Dimethyl Ether and its Innovative Impact on Utility Solutions

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Technology Evolution

Dimethyl Ether (DME) technology has undergone significant evolution since its inception, marking several key milestones in its development and application. The journey of DME as a versatile energy carrier and utility solution began in the early 20th century, with its first synthesis reported in 1924. However, it wasn't until the late 1990s that DME gained serious attention as a potential alternative fuel and chemical feedstock.

The initial phase of DME technology development focused primarily on its production methods. Early techniques involved the dehydration of methanol, which remained the dominant production route for several decades. As research progressed, scientists and engineers explored more efficient and cost-effective production methods, leading to the development of direct synthesis processes from syngas in the 1990s.

A significant breakthrough came in the early 2000s with the introduction of the single-step DME production process. This innovation allowed for the direct conversion of natural gas or coal to DME, bypassing the methanol intermediate stage. This development not only improved production efficiency but also reduced overall costs, making DME more competitive in the energy market.

The mid-2000s saw a surge in DME research and development, particularly in Asia. Countries like Japan, China, and South Korea invested heavily in DME technology, recognizing its potential as a clean-burning fuel and chemical intermediate. This period marked the beginning of large-scale DME production facilities and pilot projects for various applications, including power generation and transportation.

From 2010 onwards, DME technology evolution has been characterized by a focus on sustainability and integration with renewable energy sources. Researchers have made significant strides in producing DME from biomass and waste materials, aligning with global efforts to reduce carbon emissions. This bio-DME pathway has opened up new possibilities for sustainable energy production and waste management.

Recent years have witnessed advancements in DME application technologies. Innovations in engine design have improved the efficiency of DME as a transportation fuel, while new catalysts and reactor designs have enhanced its production processes. The integration of DME production with carbon capture and utilization technologies represents a cutting-edge development, positioning DME as a potential player in the circular carbon economy.

Looking ahead, the evolution of DME technology is expected to continue along several trajectories. These include further improvements in production efficiency, expansion of feedstock options, and development of novel applications in sectors such as energy storage and chemical manufacturing. The ongoing research into DME as a hydrogen carrier also promises to open new frontiers in clean energy solutions.

The initial phase of DME technology development focused primarily on its production methods. Early techniques involved the dehydration of methanol, which remained the dominant production route for several decades. As research progressed, scientists and engineers explored more efficient and cost-effective production methods, leading to the development of direct synthesis processes from syngas in the 1990s.

A significant breakthrough came in the early 2000s with the introduction of the single-step DME production process. This innovation allowed for the direct conversion of natural gas or coal to DME, bypassing the methanol intermediate stage. This development not only improved production efficiency but also reduced overall costs, making DME more competitive in the energy market.

The mid-2000s saw a surge in DME research and development, particularly in Asia. Countries like Japan, China, and South Korea invested heavily in DME technology, recognizing its potential as a clean-burning fuel and chemical intermediate. This period marked the beginning of large-scale DME production facilities and pilot projects for various applications, including power generation and transportation.

From 2010 onwards, DME technology evolution has been characterized by a focus on sustainability and integration with renewable energy sources. Researchers have made significant strides in producing DME from biomass and waste materials, aligning with global efforts to reduce carbon emissions. This bio-DME pathway has opened up new possibilities for sustainable energy production and waste management.

Recent years have witnessed advancements in DME application technologies. Innovations in engine design have improved the efficiency of DME as a transportation fuel, while new catalysts and reactor designs have enhanced its production processes. The integration of DME production with carbon capture and utilization technologies represents a cutting-edge development, positioning DME as a potential player in the circular carbon economy.

Looking ahead, the evolution of DME technology is expected to continue along several trajectories. These include further improvements in production efficiency, expansion of feedstock options, and development of novel applications in sectors such as energy storage and chemical manufacturing. The ongoing research into DME as a hydrogen carrier also promises to open new frontiers in clean energy solutions.

DME Market Potential

The market potential for Dimethyl Ether (DME) as an innovative utility solution is significant and growing. DME's versatility as a clean-burning, non-toxic fuel positions it as a promising alternative in various sectors, particularly in energy and transportation. The global DME market is experiencing steady growth, driven by increasing environmental concerns and the push for cleaner energy sources.

In the energy sector, DME shows considerable promise as a substitute for liquefied petroleum gas (LPG) in household and industrial applications. Its similar properties to LPG make it an attractive option for cooking and heating, especially in regions with limited access to traditional energy sources. The ease of adapting existing LPG infrastructure for DME use further enhances its market potential in this area.

The transportation sector represents another substantial market for DME. As a diesel substitute, DME offers reduced emissions and improved engine performance. This makes it particularly appealing for heavy-duty vehicles and fleet operations, where environmental regulations are becoming increasingly stringent. The potential for DME in this sector is further bolstered by ongoing research and development efforts to optimize engine designs for DME use.

Power generation is another area where DME shows significant market potential. Its clean-burning properties make it an attractive option for gas turbines and combined cycle power plants, offering a cleaner alternative to traditional fossil fuels. This application is particularly relevant in regions seeking to reduce their carbon footprint while maintaining reliable power generation capabilities.

The chemical industry also presents a growing market for DME. Its use as a propellant in aerosol products and as a refrigerant in cooling systems is expanding, driven by the phase-out of ozone-depleting substances. Additionally, DME's potential as a feedstock for various chemical processes opens up new avenues for market growth in this sector.

Geographically, the Asia-Pacific region is expected to be a key driver of DME market growth. Countries like China and India, with their rapidly growing economies and increasing energy demands, are showing significant interest in DME as a cleaner fuel alternative. Europe and North America are also anticipated to contribute to market expansion, driven by stringent environmental regulations and the push for sustainable energy solutions.

However, the realization of DME's market potential faces challenges. These include the need for infrastructure development, regulatory support, and public awareness. Overcoming these hurdles will be crucial for DME to fully capitalize on its market potential across various utility solutions.

In the energy sector, DME shows considerable promise as a substitute for liquefied petroleum gas (LPG) in household and industrial applications. Its similar properties to LPG make it an attractive option for cooking and heating, especially in regions with limited access to traditional energy sources. The ease of adapting existing LPG infrastructure for DME use further enhances its market potential in this area.

The transportation sector represents another substantial market for DME. As a diesel substitute, DME offers reduced emissions and improved engine performance. This makes it particularly appealing for heavy-duty vehicles and fleet operations, where environmental regulations are becoming increasingly stringent. The potential for DME in this sector is further bolstered by ongoing research and development efforts to optimize engine designs for DME use.

Power generation is another area where DME shows significant market potential. Its clean-burning properties make it an attractive option for gas turbines and combined cycle power plants, offering a cleaner alternative to traditional fossil fuels. This application is particularly relevant in regions seeking to reduce their carbon footprint while maintaining reliable power generation capabilities.

The chemical industry also presents a growing market for DME. Its use as a propellant in aerosol products and as a refrigerant in cooling systems is expanding, driven by the phase-out of ozone-depleting substances. Additionally, DME's potential as a feedstock for various chemical processes opens up new avenues for market growth in this sector.

Geographically, the Asia-Pacific region is expected to be a key driver of DME market growth. Countries like China and India, with their rapidly growing economies and increasing energy demands, are showing significant interest in DME as a cleaner fuel alternative. Europe and North America are also anticipated to contribute to market expansion, driven by stringent environmental regulations and the push for sustainable energy solutions.

However, the realization of DME's market potential faces challenges. These include the need for infrastructure development, regulatory support, and public awareness. Overcoming these hurdles will be crucial for DME to fully capitalize on its market potential across various utility solutions.

DME Technical Challenges

Despite the promising potential of Dimethyl Ether (DME) in utility solutions, several technical challenges hinder its widespread adoption and implementation. One of the primary obstacles is the need for specialized infrastructure to handle DME effectively. Unlike conventional fuels, DME requires specific storage, transportation, and distribution systems due to its unique physical properties. This necessitates significant investments in new infrastructure or modifications to existing systems, which can be costly and time-consuming for utility providers.

Another critical challenge lies in the production process of DME. While it can be synthesized from various feedstocks, including natural gas, coal, and biomass, optimizing the production efficiency and reducing costs remain ongoing concerns. The current production methods often involve multiple steps and energy-intensive processes, which can impact the overall sustainability and economic viability of DME as a utility solution.

Material compatibility issues also pose technical hurdles in DME applications. Some common materials used in conventional fuel systems may degrade or react unfavorably when exposed to DME. This necessitates the development and testing of new materials that can withstand long-term exposure to DME without compromising safety or performance. The selection of appropriate seals, gaskets, and other components is crucial to prevent leaks and ensure the longevity of DME-based systems.

The combustion characteristics of DME present both advantages and challenges. While DME offers cleaner combustion with lower particulate emissions compared to conventional fuels, it also has a lower energy density. This means that larger storage tanks and more frequent refueling may be required to achieve the same energy output as traditional fuels. Additionally, optimizing engine and burner designs to fully leverage DME's combustion properties while maintaining efficiency and performance is an ongoing area of research and development.

Safety considerations also play a significant role in the technical challenges surrounding DME. As a highly flammable gas at room temperature and atmospheric pressure, DME requires robust safety measures in its handling, storage, and use. Developing reliable leak detection systems, implementing appropriate ventilation strategies, and establishing comprehensive safety protocols are essential for the safe integration of DME into utility solutions.

Lastly, the regulatory landscape presents a complex challenge for DME adoption. Establishing clear standards and regulations for DME production, distribution, and use across different applications is crucial. This involves coordinating with various regulatory bodies, addressing potential environmental concerns, and ensuring compliance with existing energy and safety regulations. The lack of harmonized standards across different regions can impede the global adoption and trade of DME-based solutions.

Another critical challenge lies in the production process of DME. While it can be synthesized from various feedstocks, including natural gas, coal, and biomass, optimizing the production efficiency and reducing costs remain ongoing concerns. The current production methods often involve multiple steps and energy-intensive processes, which can impact the overall sustainability and economic viability of DME as a utility solution.

Material compatibility issues also pose technical hurdles in DME applications. Some common materials used in conventional fuel systems may degrade or react unfavorably when exposed to DME. This necessitates the development and testing of new materials that can withstand long-term exposure to DME without compromising safety or performance. The selection of appropriate seals, gaskets, and other components is crucial to prevent leaks and ensure the longevity of DME-based systems.

The combustion characteristics of DME present both advantages and challenges. While DME offers cleaner combustion with lower particulate emissions compared to conventional fuels, it also has a lower energy density. This means that larger storage tanks and more frequent refueling may be required to achieve the same energy output as traditional fuels. Additionally, optimizing engine and burner designs to fully leverage DME's combustion properties while maintaining efficiency and performance is an ongoing area of research and development.

Safety considerations also play a significant role in the technical challenges surrounding DME. As a highly flammable gas at room temperature and atmospheric pressure, DME requires robust safety measures in its handling, storage, and use. Developing reliable leak detection systems, implementing appropriate ventilation strategies, and establishing comprehensive safety protocols are essential for the safe integration of DME into utility solutions.

Lastly, the regulatory landscape presents a complex challenge for DME adoption. Establishing clear standards and regulations for DME production, distribution, and use across different applications is crucial. This involves coordinating with various regulatory bodies, addressing potential environmental concerns, and ensuring compliance with existing energy and safety regulations. The lack of harmonized standards across different regions can impede the global adoption and trade of DME-based solutions.

Current DME Applications

01 Production of dimethyl ether

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.- Production of dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

- Catalysts for dimethyl ether synthesis: Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.

- Applications of dimethyl ether: Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as a potential alternative fuel for diesel engines due to its clean-burning properties and high cetane number.

- Purification and separation of dimethyl ether: Techniques for purifying and separating dimethyl ether from reaction mixtures or other compounds are crucial in its production process. These may include distillation, adsorption, and membrane separation methods to achieve high-purity dimethyl ether.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and storage requirements to ensure safe and sustainable utilization of dimethyl ether.

02 Catalysts for dimethyl ether synthesis

Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice and preparation of catalysts significantly influence the efficiency and selectivity of the dimethyl ether synthesis process.Expand Specific Solutions03 Applications of dimethyl ether

Dimethyl ether has various applications, including use as a fuel additive, propellant, refrigerant, and chemical intermediate. Its properties make it suitable for use in diesel engines, aerosol products, and as a raw material for other chemical processes.Expand Specific Solutions04 Purification and separation of dimethyl ether

Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes often involve distillation, adsorption, or membrane separation techniques to obtain high-purity dimethyl ether.Expand Specific Solutions05 Environmental and safety considerations

Research on the environmental impact and safety aspects of dimethyl ether production and use is conducted. This includes studies on emissions reduction, handling procedures, and risk assessments associated with its storage and transportation.Expand Specific Solutions

DME Industry Players

The dimethyl ether (DME) market is in a growth phase, driven by increasing demand for clean alternative fuels. The global DME market size is projected to expand significantly in the coming years, with Asia-Pacific emerging as a key region. Technologically, DME production is relatively mature, but innovations in catalysts and process efficiency are ongoing. Major players like China Petroleum & Chemical Corp., SK Energy, and BASF are investing in R&D to improve DME production methods. Smaller companies such as Hebi Baofa Energy Technology are also contributing to technological advancements. Academic institutions like Zhejiang University and research centers like Qingdao Institute of Bioenergy and Bioprocess Technology are collaborating with industry to further develop DME technologies and applications in utility solutions.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative dimethyl ether (DME) production process using coal as feedstock. Their technology involves coal gasification to produce syngas, followed by methanol synthesis and dehydration to DME. The process achieves high conversion rates of up to 90% and selectivity above 95%[1]. Sinopec has also implemented large-scale DME production facilities with capacities exceeding 1 million tons per year[2]. Additionally, they have explored DME as a clean alternative fuel for vehicles and household cooking, conducting extensive field trials and developing DME-compatible engines and infrastructure[3].

Strengths: Vast coal resources for feedstock, established production infrastructure, and extensive R&D capabilities. Weaknesses: Dependence on coal may face environmental scrutiny, and market adoption of DME as a fuel alternative remains challenging.

BASF Corp.

Technical Solution: BASF Corp. has developed a novel catalytic process for DME production directly from syngas, bypassing the methanol intermediate step. This one-step process utilizes a bifunctional catalyst that combines methanol synthesis and dehydration functions, achieving higher efficiency and lower production costs[4]. BASF's technology can produce DME from various feedstocks, including natural gas, coal, and biomass, offering flexibility in raw material sourcing. The company has also focused on developing DME as a green aerosol propellant, replacing harmful chlorofluorocarbons (CFCs) in various consumer and industrial products[5]. BASF has further explored DME's potential as a hydrogen carrier for fuel cell applications, contributing to the advancement of clean energy solutions[6].

Strengths: Versatile feedstock options, innovative catalytic processes, and diverse applications beyond fuel. Weaknesses: May face competition from established methanol-based DME production methods and requires significant infrastructure changes for widespread fuel adoption.

DME Production Processes

Energy supply method and system

PatentWO2006004140A1

Innovation

- The introduction of Dimethyl Ether (DME) as a versatile energy circulation medium, which can be derived from biomass, waste, and petroleum residues, and used for power generation, transportation, and heating, allowing for efficient energy storage and distribution without relying on pipelines, and enabling the conversion of waste heat into usable energy.

Biogas conversion process

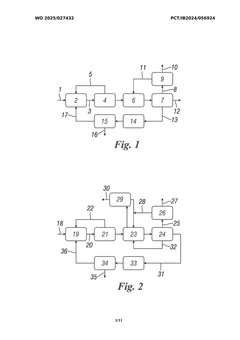

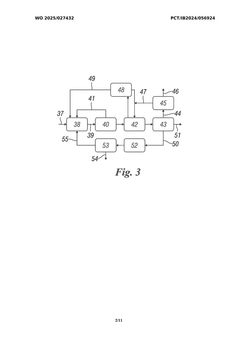

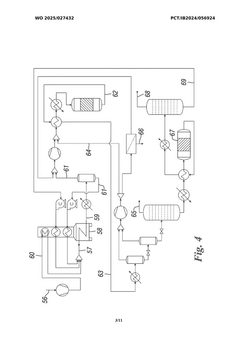

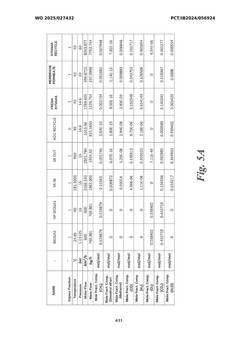

PatentWO2025027432A1

Innovation

- A process involving tri-reformation of biogas to syngas, followed by methanol synthesis, and subsequent DME synthesis, with integrated steps for syngas recycling, CO2 removal, and simplified purification, achieving high yield and selectivity of DME.

Environmental Impact

The environmental impact of dimethyl ether (DME) as an innovative utility solution is multifaceted and generally positive when compared to traditional fossil fuels. DME is a clean-burning, non-toxic fuel that can be produced from various renewable sources, including biomass, waste, and carbon dioxide. This versatility in production methods contributes to its potential as a sustainable energy carrier.

One of the most significant environmental benefits of DME is its low emissions profile. When used as a fuel in combustion engines or power generation systems, DME produces significantly lower levels of particulate matter, nitrogen oxides, and sulfur oxides compared to conventional diesel or coal. This reduction in harmful emissions can lead to improved air quality, particularly in urban areas where air pollution is a major concern.

Furthermore, DME has a lower global warming potential than many other fossil fuels. Its combustion produces less carbon dioxide per unit of energy released, and when produced from renewable sources, it can be considered nearly carbon-neutral. This characteristic makes DME an attractive option for countries and industries seeking to reduce their carbon footprint and meet increasingly stringent emissions targets.

In terms of its impact on water resources, DME offers advantages over some alternative fuels. Unlike ethanol production, which can be water-intensive, DME production generally requires less water. Additionally, DME is non-toxic and biodegradable, meaning accidental spills or leaks pose minimal risk to aquatic ecosystems and groundwater resources.

The production of DME from waste materials, such as agricultural residues or municipal solid waste, presents an opportunity to address multiple environmental challenges simultaneously. By utilizing these waste streams, DME production can help reduce landfill usage and methane emissions associated with waste decomposition, while also providing a valuable energy product.

However, it is important to consider the full lifecycle environmental impact of DME. The production process, particularly when derived from fossil fuels, can still contribute to greenhouse gas emissions. The energy intensity of DME production and the efficiency of its use in various applications must be carefully evaluated to ensure a net positive environmental impact.

In conclusion, while DME offers significant environmental benefits as an innovative utility solution, its overall impact depends on factors such as production methods, feedstock sources, and end-use applications. As technology advances and production scales up, the potential for DME to contribute to a cleaner, more sustainable energy landscape continues to grow.

One of the most significant environmental benefits of DME is its low emissions profile. When used as a fuel in combustion engines or power generation systems, DME produces significantly lower levels of particulate matter, nitrogen oxides, and sulfur oxides compared to conventional diesel or coal. This reduction in harmful emissions can lead to improved air quality, particularly in urban areas where air pollution is a major concern.

Furthermore, DME has a lower global warming potential than many other fossil fuels. Its combustion produces less carbon dioxide per unit of energy released, and when produced from renewable sources, it can be considered nearly carbon-neutral. This characteristic makes DME an attractive option for countries and industries seeking to reduce their carbon footprint and meet increasingly stringent emissions targets.

In terms of its impact on water resources, DME offers advantages over some alternative fuels. Unlike ethanol production, which can be water-intensive, DME production generally requires less water. Additionally, DME is non-toxic and biodegradable, meaning accidental spills or leaks pose minimal risk to aquatic ecosystems and groundwater resources.

The production of DME from waste materials, such as agricultural residues or municipal solid waste, presents an opportunity to address multiple environmental challenges simultaneously. By utilizing these waste streams, DME production can help reduce landfill usage and methane emissions associated with waste decomposition, while also providing a valuable energy product.

However, it is important to consider the full lifecycle environmental impact of DME. The production process, particularly when derived from fossil fuels, can still contribute to greenhouse gas emissions. The energy intensity of DME production and the efficiency of its use in various applications must be carefully evaluated to ensure a net positive environmental impact.

In conclusion, while DME offers significant environmental benefits as an innovative utility solution, its overall impact depends on factors such as production methods, feedstock sources, and end-use applications. As technology advances and production scales up, the potential for DME to contribute to a cleaner, more sustainable energy landscape continues to grow.

Regulatory Framework

The regulatory framework surrounding Dimethyl Ether (DME) and its utility solutions is complex and multifaceted, reflecting the diverse applications and potential impacts of this versatile compound. As DME gains traction as an alternative fuel and chemical feedstock, governments and regulatory bodies worldwide are adapting their policies to address its unique characteristics and potential risks.

In the energy sector, DME is increasingly recognized as a clean-burning fuel with potential to replace conventional diesel and liquefied petroleum gas (LPG). Consequently, many countries are developing specific regulations for DME as a transportation fuel. These regulations often focus on fuel quality standards, emissions limits, and safety requirements for storage and handling. For instance, the European Union has included DME in its Renewable Energy Directive, promoting its use as a renewable fuel when produced from biomass.

Environmental regulations play a crucial role in shaping the DME landscape. As a low-carbon alternative to traditional fuels, DME aligns well with greenhouse gas reduction targets set by various international agreements. However, regulators must also consider the potential environmental impacts of DME production, particularly when derived from fossil fuels. This has led to the development of lifecycle assessment methodologies to evaluate the overall environmental footprint of DME across its production and use cycle.

Safety regulations are another critical aspect of the DME regulatory framework. Given its flammable nature and potential for high-pressure storage, stringent safety standards have been established for DME handling, transportation, and storage. These regulations often draw from existing standards for LPG and other similar fuels, but with modifications to account for DME's specific properties.

In the chemical industry, DME's use as a propellant and aerosol spray has led to regulations governing its application in consumer products. These regulations typically address issues such as product labeling, permissible concentrations, and restrictions on use in certain product categories. The regulatory landscape in this area varies significantly between jurisdictions, reflecting different approaches to consumer protection and environmental concerns.

As DME technology continues to evolve, regulatory frameworks are likely to undergo further refinement. This may include the development of new standards for DME-specific equipment, updates to building codes to accommodate DME infrastructure, and revisions to air quality regulations to reflect DME's emissions profile. The ongoing dialogue between industry stakeholders, policymakers, and environmental groups will be crucial in shaping a balanced and effective regulatory environment that supports the innovative potential of DME while ensuring public safety and environmental protection.

In the energy sector, DME is increasingly recognized as a clean-burning fuel with potential to replace conventional diesel and liquefied petroleum gas (LPG). Consequently, many countries are developing specific regulations for DME as a transportation fuel. These regulations often focus on fuel quality standards, emissions limits, and safety requirements for storage and handling. For instance, the European Union has included DME in its Renewable Energy Directive, promoting its use as a renewable fuel when produced from biomass.

Environmental regulations play a crucial role in shaping the DME landscape. As a low-carbon alternative to traditional fuels, DME aligns well with greenhouse gas reduction targets set by various international agreements. However, regulators must also consider the potential environmental impacts of DME production, particularly when derived from fossil fuels. This has led to the development of lifecycle assessment methodologies to evaluate the overall environmental footprint of DME across its production and use cycle.

Safety regulations are another critical aspect of the DME regulatory framework. Given its flammable nature and potential for high-pressure storage, stringent safety standards have been established for DME handling, transportation, and storage. These regulations often draw from existing standards for LPG and other similar fuels, but with modifications to account for DME's specific properties.

In the chemical industry, DME's use as a propellant and aerosol spray has led to regulations governing its application in consumer products. These regulations typically address issues such as product labeling, permissible concentrations, and restrictions on use in certain product categories. The regulatory landscape in this area varies significantly between jurisdictions, reflecting different approaches to consumer protection and environmental concerns.

As DME technology continues to evolve, regulatory frameworks are likely to undergo further refinement. This may include the development of new standards for DME-specific equipment, updates to building codes to accommodate DME infrastructure, and revisions to air quality regulations to reflect DME's emissions profile. The ongoing dialogue between industry stakeholders, policymakers, and environmental groups will be crucial in shaping a balanced and effective regulatory environment that supports the innovative potential of DME while ensuring public safety and environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!