How Dimethyl Ether Supports Energy Policy Enhancements?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Background and Objectives

Dimethyl ether (DME) has emerged as a promising alternative fuel with the potential to significantly enhance energy policies worldwide. The development of DME as an energy source dates back to the 1990s, when researchers began exploring its properties as a clean-burning, high-cetane fuel. Since then, DME has gained attention for its versatility and environmental benefits, positioning itself as a key player in the transition towards sustainable energy systems.

The evolution of DME technology has been driven by the growing need for cleaner energy sources and the imperative to reduce greenhouse gas emissions. As a synthetic fuel produced from various feedstocks, including natural gas, coal, and biomass, DME offers a pathway to diversify energy portfolios and reduce dependence on traditional fossil fuels. Its chemical properties make it an excellent substitute for diesel fuel in compression ignition engines, as well as a potential replacement for liquefied petroleum gas (LPG) in heating and cooking applications.

The primary objective of DME technology development is to establish a viable, large-scale production and distribution infrastructure that can support its widespread adoption. This involves optimizing production processes to improve efficiency and reduce costs, as well as developing compatible engine technologies and fuel systems. Additionally, researchers aim to expand the range of feedstocks used for DME production, with a particular focus on renewable sources to enhance its sustainability credentials.

Another critical goal is to demonstrate DME's potential in addressing key energy policy challenges. These include reducing air pollution in urban areas, mitigating climate change through lower carbon emissions, and enhancing energy security by diversifying fuel sources. By positioning DME as a multi-purpose fuel capable of serving various sectors, from transportation to power generation, policymakers and industry stakeholders seek to create a more resilient and flexible energy ecosystem.

The technological trajectory of DME is closely aligned with broader energy transition goals. As countries worldwide commit to ambitious carbon reduction targets, DME presents an opportunity to bridge the gap between current fossil fuel-dependent systems and future renewable energy landscapes. Its compatibility with existing infrastructure, coupled with its clean-burning properties, makes DME an attractive option for policymakers looking to implement incremental yet impactful changes to their energy policies.

Looking ahead, the DME sector aims to achieve greater market penetration by overcoming technical and economic barriers. This includes scaling up production facilities, refining distribution networks, and fostering collaboration between industry players, research institutions, and government bodies. By setting clear benchmarks for DME adoption and integration into national energy strategies, stakeholders hope to accelerate its development and deployment, ultimately contributing to a more sustainable and secure energy future.

The evolution of DME technology has been driven by the growing need for cleaner energy sources and the imperative to reduce greenhouse gas emissions. As a synthetic fuel produced from various feedstocks, including natural gas, coal, and biomass, DME offers a pathway to diversify energy portfolios and reduce dependence on traditional fossil fuels. Its chemical properties make it an excellent substitute for diesel fuel in compression ignition engines, as well as a potential replacement for liquefied petroleum gas (LPG) in heating and cooking applications.

The primary objective of DME technology development is to establish a viable, large-scale production and distribution infrastructure that can support its widespread adoption. This involves optimizing production processes to improve efficiency and reduce costs, as well as developing compatible engine technologies and fuel systems. Additionally, researchers aim to expand the range of feedstocks used for DME production, with a particular focus on renewable sources to enhance its sustainability credentials.

Another critical goal is to demonstrate DME's potential in addressing key energy policy challenges. These include reducing air pollution in urban areas, mitigating climate change through lower carbon emissions, and enhancing energy security by diversifying fuel sources. By positioning DME as a multi-purpose fuel capable of serving various sectors, from transportation to power generation, policymakers and industry stakeholders seek to create a more resilient and flexible energy ecosystem.

The technological trajectory of DME is closely aligned with broader energy transition goals. As countries worldwide commit to ambitious carbon reduction targets, DME presents an opportunity to bridge the gap between current fossil fuel-dependent systems and future renewable energy landscapes. Its compatibility with existing infrastructure, coupled with its clean-burning properties, makes DME an attractive option for policymakers looking to implement incremental yet impactful changes to their energy policies.

Looking ahead, the DME sector aims to achieve greater market penetration by overcoming technical and economic barriers. This includes scaling up production facilities, refining distribution networks, and fostering collaboration between industry players, research institutions, and government bodies. By setting clear benchmarks for DME adoption and integration into national energy strategies, stakeholders hope to accelerate its development and deployment, ultimately contributing to a more sustainable and secure energy future.

DME Market Analysis

The global dimethyl ether (DME) market has been experiencing significant growth in recent years, driven by increasing demand for clean and alternative fuels. DME, a colorless gas at ambient conditions, is gaining traction as a versatile energy carrier due to its potential to support energy policy enhancements across various sectors.

The market for DME is primarily segmented into two main applications: fuel and chemical feedstock. As a fuel, DME is increasingly being used as a substitute for diesel in transportation and as a cooking fuel in households. Its low emissions profile and high cetane number make it an attractive option for policymakers seeking to reduce greenhouse gas emissions and improve air quality in urban areas.

In the chemical industry, DME serves as a crucial intermediate in the production of various chemicals, including methyl acetate, dimethyl sulfate, and acetic acid. This diversification of applications has contributed to the steady growth of the DME market, with chemical manufacturers exploring new ways to incorporate DME into their production processes.

Geographically, the Asia-Pacific region dominates the DME market, with China leading in both production and consumption. The Chinese government's push for cleaner energy alternatives has been a significant driver for DME adoption, particularly in the transportation and domestic fuel sectors. Other key markets include Japan, South Korea, and several European countries, where stringent environmental regulations are fostering the transition to cleaner fuels.

The market dynamics of DME are closely tied to energy policy developments worldwide. As governments increasingly focus on reducing carbon emissions and promoting sustainable energy solutions, DME is positioned as a key player in the transition towards a cleaner energy mix. Its potential to be produced from various feedstocks, including natural gas, coal, and biomass, aligns well with the diversification strategies of many national energy policies.

However, the DME market faces challenges in terms of infrastructure development and competition from other alternative fuels. The lack of widespread distribution networks and the need for specialized handling equipment pose barriers to rapid market expansion. Additionally, the volatility of feedstock prices, particularly natural gas, can impact the economic viability of DME production and influence market growth rates.

Despite these challenges, the DME market is projected to continue its growth trajectory, supported by ongoing research and development efforts to improve production efficiency and expand applications. The increasing focus on circular economy principles and the potential for bio-based DME production are expected to open new avenues for market expansion, further solidifying DME's role in supporting energy policy enhancements globally.

The market for DME is primarily segmented into two main applications: fuel and chemical feedstock. As a fuel, DME is increasingly being used as a substitute for diesel in transportation and as a cooking fuel in households. Its low emissions profile and high cetane number make it an attractive option for policymakers seeking to reduce greenhouse gas emissions and improve air quality in urban areas.

In the chemical industry, DME serves as a crucial intermediate in the production of various chemicals, including methyl acetate, dimethyl sulfate, and acetic acid. This diversification of applications has contributed to the steady growth of the DME market, with chemical manufacturers exploring new ways to incorporate DME into their production processes.

Geographically, the Asia-Pacific region dominates the DME market, with China leading in both production and consumption. The Chinese government's push for cleaner energy alternatives has been a significant driver for DME adoption, particularly in the transportation and domestic fuel sectors. Other key markets include Japan, South Korea, and several European countries, where stringent environmental regulations are fostering the transition to cleaner fuels.

The market dynamics of DME are closely tied to energy policy developments worldwide. As governments increasingly focus on reducing carbon emissions and promoting sustainable energy solutions, DME is positioned as a key player in the transition towards a cleaner energy mix. Its potential to be produced from various feedstocks, including natural gas, coal, and biomass, aligns well with the diversification strategies of many national energy policies.

However, the DME market faces challenges in terms of infrastructure development and competition from other alternative fuels. The lack of widespread distribution networks and the need for specialized handling equipment pose barriers to rapid market expansion. Additionally, the volatility of feedstock prices, particularly natural gas, can impact the economic viability of DME production and influence market growth rates.

Despite these challenges, the DME market is projected to continue its growth trajectory, supported by ongoing research and development efforts to improve production efficiency and expand applications. The increasing focus on circular economy principles and the potential for bio-based DME production are expected to open new avenues for market expansion, further solidifying DME's role in supporting energy policy enhancements globally.

DME Technical Challenges

Despite the promising potential of dimethyl ether (DME) as a clean alternative fuel, several technical challenges hinder its widespread adoption and integration into energy policies. One of the primary obstacles is the production cost of DME, which remains higher than conventional fossil fuels. This economic barrier is largely due to the energy-intensive processes involved in DME synthesis, particularly when derived from renewable sources. Improving production efficiency and reducing costs are crucial for DME to become competitive in the energy market.

Another significant challenge lies in the infrastructure requirements for DME distribution and storage. Unlike traditional liquid fuels, DME is a gas at room temperature and atmospheric pressure, necessitating specialized handling and storage facilities. This presents logistical hurdles in terms of transportation, storage tanks, and fueling stations, all of which require substantial investments to establish a viable DME supply chain.

The compatibility of DME with existing engine technologies also poses a technical challenge. While DME can be used in modified diesel engines, widespread adoption would require significant adjustments to current engine designs and fuel systems. This includes addressing issues such as fuel injection systems, seals, and lubricants that are compatible with DME's unique properties. The automotive industry would need to invest heavily in research and development to optimize engines for DME use without compromising performance or durability.

Furthermore, the purity and quality control of DME production present ongoing challenges. Impurities in DME can lead to engine performance issues and increased emissions. Developing robust purification processes and establishing stringent quality standards are essential for ensuring the consistent quality of DME fuel across different production methods and feedstocks.

The environmental impact of DME production, particularly when derived from fossil fuels, remains a concern. While DME combustion produces lower emissions compared to conventional diesel, the overall life-cycle emissions depend heavily on the production pathway. Advancing technologies for carbon-neutral or carbon-negative DME production, such as utilizing renewable feedstocks or implementing carbon capture and utilization techniques, is crucial for maximizing DME's potential as a sustainable energy solution.

Lastly, the lack of comprehensive long-term studies on the health and environmental effects of DME emissions poses a challenge for policymakers. While initial studies suggest lower toxicity compared to diesel emissions, more extensive research is needed to fully understand the long-term impacts of DME use on air quality and public health. This knowledge gap creates uncertainty in policy formulation and may slow down the integration of DME into energy strategies.

Another significant challenge lies in the infrastructure requirements for DME distribution and storage. Unlike traditional liquid fuels, DME is a gas at room temperature and atmospheric pressure, necessitating specialized handling and storage facilities. This presents logistical hurdles in terms of transportation, storage tanks, and fueling stations, all of which require substantial investments to establish a viable DME supply chain.

The compatibility of DME with existing engine technologies also poses a technical challenge. While DME can be used in modified diesel engines, widespread adoption would require significant adjustments to current engine designs and fuel systems. This includes addressing issues such as fuel injection systems, seals, and lubricants that are compatible with DME's unique properties. The automotive industry would need to invest heavily in research and development to optimize engines for DME use without compromising performance or durability.

Furthermore, the purity and quality control of DME production present ongoing challenges. Impurities in DME can lead to engine performance issues and increased emissions. Developing robust purification processes and establishing stringent quality standards are essential for ensuring the consistent quality of DME fuel across different production methods and feedstocks.

The environmental impact of DME production, particularly when derived from fossil fuels, remains a concern. While DME combustion produces lower emissions compared to conventional diesel, the overall life-cycle emissions depend heavily on the production pathway. Advancing technologies for carbon-neutral or carbon-negative DME production, such as utilizing renewable feedstocks or implementing carbon capture and utilization techniques, is crucial for maximizing DME's potential as a sustainable energy solution.

Lastly, the lack of comprehensive long-term studies on the health and environmental effects of DME emissions poses a challenge for policymakers. While initial studies suggest lower toxicity compared to diesel emissions, more extensive research is needed to fully understand the long-term impacts of DME use on air quality and public health. This knowledge gap creates uncertainty in policy formulation and may slow down the integration of DME into energy strategies.

Current DME Solutions

01 Production of dimethyl ether

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.- Production of dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

- Catalysts for dimethyl ether synthesis: Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.

- Applications of dimethyl ether: Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as a potential alternative fuel for diesel engines due to its clean-burning properties and high cetane number.

- Purification and separation of dimethyl ether: Techniques for purifying and separating dimethyl ether from reaction mixtures or other compounds are crucial in the production process. These may include distillation, adsorption, and membrane separation methods to achieve high-purity dimethyl ether for various applications.

- Environmental and safety considerations: Research and development efforts focus on improving the environmental impact and safety aspects of dimethyl ether production and use. This includes developing more efficient production processes, reducing emissions, and ensuring safe handling and storage of the compound.

02 Catalysts for dimethyl ether synthesis

Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.Expand Specific Solutions03 Applications of dimethyl ether

Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as an alternative fuel for diesel engines and as a feedstock for chemical synthesis.Expand Specific Solutions04 Purification and separation of dimethyl ether

Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes often involve distillation, adsorption, or membrane separation techniques to achieve high-purity dimethyl ether.Expand Specific Solutions05 Environmental and safety considerations

Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and storage requirements to ensure safe and sustainable utilization of dimethyl ether.Expand Specific Solutions

Key DME Industry Players

The dimethyl ether (DME) market is in a growth phase, driven by increasing focus on clean energy alternatives. The global DME market size is projected to expand significantly, with estimates ranging from $8-10 billion by 2025. Technologically, DME production is relatively mature, but innovations continue in areas like catalysts and process efficiency. Key players advancing DME technology include China Petroleum & Chemical Corp., BASF, and Toshiba, who are developing improved production methods and applications. Universities like USC and Xi'an Jiaotong University are also contributing to R&D efforts. While DME faces competition from other alternative fuels, its versatility and clean-burning properties position it as a promising option for supporting energy policy goals related to emissions reduction and energy security.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced DME production technologies using coal and natural gas as feedstocks. Their process involves gasification, methanol synthesis, and DME synthesis. They have implemented large-scale DME production facilities with capacities exceeding 1 million tons per year[1]. Sinopec has also explored DME as a clean alternative fuel for vehicles and household cooking, conducting extensive field trials and demonstrations[2]. Their research focuses on improving DME production efficiency, reducing costs, and expanding its applications in the energy sector[3].

Strengths: Large-scale production capabilities, integrated value chain from feedstock to end-use applications. Weaknesses: Dependence on coal-based feedstock may face environmental challenges in the long term.

BASF Corp.

Technical Solution: BASF Corp. has developed innovative catalysts and process technologies for DME production. Their approach focuses on direct synthesis of DME from syngas, bypassing the methanol intermediate step. This one-step process improves overall efficiency and reduces production costs[4]. BASF has also explored the use of CO2 as a co-feedstock in DME synthesis, contributing to carbon utilization strategies[5]. Additionally, they have investigated DME as a hydrogen carrier for fuel cell applications, potentially supporting the transition to a hydrogen economy[6].

Strengths: Advanced catalyst technology, process integration expertise. Weaknesses: Limited direct involvement in large-scale DME production and distribution infrastructure.

DME Core Technologies

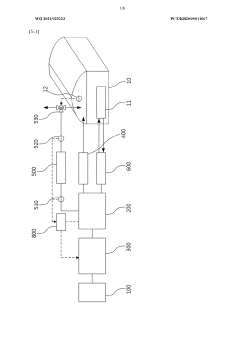

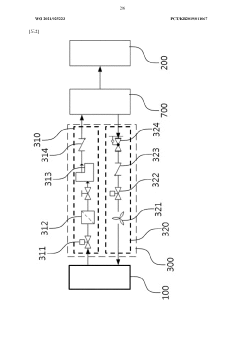

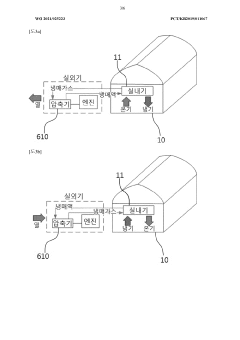

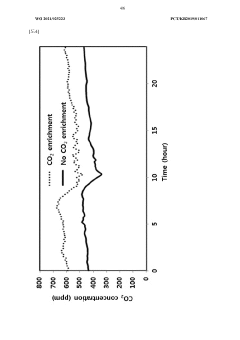

Trigeneration system using dme

PatentWO2021025223A1

Innovation

- A DME Trigen system that includes a DME tank, engine, fuel supply unit, processing unit for exhaust gases, power generation unit, and a cooling/heating unit, which uses DME as a clean fuel to produce electricity, control temperature, and supply carbon dioxide for increased photosynthesis, thereby enhancing fruit and vegetable growth.

Energy supply method and system

PatentWO2006004140A1

Innovation

- The introduction of Dimethyl Ether (DME) as a versatile energy circulation medium, which can be derived from biomass, waste, and petroleum residues, and used for power generation, transportation, and heating, allowing for efficient energy storage and distribution without relying on pipelines, and enabling the conversion of waste heat into usable energy.

DME Policy Framework

The DME policy framework plays a crucial role in supporting energy policy enhancements through the promotion and regulation of dimethyl ether (DME) as an alternative fuel. This framework encompasses a comprehensive set of guidelines, regulations, and incentives designed to facilitate the integration of DME into the existing energy landscape.

At its core, the DME policy framework addresses key aspects of production, distribution, and utilization. It establishes standards for DME quality and safety, ensuring consistency and reliability across the supply chain. These standards are essential for building consumer confidence and promoting widespread adoption of DME as a viable energy source.

The framework also outlines regulatory measures for DME production facilities, covering environmental impact assessments, emissions controls, and safety protocols. By setting clear guidelines, it enables manufacturers to operate within established parameters while minimizing potential risks to the environment and public health.

To encourage investment in DME infrastructure, the policy framework often includes financial incentives such as tax credits, grants, or subsidies for producers and distributors. These incentives aim to offset initial costs associated with developing DME production capabilities and establishing distribution networks, thereby accelerating market growth and accessibility.

The DME policy framework extends to end-user applications, particularly in the transportation and industrial sectors. It may include provisions for vehicle conversion programs, promoting the use of DME in heavy-duty trucks and buses. Additionally, it outlines regulations for DME use in power generation and heating systems, ensuring compliance with emissions standards and energy efficiency requirements.

Research and development initiatives are also addressed within the framework, with provisions for funding and collaboration between academic institutions, industry partners, and government agencies. This support for innovation helps drive technological advancements in DME production, storage, and utilization, further enhancing its viability as an alternative fuel source.

The framework incorporates mechanisms for monitoring and evaluating the impact of DME implementation on energy security, environmental sustainability, and economic growth. Regular assessments allow policymakers to refine and adapt the framework as needed, ensuring its continued effectiveness in supporting broader energy policy objectives.

By providing a comprehensive and adaptable structure for DME integration, the policy framework serves as a critical tool in enhancing energy policies. It facilitates the transition towards cleaner, more sustainable energy sources while addressing the complex challenges associated with energy security and environmental stewardship.

At its core, the DME policy framework addresses key aspects of production, distribution, and utilization. It establishes standards for DME quality and safety, ensuring consistency and reliability across the supply chain. These standards are essential for building consumer confidence and promoting widespread adoption of DME as a viable energy source.

The framework also outlines regulatory measures for DME production facilities, covering environmental impact assessments, emissions controls, and safety protocols. By setting clear guidelines, it enables manufacturers to operate within established parameters while minimizing potential risks to the environment and public health.

To encourage investment in DME infrastructure, the policy framework often includes financial incentives such as tax credits, grants, or subsidies for producers and distributors. These incentives aim to offset initial costs associated with developing DME production capabilities and establishing distribution networks, thereby accelerating market growth and accessibility.

The DME policy framework extends to end-user applications, particularly in the transportation and industrial sectors. It may include provisions for vehicle conversion programs, promoting the use of DME in heavy-duty trucks and buses. Additionally, it outlines regulations for DME use in power generation and heating systems, ensuring compliance with emissions standards and energy efficiency requirements.

Research and development initiatives are also addressed within the framework, with provisions for funding and collaboration between academic institutions, industry partners, and government agencies. This support for innovation helps drive technological advancements in DME production, storage, and utilization, further enhancing its viability as an alternative fuel source.

The framework incorporates mechanisms for monitoring and evaluating the impact of DME implementation on energy security, environmental sustainability, and economic growth. Regular assessments allow policymakers to refine and adapt the framework as needed, ensuring its continued effectiveness in supporting broader energy policy objectives.

By providing a comprehensive and adaptable structure for DME integration, the policy framework serves as a critical tool in enhancing energy policies. It facilitates the transition towards cleaner, more sustainable energy sources while addressing the complex challenges associated with energy security and environmental stewardship.

Environmental Impact of DME

Dimethyl ether (DME) has emerged as a promising alternative fuel with significant potential to support energy policy enhancements due to its favorable environmental characteristics. As a clean-burning, non-toxic fuel, DME offers several advantages in terms of reducing environmental impact compared to conventional fossil fuels.

One of the primary environmental benefits of DME is its low emissions profile. When used as a fuel in compression ignition engines, DME produces significantly lower levels of particulate matter, nitrogen oxides, and carbon monoxide compared to diesel fuel. This reduction in harmful emissions can contribute to improved air quality, particularly in urban areas where vehicle emissions are a major concern.

Furthermore, DME has a lower carbon footprint compared to many conventional fuels. It can be produced from a variety of feedstocks, including renewable sources such as biomass, which allows for the potential of carbon-neutral or even carbon-negative fuel production. This aligns well with energy policies aimed at reducing greenhouse gas emissions and combating climate change.

The use of DME as a fuel also presents opportunities for waste reduction and circular economy principles. For instance, DME can be produced from waste materials or by-products of other industrial processes, turning potential environmental liabilities into valuable energy resources. This approach not only reduces waste but also creates additional value streams, supporting sustainable resource management.

In terms of land use and ecosystem impact, DME production facilities generally have a smaller footprint compared to traditional oil refineries. This can lead to reduced land disturbance and habitat fragmentation, particularly when DME is produced from renewable feedstocks that do not require extensive agricultural expansion.

Water conservation is another area where DME can support environmental goals. The production process for DME typically requires less water compared to the refining of conventional petroleum fuels, potentially reducing strain on water resources in areas where water scarcity is a concern.

Additionally, DME's properties make it less harmful to soil and water ecosystems in the event of spills or leaks. Unlike petroleum-based fuels, DME is biodegradable and does not persist in the environment, minimizing long-term ecological damage from accidental releases.

The adoption of DME as a fuel can also indirectly support other environmental initiatives. For example, by providing a cleaner alternative for heavy-duty vehicles and industrial applications, DME can facilitate the transition away from more polluting fuels, supporting broader air quality improvement efforts and helping regions meet their environmental regulatory targets.

One of the primary environmental benefits of DME is its low emissions profile. When used as a fuel in compression ignition engines, DME produces significantly lower levels of particulate matter, nitrogen oxides, and carbon monoxide compared to diesel fuel. This reduction in harmful emissions can contribute to improved air quality, particularly in urban areas where vehicle emissions are a major concern.

Furthermore, DME has a lower carbon footprint compared to many conventional fuels. It can be produced from a variety of feedstocks, including renewable sources such as biomass, which allows for the potential of carbon-neutral or even carbon-negative fuel production. This aligns well with energy policies aimed at reducing greenhouse gas emissions and combating climate change.

The use of DME as a fuel also presents opportunities for waste reduction and circular economy principles. For instance, DME can be produced from waste materials or by-products of other industrial processes, turning potential environmental liabilities into valuable energy resources. This approach not only reduces waste but also creates additional value streams, supporting sustainable resource management.

In terms of land use and ecosystem impact, DME production facilities generally have a smaller footprint compared to traditional oil refineries. This can lead to reduced land disturbance and habitat fragmentation, particularly when DME is produced from renewable feedstocks that do not require extensive agricultural expansion.

Water conservation is another area where DME can support environmental goals. The production process for DME typically requires less water compared to the refining of conventional petroleum fuels, potentially reducing strain on water resources in areas where water scarcity is a concern.

Additionally, DME's properties make it less harmful to soil and water ecosystems in the event of spills or leaks. Unlike petroleum-based fuels, DME is biodegradable and does not persist in the environment, minimizing long-term ecological damage from accidental releases.

The adoption of DME as a fuel can also indirectly support other environmental initiatives. For example, by providing a cleaner alternative for heavy-duty vehicles and industrial applications, DME can facilitate the transition away from more polluting fuels, supporting broader air quality improvement efforts and helping regions meet their environmental regulatory targets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!