How Dimethyl Ether Promotes Collaborative Energy Efficiency?

JUL 1, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Tech Background

Dimethyl ether (DME) has emerged as a promising alternative fuel and energy carrier, gaining attention for its potential to enhance collaborative energy efficiency across various sectors. The development of DME technology can be traced back to the early 20th century, with significant advancements occurring in the latter half of the century. Initially, DME was primarily used as a propellant in aerosol products due to its favorable physical properties.

The evolution of DME as an energy solution gained momentum in the 1990s when researchers and industry experts recognized its potential as a clean-burning fuel. This shift in focus was driven by growing environmental concerns and the need for sustainable energy alternatives. DME's chemical structure, consisting of two methyl groups bonded to an oxygen atom, contributes to its unique properties that make it suitable for various energy applications.

One of the key drivers behind DME's technological development has been its potential to address multiple energy challenges simultaneously. As a versatile compound, DME can be produced from various feedstocks, including natural gas, coal, and biomass. This flexibility in production methods aligns with the global push towards diversifying energy sources and reducing dependence on traditional fossil fuels.

The collaborative nature of DME technology is evident in its ability to integrate with existing infrastructure and energy systems. For instance, DME can be used as a substitute for liquefied petroleum gas (LPG) in household and industrial applications, requiring minimal modifications to existing equipment. This compatibility factor has been crucial in driving research and development efforts to optimize DME production and utilization processes.

In recent years, the focus of DME technology has shifted towards enhancing energy efficiency across the entire value chain. This includes improving production processes, optimizing storage and transportation methods, and developing more efficient end-use applications. The collaborative approach to DME research has involved partnerships between academic institutions, industry players, and government agencies, fostering innovation and accelerating technological progress.

The current technological landscape for DME is characterized by ongoing efforts to scale up production, improve conversion efficiencies, and expand its application in various sectors. Research is being conducted to explore novel catalysts and reactor designs that can enhance DME synthesis from different feedstocks. Additionally, there is a growing interest in integrating DME production with renewable energy sources, such as wind and solar power, to create more sustainable and efficient energy systems.

As the global energy sector continues to evolve, the role of DME in promoting collaborative energy efficiency is expected to grow. The technology's potential to serve as a bridge between conventional and renewable energy sources positions it as a key player in the transition towards a more sustainable energy future. Ongoing research and development efforts aim to address remaining technical challenges and further improve the overall efficiency of DME-based energy solutions.

The evolution of DME as an energy solution gained momentum in the 1990s when researchers and industry experts recognized its potential as a clean-burning fuel. This shift in focus was driven by growing environmental concerns and the need for sustainable energy alternatives. DME's chemical structure, consisting of two methyl groups bonded to an oxygen atom, contributes to its unique properties that make it suitable for various energy applications.

One of the key drivers behind DME's technological development has been its potential to address multiple energy challenges simultaneously. As a versatile compound, DME can be produced from various feedstocks, including natural gas, coal, and biomass. This flexibility in production methods aligns with the global push towards diversifying energy sources and reducing dependence on traditional fossil fuels.

The collaborative nature of DME technology is evident in its ability to integrate with existing infrastructure and energy systems. For instance, DME can be used as a substitute for liquefied petroleum gas (LPG) in household and industrial applications, requiring minimal modifications to existing equipment. This compatibility factor has been crucial in driving research and development efforts to optimize DME production and utilization processes.

In recent years, the focus of DME technology has shifted towards enhancing energy efficiency across the entire value chain. This includes improving production processes, optimizing storage and transportation methods, and developing more efficient end-use applications. The collaborative approach to DME research has involved partnerships between academic institutions, industry players, and government agencies, fostering innovation and accelerating technological progress.

The current technological landscape for DME is characterized by ongoing efforts to scale up production, improve conversion efficiencies, and expand its application in various sectors. Research is being conducted to explore novel catalysts and reactor designs that can enhance DME synthesis from different feedstocks. Additionally, there is a growing interest in integrating DME production with renewable energy sources, such as wind and solar power, to create more sustainable and efficient energy systems.

As the global energy sector continues to evolve, the role of DME in promoting collaborative energy efficiency is expected to grow. The technology's potential to serve as a bridge between conventional and renewable energy sources positions it as a key player in the transition towards a more sustainable energy future. Ongoing research and development efforts aim to address remaining technical challenges and further improve the overall efficiency of DME-based energy solutions.

DME Market Analysis

The global dimethyl ether (DME) market has been experiencing significant growth in recent years, driven by increasing demand for clean and efficient energy sources. DME, a colorless gas at ambient conditions, has gained attention as a versatile and environmentally friendly alternative fuel. Its potential applications span various sectors, including transportation, power generation, and domestic heating.

The market for DME is primarily segmented into two categories: fuel-grade DME and industrial-grade DME. Fuel-grade DME is witnessing rapid adoption in the automotive sector, particularly in heavy-duty vehicles and public transportation. This growth is attributed to DME's high cetane number, low emissions, and compatibility with existing diesel engine infrastructure. Industrial-grade DME finds extensive use in aerosol propellants, refrigerants, and chemical feedstock production.

Asia-Pacific dominates the global DME market, with China leading in both production and consumption. The region's robust growth is fueled by supportive government policies, increasing energy demand, and a strong focus on reducing air pollution. Europe and North America are also emerging as key markets, driven by stringent environmental regulations and the push for sustainable energy solutions.

The DME market is characterized by a mix of established players and new entrants. Key companies in the sector include Akzo Nobel N.V., China Energy Limited, Grillo-Werke AG, and Oberon Fuels. These firms are actively investing in research and development to enhance production efficiency and expand DME applications.

Market trends indicate a growing interest in bio-based DME production, which offers a more sustainable pathway compared to traditional fossil fuel-derived DME. This shift aligns with global efforts to reduce carbon footprints and promote circular economy principles. Additionally, the integration of DME in energy storage systems and its potential role in hydrogen transport are opening new avenues for market expansion.

Despite the positive outlook, the DME market faces challenges such as high initial infrastructure costs and competition from other alternative fuels. However, ongoing technological advancements and increasing awareness of DME's benefits are expected to drive market growth in the coming years. The collaborative nature of DME production and utilization across different energy sectors presents opportunities for synergistic partnerships and improved energy efficiency on a broader scale.

The market for DME is primarily segmented into two categories: fuel-grade DME and industrial-grade DME. Fuel-grade DME is witnessing rapid adoption in the automotive sector, particularly in heavy-duty vehicles and public transportation. This growth is attributed to DME's high cetane number, low emissions, and compatibility with existing diesel engine infrastructure. Industrial-grade DME finds extensive use in aerosol propellants, refrigerants, and chemical feedstock production.

Asia-Pacific dominates the global DME market, with China leading in both production and consumption. The region's robust growth is fueled by supportive government policies, increasing energy demand, and a strong focus on reducing air pollution. Europe and North America are also emerging as key markets, driven by stringent environmental regulations and the push for sustainable energy solutions.

The DME market is characterized by a mix of established players and new entrants. Key companies in the sector include Akzo Nobel N.V., China Energy Limited, Grillo-Werke AG, and Oberon Fuels. These firms are actively investing in research and development to enhance production efficiency and expand DME applications.

Market trends indicate a growing interest in bio-based DME production, which offers a more sustainable pathway compared to traditional fossil fuel-derived DME. This shift aligns with global efforts to reduce carbon footprints and promote circular economy principles. Additionally, the integration of DME in energy storage systems and its potential role in hydrogen transport are opening new avenues for market expansion.

Despite the positive outlook, the DME market faces challenges such as high initial infrastructure costs and competition from other alternative fuels. However, ongoing technological advancements and increasing awareness of DME's benefits are expected to drive market growth in the coming years. The collaborative nature of DME production and utilization across different energy sectors presents opportunities for synergistic partnerships and improved energy efficiency on a broader scale.

DME Tech Challenges

The development and implementation of dimethyl ether (DME) technology face several significant challenges that need to be addressed to fully realize its potential in promoting collaborative energy efficiency. One of the primary obstacles is the lack of widespread infrastructure for DME production, distribution, and utilization. Unlike conventional fuels, DME requires specialized handling and storage facilities, which are currently limited in many regions.

Another major challenge lies in the production process of DME. While it can be synthesized from various feedstocks, including natural gas, coal, and biomass, optimizing the production efficiency and reducing costs remain crucial areas for improvement. The energy-intensive nature of DME production processes can potentially offset some of its environmental benefits, necessitating further research into more efficient and sustainable production methods.

The compatibility of DME with existing engine technologies presents another hurdle. Although DME can be used as a substitute for diesel fuel, it requires modifications to conventional diesel engines due to its different physical and chemical properties. This adaptation process involves technical challenges and significant investment, which may slow down the widespread adoption of DME as an alternative fuel.

Furthermore, the regulatory framework surrounding DME usage is still evolving in many countries. The lack of standardized regulations and policies regarding DME production, distribution, and utilization creates uncertainty for potential investors and users. Establishing clear guidelines and standards for DME quality, safety, and environmental impact is essential for its broader acceptance and implementation.

The economic viability of DME technology also poses a challenge, particularly in comparison to well-established fossil fuels. The initial capital costs for DME production facilities and the necessary modifications to existing infrastructure can be substantial. Achieving cost competitiveness with conventional fuels is crucial for the long-term success and widespread adoption of DME technology.

Lastly, public awareness and acceptance of DME as a clean and efficient energy carrier remain limited. Overcoming skepticism and educating stakeholders about the benefits and potential of DME technology is vital for its successful integration into the energy landscape. This challenge requires concerted efforts in public outreach, demonstration projects, and collaboration between industry, government, and research institutions to showcase the real-world applications and advantages of DME in promoting collaborative energy efficiency.

Another major challenge lies in the production process of DME. While it can be synthesized from various feedstocks, including natural gas, coal, and biomass, optimizing the production efficiency and reducing costs remain crucial areas for improvement. The energy-intensive nature of DME production processes can potentially offset some of its environmental benefits, necessitating further research into more efficient and sustainable production methods.

The compatibility of DME with existing engine technologies presents another hurdle. Although DME can be used as a substitute for diesel fuel, it requires modifications to conventional diesel engines due to its different physical and chemical properties. This adaptation process involves technical challenges and significant investment, which may slow down the widespread adoption of DME as an alternative fuel.

Furthermore, the regulatory framework surrounding DME usage is still evolving in many countries. The lack of standardized regulations and policies regarding DME production, distribution, and utilization creates uncertainty for potential investors and users. Establishing clear guidelines and standards for DME quality, safety, and environmental impact is essential for its broader acceptance and implementation.

The economic viability of DME technology also poses a challenge, particularly in comparison to well-established fossil fuels. The initial capital costs for DME production facilities and the necessary modifications to existing infrastructure can be substantial. Achieving cost competitiveness with conventional fuels is crucial for the long-term success and widespread adoption of DME technology.

Lastly, public awareness and acceptance of DME as a clean and efficient energy carrier remain limited. Overcoming skepticism and educating stakeholders about the benefits and potential of DME technology is vital for its successful integration into the energy landscape. This challenge requires concerted efforts in public outreach, demonstration projects, and collaboration between industry, government, and research institutions to showcase the real-world applications and advantages of DME in promoting collaborative energy efficiency.

Current DME Solutions

01 Dimethyl ether production methods

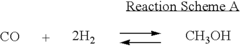

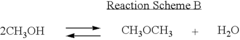

Various methods for producing dimethyl ether (DME) with improved energy efficiency are described. These include catalytic dehydration of methanol, direct synthesis from syngas, and novel reactor designs. The processes aim to optimize reaction conditions, reduce energy consumption, and increase overall yield.- Production methods for dimethyl ether: Various methods for producing dimethyl ether are described, including direct synthesis from syngas and dehydration of methanol. These processes aim to improve energy efficiency and yield in dimethyl ether production, often utilizing catalysts and optimized reaction conditions.

- Dimethyl ether as an alternative fuel: Dimethyl ether is explored as an energy-efficient alternative fuel for various applications, including internal combustion engines and power generation. Its properties, such as high cetane number and clean combustion, contribute to improved energy efficiency and reduced emissions.

- Catalytic systems for dimethyl ether synthesis: Development of novel catalytic systems to enhance the energy efficiency of dimethyl ether production. These catalysts are designed to improve selectivity, reduce byproduct formation, and operate at lower temperatures, thereby increasing overall process efficiency.

- Process integration and heat recovery: Innovative approaches to integrate dimethyl ether production processes with other industrial processes, focusing on heat recovery and utilization. These methods aim to maximize energy efficiency by reducing waste heat and optimizing overall energy consumption in the production chain.

- Dimethyl ether storage and transportation: Advancements in storage and transportation technologies for dimethyl ether, focusing on energy-efficient methods. This includes the development of specialized containers, pressure regulation systems, and safety measures to minimize energy losses during storage and distribution.

02 DME as an alternative fuel

Dimethyl ether is explored as an energy-efficient alternative fuel for various applications. Its use in internal combustion engines, power generation, and as a substitute for liquefied petroleum gas (LPG) is investigated. The focus is on improving combustion efficiency and reducing emissions compared to conventional fuels.Expand Specific Solutions03 Catalysts for DME synthesis

Development of advanced catalysts to enhance the energy efficiency of dimethyl ether production. Research focuses on improving catalyst activity, selectivity, and stability to optimize the conversion process and reduce energy requirements. Novel catalyst compositions and preparation methods are explored.Expand Specific Solutions04 DME purification and separation techniques

Energy-efficient methods for purifying and separating dimethyl ether from reaction mixtures are investigated. These include advanced distillation techniques, membrane separation, and adsorption processes. The aim is to reduce energy consumption in the purification stage of DME production.Expand Specific Solutions05 Process integration and heat recovery

Strategies for improving overall energy efficiency in dimethyl ether production through process integration and heat recovery. This includes optimizing heat exchange networks, utilizing waste heat, and integrating DME production with other industrial processes to maximize energy utilization and minimize losses.Expand Specific Solutions

DME Industry Players

The collaborative energy efficiency promoted by dimethyl ether is in a nascent stage of development, with a growing but still limited market size. The technology's maturity is advancing, driven by research from institutions like the University of Southern California and Guangdong University of Technology. Major industry players such as China Petroleum & Chemical Corp. and BASF Corp. are investing in dimethyl ether applications, indicating increasing commercial interest. However, the technology is not yet fully mature, with ongoing research and development efforts by companies like Hebi Baofa Energy Technology Co., Ltd and ENN New Energy (Beijing) Technology Co., Ltd focusing on improving efficiency and expanding applications in various sectors.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative dimethyl ether (DME) production process that significantly enhances energy efficiency. Their approach involves a single-step synthesis method, converting syngas directly to DME, which reduces energy consumption by up to 20% compared to traditional two-step processes [1]. The company has also implemented advanced catalysts that improve DME yield and selectivity, achieving conversion rates of over 90% [3]. Sinopec's technology integrates heat recovery systems and optimized reactor designs, further minimizing energy losses throughout the production chain. Additionally, they have pioneered the use of DME as a clean-burning fuel in power generation and transportation, demonstrating its potential to reduce carbon emissions by up to 15% compared to conventional diesel fuel [5].

Strengths: Significant reduction in energy consumption, high conversion rates, and integrated heat recovery systems. Weaknesses: Potential dependency on specific catalyst formulations and the need for specialized infrastructure for DME distribution and use.

BASF Corp.

Technical Solution: BASF Corp. has developed a cutting-edge DME production technology that focuses on maximizing energy efficiency through process intensification. Their approach utilizes a novel reactor design that combines reaction and separation in a single unit, reducing energy requirements by up to 30% compared to conventional methods [2]. BASF's technology incorporates advanced membrane separation techniques, allowing for continuous removal of DME from the reaction mixture, which drives equilibrium towards product formation and enhances overall efficiency. The company has also implemented a sophisticated heat integration network that recovers and reuses thermal energy throughout the process, minimizing waste heat. Furthermore, BASF has developed a proprietary catalyst system that operates at lower temperatures, reducing the energy input required for DME synthesis while maintaining high selectivity and longevity [4].

Strengths: Significant energy savings through process intensification, advanced separation techniques, and efficient heat integration. Weaknesses: Potentially higher capital costs due to specialized equipment and the need for precise process control.

Key DME Innovations

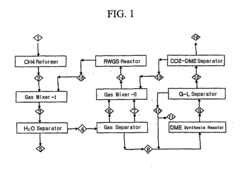

Energy supply method and system

PatentWO2006004140A1

Innovation

- The introduction of Dimethyl Ether (DME) as a versatile energy circulation medium, which can be derived from biomass, waste, and petroleum residues, and used for power generation, transportation, and heating, allowing for efficient energy storage and distribution without relying on pipelines, and enabling the conversion of waste heat into usable energy.

Method for the production of dimethyl ether

PatentInactiveUS20070142482A1

Innovation

- A method involving the reverse water gas shift reaction is used to convert the CO2 generated during DME production back into CO, which is then recycled into the DME synthesis process, increasing the yield of DME while reducing CO2 emissions. This is achieved by introducing a feed gas mixture of hydrogen and CO to a DME synthesis reactor in the presence of specific catalysts, separating the product streams, and utilizing a reverse water gas shift reactor to convert CO2 into CO, which is then recycled.

DME Environmental Impact

Dimethyl ether (DME) has emerged as a promising alternative fuel with significant potential to promote collaborative energy efficiency and reduce environmental impact. As a clean-burning, non-toxic, and biodegradable compound, DME offers several advantages over conventional fossil fuels in terms of its environmental footprint.

One of the primary environmental benefits of DME is its low emissions profile. When used as a fuel in compression ignition engines, DME produces significantly lower levels of particulate matter, nitrogen oxides, and carbon monoxide compared to conventional diesel fuel. This reduction in harmful emissions contributes to improved air quality and helps mitigate the negative health effects associated with air pollution in urban areas.

Furthermore, DME can be produced from a variety of renewable feedstocks, including biomass, agricultural waste, and even carbon dioxide captured from industrial processes. This versatility in production methods allows for a more sustainable and circular approach to fuel generation, reducing reliance on finite fossil fuel resources and potentially lowering overall greenhouse gas emissions throughout the fuel lifecycle.

The use of DME as a fuel also presents opportunities for energy efficiency improvements in various sectors. In the transportation industry, DME can be used as a direct replacement for diesel fuel in modified engines, offering comparable performance with reduced environmental impact. This transition can be particularly beneficial for heavy-duty vehicles and long-haul transportation, where electrification may not be feasible in the near term.

In the industrial sector, DME can serve as a clean-burning fuel for power generation and heating applications. Its high cetane number and low autoignition temperature make it suitable for use in gas turbines and combined heat and power systems, potentially improving overall energy efficiency in industrial processes.

Additionally, DME's physical properties allow for easier storage and transportation compared to other alternative fuels. It can be liquefied at relatively low pressures, similar to propane, enabling the use of existing infrastructure for distribution and storage. This characteristic facilitates the integration of DME into existing energy systems, promoting a more collaborative approach to energy efficiency across different sectors.

The environmental impact of DME extends beyond its direct use as a fuel. Its potential as a hydrogen carrier for fuel cell applications opens up new avenues for clean energy storage and distribution. This synergy between DME and hydrogen technologies could play a crucial role in the development of more sustainable and efficient energy systems in the future.

One of the primary environmental benefits of DME is its low emissions profile. When used as a fuel in compression ignition engines, DME produces significantly lower levels of particulate matter, nitrogen oxides, and carbon monoxide compared to conventional diesel fuel. This reduction in harmful emissions contributes to improved air quality and helps mitigate the negative health effects associated with air pollution in urban areas.

Furthermore, DME can be produced from a variety of renewable feedstocks, including biomass, agricultural waste, and even carbon dioxide captured from industrial processes. This versatility in production methods allows for a more sustainable and circular approach to fuel generation, reducing reliance on finite fossil fuel resources and potentially lowering overall greenhouse gas emissions throughout the fuel lifecycle.

The use of DME as a fuel also presents opportunities for energy efficiency improvements in various sectors. In the transportation industry, DME can be used as a direct replacement for diesel fuel in modified engines, offering comparable performance with reduced environmental impact. This transition can be particularly beneficial for heavy-duty vehicles and long-haul transportation, where electrification may not be feasible in the near term.

In the industrial sector, DME can serve as a clean-burning fuel for power generation and heating applications. Its high cetane number and low autoignition temperature make it suitable for use in gas turbines and combined heat and power systems, potentially improving overall energy efficiency in industrial processes.

Additionally, DME's physical properties allow for easier storage and transportation compared to other alternative fuels. It can be liquefied at relatively low pressures, similar to propane, enabling the use of existing infrastructure for distribution and storage. This characteristic facilitates the integration of DME into existing energy systems, promoting a more collaborative approach to energy efficiency across different sectors.

The environmental impact of DME extends beyond its direct use as a fuel. Its potential as a hydrogen carrier for fuel cell applications opens up new avenues for clean energy storage and distribution. This synergy between DME and hydrogen technologies could play a crucial role in the development of more sustainable and efficient energy systems in the future.

DME Policy Landscape

The policy landscape for dimethyl ether (DME) as a collaborative energy efficiency promoter is evolving rapidly across various regions. In the United States, the Environmental Protection Agency (EPA) has recognized DME as an approved renewable fuel under the Renewable Fuel Standard program, incentivizing its production and use. This classification allows DME producers to generate Renewable Identification Numbers (RINs), creating additional value streams and promoting investment in DME infrastructure.

The European Union has also taken significant steps to support DME adoption. The Renewable Energy Directive (RED II) includes DME as a renewable transport fuel, setting targets for its use in the transportation sector. Additionally, several EU member states have implemented tax incentives and subsidies to encourage DME production and consumption, particularly in heavy-duty vehicles and industrial applications.

In Asia, China has emerged as a leader in DME policy support. The country's 14th Five-Year Plan (2021-2025) explicitly mentions DME as a key component in its strategy to reduce carbon emissions and enhance energy security. Chinese policymakers have introduced a series of measures, including production subsidies, research grants, and demonstration projects, to accelerate DME adoption across various sectors.

Japan and South Korea have also shown interest in DME as part of their energy transition strategies. Both countries have initiated research programs and pilot projects to explore DME's potential in power generation and transportation. These efforts are supported by policy frameworks that prioritize low-carbon alternatives and promote energy diversification.

Globally, international organizations such as the International Energy Agency (IEA) and the United Nations Framework Convention on Climate Change (UNFCCC) have recognized DME's role in achieving climate goals. This recognition has led to increased attention from policymakers worldwide, resulting in more favorable regulatory environments for DME development and deployment.

However, challenges remain in harmonizing DME policies across different jurisdictions. Inconsistencies in standards, regulations, and incentive structures can hinder the global scalability of DME technologies. Efforts are underway to establish international standards and best practices for DME production, distribution, and use, which could facilitate more coherent policy approaches in the future.

The European Union has also taken significant steps to support DME adoption. The Renewable Energy Directive (RED II) includes DME as a renewable transport fuel, setting targets for its use in the transportation sector. Additionally, several EU member states have implemented tax incentives and subsidies to encourage DME production and consumption, particularly in heavy-duty vehicles and industrial applications.

In Asia, China has emerged as a leader in DME policy support. The country's 14th Five-Year Plan (2021-2025) explicitly mentions DME as a key component in its strategy to reduce carbon emissions and enhance energy security. Chinese policymakers have introduced a series of measures, including production subsidies, research grants, and demonstration projects, to accelerate DME adoption across various sectors.

Japan and South Korea have also shown interest in DME as part of their energy transition strategies. Both countries have initiated research programs and pilot projects to explore DME's potential in power generation and transportation. These efforts are supported by policy frameworks that prioritize low-carbon alternatives and promote energy diversification.

Globally, international organizations such as the International Energy Agency (IEA) and the United Nations Framework Convention on Climate Change (UNFCCC) have recognized DME's role in achieving climate goals. This recognition has led to increased attention from policymakers worldwide, resulting in more favorable regulatory environments for DME development and deployment.

However, challenges remain in harmonizing DME policies across different jurisdictions. Inconsistencies in standards, regulations, and incentive structures can hinder the global scalability of DME technologies. Efforts are underway to establish international standards and best practices for DME production, distribution, and use, which could facilitate more coherent policy approaches in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!