How Dimethyl Ether Simplifies Overarching Fuel Management?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Fuel Evolution

The evolution of Dimethyl Ether (DME) as a fuel has been marked by significant technological advancements and growing recognition of its potential to simplify fuel management across various sectors. Initially developed as a propellant for aerosol products, DME's journey as an alternative fuel began in the late 20th century when researchers identified its promising characteristics for combustion engines.

In the 1990s, the first major breakthrough came with the successful demonstration of DME as a diesel substitute in compression ignition engines. This milestone sparked interest from automotive manufacturers and energy companies, leading to increased research and development efforts. The early 2000s saw the establishment of pilot plants for DME production, primarily using methanol as a feedstock.

As environmental concerns grew, DME gained attention for its clean-burning properties. Unlike conventional diesel, DME produces virtually no particulate matter and significantly lower NOx emissions. This characteristic aligned well with increasingly stringent emission regulations, particularly in Europe and North America. Consequently, the mid-2000s witnessed a surge in DME-related patents and publications, focusing on production methods, engine modifications, and fuel handling systems.

The late 2000s and early 2010s marked a period of commercial scale-up and real-world testing. Several countries, including Sweden, Japan, and China, initiated DME fuel trials in heavy-duty vehicles and power generation. These trials provided valuable data on DME's performance, efficiency, and long-term effects on engine components, further refining the technology.

A significant shift occurred in the mid-2010s with the development of advanced production techniques. The emergence of bio-based DME production methods, utilizing renewable feedstocks such as biomass and waste, addressed sustainability concerns and positioned DME as a potential carbon-neutral fuel option. This development expanded DME's appeal beyond traditional transportation sectors to include renewable energy storage and grid balancing applications.

Recent years have seen a focus on integrating DME into existing fuel infrastructure. Innovations in fuel blending, storage, and distribution systems have aimed to minimize the need for extensive modifications to current fuel management practices. This approach has been crucial in addressing one of the main challenges in DME adoption: the requirement for dedicated infrastructure.

The latest phase in DME's evolution involves its role in the broader context of energy transition. As countries and industries seek to decarbonize, DME is being explored as part of a diversified fuel portfolio, complementing other alternative fuels and energy storage solutions. This has led to increased collaboration between energy companies, automotive manufacturers, and policymakers to create roadmaps for DME integration into future energy systems.

In the 1990s, the first major breakthrough came with the successful demonstration of DME as a diesel substitute in compression ignition engines. This milestone sparked interest from automotive manufacturers and energy companies, leading to increased research and development efforts. The early 2000s saw the establishment of pilot plants for DME production, primarily using methanol as a feedstock.

As environmental concerns grew, DME gained attention for its clean-burning properties. Unlike conventional diesel, DME produces virtually no particulate matter and significantly lower NOx emissions. This characteristic aligned well with increasingly stringent emission regulations, particularly in Europe and North America. Consequently, the mid-2000s witnessed a surge in DME-related patents and publications, focusing on production methods, engine modifications, and fuel handling systems.

The late 2000s and early 2010s marked a period of commercial scale-up and real-world testing. Several countries, including Sweden, Japan, and China, initiated DME fuel trials in heavy-duty vehicles and power generation. These trials provided valuable data on DME's performance, efficiency, and long-term effects on engine components, further refining the technology.

A significant shift occurred in the mid-2010s with the development of advanced production techniques. The emergence of bio-based DME production methods, utilizing renewable feedstocks such as biomass and waste, addressed sustainability concerns and positioned DME as a potential carbon-neutral fuel option. This development expanded DME's appeal beyond traditional transportation sectors to include renewable energy storage and grid balancing applications.

Recent years have seen a focus on integrating DME into existing fuel infrastructure. Innovations in fuel blending, storage, and distribution systems have aimed to minimize the need for extensive modifications to current fuel management practices. This approach has been crucial in addressing one of the main challenges in DME adoption: the requirement for dedicated infrastructure.

The latest phase in DME's evolution involves its role in the broader context of energy transition. As countries and industries seek to decarbonize, DME is being explored as part of a diversified fuel portfolio, complementing other alternative fuels and energy storage solutions. This has led to increased collaboration between energy companies, automotive manufacturers, and policymakers to create roadmaps for DME integration into future energy systems.

DME Market Analysis

The global dimethyl ether (DME) market has been experiencing significant growth in recent years, driven by the increasing demand for clean and efficient alternative fuels. DME, with its favorable combustion properties and potential to simplify fuel management, has garnered attention across various industries, particularly in the energy and transportation sectors.

The market for DME is primarily segmented into two main applications: fuel and aerosol propellant. As a fuel, DME offers several advantages over conventional diesel, including lower emissions of particulate matter, nitrogen oxides, and carbon monoxide. This has led to its adoption in heavy-duty vehicles, power generation, and domestic cooking applications, especially in regions with stringent environmental regulations.

In terms of regional distribution, Asia-Pacific dominates the DME market, with China being the largest producer and consumer. The region's rapid industrialization, coupled with government initiatives to reduce air pollution, has been a key driver for DME adoption. Europe and North America are also witnessing growing interest in DME as a renewable fuel option, particularly in the transportation sector.

The market dynamics are further influenced by the increasing focus on energy security and the transition towards low-carbon economies. DME's potential as a hydrogen carrier and its compatibility with existing LPG infrastructure have positioned it as a versatile solution in the evolving energy landscape.

From a supply perspective, the DME market is characterized by a mix of established chemical companies and emerging specialized producers. The production methods for DME have been evolving, with traditional coal-based production being complemented by more sustainable routes using natural gas, biomass, and even carbon capture technologies.

Despite the positive growth trajectory, the DME market faces challenges such as the need for dedicated infrastructure development and competition from other alternative fuels. However, ongoing research and development efforts are addressing these hurdles, focusing on improving production efficiencies and expanding end-use applications.

Looking ahead, the DME market is projected to continue its growth trend, driven by increasing environmental concerns, supportive government policies, and technological advancements in production and utilization. The simplification of fuel management through DME adoption is expected to play a crucial role in shaping the future energy mix, particularly in sectors seeking to reduce their carbon footprint while maintaining operational efficiency.

The market for DME is primarily segmented into two main applications: fuel and aerosol propellant. As a fuel, DME offers several advantages over conventional diesel, including lower emissions of particulate matter, nitrogen oxides, and carbon monoxide. This has led to its adoption in heavy-duty vehicles, power generation, and domestic cooking applications, especially in regions with stringent environmental regulations.

In terms of regional distribution, Asia-Pacific dominates the DME market, with China being the largest producer and consumer. The region's rapid industrialization, coupled with government initiatives to reduce air pollution, has been a key driver for DME adoption. Europe and North America are also witnessing growing interest in DME as a renewable fuel option, particularly in the transportation sector.

The market dynamics are further influenced by the increasing focus on energy security and the transition towards low-carbon economies. DME's potential as a hydrogen carrier and its compatibility with existing LPG infrastructure have positioned it as a versatile solution in the evolving energy landscape.

From a supply perspective, the DME market is characterized by a mix of established chemical companies and emerging specialized producers. The production methods for DME have been evolving, with traditional coal-based production being complemented by more sustainable routes using natural gas, biomass, and even carbon capture technologies.

Despite the positive growth trajectory, the DME market faces challenges such as the need for dedicated infrastructure development and competition from other alternative fuels. However, ongoing research and development efforts are addressing these hurdles, focusing on improving production efficiencies and expanding end-use applications.

Looking ahead, the DME market is projected to continue its growth trend, driven by increasing environmental concerns, supportive government policies, and technological advancements in production and utilization. The simplification of fuel management through DME adoption is expected to play a crucial role in shaping the future energy mix, particularly in sectors seeking to reduce their carbon footprint while maintaining operational efficiency.

DME Tech Challenges

The adoption of dimethyl ether (DME) as a fuel presents several technical challenges that need to be addressed for its widespread implementation. One of the primary obstacles is the low viscosity and lubricity of DME, which can lead to increased wear and tear on engine components, particularly fuel injection systems. This issue necessitates the development of specialized materials and coatings for fuel system components to ensure longevity and reliability.

Another significant challenge lies in the storage and distribution infrastructure for DME. Its low boiling point and high vapor pressure require pressurized storage and handling systems, similar to those used for liquefied petroleum gas (LPG). This necessitates modifications to existing fuel storage and transportation networks, as well as the development of new safety protocols and equipment for handling DME.

The energy density of DME is lower than that of conventional diesel fuel, which impacts vehicle range and fuel tank design. Engineers must optimize engine performance and fuel system design to compensate for this difference, potentially requiring larger fuel tanks or more frequent refueling stops. This challenge extends to the development of efficient and compact on-board storage solutions for DME-powered vehicles.

Compatibility with existing engine technologies poses another hurdle. While DME can be used in modified diesel engines, significant adaptations are required to accommodate its unique combustion characteristics. These modifications include changes to fuel injection systems, compression ratios, and engine control units. The development of purpose-built DME engines that fully exploit the fuel's properties is an ongoing area of research and development.

Environmental considerations also present challenges. Although DME combustion produces lower emissions of particulate matter and nitrogen oxides compared to diesel, there are concerns about potential increases in formaldehyde emissions. Addressing this issue requires advanced catalytic converter technologies and engine combustion optimization to minimize harmful emissions while maintaining performance.

The production of DME at scale presents its own set of technical challenges. Current production methods, primarily through methanol dehydration or direct synthesis from syngas, need to be optimized for efficiency and cost-effectiveness. Developing more sustainable production pathways, such as using renewable feedstocks or capturing and utilizing CO2, is crucial for enhancing DME's environmental credentials.

Lastly, the integration of DME into existing fuel management systems and logistics chains poses significant challenges. This includes developing accurate metering systems for DME, which behaves differently from conventional liquid fuels, and creating standardized quality control measures to ensure consistent fuel properties across different production sources and distribution networks.

Another significant challenge lies in the storage and distribution infrastructure for DME. Its low boiling point and high vapor pressure require pressurized storage and handling systems, similar to those used for liquefied petroleum gas (LPG). This necessitates modifications to existing fuel storage and transportation networks, as well as the development of new safety protocols and equipment for handling DME.

The energy density of DME is lower than that of conventional diesel fuel, which impacts vehicle range and fuel tank design. Engineers must optimize engine performance and fuel system design to compensate for this difference, potentially requiring larger fuel tanks or more frequent refueling stops. This challenge extends to the development of efficient and compact on-board storage solutions for DME-powered vehicles.

Compatibility with existing engine technologies poses another hurdle. While DME can be used in modified diesel engines, significant adaptations are required to accommodate its unique combustion characteristics. These modifications include changes to fuel injection systems, compression ratios, and engine control units. The development of purpose-built DME engines that fully exploit the fuel's properties is an ongoing area of research and development.

Environmental considerations also present challenges. Although DME combustion produces lower emissions of particulate matter and nitrogen oxides compared to diesel, there are concerns about potential increases in formaldehyde emissions. Addressing this issue requires advanced catalytic converter technologies and engine combustion optimization to minimize harmful emissions while maintaining performance.

The production of DME at scale presents its own set of technical challenges. Current production methods, primarily through methanol dehydration or direct synthesis from syngas, need to be optimized for efficiency and cost-effectiveness. Developing more sustainable production pathways, such as using renewable feedstocks or capturing and utilizing CO2, is crucial for enhancing DME's environmental credentials.

Lastly, the integration of DME into existing fuel management systems and logistics chains poses significant challenges. This includes developing accurate metering systems for DME, which behaves differently from conventional liquid fuels, and creating standardized quality control measures to ensure consistent fuel properties across different production sources and distribution networks.

DME Fuel Solutions

01 Dimethyl ether production methods

Various methods for producing dimethyl ether (DME) are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of biomass. These processes aim to improve efficiency and yield in DME production for use as a fuel.- Dimethyl ether production methods: Various methods for producing dimethyl ether (DME) are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of biomass. These processes aim to improve efficiency and yield in DME production for use as a fuel.

- Fuel system design for DME: Specialized fuel systems are developed to handle the unique properties of DME as a fuel. These systems include modified injectors, fuel pumps, and storage tanks to accommodate DME's low viscosity and high vapor pressure, ensuring efficient fuel delivery and engine performance.

- DME blending and additives: Research focuses on blending DME with other fuels or incorporating additives to enhance its performance and compatibility with existing engines. This includes improving lubricity, reducing emissions, and optimizing combustion characteristics of DME-based fuels.

- DME storage and transportation: Innovations in DME storage and transportation address the challenges posed by its physical properties. This includes the development of specialized containers, handling procedures, and infrastructure to ensure safe and efficient distribution of DME as a fuel.

- Catalysts for DME synthesis and utilization: Advanced catalysts are developed to improve the efficiency of DME production and its use as a fuel. These catalysts aim to enhance conversion rates, selectivity, and stability in DME synthesis processes and engine combustion.

02 Fuel systems and engine modifications for DME

Specialized fuel systems and engine modifications are developed to accommodate the unique properties of DME as a fuel. These include adaptations to fuel injection systems, storage tanks, and combustion chambers to optimize performance and efficiency when using DME in internal combustion engines.Expand Specific Solutions03 DME fuel blends and additives

Research into DME fuel blends and additives focuses on improving fuel properties and performance. This includes mixing DME with other fuels or adding compounds to enhance combustion characteristics, reduce emissions, or improve storage stability.Expand Specific Solutions04 DME storage and transportation

Developing safe and efficient methods for storing and transporting DME is crucial for its widespread adoption as a fuel. This includes designing specialized containers, handling equipment, and distribution systems that account for DME's physical properties and safety requirements.Expand Specific Solutions05 Catalysts for DME-related processes

Advanced catalysts play a key role in DME production and utilization. Research focuses on developing and optimizing catalysts for various processes, including DME synthesis, reforming, and combustion, to improve efficiency and reduce environmental impact.Expand Specific Solutions

DME Industry Players

The dimethyl ether (DME) fuel management landscape is evolving rapidly, with significant potential for market growth and technological advancement. The industry is in an early growth stage, characterized by increasing research and development efforts across academia and industry. Key players like China Petroleum & Chemical Corp., Ford Motor Co., and Volvo Lastvagnar AB are driving innovation in DME fuel systems. The market size is expanding, particularly in regions prioritizing clean energy alternatives. While DME technology is not yet fully mature, collaborations between universities (e.g., University of Southern California, Xi'an Jiaotong University) and corporations are accelerating progress towards commercial viability. The involvement of major energy and automotive companies signals growing confidence in DME's potential to simplify fuel management and reduce emissions.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive dimethyl ether (DME) production and utilization system. Their approach involves producing DME from coal and natural gas through gasification and methanol synthesis[1]. They have implemented large-scale DME production facilities with capacities exceeding 1 million tons per year[2]. Sinopec has also developed DME blending technologies for use in liquefied petroleum gas (LPG) and diesel fuel applications. Their research focuses on optimizing DME production efficiency, reducing carbon emissions, and enhancing the fuel properties of DME blends for various engine types[3].

Strengths: Extensive experience in large-scale DME production and integration with existing fuel infrastructure. Weaknesses: Potential challenges in transitioning from fossil fuel-based DME production to more sustainable feedstocks.

Isuzu Motors Ltd.

Technical Solution: Isuzu Motors has been at the forefront of DME engine technology development. They have successfully designed and tested DME-powered engines for commercial vehicles, focusing on heavy-duty trucks and buses. Isuzu's approach involves modifying existing diesel engines to run on DME, which requires changes to the fuel injection system, fuel tanks, and engine control units[4]. Their DME engines have demonstrated reduced emissions, particularly in terms of particulate matter and NOx, compared to conventional diesel engines. Isuzu has also conducted extensive field trials of DME vehicles in various operating conditions to validate the technology's reliability and performance[5].

Strengths: Proven expertise in adapting commercial vehicle engines to DME fuel, with real-world testing experience. Weaknesses: Limited by the availability of widespread DME fueling infrastructure.

DME Key Innovations

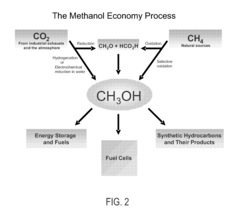

Conversion of carbon dioxide to methanol and/or dimethyl ether using bi-reforming of methane or natural gas

PatentActiveUS7906559B2

Innovation

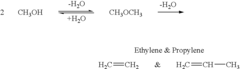

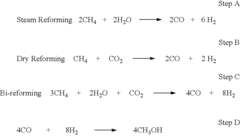

- A bi-reforming process combining steam and dry reforming of methane to achieve a specific CO/H2 molar ratio of 1:2, allowing for the efficient conversion of carbon dioxide and methane to methanol and dimethyl ether without producing CO2 or other by-products, using a catalyst such as V2O5 and NiO on a silica carrier.

Conversion of carbon dioxide to dimethyl ether using bi-reforming of methane or natural gas

PatentActiveUS8133926B2

Innovation

- The BI-REFORMING™ process combines steam and dry reforming of methane to produce a mixture of hydrogen and carbon monoxide with a 2:1 molar ratio, allowing for the conversion to methanol and dimethyl ether without releasing CO2 into the atmosphere and without using external hydrogen, using catalysts like Nafion-H for dehydration and recycling water to form dimethyl ether.

DME Environmental Impact

Dimethyl ether (DME) has emerged as a promising alternative fuel with significant environmental benefits compared to conventional fossil fuels. Its production and use offer several advantages in terms of reducing greenhouse gas emissions and improving air quality.

DME combustion produces lower levels of particulate matter, nitrogen oxides, and sulfur oxides compared to diesel fuel. This characteristic makes DME an attractive option for reducing urban air pollution, particularly in densely populated areas where vehicle emissions are a major concern. The reduction in these harmful pollutants can lead to improved public health outcomes and decreased environmental degradation.

From a lifecycle perspective, DME derived from renewable sources such as biomass or waste materials can achieve substantial reductions in carbon dioxide emissions. Studies have shown that the use of bio-based DME can result in greenhouse gas emission reductions of up to 95% compared to conventional diesel fuel. This significant reduction in carbon footprint aligns with global efforts to mitigate climate change and transition towards a low-carbon economy.

The production of DME also offers environmental benefits in terms of resource efficiency. DME can be synthesized from a variety of feedstocks, including natural gas, coal, and biomass. This flexibility allows for the utilization of locally available resources, potentially reducing the environmental impact associated with long-distance transportation of fuel feedstocks.

Furthermore, DME's physical properties contribute to its environmental advantages. As a gas at ambient conditions, DME vaporizes quickly if spilled, reducing the risk of soil and water contamination compared to liquid fuels. This characteristic simplifies fuel handling and storage procedures, potentially lowering the environmental risks associated with fuel management infrastructure.

In the context of fuel management, DME's environmental impact extends to the simplification of distribution systems. Its compatibility with existing LPG infrastructure means that the transition to DME can be achieved with minimal modifications to current fuel distribution networks. This reduces the need for extensive new infrastructure development, which can have significant environmental impacts in terms of land use and resource consumption.

However, it is important to note that the full environmental impact of DME depends on its production pathway. While DME derived from renewable sources offers the greatest environmental benefits, DME produced from fossil fuels may have a more limited positive impact. As such, the development of sustainable production methods and the expansion of renewable feedstock sources are crucial for maximizing the environmental advantages of DME as an alternative fuel.

DME combustion produces lower levels of particulate matter, nitrogen oxides, and sulfur oxides compared to diesel fuel. This characteristic makes DME an attractive option for reducing urban air pollution, particularly in densely populated areas where vehicle emissions are a major concern. The reduction in these harmful pollutants can lead to improved public health outcomes and decreased environmental degradation.

From a lifecycle perspective, DME derived from renewable sources such as biomass or waste materials can achieve substantial reductions in carbon dioxide emissions. Studies have shown that the use of bio-based DME can result in greenhouse gas emission reductions of up to 95% compared to conventional diesel fuel. This significant reduction in carbon footprint aligns with global efforts to mitigate climate change and transition towards a low-carbon economy.

The production of DME also offers environmental benefits in terms of resource efficiency. DME can be synthesized from a variety of feedstocks, including natural gas, coal, and biomass. This flexibility allows for the utilization of locally available resources, potentially reducing the environmental impact associated with long-distance transportation of fuel feedstocks.

Furthermore, DME's physical properties contribute to its environmental advantages. As a gas at ambient conditions, DME vaporizes quickly if spilled, reducing the risk of soil and water contamination compared to liquid fuels. This characteristic simplifies fuel handling and storage procedures, potentially lowering the environmental risks associated with fuel management infrastructure.

In the context of fuel management, DME's environmental impact extends to the simplification of distribution systems. Its compatibility with existing LPG infrastructure means that the transition to DME can be achieved with minimal modifications to current fuel distribution networks. This reduces the need for extensive new infrastructure development, which can have significant environmental impacts in terms of land use and resource consumption.

However, it is important to note that the full environmental impact of DME depends on its production pathway. While DME derived from renewable sources offers the greatest environmental benefits, DME produced from fossil fuels may have a more limited positive impact. As such, the development of sustainable production methods and the expansion of renewable feedstock sources are crucial for maximizing the environmental advantages of DME as an alternative fuel.

DME Regulatory Framework

The regulatory framework surrounding Dimethyl Ether (DME) plays a crucial role in shaping its adoption and implementation as a simplified fuel management solution. As DME gains traction as an alternative fuel, governments and regulatory bodies worldwide are developing and refining policies to ensure its safe and efficient use.

At the international level, organizations such as the International Organization for Standardization (ISO) have established standards for DME production, storage, and handling. These standards provide a foundation for consistent quality and safety measures across borders, facilitating global trade and adoption of DME technology.

In the United States, the Environmental Protection Agency (EPA) has recognized DME as a renewable fuel under the Renewable Fuel Standard (RFS) program. This classification allows DME producers to generate Renewable Identification Numbers (RINs), providing economic incentives for its production and use. Additionally, the Department of Energy (DOE) has supported research and development initiatives to advance DME technology and infrastructure.

The European Union has also taken steps to incorporate DME into its regulatory framework. The Renewable Energy Directive (RED) includes DME as an eligible biofuel, promoting its use in the transportation sector. Furthermore, the European Committee for Standardization (CEN) has developed specific standards for DME as a fuel for automotive use.

In Asia, countries like China and Japan have implemented supportive policies for DME adoption. China has included DME in its national energy strategy, offering tax incentives and subsidies for DME production and utilization. Japan has established safety standards for DME handling and storage, paving the way for its widespread use in various applications.

Regulatory bodies are also addressing the infrastructure requirements for DME implementation. This includes guidelines for retrofitting existing fuel storage and distribution systems, as well as standards for DME-compatible vehicles and equipment. These regulations aim to ensure a smooth transition to DME as a fuel alternative while maintaining safety and performance standards.

As the DME market evolves, regulatory frameworks continue to adapt. Ongoing efforts focus on harmonizing international standards, streamlining approval processes for DME-based technologies, and developing comprehensive lifecycle assessments to evaluate DME's environmental impact. These regulatory developments are essential in creating a supportive ecosystem for DME adoption and realizing its potential to simplify overarching fuel management.

At the international level, organizations such as the International Organization for Standardization (ISO) have established standards for DME production, storage, and handling. These standards provide a foundation for consistent quality and safety measures across borders, facilitating global trade and adoption of DME technology.

In the United States, the Environmental Protection Agency (EPA) has recognized DME as a renewable fuel under the Renewable Fuel Standard (RFS) program. This classification allows DME producers to generate Renewable Identification Numbers (RINs), providing economic incentives for its production and use. Additionally, the Department of Energy (DOE) has supported research and development initiatives to advance DME technology and infrastructure.

The European Union has also taken steps to incorporate DME into its regulatory framework. The Renewable Energy Directive (RED) includes DME as an eligible biofuel, promoting its use in the transportation sector. Furthermore, the European Committee for Standardization (CEN) has developed specific standards for DME as a fuel for automotive use.

In Asia, countries like China and Japan have implemented supportive policies for DME adoption. China has included DME in its national energy strategy, offering tax incentives and subsidies for DME production and utilization. Japan has established safety standards for DME handling and storage, paving the way for its widespread use in various applications.

Regulatory bodies are also addressing the infrastructure requirements for DME implementation. This includes guidelines for retrofitting existing fuel storage and distribution systems, as well as standards for DME-compatible vehicles and equipment. These regulations aim to ensure a smooth transition to DME as a fuel alternative while maintaining safety and performance standards.

As the DME market evolves, regulatory frameworks continue to adapt. Ongoing efforts focus on harmonizing international standards, streamlining approval processes for DME-based technologies, and developing comprehensive lifecycle assessments to evaluate DME's environmental impact. These regulatory developments are essential in creating a supportive ecosystem for DME adoption and realizing its potential to simplify overarching fuel management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!