Evaluation Studies for Dimethyl Ether Fueling Infrastructure

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Fuel Background

Dimethyl ether (DME) has emerged as a promising alternative fuel for internal combustion engines, particularly in the transportation sector. This colorless, non-toxic gas is derived from various feedstocks, including natural gas, coal, and biomass, making it a versatile and potentially sustainable energy source. DME's chemical properties, such as its high cetane number and low auto-ignition temperature, make it particularly suitable for use in compression ignition engines.

The interest in DME as a fuel has grown significantly over the past few decades, driven by the need for cleaner-burning alternatives to conventional diesel fuel. DME produces lower emissions of particulate matter, nitrogen oxides, and carbon monoxide compared to diesel, aligning with increasingly stringent environmental regulations worldwide. Additionally, its production process can be designed to have a lower carbon footprint, especially when derived from renewable sources.

From a historical perspective, DME was first synthesized in the 19th century, but its potential as a fuel was not seriously explored until the late 20th century. Initial research focused on its use as a propellant and refrigerant. However, in the 1990s, several countries, notably Japan and Sweden, began investigating DME as a potential automotive fuel. This shift was primarily motivated by the desire to reduce dependence on petroleum-based fuels and to address growing environmental concerns.

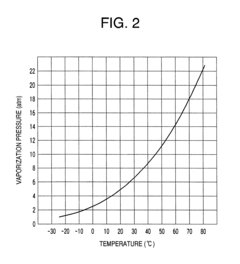

The physical properties of DME present both advantages and challenges for its use as a fuel. Its low boiling point (-25°C at atmospheric pressure) means it can be stored as a liquid under moderate pressure, similar to liquefied petroleum gas (LPG). This characteristic simplifies storage and distribution but requires specialized fuel systems different from those used for conventional liquid fuels.

In terms of energy content, DME has a lower volumetric energy density compared to diesel fuel, necessitating larger fuel tanks or more frequent refueling. However, its high cetane number (55-60) compensates for this drawback by enabling efficient combustion in diesel engines with minimal modifications. The clean-burning nature of DME also reduces the need for complex exhaust after-treatment systems, potentially simplifying engine design and maintenance.

The development of DME fueling infrastructure faces several technical and economic challenges. These include the need for specialized storage and handling equipment, the adaptation of existing distribution networks, and the establishment of production facilities capable of meeting potential demand. Despite these hurdles, several pilot projects and commercial-scale demonstrations have been conducted globally, providing valuable insights into the practical aspects of DME fuel implementation.

The interest in DME as a fuel has grown significantly over the past few decades, driven by the need for cleaner-burning alternatives to conventional diesel fuel. DME produces lower emissions of particulate matter, nitrogen oxides, and carbon monoxide compared to diesel, aligning with increasingly stringent environmental regulations worldwide. Additionally, its production process can be designed to have a lower carbon footprint, especially when derived from renewable sources.

From a historical perspective, DME was first synthesized in the 19th century, but its potential as a fuel was not seriously explored until the late 20th century. Initial research focused on its use as a propellant and refrigerant. However, in the 1990s, several countries, notably Japan and Sweden, began investigating DME as a potential automotive fuel. This shift was primarily motivated by the desire to reduce dependence on petroleum-based fuels and to address growing environmental concerns.

The physical properties of DME present both advantages and challenges for its use as a fuel. Its low boiling point (-25°C at atmospheric pressure) means it can be stored as a liquid under moderate pressure, similar to liquefied petroleum gas (LPG). This characteristic simplifies storage and distribution but requires specialized fuel systems different from those used for conventional liquid fuels.

In terms of energy content, DME has a lower volumetric energy density compared to diesel fuel, necessitating larger fuel tanks or more frequent refueling. However, its high cetane number (55-60) compensates for this drawback by enabling efficient combustion in diesel engines with minimal modifications. The clean-burning nature of DME also reduces the need for complex exhaust after-treatment systems, potentially simplifying engine design and maintenance.

The development of DME fueling infrastructure faces several technical and economic challenges. These include the need for specialized storage and handling equipment, the adaptation of existing distribution networks, and the establishment of production facilities capable of meeting potential demand. Despite these hurdles, several pilot projects and commercial-scale demonstrations have been conducted globally, providing valuable insights into the practical aspects of DME fuel implementation.

DME Market Analysis

The global market for dimethyl ether (DME) as a fuel is experiencing significant growth, driven by increasing environmental concerns and the search for cleaner alternative fuels. DME offers several advantages as a fuel, including its clean-burning properties, high cetane number, and potential to be produced from renewable sources. These factors contribute to its growing adoption in various sectors, particularly in transportation and power generation.

The market demand for DME is primarily concentrated in regions with stringent emissions regulations and a focus on reducing dependence on conventional fossil fuels. Asia-Pacific, particularly China, leads the market due to government initiatives promoting clean energy and the presence of established DME production facilities. Europe and North America are also emerging as key markets, with increasing investments in DME production and infrastructure development.

In the transportation sector, DME is gaining traction as a potential replacement for diesel fuel in heavy-duty vehicles. The automotive industry's shift towards cleaner alternatives has created opportunities for DME in truck and bus fleets. Additionally, the marine sector is exploring DME as a low-emission fuel option to comply with stricter maritime regulations.

The power generation sector represents another significant market for DME. As countries aim to reduce their carbon footprint, DME is being considered as a cleaner alternative to coal and oil in power plants. Its compatibility with existing infrastructure and lower emissions profile make it an attractive option for both centralized and distributed power generation systems.

The industrial sector, particularly in developing economies, is also contributing to the growth of the DME market. DME's use as a propellant, solvent, and refrigerant in various industrial applications is expanding its market potential beyond fuel applications.

However, the DME market faces challenges in terms of infrastructure development and competition from other alternative fuels. The lack of widespread fueling infrastructure remains a significant barrier to large-scale adoption. Investments in production facilities, storage, and distribution networks are crucial for market growth.

Despite these challenges, the DME market is projected to grow steadily in the coming years. Technological advancements in production processes, increasing awareness of environmental benefits, and supportive government policies are expected to drive market expansion. The development of bio-based DME production methods is likely to further enhance its appeal as a sustainable fuel option, potentially opening new market segments and applications.

The market demand for DME is primarily concentrated in regions with stringent emissions regulations and a focus on reducing dependence on conventional fossil fuels. Asia-Pacific, particularly China, leads the market due to government initiatives promoting clean energy and the presence of established DME production facilities. Europe and North America are also emerging as key markets, with increasing investments in DME production and infrastructure development.

In the transportation sector, DME is gaining traction as a potential replacement for diesel fuel in heavy-duty vehicles. The automotive industry's shift towards cleaner alternatives has created opportunities for DME in truck and bus fleets. Additionally, the marine sector is exploring DME as a low-emission fuel option to comply with stricter maritime regulations.

The power generation sector represents another significant market for DME. As countries aim to reduce their carbon footprint, DME is being considered as a cleaner alternative to coal and oil in power plants. Its compatibility with existing infrastructure and lower emissions profile make it an attractive option for both centralized and distributed power generation systems.

The industrial sector, particularly in developing economies, is also contributing to the growth of the DME market. DME's use as a propellant, solvent, and refrigerant in various industrial applications is expanding its market potential beyond fuel applications.

However, the DME market faces challenges in terms of infrastructure development and competition from other alternative fuels. The lack of widespread fueling infrastructure remains a significant barrier to large-scale adoption. Investments in production facilities, storage, and distribution networks are crucial for market growth.

Despite these challenges, the DME market is projected to grow steadily in the coming years. Technological advancements in production processes, increasing awareness of environmental benefits, and supportive government policies are expected to drive market expansion. The development of bio-based DME production methods is likely to further enhance its appeal as a sustainable fuel option, potentially opening new market segments and applications.

DME Infra Challenges

The implementation of dimethyl ether (DME) fueling infrastructure faces several significant challenges that need to be addressed for successful adoption. One of the primary obstacles is the lack of existing infrastructure specifically designed for DME distribution and storage. Unlike conventional fuels, DME requires specialized equipment and handling procedures, which necessitates substantial investments in new infrastructure development.

The physical properties of DME, particularly its low boiling point and high vapor pressure, pose unique challenges for storage and transportation. Conventional fuel tanks and pipelines are not suitable for DME, requiring the development and implementation of new storage solutions and transportation systems. This includes the need for pressurized tanks and modified fuel dispensing equipment at refueling stations.

Another critical challenge is the limited availability of DME production facilities. Currently, there are few large-scale DME production plants worldwide, which constrains the supply chain and makes it difficult to ensure a steady and reliable fuel supply. Expanding production capacity to meet potential demand requires significant capital investment and long-term planning.

The regulatory framework surrounding DME as a fuel is still evolving in many regions. The lack of standardized regulations and codes for DME handling, storage, and use creates uncertainty for infrastructure developers and potential investors. Establishing comprehensive safety standards and regulatory guidelines is essential for the widespread adoption of DME fueling infrastructure.

The economic viability of DME infrastructure development is another major concern. The high initial costs associated with building new production facilities, modifying existing infrastructure, and developing specialized equipment can be prohibitive. Without clear market demand and supportive policies, attracting investment for large-scale infrastructure projects remains challenging.

Technical expertise in DME handling and infrastructure management is currently limited. There is a need for specialized training programs and knowledge transfer to develop a workforce capable of safely operating and maintaining DME fueling systems. This skills gap could potentially slow down the implementation and expansion of DME infrastructure.

Compatibility issues with existing vehicle fleets also present a significant hurdle. While DME can be used in modified diesel engines, widespread adoption would require either extensive retrofitting of existing vehicles or the introduction of new DME-compatible vehicles. This chicken-and-egg problem between infrastructure development and vehicle availability needs to be carefully addressed to ensure successful market penetration.

The physical properties of DME, particularly its low boiling point and high vapor pressure, pose unique challenges for storage and transportation. Conventional fuel tanks and pipelines are not suitable for DME, requiring the development and implementation of new storage solutions and transportation systems. This includes the need for pressurized tanks and modified fuel dispensing equipment at refueling stations.

Another critical challenge is the limited availability of DME production facilities. Currently, there are few large-scale DME production plants worldwide, which constrains the supply chain and makes it difficult to ensure a steady and reliable fuel supply. Expanding production capacity to meet potential demand requires significant capital investment and long-term planning.

The regulatory framework surrounding DME as a fuel is still evolving in many regions. The lack of standardized regulations and codes for DME handling, storage, and use creates uncertainty for infrastructure developers and potential investors. Establishing comprehensive safety standards and regulatory guidelines is essential for the widespread adoption of DME fueling infrastructure.

The economic viability of DME infrastructure development is another major concern. The high initial costs associated with building new production facilities, modifying existing infrastructure, and developing specialized equipment can be prohibitive. Without clear market demand and supportive policies, attracting investment for large-scale infrastructure projects remains challenging.

Technical expertise in DME handling and infrastructure management is currently limited. There is a need for specialized training programs and knowledge transfer to develop a workforce capable of safely operating and maintaining DME fueling systems. This skills gap could potentially slow down the implementation and expansion of DME infrastructure.

Compatibility issues with existing vehicle fleets also present a significant hurdle. While DME can be used in modified diesel engines, widespread adoption would require either extensive retrofitting of existing vehicles or the introduction of new DME-compatible vehicles. This chicken-and-egg problem between infrastructure development and vehicle availability needs to be carefully addressed to ensure successful market penetration.

DME Fueling Solutions

01 Dimethyl ether production and storage systems

This category focuses on the development of systems for producing and storing dimethyl ether (DME) as a fuel. It includes methods for synthesizing DME from various feedstocks, as well as storage solutions that address the unique properties of DME. These systems are crucial for establishing a reliable DME fueling infrastructure.- Dimethyl ether production and storage systems: This category focuses on the production and storage systems for dimethyl ether (DME) as a fuel. It includes methods for synthesizing DME from various feedstocks, as well as storage solutions that address the unique properties of DME. These systems are crucial for establishing a reliable supply chain for DME fueling infrastructure.

- DME fuel dispensing and distribution: This point covers the equipment and methods used for dispensing and distributing DME as a fuel. It includes specialized fuel pumps, nozzles, and distribution systems designed to handle the specific properties of DME. These components are essential for creating a functional DME fueling infrastructure at retail and commercial levels.

- DME fuel blending and additives: This category addresses the formulation of DME fuel blends and the use of additives to enhance its performance. It includes methods for blending DME with other fuels to improve combustion characteristics, as well as additives that can address issues such as lubricity and corrosion. These innovations are important for optimizing DME as a fuel in various applications.

- DME fuel compatibility with existing infrastructure: This point focuses on adapting existing fuel infrastructure to accommodate DME. It includes modifications to storage tanks, pipelines, and fueling stations to ensure compatibility with DME's unique properties. These adaptations are crucial for integrating DME into the current fuel distribution network and facilitating its widespread adoption.

- Safety and environmental considerations for DME fueling: This category addresses the safety and environmental aspects of DME fueling infrastructure. It includes leak detection systems, safety protocols, and environmental impact assessments specific to DME. These considerations are essential for ensuring the safe and sustainable implementation of DME as an alternative fuel source.

02 DME fuel distribution and transportation

This point covers the methods and equipment used for distributing and transporting DME fuel. It includes specialized tankers, pipelines, and other logistics solutions designed to handle DME's specific characteristics. Efficient distribution systems are essential for making DME widely available as an alternative fuel.Expand Specific Solutions03 DME fueling stations and dispensing systems

This category encompasses the design and implementation of fueling stations and dispensing systems specifically for DME. It includes innovations in pump technology, safety measures, and user interfaces that allow for the safe and efficient refueling of DME-powered vehicles.Expand Specific Solutions04 DME fuel quality control and purification

This point focuses on methods and systems for ensuring the quality and purity of DME fuel throughout the supply chain. It includes purification techniques, contaminant removal processes, and quality control measures that are crucial for maintaining the performance and reliability of DME as a fuel.Expand Specific Solutions05 Integration of DME infrastructure with existing fuel systems

This category covers strategies and technologies for integrating DME fueling infrastructure with existing fuel distribution systems. It includes dual-fuel systems, conversion kits, and adaptable fueling stations that can accommodate both conventional fuels and DME, facilitating a smoother transition to DME as an alternative fuel.Expand Specific Solutions

DME Industry Players

The evaluation of dimethyl ether (DME) fueling infrastructure is in an early development stage, with a growing market driven by the need for cleaner alternative fuels. The global DME market size was valued at $5.2 billion in 2020 and is projected to reach $13.8 billion by 2030, indicating significant growth potential. The technology is still maturing, with key players like Ford Motor Co., Volvo Lastvagnar AB, and Isuzu Motors Ltd. investing in DME-powered vehicle development. Energy companies such as BP Corporation North America, Inc., China Petroleum & Chemical Corp., and Indian Oil Corp. Ltd. are exploring DME production and distribution. Research institutions like the University of Southern California and Xi'an Jiaotong University are contributing to advancing DME technology, focusing on improving efficiency and reducing costs.

BP Corporation North America, Inc.

Technical Solution: BP has been actively involved in dimethyl ether (DME) fueling infrastructure research and development. They have developed a proprietary DME production process that converts natural gas or other hydrocarbon feedstocks into DME[1]. This process involves syngas production, methanol synthesis, and methanol dehydration to produce high-purity DME. BP has also conducted extensive studies on DME storage, transportation, and dispensing systems, focusing on optimizing the infrastructure for commercial-scale DME fuel distribution[2]. Their research includes the development of specialized DME fuel tanks, pumps, and dispensing nozzles that can handle the unique properties of DME, such as its low viscosity and tendency to vaporize at room temperature[3].

Strengths: Extensive experience in fuel production and distribution, global reach for potential DME infrastructure implementation. Weaknesses: Potential conflict with existing petroleum-based fuel infrastructure investments.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been at the forefront of DME fueling infrastructure evaluation and development in China. They have conducted comprehensive studies on DME production from coal and natural gas, focusing on large-scale synthesis processes[4]. Sinopec has also invested in pilot projects for DME fueling stations, evaluating various storage and dispensing technologies suitable for the Chinese market[5]. Their research includes the assessment of DME as a substitute for liquefied petroleum gas (LPG) in household and industrial applications, as well as its potential as a diesel replacement in the transportation sector[6]. Sinopec has developed specialized DME handling equipment and has been working on standardizing DME fuel specifications to facilitate wider adoption.

Strengths: Strong government support, extensive domestic market for potential DME implementation. Weaknesses: Limited international experience in DME infrastructure development.

DME Infra Innovations

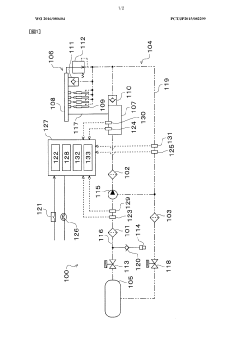

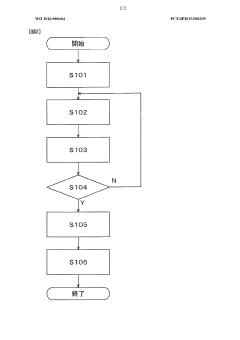

Dimethyl ether automobile fuel supply device

PatentWO2016080404A1

Innovation

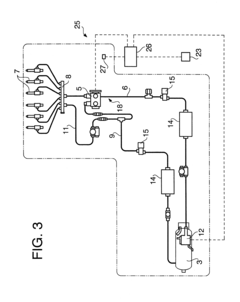

- A dimethyl ether automotive fuel supply system that includes a fuel circulation switch, pressure sensors, a fuel circulation lamp, and a specified pressure changing unit, which allows the driver to verify the completion of dimethyl ether circulation by monitoring pressure and temperature, and includes a starter start prohibition unit to prevent engine starting during circulation.

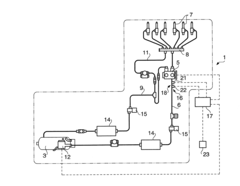

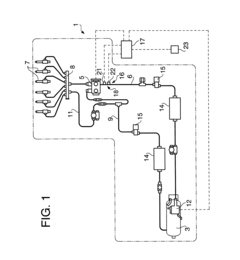

Fuel supply system for dimethyl ether engine

PatentInactiveUS6742479B2

Innovation

- A fuel supply system that includes a dimethyl ether detecting device and electronic control unit to ensure the high-pressure fuel pump is driven only when dimethyl ether is in a liquid state, using a combination of temperature and pressure sensors to determine the state and activate the pumps accordingly.

DME Safety Standards

Safety standards for dimethyl ether (DME) fueling infrastructure are crucial for ensuring the safe handling, storage, and distribution of this alternative fuel. The development of comprehensive safety standards requires a thorough understanding of DME's properties and potential hazards.

DME is a colorless, odorless gas at ambient temperature and pressure, with a boiling point of -25°C. It is typically stored and transported as a liquefied gas under moderate pressure. The primary safety concerns associated with DME include its flammability, potential for rapid vaporization, and asphyxiation risk in confined spaces.

Existing safety standards for liquefied petroleum gas (LPG) and compressed natural gas (CNG) serve as a foundation for DME safety protocols. However, specific standards tailored to DME's unique properties are necessary. These standards must address various aspects of the fueling infrastructure, including storage tanks, piping systems, dispensing equipment, and emergency response procedures.

Key components of DME safety standards include proper material selection for storage and handling equipment, as DME can degrade certain elastomers and plastics. Corrosion-resistant materials such as stainless steel are recommended for DME-compatible components. Adequate ventilation systems are essential to prevent the accumulation of DME vapors in enclosed spaces.

Leak detection and mitigation strategies form a critical part of DME safety standards. Regular inspections, maintenance procedures, and the use of appropriate sensors and alarms are necessary to identify and address potential leaks promptly. Emergency shutdown systems and pressure relief devices must be incorporated into the fueling infrastructure design to prevent overpressurization and minimize the risk of accidents.

Personal protective equipment (PPE) requirements for workers handling DME should be clearly defined in the safety standards. This includes appropriate gloves, eye protection, and respiratory equipment when necessary. Training programs for personnel involved in DME fueling operations are essential to ensure proper understanding of safety protocols and emergency procedures.

Fire safety measures are particularly important due to DME's flammability. Standards should specify appropriate fire suppression systems, the use of flame-resistant materials in fueling areas, and the establishment of safety zones around DME storage and dispensing equipment. Electrical equipment in DME fueling areas must be explosion-proof to prevent potential ignition sources.

As the adoption of DME as an alternative fuel grows, ongoing research and collaboration between industry stakeholders, regulatory bodies, and safety experts will be crucial for refining and updating safety standards. This continuous improvement process will help ensure that DME fueling infrastructure remains safe and reliable as technology and best practices evolve.

DME is a colorless, odorless gas at ambient temperature and pressure, with a boiling point of -25°C. It is typically stored and transported as a liquefied gas under moderate pressure. The primary safety concerns associated with DME include its flammability, potential for rapid vaporization, and asphyxiation risk in confined spaces.

Existing safety standards for liquefied petroleum gas (LPG) and compressed natural gas (CNG) serve as a foundation for DME safety protocols. However, specific standards tailored to DME's unique properties are necessary. These standards must address various aspects of the fueling infrastructure, including storage tanks, piping systems, dispensing equipment, and emergency response procedures.

Key components of DME safety standards include proper material selection for storage and handling equipment, as DME can degrade certain elastomers and plastics. Corrosion-resistant materials such as stainless steel are recommended for DME-compatible components. Adequate ventilation systems are essential to prevent the accumulation of DME vapors in enclosed spaces.

Leak detection and mitigation strategies form a critical part of DME safety standards. Regular inspections, maintenance procedures, and the use of appropriate sensors and alarms are necessary to identify and address potential leaks promptly. Emergency shutdown systems and pressure relief devices must be incorporated into the fueling infrastructure design to prevent overpressurization and minimize the risk of accidents.

Personal protective equipment (PPE) requirements for workers handling DME should be clearly defined in the safety standards. This includes appropriate gloves, eye protection, and respiratory equipment when necessary. Training programs for personnel involved in DME fueling operations are essential to ensure proper understanding of safety protocols and emergency procedures.

Fire safety measures are particularly important due to DME's flammability. Standards should specify appropriate fire suppression systems, the use of flame-resistant materials in fueling areas, and the establishment of safety zones around DME storage and dispensing equipment. Electrical equipment in DME fueling areas must be explosion-proof to prevent potential ignition sources.

As the adoption of DME as an alternative fuel grows, ongoing research and collaboration between industry stakeholders, regulatory bodies, and safety experts will be crucial for refining and updating safety standards. This continuous improvement process will help ensure that DME fueling infrastructure remains safe and reliable as technology and best practices evolve.

DME Environmental Impact

The environmental impact of dimethyl ether (DME) as a fuel is a critical consideration in the evaluation of DME fueling infrastructure. DME offers several environmental advantages compared to conventional fossil fuels, particularly in terms of reduced emissions and improved air quality.

One of the primary environmental benefits of DME is its potential to significantly reduce greenhouse gas emissions. When produced from renewable sources such as biomass or waste materials, DME can achieve near-zero or even negative carbon footprints. This characteristic makes it an attractive option for countries and industries seeking to meet ambitious climate change mitigation targets.

In terms of air quality, DME combustion produces virtually no particulate matter and very low levels of nitrogen oxides (NOx) and sulfur oxides (SOx). This is particularly important in urban areas where air pollution from transportation is a major health concern. The use of DME in heavy-duty vehicles and industrial applications could lead to substantial improvements in local air quality.

DME also presents advantages in terms of soil and water contamination risks. Unlike conventional diesel fuel, DME evaporates quickly if spilled, reducing the risk of soil and groundwater pollution. This property simplifies the handling and storage requirements for DME fueling infrastructure, potentially lowering environmental risks associated with fuel transportation and distribution.

However, the environmental impact of DME is not without challenges. The production process, particularly when derived from fossil fuels, can still contribute to greenhouse gas emissions. Additionally, the large-scale production of DME from biomass raises concerns about land use changes and potential competition with food crops.

The lifecycle assessment of DME's environmental impact must also consider the energy efficiency of its production and use. While DME can be produced from a variety of feedstocks, the overall energy balance and efficiency of the production process can vary significantly, affecting its net environmental benefit.

In the context of fueling infrastructure, the environmental impact of DME extends to the construction and operation of storage and distribution facilities. The compatibility of DME with existing infrastructure and the potential need for new, specialized equipment may have implications for resource use and environmental footprint.

One of the primary environmental benefits of DME is its potential to significantly reduce greenhouse gas emissions. When produced from renewable sources such as biomass or waste materials, DME can achieve near-zero or even negative carbon footprints. This characteristic makes it an attractive option for countries and industries seeking to meet ambitious climate change mitigation targets.

In terms of air quality, DME combustion produces virtually no particulate matter and very low levels of nitrogen oxides (NOx) and sulfur oxides (SOx). This is particularly important in urban areas where air pollution from transportation is a major health concern. The use of DME in heavy-duty vehicles and industrial applications could lead to substantial improvements in local air quality.

DME also presents advantages in terms of soil and water contamination risks. Unlike conventional diesel fuel, DME evaporates quickly if spilled, reducing the risk of soil and groundwater pollution. This property simplifies the handling and storage requirements for DME fueling infrastructure, potentially lowering environmental risks associated with fuel transportation and distribution.

However, the environmental impact of DME is not without challenges. The production process, particularly when derived from fossil fuels, can still contribute to greenhouse gas emissions. Additionally, the large-scale production of DME from biomass raises concerns about land use changes and potential competition with food crops.

The lifecycle assessment of DME's environmental impact must also consider the energy efficiency of its production and use. While DME can be produced from a variety of feedstocks, the overall energy balance and efficiency of the production process can vary significantly, affecting its net environmental benefit.

In the context of fueling infrastructure, the environmental impact of DME extends to the construction and operation of storage and distribution facilities. The compatibility of DME with existing infrastructure and the potential need for new, specialized equipment may have implications for resource use and environmental footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!