into deep-water reservoirs, where it acts as both a solvent and a miscible gas[1]. This dual-action approach helps to reduce oil viscosity and increase reservoir pressure, leading to improved oil recovery rates. Shell's research has shown that DME can be particularly effective in heavy oil reservoirs, where conventional methods struggle[2]. Additionally, the company has explored using DME as a carrier fluid for chemical treatments in deep-water wells, taking advantage of its solvent properties to deliver additives more effectively to target zones[3].

Strengths: Dual-action EOR capability, effective in heavy oil reservoirs, and versatile as a carrier fluid. Weaknesses: May require significant infrastructure modifications for large-scale implementation in deep-water operations.

Core Innovations in DME Deep-water Applications

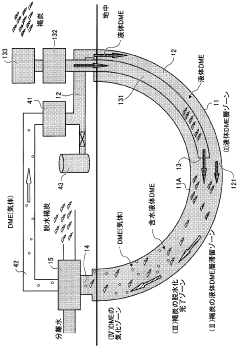

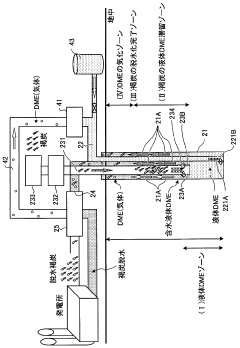

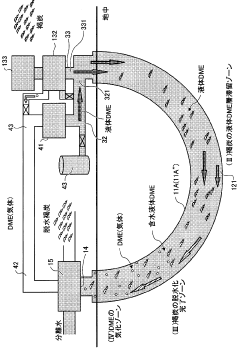

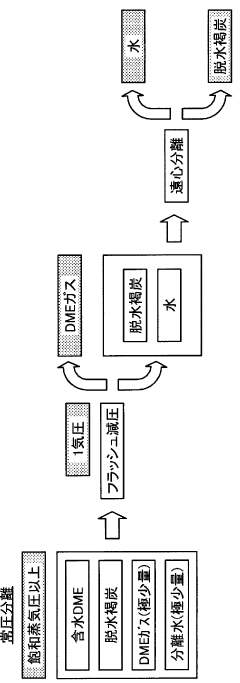

Dehydration system and dehydration process for water-containing substances

PatentWO2009022726A1

Innovation

- A dehydration system utilizing dimethyl ether (DME) that brings DME into contact with a water-containing substance through a contact portion in a well system, leveraging height differences and hydrostatic pressure to facilitate water absorption and evaporation, allowing for efficient separation with lower energy input.

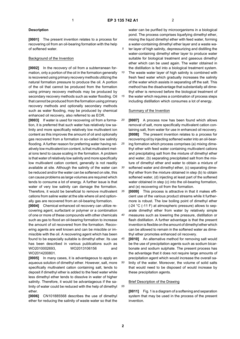

Process for oil recovery

PatentInactiveEP3135742A1

Innovation

- A process involving mixing dimethyl ether with feed water to precipitate salt, separating the precipitated salt, and then separating dimethyl ether from the mixture to produce softened water, which is injected into the formation for oil recovery, allowing for efficient use of resources and flexible dimethyl ether levels.

Environmental Impact of DME in Deep-water Operations

The environmental impact of Dimethyl Ether (DME) in deep-water operations is a critical consideration as this innovative technology gains traction in marine applications. DME's unique properties offer several environmental advantages over traditional fuels and chemicals used in deep-water environments.

One of the primary benefits of DME in deep-water operations is its low toxicity and high biodegradability. Unlike many petroleum-based products, DME rapidly breaks down in water, significantly reducing the risk of long-term environmental contamination in case of accidental release. This characteristic is particularly important in sensitive marine ecosystems, where the persistence of pollutants can have devastating effects on aquatic life.

DME's clean-burning properties also contribute to its positive environmental profile. When used as a fuel in deep-water operations, DME produces lower emissions of particulate matter, nitrogen oxides, and sulfur oxides compared to conventional diesel fuels. This reduction in harmful emissions helps to minimize the impact on marine air quality and reduces the potential for acid rain formation, which can affect both aquatic and terrestrial ecosystems.

Furthermore, the production of DME can be achieved through renewable resources, such as biomass or captured CO2, offering a pathway to carbon-neutral or even carbon-negative operations in deep-water environments. This aligns with global efforts to reduce greenhouse gas emissions and combat climate change, making DME an attractive option for companies seeking to improve their environmental sustainability.

In terms of operational safety, DME's high cetane number and low auto-ignition temperature contribute to improved combustion efficiency and reduced risk of engine knock. This not only enhances the performance of deep-water equipment but also minimizes the potential for mechanical failures that could lead to environmental incidents.

However, it is important to note that the widespread adoption of DME in deep-water operations may require modifications to existing infrastructure and equipment. The transition period could potentially lead to temporary increases in environmental impact as new systems are implemented and optimized. Additionally, while DME itself has a low global warming potential, the production process must be carefully managed to ensure that the overall lifecycle emissions remain favorable compared to alternative fuels.

As research and development in DME technology continue, further improvements in its environmental performance are expected. This includes advancements in production efficiency, storage solutions, and application-specific formulations tailored for deep-water environments. Ongoing monitoring and assessment of DME's long-term effects on marine ecosystems will be crucial to fully understand and mitigate any potential negative impacts.

One of the primary benefits of DME in deep-water operations is its low toxicity and high biodegradability. Unlike many petroleum-based products, DME rapidly breaks down in water, significantly reducing the risk of long-term environmental contamination in case of accidental release. This characteristic is particularly important in sensitive marine ecosystems, where the persistence of pollutants can have devastating effects on aquatic life.

DME's clean-burning properties also contribute to its positive environmental profile. When used as a fuel in deep-water operations, DME produces lower emissions of particulate matter, nitrogen oxides, and sulfur oxides compared to conventional diesel fuels. This reduction in harmful emissions helps to minimize the impact on marine air quality and reduces the potential for acid rain formation, which can affect both aquatic and terrestrial ecosystems.

Furthermore, the production of DME can be achieved through renewable resources, such as biomass or captured CO2, offering a pathway to carbon-neutral or even carbon-negative operations in deep-water environments. This aligns with global efforts to reduce greenhouse gas emissions and combat climate change, making DME an attractive option for companies seeking to improve their environmental sustainability.

In terms of operational safety, DME's high cetane number and low auto-ignition temperature contribute to improved combustion efficiency and reduced risk of engine knock. This not only enhances the performance of deep-water equipment but also minimizes the potential for mechanical failures that could lead to environmental incidents.

However, it is important to note that the widespread adoption of DME in deep-water operations may require modifications to existing infrastructure and equipment. The transition period could potentially lead to temporary increases in environmental impact as new systems are implemented and optimized. Additionally, while DME itself has a low global warming potential, the production process must be carefully managed to ensure that the overall lifecycle emissions remain favorable compared to alternative fuels.

As research and development in DME technology continue, further improvements in its environmental performance are expected. This includes advancements in production efficiency, storage solutions, and application-specific formulations tailored for deep-water environments. Ongoing monitoring and assessment of DME's long-term effects on marine ecosystems will be crucial to fully understand and mitigate any potential negative impacts.

Safety Regulations for DME Use in Deep-water Environments

The implementation of Dimethyl Ether (DME) technology in deep-water environments necessitates stringent safety regulations to mitigate potential risks and ensure operational integrity. These regulations are primarily focused on addressing the unique challenges posed by the combination of DME's properties and the extreme conditions found in deep-water settings.

One of the key safety considerations is the prevention of leaks and spills. Regulations mandate the use of specialized containment systems and robust sealing mechanisms designed to withstand high pressures and corrosive environments. Regular inspections and maintenance protocols are enforced to ensure the ongoing integrity of these systems.

Fire safety is another critical aspect addressed by the regulations. Given DME's flammability, strict guidelines are in place for fire suppression systems, including the use of specialized extinguishing agents effective in deep-water conditions. Emergency shutdown procedures and isolation mechanisms are also mandated to quickly contain potential fire hazards.

The regulations also emphasize the importance of personnel safety. Specialized training programs are required for all staff working with DME in deep-water environments. These programs cover proper handling procedures, emergency response protocols, and the use of personal protective equipment (PPE) designed for deep-water operations.

Environmental protection is a significant focus of the safety regulations. Stringent monitoring and reporting requirements are in place to detect and mitigate any potential environmental impacts. This includes regular water quality assessments and the implementation of advanced leak detection systems.

The regulations also address the unique challenges of transportation and storage in deep-water environments. Specific guidelines are provided for the design and operation of subsea storage facilities, including pressure management systems and corrosion-resistant materials.

Risk assessment and management form a crucial part of the safety framework. Operators are required to conduct comprehensive risk analyses and develop detailed contingency plans for various scenarios. These plans must be regularly updated and tested to ensure their effectiveness in real-world situations.

Lastly, the regulations emphasize the importance of continuous improvement and adaptation. Regular reviews of safety protocols are mandated, incorporating lessons learned from incidents and near-misses, as well as advancements in technology and best practices. This ensures that the safety regulations remain relevant and effective in the rapidly evolving field of deep-water DME applications.

One of the key safety considerations is the prevention of leaks and spills. Regulations mandate the use of specialized containment systems and robust sealing mechanisms designed to withstand high pressures and corrosive environments. Regular inspections and maintenance protocols are enforced to ensure the ongoing integrity of these systems.

Fire safety is another critical aspect addressed by the regulations. Given DME's flammability, strict guidelines are in place for fire suppression systems, including the use of specialized extinguishing agents effective in deep-water conditions. Emergency shutdown procedures and isolation mechanisms are also mandated to quickly contain potential fire hazards.

The regulations also emphasize the importance of personnel safety. Specialized training programs are required for all staff working with DME in deep-water environments. These programs cover proper handling procedures, emergency response protocols, and the use of personal protective equipment (PPE) designed for deep-water operations.

Environmental protection is a significant focus of the safety regulations. Stringent monitoring and reporting requirements are in place to detect and mitigate any potential environmental impacts. This includes regular water quality assessments and the implementation of advanced leak detection systems.

The regulations also address the unique challenges of transportation and storage in deep-water environments. Specific guidelines are provided for the design and operation of subsea storage facilities, including pressure management systems and corrosion-resistant materials.

Risk assessment and management form a crucial part of the safety framework. Operators are required to conduct comprehensive risk analyses and develop detailed contingency plans for various scenarios. These plans must be regularly updated and tested to ensure their effectiveness in real-world situations.

Lastly, the regulations emphasize the importance of continuous improvement and adaptation. Regular reviews of safety protocols are mandated, incorporating lessons learned from incidents and near-misses, as well as advancements in technology and best practices. This ensures that the safety regulations remain relevant and effective in the rapidly evolving field of deep-water DME applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!