How Dimethyl Ether Nurtures Sustainable Industrial Policies?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Technology Background and Objectives

Dimethyl ether (DME) has emerged as a promising alternative fuel and chemical feedstock, gaining significant attention in recent years due to its potential to address sustainability challenges in various industrial sectors. The technology behind DME production and utilization has evolved considerably over the past few decades, driven by the growing need for cleaner energy sources and more environmentally friendly industrial processes.

The development of DME technology can be traced back to the 1960s when it was first synthesized on a commercial scale. Initially, DME was primarily used as a propellant in aerosol products. However, its potential as a fuel and chemical intermediate became increasingly apparent in the 1990s, leading to a surge in research and development efforts worldwide.

The primary objective of DME technology is to provide a versatile and sustainable alternative to conventional fossil fuels and petrochemical feedstocks. DME offers several advantages, including its clean-burning properties, high cetane number, and compatibility with existing infrastructure for liquefied petroleum gas (LPG). These characteristics make it an attractive option for various applications, ranging from transportation fuels to power generation and domestic heating.

One of the key drivers behind the advancement of DME technology is its potential to contribute to the reduction of greenhouse gas emissions. As a fuel, DME produces significantly lower levels of particulate matter, nitrogen oxides, and sulfur oxides compared to conventional diesel. This aligns with global efforts to combat climate change and improve air quality in urban areas.

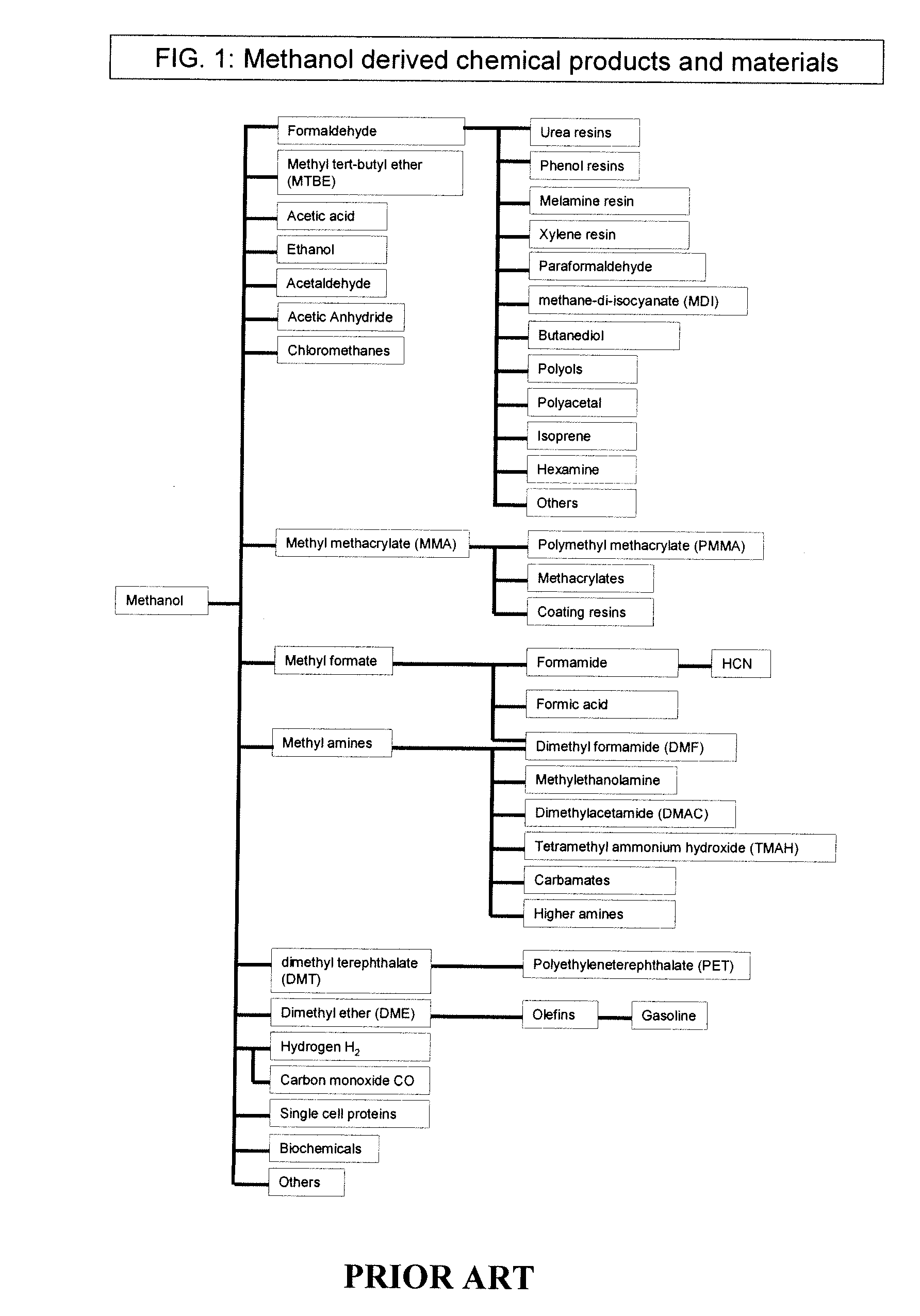

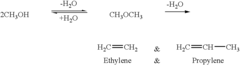

The technology landscape for DME production has witnessed significant evolution, with various pathways being explored and optimized. The most common method involves the dehydration of methanol, which can be derived from a wide range of feedstocks, including natural gas, coal, and biomass. This flexibility in feedstock options enhances the potential for DME to play a role in diverse regional contexts and support local energy security initiatives.

Recent technological advancements have focused on improving the efficiency and cost-effectiveness of DME production processes. Innovations in catalyst design, process integration, and the development of direct synthesis methods from syngas have contributed to making DME more competitive with traditional fuels and chemicals. These developments are crucial for scaling up DME production and facilitating its wider adoption across industries.

As the world transitions towards a more sustainable energy future, the objectives of DME technology continue to expand. Current research efforts are aimed at further reducing the carbon footprint of DME production, exploring renewable feedstock options, and developing novel applications in sectors such as chemical manufacturing and energy storage. The ultimate goal is to position DME as a key enabler of sustainable industrial policies, supporting the transition to a circular economy and contributing to global decarbonization efforts.

The development of DME technology can be traced back to the 1960s when it was first synthesized on a commercial scale. Initially, DME was primarily used as a propellant in aerosol products. However, its potential as a fuel and chemical intermediate became increasingly apparent in the 1990s, leading to a surge in research and development efforts worldwide.

The primary objective of DME technology is to provide a versatile and sustainable alternative to conventional fossil fuels and petrochemical feedstocks. DME offers several advantages, including its clean-burning properties, high cetane number, and compatibility with existing infrastructure for liquefied petroleum gas (LPG). These characteristics make it an attractive option for various applications, ranging from transportation fuels to power generation and domestic heating.

One of the key drivers behind the advancement of DME technology is its potential to contribute to the reduction of greenhouse gas emissions. As a fuel, DME produces significantly lower levels of particulate matter, nitrogen oxides, and sulfur oxides compared to conventional diesel. This aligns with global efforts to combat climate change and improve air quality in urban areas.

The technology landscape for DME production has witnessed significant evolution, with various pathways being explored and optimized. The most common method involves the dehydration of methanol, which can be derived from a wide range of feedstocks, including natural gas, coal, and biomass. This flexibility in feedstock options enhances the potential for DME to play a role in diverse regional contexts and support local energy security initiatives.

Recent technological advancements have focused on improving the efficiency and cost-effectiveness of DME production processes. Innovations in catalyst design, process integration, and the development of direct synthesis methods from syngas have contributed to making DME more competitive with traditional fuels and chemicals. These developments are crucial for scaling up DME production and facilitating its wider adoption across industries.

As the world transitions towards a more sustainable energy future, the objectives of DME technology continue to expand. Current research efforts are aimed at further reducing the carbon footprint of DME production, exploring renewable feedstock options, and developing novel applications in sectors such as chemical manufacturing and energy storage. The ultimate goal is to position DME as a key enabler of sustainable industrial policies, supporting the transition to a circular economy and contributing to global decarbonization efforts.

Market Demand Analysis for DME

The market demand for dimethyl ether (DME) has been steadily growing, driven by its potential as a clean-burning, renewable fuel and its versatility in various industrial applications. As governments worldwide push for sustainable industrial policies, DME has emerged as a promising alternative to conventional fossil fuels, particularly in the transportation and energy sectors.

In the transportation industry, DME has gained traction as a substitute for diesel fuel in heavy-duty vehicles. Its high cetane number and low emissions profile make it an attractive option for fleet operators looking to reduce their carbon footprint. Several major automotive manufacturers have shown interest in developing DME-compatible engines, indicating a potential surge in demand for this alternative fuel.

The energy sector represents another significant market for DME. As a liquefied petroleum gas (LPG) substitute, DME can be used for heating and cooking in both residential and industrial settings. Countries with limited natural gas infrastructure have shown particular interest in DME as a cleaner alternative to traditional cooking fuels like kerosene or wood.

In the chemical industry, DME serves as a valuable feedstock for the production of various chemicals, including olefins, gasoline, and dimethyl sulfate. This versatility has led to increased demand from chemical manufacturers seeking to diversify their raw material sources and reduce reliance on petroleum-based feedstocks.

The Asia-Pacific region, particularly China and Japan, has been at the forefront of DME adoption and market growth. China has implemented policies to promote DME as a clean fuel alternative, leading to significant investments in production capacity and infrastructure. Japan has also shown strong interest in DME, with several pilot projects exploring its use in power generation and transportation.

Despite the growing market demand, challenges remain in scaling up DME production and distribution. The lack of widespread infrastructure for DME handling and storage has been a limiting factor in its adoption. However, as more countries implement sustainable industrial policies, investments in DME infrastructure are expected to increase, further driving market growth.

The global DME market is projected to expand significantly in the coming years, with some analysts predicting a compound annual growth rate (CAGR) of over 10% through 2025. This growth is expected to be fueled by increasing environmental regulations, rising energy demand, and the push for cleaner fuel alternatives across various industries.

In the transportation industry, DME has gained traction as a substitute for diesel fuel in heavy-duty vehicles. Its high cetane number and low emissions profile make it an attractive option for fleet operators looking to reduce their carbon footprint. Several major automotive manufacturers have shown interest in developing DME-compatible engines, indicating a potential surge in demand for this alternative fuel.

The energy sector represents another significant market for DME. As a liquefied petroleum gas (LPG) substitute, DME can be used for heating and cooking in both residential and industrial settings. Countries with limited natural gas infrastructure have shown particular interest in DME as a cleaner alternative to traditional cooking fuels like kerosene or wood.

In the chemical industry, DME serves as a valuable feedstock for the production of various chemicals, including olefins, gasoline, and dimethyl sulfate. This versatility has led to increased demand from chemical manufacturers seeking to diversify their raw material sources and reduce reliance on petroleum-based feedstocks.

The Asia-Pacific region, particularly China and Japan, has been at the forefront of DME adoption and market growth. China has implemented policies to promote DME as a clean fuel alternative, leading to significant investments in production capacity and infrastructure. Japan has also shown strong interest in DME, with several pilot projects exploring its use in power generation and transportation.

Despite the growing market demand, challenges remain in scaling up DME production and distribution. The lack of widespread infrastructure for DME handling and storage has been a limiting factor in its adoption. However, as more countries implement sustainable industrial policies, investments in DME infrastructure are expected to increase, further driving market growth.

The global DME market is projected to expand significantly in the coming years, with some analysts predicting a compound annual growth rate (CAGR) of over 10% through 2025. This growth is expected to be fueled by increasing environmental regulations, rising energy demand, and the push for cleaner fuel alternatives across various industries.

Current State and Challenges of DME Technology

Dimethyl ether (DME) technology has made significant strides in recent years, positioning itself as a promising alternative fuel and chemical feedstock. The current state of DME technology is characterized by a growing interest in its production and application across various industries, driven by its potential to contribute to sustainable development goals.

One of the primary challenges facing DME technology is the optimization of production processes. While DME can be produced from a variety of feedstocks, including natural gas, coal, and biomass, the efficiency and cost-effectiveness of these processes still require improvement. The most common method, involving methanol dehydration, has seen advancements in catalyst technology, but further research is needed to enhance conversion rates and reduce energy consumption.

Another significant challenge lies in the infrastructure development required for widespread DME adoption. The lack of dedicated distribution networks and storage facilities hinders the large-scale implementation of DME as a fuel or chemical intermediate. This infrastructure gap presents a chicken-and-egg problem, where investment in infrastructure is contingent on demand, yet demand growth is limited by the absence of infrastructure.

From a regulatory perspective, the integration of DME into existing fuel and chemical standards poses a challenge. While some countries have made progress in establishing DME standards, a global consensus on specifications and regulations is still lacking. This regulatory uncertainty can impede investment and slow down market penetration.

The environmental impact of DME production and use is another area of focus. While DME is generally considered cleaner than conventional fossil fuels, there are ongoing efforts to further reduce its carbon footprint. This includes exploring more sustainable feedstock options and developing carbon capture and utilization technologies in the production process.

In terms of geographical distribution, DME technology development is not uniform across the globe. Countries like China, Japan, and Sweden have made significant progress in DME research and application, while other regions lag behind. This uneven development creates both challenges and opportunities for technology transfer and international collaboration.

The economic viability of DME in comparison to established fuels and chemicals remains a critical challenge. Fluctuations in oil prices and the competitiveness of alternative clean energy solutions impact the attractiveness of DME investments. Overcoming this challenge requires continued efforts to reduce production costs and demonstrate the long-term value proposition of DME in various applications.

One of the primary challenges facing DME technology is the optimization of production processes. While DME can be produced from a variety of feedstocks, including natural gas, coal, and biomass, the efficiency and cost-effectiveness of these processes still require improvement. The most common method, involving methanol dehydration, has seen advancements in catalyst technology, but further research is needed to enhance conversion rates and reduce energy consumption.

Another significant challenge lies in the infrastructure development required for widespread DME adoption. The lack of dedicated distribution networks and storage facilities hinders the large-scale implementation of DME as a fuel or chemical intermediate. This infrastructure gap presents a chicken-and-egg problem, where investment in infrastructure is contingent on demand, yet demand growth is limited by the absence of infrastructure.

From a regulatory perspective, the integration of DME into existing fuel and chemical standards poses a challenge. While some countries have made progress in establishing DME standards, a global consensus on specifications and regulations is still lacking. This regulatory uncertainty can impede investment and slow down market penetration.

The environmental impact of DME production and use is another area of focus. While DME is generally considered cleaner than conventional fossil fuels, there are ongoing efforts to further reduce its carbon footprint. This includes exploring more sustainable feedstock options and developing carbon capture and utilization technologies in the production process.

In terms of geographical distribution, DME technology development is not uniform across the globe. Countries like China, Japan, and Sweden have made significant progress in DME research and application, while other regions lag behind. This uneven development creates both challenges and opportunities for technology transfer and international collaboration.

The economic viability of DME in comparison to established fuels and chemicals remains a critical challenge. Fluctuations in oil prices and the competitiveness of alternative clean energy solutions impact the attractiveness of DME investments. Overcoming this challenge requires continued efforts to reduce production costs and demonstrate the long-term value proposition of DME in various applications.

Current DME Production Methods

01 Production of dimethyl ether

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.- Production of dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

- Catalysts for dimethyl ether synthesis: Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.

- Applications of dimethyl ether: Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as a potential alternative fuel for diesel engines due to its clean-burning properties and high cetane number.

- Purification and separation of dimethyl ether: Techniques for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These may include distillation, adsorption, and membrane separation processes to achieve high-purity dimethyl ether for various applications.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and storage requirements to ensure safe and sustainable utilization of dimethyl ether.

02 Catalysts for dimethyl ether synthesis

Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.Expand Specific Solutions03 Applications of dimethyl ether

Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as a potential alternative fuel for diesel engines due to its clean-burning properties and high cetane number.Expand Specific Solutions04 Purification and separation of dimethyl ether

Techniques for purifying and separating dimethyl ether from reaction mixtures or other compounds are crucial in its production process. These may include distillation, adsorption, and membrane separation methods to achieve high-purity dimethyl ether.Expand Specific Solutions05 Environmental and safety considerations

Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and storage requirements to ensure safe and sustainable utilization of dimethyl ether.Expand Specific Solutions

Key Players in DME Industry

The development of Dimethyl Ether (DME) as a sustainable industrial solution is in its growth phase, with increasing market size and technological advancements. The global DME market is projected to expand significantly due to its potential as a clean-burning alternative fuel. Technologically, DME production is maturing, with major players like China Petroleum & Chemical Corp. and SK Energy Co., Ltd. leading research and development efforts. Universities such as the University of Southern California and Okayama University are contributing to scientific advancements, while companies like Linde GmbH and Mitsubishi Gas Chemical Co., Inc. are focusing on industrial applications. The involvement of diverse stakeholders, including research institutions and energy companies, indicates a growing ecosystem around DME technology, suggesting its increasing importance in sustainable industrial policies.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive dimethyl ether (DME) production and utilization strategy to support sustainable industrial policies. Their approach includes large-scale DME production from coal and natural gas, as well as innovative catalytic processes for DME synthesis[1]. Sinopec has implemented a closed-loop system that integrates DME production with existing petrochemical infrastructure, reducing carbon emissions by up to 20% compared to traditional fossil fuel processes[2]. The company has also pioneered the use of DME as a clean-burning alternative fuel for vehicles and industrial applications, with pilot programs demonstrating a 90% reduction in particulate matter emissions compared to diesel[3].

Strengths: Integrated production system, reduced carbon footprint, and extensive distribution network. Weaknesses: Dependence on fossil fuel feedstocks and potential competition from other alternative fuels.

Linde GmbH

Technical Solution: Linde GmbH has developed advanced technologies for the production and application of dimethyl ether (DME) in sustainable industrial processes. Their innovative approach includes a proprietary catalytic process that enables direct synthesis of DME from syngas, improving efficiency by up to 15% compared to traditional methanol-based routes[4]. Linde has also pioneered the use of renewable feedstocks, such as biomass and captured CO2, for DME production, reducing the carbon intensity of the process by up to 70%[5]. The company's DME technology portfolio includes specialized storage and handling solutions, as well as DME-based power generation systems that offer a 30% reduction in greenhouse gas emissions compared to conventional natural gas turbines[6].

Strengths: Efficient production process, renewable feedstock utilization, and diverse application portfolio. Weaknesses: Higher initial investment costs and limited market penetration in some regions.

Key DME Technology Innovations

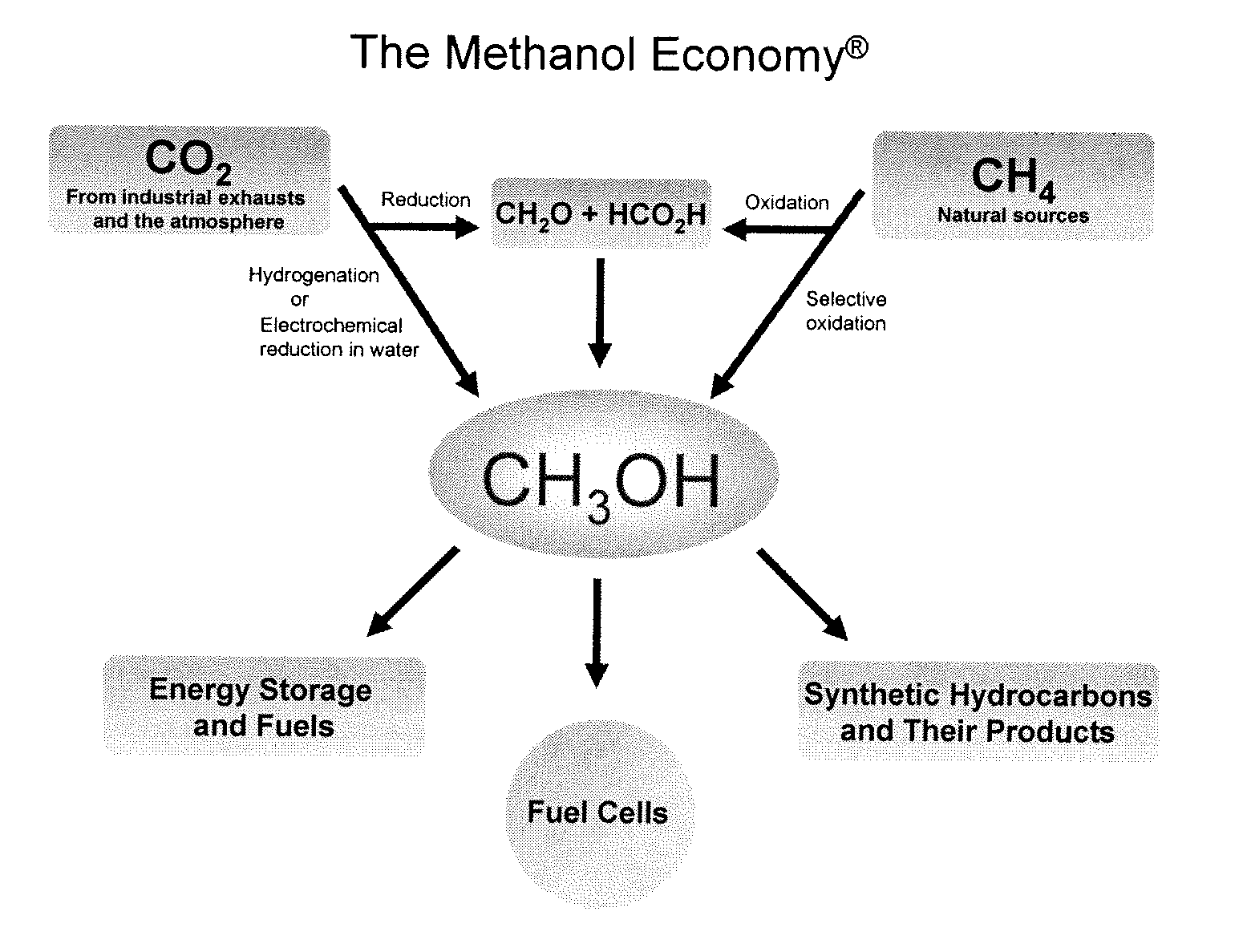

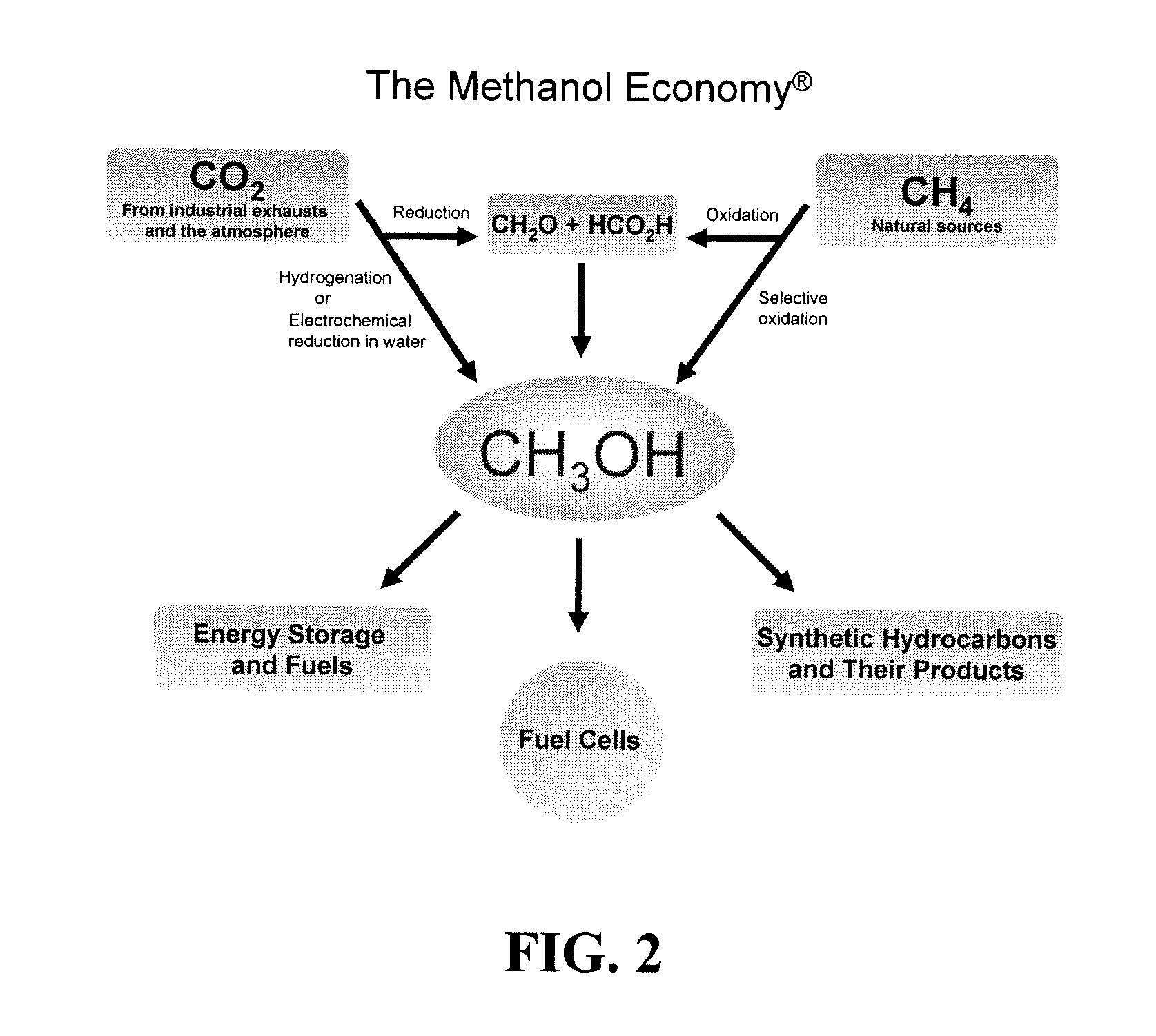

Efficient and selective chemical recycling of carbon dioxide to methanol, dimethyl ether and derived products

PatentActiveUS20070254969A1

Innovation

- A process that converts carbon dioxide from industrial or natural sources, including the atmosphere, into methanol and dimethyl ether through catalytic, photochemical, or electrochemical hydrogenation, followed by subsequent treatments to enhance methanol production, allowing for a carbon-neutral cycle of energy storage and fuel production.

Stockpiling methanol and/or dimethyl ether for fuel and energy reserves

PatentInactiveEP2291496A2

Innovation

- Stockpiling methanol and/or dimethyl ether in appropriate storage facilities, produced through chemical recycling of carbon dioxide and methane, which can be safely stored and transported, offering a renewable and environmentally friendly alternative fuel source.

Environmental Impact of DME

Dimethyl ether (DME) has emerged as a promising alternative fuel with significant environmental benefits, positioning it as a key player in sustainable industrial policies. The environmental impact of DME is multifaceted, encompassing various aspects of its production, distribution, and utilization.

One of the primary environmental advantages of DME is its potential to reduce greenhouse gas emissions. When produced from renewable sources such as biomass or waste materials, DME can achieve near-zero or even negative carbon footprints. This characteristic aligns with global efforts to mitigate climate change and transition towards a low-carbon economy. Furthermore, DME combustion produces lower levels of particulate matter and nitrogen oxides compared to conventional diesel fuel, contributing to improved air quality in urban areas.

The production of DME also offers environmental benefits in terms of resource efficiency. The synthesis process can utilize a wide range of feedstocks, including natural gas, coal, and biomass, allowing for flexibility in resource utilization and potentially reducing dependence on fossil fuels. Additionally, DME production facilities can be integrated with existing industrial processes, such as methanol production or biogas upgrading, leading to improved overall energy efficiency and reduced waste.

In terms of transportation and storage, DME presents several environmental advantages. Its physical properties allow for easy liquefaction at moderate pressures, simplifying storage and distribution infrastructure requirements. This characteristic reduces the energy intensity and associated emissions of fuel transportation compared to some other alternative fuels. Moreover, DME's non-toxic and non-corrosive nature minimizes the risk of environmental contamination in case of accidental spills or leaks.

The use of DME in various industrial applications can lead to significant environmental improvements. In the power generation sector, DME can serve as a cleaner alternative to coal or heavy fuel oil, reducing emissions of sulfur dioxide and other pollutants. In the chemical industry, DME can act as a versatile feedstock for the production of various chemicals, potentially replacing more environmentally harmful processes.

However, it is important to consider the potential environmental challenges associated with large-scale DME adoption. These may include land use changes for biomass cultivation, water consumption in production processes, and the need for new infrastructure development. Comprehensive life cycle assessments are crucial to fully understand and optimize the environmental impact of DME across its entire value chain.

As industrial policies increasingly prioritize sustainability, the environmental benefits of DME position it as a valuable tool in achieving cleaner production processes and reducing the carbon footprint of various sectors. The continued research and development in DME technologies are likely to further enhance its environmental performance, solidifying its role in sustainable industrial strategies.

One of the primary environmental advantages of DME is its potential to reduce greenhouse gas emissions. When produced from renewable sources such as biomass or waste materials, DME can achieve near-zero or even negative carbon footprints. This characteristic aligns with global efforts to mitigate climate change and transition towards a low-carbon economy. Furthermore, DME combustion produces lower levels of particulate matter and nitrogen oxides compared to conventional diesel fuel, contributing to improved air quality in urban areas.

The production of DME also offers environmental benefits in terms of resource efficiency. The synthesis process can utilize a wide range of feedstocks, including natural gas, coal, and biomass, allowing for flexibility in resource utilization and potentially reducing dependence on fossil fuels. Additionally, DME production facilities can be integrated with existing industrial processes, such as methanol production or biogas upgrading, leading to improved overall energy efficiency and reduced waste.

In terms of transportation and storage, DME presents several environmental advantages. Its physical properties allow for easy liquefaction at moderate pressures, simplifying storage and distribution infrastructure requirements. This characteristic reduces the energy intensity and associated emissions of fuel transportation compared to some other alternative fuels. Moreover, DME's non-toxic and non-corrosive nature minimizes the risk of environmental contamination in case of accidental spills or leaks.

The use of DME in various industrial applications can lead to significant environmental improvements. In the power generation sector, DME can serve as a cleaner alternative to coal or heavy fuel oil, reducing emissions of sulfur dioxide and other pollutants. In the chemical industry, DME can act as a versatile feedstock for the production of various chemicals, potentially replacing more environmentally harmful processes.

However, it is important to consider the potential environmental challenges associated with large-scale DME adoption. These may include land use changes for biomass cultivation, water consumption in production processes, and the need for new infrastructure development. Comprehensive life cycle assessments are crucial to fully understand and optimize the environmental impact of DME across its entire value chain.

As industrial policies increasingly prioritize sustainability, the environmental benefits of DME position it as a valuable tool in achieving cleaner production processes and reducing the carbon footprint of various sectors. The continued research and development in DME technologies are likely to further enhance its environmental performance, solidifying its role in sustainable industrial strategies.

Policy Support for DME Adoption

Policy support plays a crucial role in fostering the adoption of Dimethyl Ether (DME) as a sustainable alternative fuel. Governments worldwide are increasingly recognizing the potential of DME to contribute to their sustainable industrial policies and are implementing various measures to encourage its use.

One of the primary policy instruments used to promote DME adoption is financial incentives. These may include tax credits, subsidies, or grants for DME production facilities and infrastructure development. Such incentives help offset the initial capital costs associated with DME production and distribution, making it more economically viable for businesses to invest in this technology.

Regulatory frameworks also play a significant role in supporting DME adoption. Many countries have implemented or are considering fuel standards that include DME as an approved alternative fuel. These standards provide a legal basis for DME use in various applications, such as transportation and industrial processes, thereby increasing market confidence and driving demand.

Research and development support is another critical aspect of policy support for DME. Governments are allocating funds for research initiatives aimed at improving DME production efficiency, exploring new applications, and addressing technical challenges. This support accelerates technological advancements and helps bridge the gap between laboratory research and commercial implementation.

Public-private partnerships are being encouraged to facilitate knowledge sharing and collaborative efforts in DME development. These partnerships bring together government agencies, research institutions, and private sector companies to pool resources and expertise, accelerating the commercialization of DME technologies.

Infrastructure development is a key focus area for policy support. Governments are investing in or providing incentives for the construction of DME production facilities, storage tanks, and distribution networks. This infrastructure support is crucial for creating a robust supply chain and ensuring the widespread availability of DME.

Education and awareness programs are also being implemented to inform industries and the public about the benefits of DME. These initiatives aim to increase acceptance and demand for DME-based products and technologies, creating a supportive market environment.

Lastly, international cooperation and technology transfer are being promoted through bilateral and multilateral agreements. These efforts facilitate the sharing of best practices, harmonization of standards, and collaborative research, contributing to the global advancement of DME technology and its integration into sustainable industrial policies.

One of the primary policy instruments used to promote DME adoption is financial incentives. These may include tax credits, subsidies, or grants for DME production facilities and infrastructure development. Such incentives help offset the initial capital costs associated with DME production and distribution, making it more economically viable for businesses to invest in this technology.

Regulatory frameworks also play a significant role in supporting DME adoption. Many countries have implemented or are considering fuel standards that include DME as an approved alternative fuel. These standards provide a legal basis for DME use in various applications, such as transportation and industrial processes, thereby increasing market confidence and driving demand.

Research and development support is another critical aspect of policy support for DME. Governments are allocating funds for research initiatives aimed at improving DME production efficiency, exploring new applications, and addressing technical challenges. This support accelerates technological advancements and helps bridge the gap between laboratory research and commercial implementation.

Public-private partnerships are being encouraged to facilitate knowledge sharing and collaborative efforts in DME development. These partnerships bring together government agencies, research institutions, and private sector companies to pool resources and expertise, accelerating the commercialization of DME technologies.

Infrastructure development is a key focus area for policy support. Governments are investing in or providing incentives for the construction of DME production facilities, storage tanks, and distribution networks. This infrastructure support is crucial for creating a robust supply chain and ensuring the widespread availability of DME.

Education and awareness programs are also being implemented to inform industries and the public about the benefits of DME. These initiatives aim to increase acceptance and demand for DME-based products and technologies, creating a supportive market environment.

Lastly, international cooperation and technology transfer are being promoted through bilateral and multilateral agreements. These efforts facilitate the sharing of best practices, harmonization of standards, and collaborative research, contributing to the global advancement of DME technology and its integration into sustainable industrial policies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!