How Dimethyl Ether Coordinates Functionality in Energy Platforms?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Energy Platforms: Background and Objectives

Dimethyl ether (DME) has emerged as a promising alternative fuel and energy carrier, garnering significant attention in recent years due to its versatile applications and potential to address various energy challenges. The evolution of DME technology can be traced back to the early 20th century, with its initial use primarily in the chemical industry. However, it wasn't until the late 1990s that researchers and industry professionals began to recognize its potential as a clean-burning fuel and energy platform.

The development of DME as an energy solution has been driven by several factors, including the need for cleaner alternatives to conventional fossil fuels, the desire to reduce greenhouse gas emissions, and the search for more efficient energy storage and transportation methods. As global energy demands continue to rise and environmental concerns become increasingly pressing, DME has gained traction as a multifunctional energy platform that can potentially address these challenges.

One of the key advantages of DME is its ability to be produced from a variety of feedstocks, including natural gas, coal, biomass, and even carbon dioxide. This flexibility in production methods has contributed to its growing appeal as a sustainable energy solution. Furthermore, DME's physical and chemical properties make it suitable for use in various applications, ranging from transportation fuels to power generation and domestic heating.

The technical objectives for DME energy platforms are multifaceted and ambitious. Researchers and industry professionals are working towards improving production efficiency, reducing costs, and expanding the range of applications for DME. Key goals include optimizing DME synthesis processes, developing more efficient catalysts, and enhancing the overall energy efficiency of DME-based systems.

Another critical objective is to overcome the challenges associated with DME infrastructure development. This includes designing and implementing storage, transportation, and distribution systems that can effectively handle DME's unique properties. Additionally, there is a focus on developing and refining DME-compatible engines and combustion systems to maximize its potential as a transportation fuel.

As the energy landscape continues to evolve, DME is positioned to play a significant role in the transition towards more sustainable and efficient energy solutions. The ongoing research and development efforts aim to unlock the full potential of DME as a coordinated energy platform, capable of addressing multiple energy needs while minimizing environmental impact.

The development of DME as an energy solution has been driven by several factors, including the need for cleaner alternatives to conventional fossil fuels, the desire to reduce greenhouse gas emissions, and the search for more efficient energy storage and transportation methods. As global energy demands continue to rise and environmental concerns become increasingly pressing, DME has gained traction as a multifunctional energy platform that can potentially address these challenges.

One of the key advantages of DME is its ability to be produced from a variety of feedstocks, including natural gas, coal, biomass, and even carbon dioxide. This flexibility in production methods has contributed to its growing appeal as a sustainable energy solution. Furthermore, DME's physical and chemical properties make it suitable for use in various applications, ranging from transportation fuels to power generation and domestic heating.

The technical objectives for DME energy platforms are multifaceted and ambitious. Researchers and industry professionals are working towards improving production efficiency, reducing costs, and expanding the range of applications for DME. Key goals include optimizing DME synthesis processes, developing more efficient catalysts, and enhancing the overall energy efficiency of DME-based systems.

Another critical objective is to overcome the challenges associated with DME infrastructure development. This includes designing and implementing storage, transportation, and distribution systems that can effectively handle DME's unique properties. Additionally, there is a focus on developing and refining DME-compatible engines and combustion systems to maximize its potential as a transportation fuel.

As the energy landscape continues to evolve, DME is positioned to play a significant role in the transition towards more sustainable and efficient energy solutions. The ongoing research and development efforts aim to unlock the full potential of DME as a coordinated energy platform, capable of addressing multiple energy needs while minimizing environmental impact.

Market Analysis for DME-based Energy Solutions

The market for Dimethyl Ether (DME) as an energy solution is experiencing significant growth and transformation. As a versatile compound with potential applications across various energy sectors, DME is attracting attention from both industry players and policymakers. The global DME market is projected to expand at a compound annual growth rate of 9.8% from 2021 to 2028, driven by increasing demand for clean and efficient fuel alternatives.

In the transportation sector, DME is emerging as a promising alternative to conventional diesel fuel. Its high cetane number and clean-burning properties make it an attractive option for heavy-duty vehicles and long-haul transportation. Several major automotive manufacturers are investing in DME-powered engine development, recognizing its potential to reduce emissions and meet stringent environmental regulations.

The power generation sector is another key market for DME-based energy solutions. As countries worldwide seek to transition away from coal-fired power plants, DME offers a cleaner alternative that can be used in existing infrastructure with minimal modifications. This adaptability is particularly appealing in regions with established natural gas networks, as DME can be blended with natural gas or used as a standalone fuel in gas turbines.

In the residential and commercial heating market, DME is gaining traction as a replacement for liquefied petroleum gas (LPG) and heating oil. Its similar properties to LPG allow for easy integration into existing distribution systems and appliances, making it an attractive option for both urban and rural areas seeking to reduce their carbon footprint.

The industrial sector presents another significant market opportunity for DME. As a feedstock for chemical production and a potential hydrogen carrier, DME is attracting interest from chemical manufacturers and companies involved in the hydrogen economy. This diversification of applications is expected to drive further market growth and investment in DME production facilities.

Geographically, Asia-Pacific is expected to dominate the DME market, with China and India leading in terms of consumption and production. These countries are actively promoting DME as part of their strategies to reduce air pollution and dependence on imported fossil fuels. In Europe and North America, the market is primarily driven by stringent emissions regulations and the push for renewable energy sources.

Despite the promising outlook, challenges remain in scaling up DME production and distribution infrastructure. The market analysis indicates that continued technological advancements and supportive policy frameworks will be crucial in overcoming these barriers and realizing the full potential of DME-based energy solutions across various sectors.

In the transportation sector, DME is emerging as a promising alternative to conventional diesel fuel. Its high cetane number and clean-burning properties make it an attractive option for heavy-duty vehicles and long-haul transportation. Several major automotive manufacturers are investing in DME-powered engine development, recognizing its potential to reduce emissions and meet stringent environmental regulations.

The power generation sector is another key market for DME-based energy solutions. As countries worldwide seek to transition away from coal-fired power plants, DME offers a cleaner alternative that can be used in existing infrastructure with minimal modifications. This adaptability is particularly appealing in regions with established natural gas networks, as DME can be blended with natural gas or used as a standalone fuel in gas turbines.

In the residential and commercial heating market, DME is gaining traction as a replacement for liquefied petroleum gas (LPG) and heating oil. Its similar properties to LPG allow for easy integration into existing distribution systems and appliances, making it an attractive option for both urban and rural areas seeking to reduce their carbon footprint.

The industrial sector presents another significant market opportunity for DME. As a feedstock for chemical production and a potential hydrogen carrier, DME is attracting interest from chemical manufacturers and companies involved in the hydrogen economy. This diversification of applications is expected to drive further market growth and investment in DME production facilities.

Geographically, Asia-Pacific is expected to dominate the DME market, with China and India leading in terms of consumption and production. These countries are actively promoting DME as part of their strategies to reduce air pollution and dependence on imported fossil fuels. In Europe and North America, the market is primarily driven by stringent emissions regulations and the push for renewable energy sources.

Despite the promising outlook, challenges remain in scaling up DME production and distribution infrastructure. The market analysis indicates that continued technological advancements and supportive policy frameworks will be crucial in overcoming these barriers and realizing the full potential of DME-based energy solutions across various sectors.

Technical Challenges in DME Energy Coordination

The coordination of dimethyl ether (DME) functionality in energy platforms presents several significant technical challenges. One of the primary obstacles is the optimization of DME production processes to achieve high efficiency and cost-effectiveness. Current methods often struggle with catalyst deactivation and selectivity issues, leading to reduced yields and increased operational costs.

Another major challenge lies in the storage and transportation of DME. Due to its low boiling point and high vapor pressure, specialized equipment and infrastructure are required to handle DME safely and efficiently. This necessitates significant investments in storage tanks, pipelines, and transportation vehicles designed to withstand the unique properties of DME.

The integration of DME into existing energy systems poses additional technical hurdles. Adapting current combustion engines and fuel delivery systems to accommodate DME's specific characteristics requires extensive modifications. Engineers must address issues such as fuel injection timing, compression ratios, and materials compatibility to ensure optimal performance and longevity of DME-powered systems.

Furthermore, the development of efficient and durable catalysts for DME synthesis and utilization remains a critical challenge. Researchers are working to create catalysts that can withstand the harsh conditions of DME production while maintaining high activity and selectivity. The search for novel catalyst materials and structures that can enhance DME conversion rates and reduce unwanted by-products is ongoing.

Environmental concerns also present technical challenges in DME energy coordination. While DME is considered a cleaner alternative to conventional fuels, minimizing emissions and improving overall environmental performance is crucial. This involves developing advanced combustion technologies, optimizing fuel formulations, and implementing effective exhaust after-treatment systems.

The scalability of DME production and distribution networks presents another significant challenge. As demand for DME as an energy carrier grows, the industry must overcome technical barriers related to large-scale production facilities, widespread distribution infrastructure, and the establishment of reliable supply chains. This requires innovative solutions in process engineering, logistics, and system integration.

Lastly, the coordination of DME functionality across different energy platforms necessitates addressing compatibility issues between various technologies and applications. Developing standardized interfaces and protocols for DME utilization in diverse energy systems, from power generation to transportation, is essential for seamless integration and widespread adoption.

Another major challenge lies in the storage and transportation of DME. Due to its low boiling point and high vapor pressure, specialized equipment and infrastructure are required to handle DME safely and efficiently. This necessitates significant investments in storage tanks, pipelines, and transportation vehicles designed to withstand the unique properties of DME.

The integration of DME into existing energy systems poses additional technical hurdles. Adapting current combustion engines and fuel delivery systems to accommodate DME's specific characteristics requires extensive modifications. Engineers must address issues such as fuel injection timing, compression ratios, and materials compatibility to ensure optimal performance and longevity of DME-powered systems.

Furthermore, the development of efficient and durable catalysts for DME synthesis and utilization remains a critical challenge. Researchers are working to create catalysts that can withstand the harsh conditions of DME production while maintaining high activity and selectivity. The search for novel catalyst materials and structures that can enhance DME conversion rates and reduce unwanted by-products is ongoing.

Environmental concerns also present technical challenges in DME energy coordination. While DME is considered a cleaner alternative to conventional fuels, minimizing emissions and improving overall environmental performance is crucial. This involves developing advanced combustion technologies, optimizing fuel formulations, and implementing effective exhaust after-treatment systems.

The scalability of DME production and distribution networks presents another significant challenge. As demand for DME as an energy carrier grows, the industry must overcome technical barriers related to large-scale production facilities, widespread distribution infrastructure, and the establishment of reliable supply chains. This requires innovative solutions in process engineering, logistics, and system integration.

Lastly, the coordination of DME functionality across different energy platforms necessitates addressing compatibility issues between various technologies and applications. Developing standardized interfaces and protocols for DME utilization in diverse energy systems, from power generation to transportation, is essential for seamless integration and widespread adoption.

Current DME Coordination Strategies

01 Synthesis of dimethyl ether

Various methods for synthesizing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.- Synthesis of dimethyl ether: Various methods for synthesizing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

- Dimethyl ether as a fuel or fuel additive: Dimethyl ether is explored as an alternative fuel or fuel additive due to its clean-burning properties and potential to reduce emissions. Its use in internal combustion engines and fuel cells is investigated, along with methods to improve its performance and storage.

- Chemical reactions involving dimethyl ether: Dimethyl ether is utilized in various chemical reactions as a reactant or intermediate. These include carbonylation, oxidation, and conversion to other valuable chemicals such as light olefins or aromatics. Catalysts and reaction conditions are optimized for these transformations.

- Dimethyl ether in material science applications: The use of dimethyl ether in material science applications is explored, including its role in the production of polymers, as a blowing agent for foam materials, and in the synthesis of nanostructured materials. Its unique properties make it suitable for various industrial processes.

- Environmental and safety considerations of dimethyl ether: Research focuses on the environmental impact and safety aspects of dimethyl ether use. This includes studies on its biodegradability, atmospheric effects, and potential as a more environmentally friendly alternative to traditional fuels and chemicals. Safety measures for handling and storage are also addressed.

02 Dimethyl ether as a fuel or fuel additive

Dimethyl ether is explored as an alternative fuel or fuel additive due to its clean-burning properties and potential to reduce emissions. It can be used in diesel engines, gas turbines, and other combustion applications, often requiring modifications to fuel systems and engine components.Expand Specific Solutions03 Chemical reactions involving dimethyl ether

Dimethyl ether serves as a reactant or intermediate in various chemical processes, including the production of other chemicals such as light olefins, aromatics, and oxygenates. Catalytic conversion of dimethyl ether to these products is a focus of research and development.Expand Specific Solutions04 Catalysts for dimethyl ether-related processes

Development of novel catalysts and optimization of existing catalytic systems for dimethyl ether synthesis, conversion, and utilization is a key area of research. This includes zeolites, metal oxides, and composite materials designed to improve selectivity, yield, and stability in various processes.Expand Specific Solutions05 Industrial applications of dimethyl ether

Dimethyl ether finds applications in various industries beyond fuel and chemical synthesis. It is used as a propellant in aerosol products, a refrigerant in cooling systems, and a blowing agent in foam production. Research focuses on expanding its use in these and other potential applications.Expand Specific Solutions

Key Players in DME Energy Industry

The dimethyl ether (DME) energy platform market is in a growth phase, driven by increasing interest in clean energy alternatives. The global market size is projected to expand significantly in the coming years, fueled by DME's versatility as a fuel and chemical feedstock. Technologically, DME production and utilization are relatively mature, with ongoing research to enhance efficiency and reduce costs. Key players like Mitsubishi Heavy Industries, Toshiba, and China Petroleum & Chemical Corp are advancing DME technologies, while academic institutions such as the University of Southern California and Taiyuan University of Technology contribute to fundamental research. The involvement of major energy companies and research institutions indicates a competitive landscape with potential for further innovation and market expansion.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced technologies for dimethyl ether (DME) production and utilization in energy platforms. They have implemented a large-scale coal-to-DME production process, with an annual capacity of 1 million tons[1]. Sinopec's approach involves gasification of coal to produce syngas, followed by methanol synthesis and subsequent dehydration to DME. They have also explored the use of DME as a clean alternative fuel for diesel engines, particularly in heavy-duty vehicles. Sinopec has conducted extensive research on DME's combustion characteristics and engine modifications required for optimal performance[2]. Additionally, they have investigated the potential of DME as a hydrogen carrier for fuel cell applications, leveraging its high hydrogen content and ease of storage and transportation[3].

Strengths: Established large-scale production capabilities, extensive research on DME applications in transportation. Weaknesses: Dependence on coal as feedstock may raise environmental concerns, potential competition from other alternative fuels.

Sinopec Research Institute of Petroleum Processing

Technical Solution: The Sinopec Research Institute of Petroleum Processing has been at the forefront of DME research, focusing on its production, properties, and applications in energy platforms. They have developed innovative catalysts for DME synthesis, improving conversion efficiency and selectivity[4]. Their research has led to the development of a novel one-step synthesis process for DME from syngas, bypassing the methanol intermediate stage. This process has shown potential for reducing production costs and energy consumption by up to 20%[5]. The institute has also conducted comprehensive studies on DME's physical and chemical properties, particularly its behavior under various engine operating conditions. They have made significant progress in optimizing DME fuel injection systems and combustion chamber designs for diesel engines, achieving comparable performance to conventional diesel fuel while reducing emissions[6].

Strengths: Cutting-edge research in DME synthesis and engine optimization, potential for cost-effective production. Weaknesses: May face challenges in scaling up new technologies for commercial implementation.

Innovative DME Functionality Research

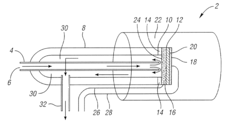

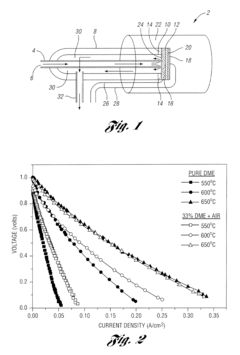

Direct operation of low temperature solid oxide fuel cells using oxygenated fuel

PatentInactiveUS20050106427A1

Innovation

- A method involving the formation of a mixture of molecular oxygen and a methyl ether compound, heated to produce carbon monoxide and hydrogen, which is then used to power a solid oxide fuel cell, preferably with a nickel-containing anode, at temperatures between 550°C to 650°C, optimizing the molar ratio of oxygen to methyl ether to minimize water and carbon dioxide production.

Energy supply method and system

PatentWO2006004140A1

Innovation

- The introduction of Dimethyl Ether (DME) as a versatile energy circulation medium, which can be derived from biomass, waste, and petroleum residues, and used for power generation, transportation, and heating, allowing for efficient energy storage and distribution without relying on pipelines, and enabling the conversion of waste heat into usable energy.

Environmental Impact of DME Energy Solutions

The environmental impact of Dimethyl Ether (DME) energy solutions is a critical aspect to consider in the broader context of sustainable energy platforms. DME, as a clean-burning fuel, offers several environmental advantages over traditional fossil fuels. Its combustion produces significantly lower levels of particulate matter, sulfur oxides, and nitrogen oxides compared to diesel fuel, contributing to improved air quality and reduced smog formation in urban areas.

One of the key environmental benefits of DME is its potential to reduce greenhouse gas emissions. When produced from renewable sources such as biomass or waste materials, DME can achieve a near-carbon-neutral footprint. This characteristic aligns with global efforts to mitigate climate change and transition towards low-carbon energy systems. Additionally, DME's production process can be integrated with carbon capture and utilization technologies, further enhancing its environmental credentials.

In terms of land use and ecosystem impact, DME energy solutions present a mixed picture. On one hand, the production of DME from biomass feedstocks may lead to increased land use for energy crops, potentially competing with food production or natural habitats. However, when DME is produced from waste materials or agricultural residues, it can contribute to waste reduction and circular economy principles, minimizing negative land use impacts.

Water consumption and quality are also important environmental considerations for DME energy solutions. The production process of DME typically requires less water compared to some other biofuels, such as ethanol. Moreover, DME's low solubility in water and rapid biodegradability reduce the risk of water pollution in case of spills or leaks during transportation and storage.

From a lifecycle perspective, the environmental impact of DME energy solutions depends heavily on the feedstock and production methods used. Lifecycle assessments have shown that DME produced from renewable sources can achieve significant reductions in overall environmental impact compared to conventional fossil fuels. However, the environmental benefits may be less pronounced when DME is produced from fossil-based feedstocks.

In the context of energy storage and distribution, DME offers advantages in terms of infrastructure compatibility. Its physical properties allow for easy liquefaction and storage at relatively low pressures, reducing the energy requirements and potential environmental risks associated with fuel transportation and storage. This characteristic also facilitates the integration of DME into existing LPG infrastructure, minimizing the need for extensive new construction and associated environmental disruptions.

One of the key environmental benefits of DME is its potential to reduce greenhouse gas emissions. When produced from renewable sources such as biomass or waste materials, DME can achieve a near-carbon-neutral footprint. This characteristic aligns with global efforts to mitigate climate change and transition towards low-carbon energy systems. Additionally, DME's production process can be integrated with carbon capture and utilization technologies, further enhancing its environmental credentials.

In terms of land use and ecosystem impact, DME energy solutions present a mixed picture. On one hand, the production of DME from biomass feedstocks may lead to increased land use for energy crops, potentially competing with food production or natural habitats. However, when DME is produced from waste materials or agricultural residues, it can contribute to waste reduction and circular economy principles, minimizing negative land use impacts.

Water consumption and quality are also important environmental considerations for DME energy solutions. The production process of DME typically requires less water compared to some other biofuels, such as ethanol. Moreover, DME's low solubility in water and rapid biodegradability reduce the risk of water pollution in case of spills or leaks during transportation and storage.

From a lifecycle perspective, the environmental impact of DME energy solutions depends heavily on the feedstock and production methods used. Lifecycle assessments have shown that DME produced from renewable sources can achieve significant reductions in overall environmental impact compared to conventional fossil fuels. However, the environmental benefits may be less pronounced when DME is produced from fossil-based feedstocks.

In the context of energy storage and distribution, DME offers advantages in terms of infrastructure compatibility. Its physical properties allow for easy liquefaction and storage at relatively low pressures, reducing the energy requirements and potential environmental risks associated with fuel transportation and storage. This characteristic also facilitates the integration of DME into existing LPG infrastructure, minimizing the need for extensive new construction and associated environmental disruptions.

DME Safety and Regulatory Considerations

Dimethyl ether (DME) has emerged as a promising alternative fuel and energy carrier, necessitating a comprehensive understanding of its safety profile and regulatory landscape. The handling and use of DME in energy platforms require careful consideration of its physical and chemical properties, as well as adherence to established safety protocols and regulatory frameworks.

From a safety perspective, DME exhibits several favorable characteristics. It has a relatively low toxicity compared to conventional fuels, and its vapors are non-carcinogenic and non-mutagenic. DME is also biodegradable, reducing environmental concerns in case of spills or leaks. However, like many other flammable gases, DME poses explosion and fire risks if not properly managed.

The regulatory landscape for DME varies across different regions and applications. In the United States, the Environmental Protection Agency (EPA) has approved DME as a renewable fuel under the Renewable Fuel Standard program. This recognition has paved the way for increased adoption of DME in transportation and energy sectors. Similarly, the European Union has included DME in its renewable energy directives, promoting its use as a clean alternative fuel.

Safety standards for DME handling and storage have been developed by various international organizations. The National Fire Protection Association (NFPA) has established guidelines for the safe storage and handling of DME, including specifications for storage tanks, piping systems, and safety equipment. These standards are crucial for ensuring the safe integration of DME into existing energy infrastructure.

In the context of energy platforms, the use of DME requires specific safety measures. These include proper ventilation systems, leak detection mechanisms, and fire suppression equipment tailored to DME's properties. Additionally, personnel working with DME must receive specialized training on its handling and emergency response procedures.

Regulatory bodies are continuously updating their frameworks to accommodate the growing use of DME. This includes developing new standards for DME quality, storage, transportation, and end-use applications. As DME gains traction in various energy sectors, it is expected that more comprehensive and harmonized regulations will emerge globally.

The ongoing research and development in DME technology also contribute to evolving safety and regulatory considerations. As new applications and production methods are explored, regulatory bodies must adapt their guidelines to address potential risks and ensure safe implementation. This dynamic regulatory environment underscores the importance of continued collaboration between industry stakeholders, researchers, and regulatory agencies to maintain the highest safety standards while promoting DME's adoption in energy platforms.

From a safety perspective, DME exhibits several favorable characteristics. It has a relatively low toxicity compared to conventional fuels, and its vapors are non-carcinogenic and non-mutagenic. DME is also biodegradable, reducing environmental concerns in case of spills or leaks. However, like many other flammable gases, DME poses explosion and fire risks if not properly managed.

The regulatory landscape for DME varies across different regions and applications. In the United States, the Environmental Protection Agency (EPA) has approved DME as a renewable fuel under the Renewable Fuel Standard program. This recognition has paved the way for increased adoption of DME in transportation and energy sectors. Similarly, the European Union has included DME in its renewable energy directives, promoting its use as a clean alternative fuel.

Safety standards for DME handling and storage have been developed by various international organizations. The National Fire Protection Association (NFPA) has established guidelines for the safe storage and handling of DME, including specifications for storage tanks, piping systems, and safety equipment. These standards are crucial for ensuring the safe integration of DME into existing energy infrastructure.

In the context of energy platforms, the use of DME requires specific safety measures. These include proper ventilation systems, leak detection mechanisms, and fire suppression equipment tailored to DME's properties. Additionally, personnel working with DME must receive specialized training on its handling and emergency response procedures.

Regulatory bodies are continuously updating their frameworks to accommodate the growing use of DME. This includes developing new standards for DME quality, storage, transportation, and end-use applications. As DME gains traction in various energy sectors, it is expected that more comprehensive and harmonized regulations will emerge globally.

The ongoing research and development in DME technology also contribute to evolving safety and regulatory considerations. As new applications and production methods are explored, regulatory bodies must adapt their guidelines to address potential risks and ensure safe implementation. This dynamic regulatory environment underscores the importance of continued collaboration between industry stakeholders, researchers, and regulatory agencies to maintain the highest safety standards while promoting DME's adoption in energy platforms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!