How Dimethyl Ether Advocates for Enhanced Fluid Dynamics?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Fluid Dynamics Background and Objectives

Dimethyl ether (DME) has emerged as a promising alternative fuel and chemical feedstock, garnering significant attention in the field of fluid dynamics. The evolution of DME research spans several decades, with initial studies focusing on its potential as a clean-burning fuel. As environmental concerns grew, DME's properties became increasingly relevant to addressing challenges in fluid dynamics and energy efficiency.

The trajectory of DME in fluid dynamics research has been marked by a series of technological advancements and scientific discoveries. Early investigations centered on understanding DME's unique physical and chemical properties, particularly its low viscosity and high cetane number. These characteristics positioned DME as an ideal candidate for enhancing fluid flow in various applications, from fuel injection systems to heat transfer processes.

As research progressed, the focus shifted towards exploring DME's behavior under different pressure and temperature conditions, crucial for optimizing its performance in fluid dynamic systems. Scientists and engineers have been working tirelessly to develop models and simulations that accurately predict DME's behavior in complex fluid environments, paving the way for more efficient and environmentally friendly technologies.

The primary objective of current DME fluid dynamics research is to leverage its unique properties to overcome limitations in traditional fluid systems. This includes improving fuel atomization in engines, enhancing heat transfer in thermal management systems, and reducing friction in fluid transport. By understanding and harnessing DME's fluid dynamic properties, researchers aim to develop more efficient combustion processes, reduce emissions, and improve overall system performance across various industries.

Another key goal is to address the challenges associated with DME's implementation in existing infrastructure. This involves studying its compatibility with different materials, optimizing storage and transport methods, and developing new technologies that can fully exploit DME's potential. Researchers are also exploring hybrid systems that combine DME with other fluids to create synergistic effects in fluid dynamic applications.

The future trajectory of DME in fluid dynamics research is expected to focus on nano-scale interactions, advanced computational modeling, and the integration of DME into smart fluid systems. These developments aim to push the boundaries of fluid dynamics, offering solutions to complex engineering challenges and contributing to the global effort towards sustainable and efficient energy systems.

The trajectory of DME in fluid dynamics research has been marked by a series of technological advancements and scientific discoveries. Early investigations centered on understanding DME's unique physical and chemical properties, particularly its low viscosity and high cetane number. These characteristics positioned DME as an ideal candidate for enhancing fluid flow in various applications, from fuel injection systems to heat transfer processes.

As research progressed, the focus shifted towards exploring DME's behavior under different pressure and temperature conditions, crucial for optimizing its performance in fluid dynamic systems. Scientists and engineers have been working tirelessly to develop models and simulations that accurately predict DME's behavior in complex fluid environments, paving the way for more efficient and environmentally friendly technologies.

The primary objective of current DME fluid dynamics research is to leverage its unique properties to overcome limitations in traditional fluid systems. This includes improving fuel atomization in engines, enhancing heat transfer in thermal management systems, and reducing friction in fluid transport. By understanding and harnessing DME's fluid dynamic properties, researchers aim to develop more efficient combustion processes, reduce emissions, and improve overall system performance across various industries.

Another key goal is to address the challenges associated with DME's implementation in existing infrastructure. This involves studying its compatibility with different materials, optimizing storage and transport methods, and developing new technologies that can fully exploit DME's potential. Researchers are also exploring hybrid systems that combine DME with other fluids to create synergistic effects in fluid dynamic applications.

The future trajectory of DME in fluid dynamics research is expected to focus on nano-scale interactions, advanced computational modeling, and the integration of DME into smart fluid systems. These developments aim to push the boundaries of fluid dynamics, offering solutions to complex engineering challenges and contributing to the global effort towards sustainable and efficient energy systems.

Market Demand Analysis for DME Applications

The market demand for Dimethyl Ether (DME) applications in fluid dynamics has been steadily growing, driven by its unique properties and potential to enhance various industrial processes. DME, with its low viscosity and high vapor pressure, offers significant advantages in improving fluid flow characteristics and heat transfer efficiency.

In the automotive sector, DME has garnered attention as a potential alternative fuel for diesel engines. Its superior combustion properties and lower emissions profile have led to increased research and development efforts. Major automotive manufacturers and engine developers are exploring DME as a cleaner substitute for conventional diesel fuel, potentially creating a substantial market for DME in the transportation industry.

The chemical processing industry has also shown growing interest in DME for its role in enhancing fluid dynamics. DME's excellent solvent properties make it valuable in extraction processes, particularly in the production of specialty chemicals and pharmaceuticals. Its ability to improve mass transfer and reduce process times has led to increased adoption in various chemical manufacturing applications.

In the refrigeration and air conditioning sector, DME has emerged as a promising working fluid due to its thermodynamic properties. As environmental regulations become more stringent, the demand for eco-friendly refrigerants has surged. DME's low global warming potential and zero ozone depletion potential position it as a viable alternative to traditional hydrofluorocarbons (HFCs) in cooling systems.

The oil and gas industry has identified DME as a potential agent for enhanced oil recovery (EOR) techniques. Its ability to reduce interfacial tension and improve fluid mobility in reservoirs has sparked interest in using DME for tertiary oil recovery methods. This application could open up a significant market as the industry seeks more efficient and environmentally friendly EOR solutions.

In the field of nanotechnology and microfluidics, DME's unique fluid properties are being explored for precise control of fluid behavior at microscale levels. This emerging application area holds promise for advanced manufacturing processes, lab-on-a-chip devices, and novel drug delivery systems.

The global push for cleaner energy solutions has also contributed to the growing market demand for DME. Its potential as a renewable fuel source, when produced from biomass or captured carbon dioxide, aligns with sustainability goals and circular economy principles. This aspect has attracted attention from policymakers and investors, potentially driving future market growth.

However, challenges remain in scaling up DME production and establishing the necessary infrastructure for widespread adoption. The market demand is closely tied to technological advancements in DME synthesis, storage, and application-specific optimizations. As research progresses and pilot projects demonstrate success, the market for DME applications in fluid dynamics is expected to expand across multiple industries.

In the automotive sector, DME has garnered attention as a potential alternative fuel for diesel engines. Its superior combustion properties and lower emissions profile have led to increased research and development efforts. Major automotive manufacturers and engine developers are exploring DME as a cleaner substitute for conventional diesel fuel, potentially creating a substantial market for DME in the transportation industry.

The chemical processing industry has also shown growing interest in DME for its role in enhancing fluid dynamics. DME's excellent solvent properties make it valuable in extraction processes, particularly in the production of specialty chemicals and pharmaceuticals. Its ability to improve mass transfer and reduce process times has led to increased adoption in various chemical manufacturing applications.

In the refrigeration and air conditioning sector, DME has emerged as a promising working fluid due to its thermodynamic properties. As environmental regulations become more stringent, the demand for eco-friendly refrigerants has surged. DME's low global warming potential and zero ozone depletion potential position it as a viable alternative to traditional hydrofluorocarbons (HFCs) in cooling systems.

The oil and gas industry has identified DME as a potential agent for enhanced oil recovery (EOR) techniques. Its ability to reduce interfacial tension and improve fluid mobility in reservoirs has sparked interest in using DME for tertiary oil recovery methods. This application could open up a significant market as the industry seeks more efficient and environmentally friendly EOR solutions.

In the field of nanotechnology and microfluidics, DME's unique fluid properties are being explored for precise control of fluid behavior at microscale levels. This emerging application area holds promise for advanced manufacturing processes, lab-on-a-chip devices, and novel drug delivery systems.

The global push for cleaner energy solutions has also contributed to the growing market demand for DME. Its potential as a renewable fuel source, when produced from biomass or captured carbon dioxide, aligns with sustainability goals and circular economy principles. This aspect has attracted attention from policymakers and investors, potentially driving future market growth.

However, challenges remain in scaling up DME production and establishing the necessary infrastructure for widespread adoption. The market demand is closely tied to technological advancements in DME synthesis, storage, and application-specific optimizations. As research progresses and pilot projects demonstrate success, the market for DME applications in fluid dynamics is expected to expand across multiple industries.

Current State and Challenges in DME Fluid Dynamics

The current state of Dimethyl Ether (DME) fluid dynamics research is characterized by significant advancements and persistent challenges. DME, a promising alternative fuel, has garnered attention due to its potential to enhance fluid dynamics in various applications. Recent studies have demonstrated DME's superior atomization characteristics and improved spray behavior compared to conventional fuels, leading to more efficient combustion processes.

One of the primary areas of focus in DME fluid dynamics is its application in internal combustion engines. Researchers have observed that DME's lower viscosity and higher vapor pressure contribute to better fuel atomization, resulting in more uniform fuel-air mixtures. This property has shown potential for reducing emissions and improving engine efficiency. However, the challenge lies in optimizing injection systems and combustion chamber designs to fully exploit DME's unique fluid dynamic properties.

In the field of heat transfer applications, DME has shown promise as a working fluid in organic Rankine cycles and heat pumps. Its thermodynamic properties allow for enhanced heat transfer rates and improved cycle efficiencies. Nevertheless, the development of suitable heat exchangers and system components tailored to DME's specific characteristics remains a significant challenge.

The use of DME in aerosol applications has also been an area of active research. Its favorable spray characteristics make it an attractive propellant for various consumer and industrial products. However, ensuring consistent spray performance across different environmental conditions and formulations presents ongoing challenges for researchers and manufacturers.

One of the major hurdles in advancing DME fluid dynamics is the limited availability of comprehensive experimental data and validated numerical models. While computational fluid dynamics (CFD) simulations have provided valuable insights, there is a need for more accurate models that can capture the complex multiphase flow behavior of DME under various operating conditions.

Additionally, the scaling up of DME fluid dynamic applications from laboratory settings to industrial-scale processes poses significant challenges. Issues such as flow instabilities, phase change phenomena, and material compatibility need to be addressed to ensure reliable and efficient operation in large-scale systems.

Furthermore, the integration of DME into existing infrastructure and equipment designed for conventional fuels requires careful consideration of its unique fluid dynamic properties. Adapting storage, transportation, and dispensing systems to accommodate DME's characteristics while maintaining safety and performance standards remains a critical challenge for widespread adoption.

In conclusion, while DME shows great promise in enhancing fluid dynamics across various applications, overcoming these challenges requires continued research efforts, interdisciplinary collaboration, and innovative engineering solutions. The development of advanced measurement techniques, improved numerical models, and novel system designs will be crucial in fully realizing the potential of DME in fluid dynamic applications.

One of the primary areas of focus in DME fluid dynamics is its application in internal combustion engines. Researchers have observed that DME's lower viscosity and higher vapor pressure contribute to better fuel atomization, resulting in more uniform fuel-air mixtures. This property has shown potential for reducing emissions and improving engine efficiency. However, the challenge lies in optimizing injection systems and combustion chamber designs to fully exploit DME's unique fluid dynamic properties.

In the field of heat transfer applications, DME has shown promise as a working fluid in organic Rankine cycles and heat pumps. Its thermodynamic properties allow for enhanced heat transfer rates and improved cycle efficiencies. Nevertheless, the development of suitable heat exchangers and system components tailored to DME's specific characteristics remains a significant challenge.

The use of DME in aerosol applications has also been an area of active research. Its favorable spray characteristics make it an attractive propellant for various consumer and industrial products. However, ensuring consistent spray performance across different environmental conditions and formulations presents ongoing challenges for researchers and manufacturers.

One of the major hurdles in advancing DME fluid dynamics is the limited availability of comprehensive experimental data and validated numerical models. While computational fluid dynamics (CFD) simulations have provided valuable insights, there is a need for more accurate models that can capture the complex multiphase flow behavior of DME under various operating conditions.

Additionally, the scaling up of DME fluid dynamic applications from laboratory settings to industrial-scale processes poses significant challenges. Issues such as flow instabilities, phase change phenomena, and material compatibility need to be addressed to ensure reliable and efficient operation in large-scale systems.

Furthermore, the integration of DME into existing infrastructure and equipment designed for conventional fuels requires careful consideration of its unique fluid dynamic properties. Adapting storage, transportation, and dispensing systems to accommodate DME's characteristics while maintaining safety and performance standards remains a critical challenge for widespread adoption.

In conclusion, while DME shows great promise in enhancing fluid dynamics across various applications, overcoming these challenges requires continued research efforts, interdisciplinary collaboration, and innovative engineering solutions. The development of advanced measurement techniques, improved numerical models, and novel system designs will be crucial in fully realizing the potential of DME in fluid dynamic applications.

Existing DME Fluid Dynamics Solutions

01 Dimethyl ether production processes

Various methods and processes for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of biomass. These processes involve different reaction conditions, catalysts, and feedstocks to optimize the production of dimethyl ether.- Dimethyl ether production processes: Various methods and processes for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of biomass. These processes involve different reaction conditions, catalysts, and feedstocks to optimize the production of dimethyl ether.

- Fluid dynamics in dimethyl ether reactors: The fluid dynamics of dimethyl ether in reactors are studied to improve process efficiency. This includes analyzing flow patterns, heat and mass transfer, and mixing characteristics in various reactor designs. Understanding these dynamics helps optimize reactor performance and product yield.

- Dimethyl ether as an alternative fuel: Research on the use of dimethyl ether as an alternative fuel for internal combustion engines and other applications is conducted. Studies focus on its combustion characteristics, emissions, and performance in comparison to conventional fuels. The fluid dynamics of dimethyl ether in fuel systems are also investigated.

- Catalysts for dimethyl ether synthesis: Development and optimization of catalysts for dimethyl ether synthesis are explored. Various catalyst compositions, preparation methods, and performance characteristics are studied to enhance the efficiency and selectivity of dimethyl ether production processes.

- Dimethyl ether purification and separation: Techniques for purifying and separating dimethyl ether from reaction mixtures and byproducts are investigated. This includes distillation, adsorption, and membrane separation processes. The fluid dynamics of these separation processes are analyzed to improve product purity and recovery.

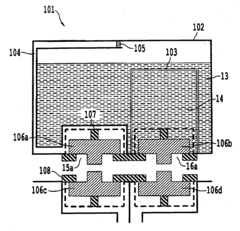

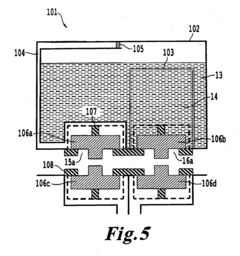

02 Fluid dynamics in dimethyl ether reactors

The fluid dynamics within dimethyl ether reactors play a crucial role in process efficiency. This includes considerations of gas-liquid interactions, heat and mass transfer, and flow patterns within the reactor. Optimizing these fluid dynamic aspects can lead to improved yields and energy efficiency in dimethyl ether production.Expand Specific Solutions03 Catalysts for dimethyl ether synthesis

Various catalysts are employed in the synthesis of dimethyl ether, including zeolites, metal oxides, and composite materials. The choice and design of catalysts significantly impact the reaction kinetics, selectivity, and overall efficiency of the dimethyl ether production process.Expand Specific Solutions04 Dimethyl ether as an alternative fuel

The use of dimethyl ether as an alternative fuel is explored, particularly in internal combustion engines and fuel cells. Its properties, such as high cetane number and clean combustion, make it an attractive option for reducing emissions and improving engine performance.Expand Specific Solutions05 Separation and purification of dimethyl ether

Various techniques for separating and purifying dimethyl ether from reaction mixtures are discussed. These include distillation, adsorption, and membrane separation processes. Efficient separation and purification are crucial for obtaining high-quality dimethyl ether for different applications.Expand Specific Solutions

Key Players in DME Fluid Dynamics Industry

The dimethyl ether (DME) market is in a growth phase, driven by increasing demand for clean-burning alternative fuels. The global market size is projected to expand significantly in the coming years, with Asia-Pacific emerging as a key region. Technologically, DME production is relatively mature, but ongoing research focuses on improving efficiency and reducing costs. Key players like China Petroleum & Chemical Corp., SK Energy, and Shell are investing in DME technology development and production capacity. Universities and research institutions, such as the University of Southern California and Zhejiang University, are contributing to advancements in DME fluid dynamics and applications. While established in some markets, DME still faces challenges in widespread adoption, indicating potential for further innovation and market expansion.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced technologies for dimethyl ether (DME) production and application in fluid dynamics. Their approach involves a two-step process: first, synthesizing methanol from syngas, then dehydrating methanol to produce DME. This method achieves a DME yield of up to 99% [1]. Sinopec has also implemented a novel reactor design that enhances heat transfer and mass transfer in the DME synthesis process, resulting in improved fluid dynamics. The company has successfully operated large-scale DME plants with capacities exceeding 1 million tons per year, demonstrating the scalability of their technology [2]. Additionally, Sinopec has conducted extensive research on DME as a clean fuel alternative, focusing on its superior spray characteristics and reduced particulate emissions in diesel engines [3].

Strengths: High DME yield, scalable production technology, and extensive experience in large-scale operations. Weaknesses: Dependence on fossil fuel feedstock for syngas production, which may limit long-term sustainability.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed innovative technologies for DME production and utilization, focusing on enhancing fluid dynamics in various applications. Their approach includes a direct DME synthesis process from syngas, bypassing the methanol intermediate step. This single-step process improves overall efficiency and reduces capital costs [4]. Shell's technology incorporates advanced catalysts and reactor designs that optimize heat and mass transfer, leading to enhanced fluid dynamics in the production process. The company has also conducted extensive research on DME as a fuel for compression ignition engines, demonstrating improved atomization and mixing characteristics compared to conventional diesel fuel [5]. Shell's DME technology has shown a reduction in NOx emissions by up to 90% and particulate matter by up to 95% in engine tests [6].

Strengths: Direct DME synthesis process, advanced catalyst technology, and significant emissions reduction in engine applications. Weaknesses: Limited commercial-scale implementation compared to traditional fuel technologies.

Core Innovations in DME Fluid Behavior

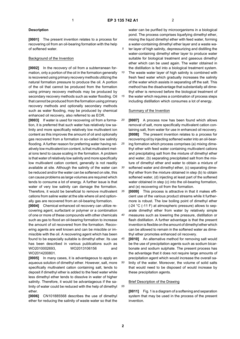

Process for oil recovery

PatentInactiveEP3135742A1

Innovation

- A process involving mixing dimethyl ether with feed water to precipitate salt, separating the precipitated salt, and then separating dimethyl ether from the mixture to produce softened water, which is injected into the formation for oil recovery, allowing for efficient use of resources and flexible dimethyl ether levels.

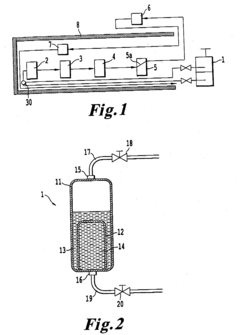

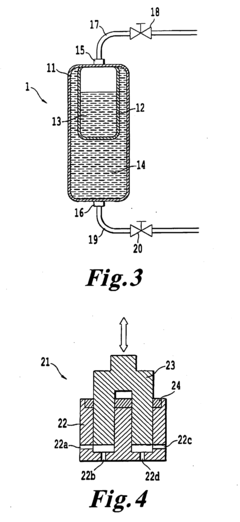

Fuel tank, fuel cell system, and hydrogen gas generator

PatentInactiveUS20060068244A1

Innovation

- A fuel tank design with a pressure tank divided into two spaces, one for dimethyl ether and one for water, with separate outlets for each, allowing controlled release and minimizing turbulence and exposure to corrosive mixtures, along with a reforming portion to produce hydrogen and a CO removing portion to enhance fuel cell performance.

Environmental Impact of DME Usage

The environmental impact of Dimethyl Ether (DME) usage in the context of enhanced fluid dynamics is a critical consideration for its widespread adoption. DME, as a clean-burning fuel and propellant, offers several environmental advantages over traditional fossil fuels. Its combustion produces significantly lower levels of particulate matter, sulfur oxides, and nitrogen oxides, contributing to improved air quality and reduced smog formation in urban areas.

In terms of greenhouse gas emissions, DME demonstrates a favorable profile compared to conventional diesel fuel. When produced from renewable sources such as biomass or waste materials, DME can achieve near-carbon neutrality, aligning with global efforts to mitigate climate change. This renewable production pathway also supports the circular economy concept, potentially reducing waste and promoting sustainable resource utilization.

The use of DME in enhanced fluid dynamics applications, such as in aerosols or refrigeration systems, presents both opportunities and challenges from an environmental perspective. Its low global warming potential (GWP) makes it an attractive alternative to hydrofluorocarbons (HFCs) in refrigeration and air conditioning systems, contributing to the phase-down of high-GWP substances under international agreements like the Kigali Amendment to the Montreal Protocol.

However, the environmental impact of DME production must be carefully managed. While DME can be synthesized from various feedstocks, including natural gas, coal, and biomass, the production process's energy intensity and associated emissions need consideration. Life cycle assessments (LCAs) are crucial in evaluating the net environmental benefit of DME across its entire value chain, from production to end-use.

Water usage and potential contamination are additional environmental factors to consider in DME production and utilization. The synthesis process may require significant water inputs, and proper wastewater management is essential to prevent adverse impacts on local ecosystems. Moreover, in the event of accidental releases, DME's high volatility ensures rapid evaporation, minimizing soil and water contamination risks compared to liquid fuels.

The adoption of DME in fluid dynamics applications also has implications for energy efficiency and resource conservation. Its favorable thermodynamic properties can lead to improved system efficiencies, potentially reducing overall energy consumption and associated environmental impacts. This aspect is particularly relevant in industrial processes and transportation sectors, where even marginal efficiency gains can translate to substantial environmental benefits at scale.

As research and development in DME applications for enhanced fluid dynamics continue, ongoing environmental monitoring and impact assessments will be crucial. These efforts should focus on optimizing production processes, minimizing emissions, and ensuring responsible end-of-life management for DME-based systems. By addressing these environmental considerations proactively, the potential of DME to contribute to more sustainable fluid dynamics solutions can be fully realized.

In terms of greenhouse gas emissions, DME demonstrates a favorable profile compared to conventional diesel fuel. When produced from renewable sources such as biomass or waste materials, DME can achieve near-carbon neutrality, aligning with global efforts to mitigate climate change. This renewable production pathway also supports the circular economy concept, potentially reducing waste and promoting sustainable resource utilization.

The use of DME in enhanced fluid dynamics applications, such as in aerosols or refrigeration systems, presents both opportunities and challenges from an environmental perspective. Its low global warming potential (GWP) makes it an attractive alternative to hydrofluorocarbons (HFCs) in refrigeration and air conditioning systems, contributing to the phase-down of high-GWP substances under international agreements like the Kigali Amendment to the Montreal Protocol.

However, the environmental impact of DME production must be carefully managed. While DME can be synthesized from various feedstocks, including natural gas, coal, and biomass, the production process's energy intensity and associated emissions need consideration. Life cycle assessments (LCAs) are crucial in evaluating the net environmental benefit of DME across its entire value chain, from production to end-use.

Water usage and potential contamination are additional environmental factors to consider in DME production and utilization. The synthesis process may require significant water inputs, and proper wastewater management is essential to prevent adverse impacts on local ecosystems. Moreover, in the event of accidental releases, DME's high volatility ensures rapid evaporation, minimizing soil and water contamination risks compared to liquid fuels.

The adoption of DME in fluid dynamics applications also has implications for energy efficiency and resource conservation. Its favorable thermodynamic properties can lead to improved system efficiencies, potentially reducing overall energy consumption and associated environmental impacts. This aspect is particularly relevant in industrial processes and transportation sectors, where even marginal efficiency gains can translate to substantial environmental benefits at scale.

As research and development in DME applications for enhanced fluid dynamics continue, ongoing environmental monitoring and impact assessments will be crucial. These efforts should focus on optimizing production processes, minimizing emissions, and ensuring responsible end-of-life management for DME-based systems. By addressing these environmental considerations proactively, the potential of DME to contribute to more sustainable fluid dynamics solutions can be fully realized.

DME Safety Regulations and Standards

The safety regulations and standards for Dimethyl Ether (DME) play a crucial role in ensuring its safe handling, storage, and use in various applications, including its potential for enhancing fluid dynamics. As DME gains traction as an alternative fuel and industrial solvent, regulatory bodies worldwide have developed comprehensive guidelines to mitigate risks associated with its flammable and potentially explosive nature.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific standards for DME handling in industrial settings. These regulations cover aspects such as proper ventilation, personal protective equipment (PPE), and emergency response procedures. The National Fire Protection Association (NFPA) has also issued guidelines for the storage and use of DME, classifying it as a Class IIA flammable liquid.

Internationally, the European Chemicals Agency (ECHA) has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations that apply to DME. These regulations mandate thorough safety assessments and risk management measures for DME production and use within the European Union. Similarly, the International Organization for Standardization (ISO) has developed standards for DME fuel quality and safety, particularly relevant to its use in automotive and industrial applications.

In the context of fluid dynamics research and applications, additional safety considerations come into play. Laboratories and research facilities working with DME must adhere to strict protocols for handling pressurized systems and potential leaks. The American Society of Mechanical Engineers (ASME) provides guidelines for pressure vessel design and testing, which are applicable to DME-based fluid dynamics experiments.

Transportation of DME is regulated by various agencies, including the U.S. Department of Transportation (DOT) and the International Maritime Organization (IMO). These regulations cover aspects such as container specifications, labeling requirements, and emergency response information. The safe transport of DME is critical for its widespread adoption in fluid dynamics applications across different industries.

As the use of DME in enhanced fluid dynamics continues to evolve, regulatory bodies are actively updating and refining safety standards. This ongoing process involves collaboration between industry stakeholders, research institutions, and government agencies to address emerging challenges and incorporate new scientific findings. The development of these standards not only ensures safety but also promotes the responsible advancement of DME technology in fluid dynamics applications.

In the United States, the Occupational Safety and Health Administration (OSHA) has established specific standards for DME handling in industrial settings. These regulations cover aspects such as proper ventilation, personal protective equipment (PPE), and emergency response procedures. The National Fire Protection Association (NFPA) has also issued guidelines for the storage and use of DME, classifying it as a Class IIA flammable liquid.

Internationally, the European Chemicals Agency (ECHA) has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations that apply to DME. These regulations mandate thorough safety assessments and risk management measures for DME production and use within the European Union. Similarly, the International Organization for Standardization (ISO) has developed standards for DME fuel quality and safety, particularly relevant to its use in automotive and industrial applications.

In the context of fluid dynamics research and applications, additional safety considerations come into play. Laboratories and research facilities working with DME must adhere to strict protocols for handling pressurized systems and potential leaks. The American Society of Mechanical Engineers (ASME) provides guidelines for pressure vessel design and testing, which are applicable to DME-based fluid dynamics experiments.

Transportation of DME is regulated by various agencies, including the U.S. Department of Transportation (DOT) and the International Maritime Organization (IMO). These regulations cover aspects such as container specifications, labeling requirements, and emergency response information. The safe transport of DME is critical for its widespread adoption in fluid dynamics applications across different industries.

As the use of DME in enhanced fluid dynamics continues to evolve, regulatory bodies are actively updating and refining safety standards. This ongoing process involves collaboration between industry stakeholders, research institutions, and government agencies to address emerging challenges and incorporate new scientific findings. The development of these standards not only ensures safety but also promotes the responsible advancement of DME technology in fluid dynamics applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!