How Dimethyl Ether Leap Ahead in Energy Advancement Routes?

JUL 1, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Technology Evolution and Objectives

Dimethyl ether (DME) has emerged as a promising alternative fuel in the quest for sustainable energy solutions. The evolution of DME technology can be traced back to the early 20th century, with significant advancements occurring in recent decades. Initially developed as a propellant and refrigerant, DME's potential as a clean-burning fuel has gained increasing attention in the energy sector.

The technological progression of DME has been driven by the growing need for cleaner energy sources and the desire to reduce dependence on traditional fossil fuels. As global concerns about climate change and air pollution have intensified, researchers and industry players have focused on optimizing DME production processes and expanding its applications. This has led to a series of innovations in catalysis, process engineering, and end-use technologies.

One of the key objectives in DME technology development has been to improve production efficiency and reduce costs. Early production methods relied heavily on methanol as a feedstock, but recent advancements have explored direct synthesis from syngas, potentially lowering production costs and expanding feedstock options. This shift has opened up new possibilities for utilizing various carbon sources, including biomass and waste materials, aligning with circular economy principles.

Another critical goal has been to enhance DME's performance as a fuel. Researchers have worked on improving its combustion characteristics, increasing energy density, and addressing challenges related to its use in existing engine technologies. These efforts aim to position DME as a viable alternative to diesel fuel in transportation and as a substitute for liquefied petroleum gas (LPG) in household and industrial applications.

The environmental benefits of DME have been a driving force behind its technological evolution. As a clean-burning fuel with low particulate emissions and no sulfur content, DME aligns well with increasingly stringent environmental regulations. Ongoing research focuses on further reducing the carbon footprint of DME production, exploring carbon capture and utilization techniques, and integrating renewable energy sources into the production process.

Looking ahead, the objectives for DME technology advancement include scaling up production to meet potential market demand, developing dedicated DME engines and infrastructure, and expanding its role in the broader energy transition. Researchers are also exploring novel applications, such as using DME as a hydrogen carrier or as a feedstock for other chemical processes, potentially opening up new avenues for energy storage and distribution.

The technological progression of DME has been driven by the growing need for cleaner energy sources and the desire to reduce dependence on traditional fossil fuels. As global concerns about climate change and air pollution have intensified, researchers and industry players have focused on optimizing DME production processes and expanding its applications. This has led to a series of innovations in catalysis, process engineering, and end-use technologies.

One of the key objectives in DME technology development has been to improve production efficiency and reduce costs. Early production methods relied heavily on methanol as a feedstock, but recent advancements have explored direct synthesis from syngas, potentially lowering production costs and expanding feedstock options. This shift has opened up new possibilities for utilizing various carbon sources, including biomass and waste materials, aligning with circular economy principles.

Another critical goal has been to enhance DME's performance as a fuel. Researchers have worked on improving its combustion characteristics, increasing energy density, and addressing challenges related to its use in existing engine technologies. These efforts aim to position DME as a viable alternative to diesel fuel in transportation and as a substitute for liquefied petroleum gas (LPG) in household and industrial applications.

The environmental benefits of DME have been a driving force behind its technological evolution. As a clean-burning fuel with low particulate emissions and no sulfur content, DME aligns well with increasingly stringent environmental regulations. Ongoing research focuses on further reducing the carbon footprint of DME production, exploring carbon capture and utilization techniques, and integrating renewable energy sources into the production process.

Looking ahead, the objectives for DME technology advancement include scaling up production to meet potential market demand, developing dedicated DME engines and infrastructure, and expanding its role in the broader energy transition. Researchers are also exploring novel applications, such as using DME as a hydrogen carrier or as a feedstock for other chemical processes, potentially opening up new avenues for energy storage and distribution.

Market Demand Analysis for DME

The market demand for dimethyl ether (DME) has been steadily growing, driven by its potential as a clean and versatile alternative fuel. DME's properties make it an attractive option for various applications, particularly in the energy and transportation sectors. The global DME market is expected to expand significantly in the coming years, with a compound annual growth rate (CAGR) projected to be in the high single digits.

One of the primary drivers of DME market demand is its use as a substitute for liquefied petroleum gas (LPG) in domestic and industrial applications. DME's similar properties to LPG, coupled with its lower emissions profile, make it an appealing choice for cooking and heating in both residential and commercial settings. This demand is particularly strong in regions with limited access to natural gas infrastructure or where LPG prices are high.

In the transportation sector, DME is gaining traction as a potential replacement for diesel fuel in heavy-duty vehicles. Its high cetane number and clean-burning characteristics make it an attractive option for reducing emissions from trucks and buses. Several major automotive manufacturers have shown interest in developing DME-powered engines, which could significantly boost market demand in the coming years.

The power generation sector also presents opportunities for DME market growth. As countries seek to reduce their reliance on coal and other high-emission fuels, DME's potential as a cleaner alternative for power plants is being explored. Its ability to be produced from various feedstocks, including renewable sources, aligns well with the global push towards sustainable energy solutions.

Geographically, the Asia-Pacific region is expected to be a key driver of DME market growth. Countries like China, Japan, and South Korea have been at the forefront of DME adoption and continue to invest in related infrastructure and technology. Europe and North America are also showing increasing interest in DME as part of their efforts to diversify energy sources and reduce carbon emissions.

However, the market demand for DME faces some challenges. The availability of competing alternative fuels, such as compressed natural gas (CNG) and electric vehicles, could potentially limit DME's market penetration in certain sectors. Additionally, the need for significant infrastructure investments to support widespread DME adoption may slow its market growth in some regions.

Despite these challenges, the overall market outlook for DME remains positive. As environmental regulations become more stringent and the focus on sustainable energy solutions intensifies, DME's unique properties and versatility position it well for future growth across multiple industries and applications.

One of the primary drivers of DME market demand is its use as a substitute for liquefied petroleum gas (LPG) in domestic and industrial applications. DME's similar properties to LPG, coupled with its lower emissions profile, make it an appealing choice for cooking and heating in both residential and commercial settings. This demand is particularly strong in regions with limited access to natural gas infrastructure or where LPG prices are high.

In the transportation sector, DME is gaining traction as a potential replacement for diesel fuel in heavy-duty vehicles. Its high cetane number and clean-burning characteristics make it an attractive option for reducing emissions from trucks and buses. Several major automotive manufacturers have shown interest in developing DME-powered engines, which could significantly boost market demand in the coming years.

The power generation sector also presents opportunities for DME market growth. As countries seek to reduce their reliance on coal and other high-emission fuels, DME's potential as a cleaner alternative for power plants is being explored. Its ability to be produced from various feedstocks, including renewable sources, aligns well with the global push towards sustainable energy solutions.

Geographically, the Asia-Pacific region is expected to be a key driver of DME market growth. Countries like China, Japan, and South Korea have been at the forefront of DME adoption and continue to invest in related infrastructure and technology. Europe and North America are also showing increasing interest in DME as part of their efforts to diversify energy sources and reduce carbon emissions.

However, the market demand for DME faces some challenges. The availability of competing alternative fuels, such as compressed natural gas (CNG) and electric vehicles, could potentially limit DME's market penetration in certain sectors. Additionally, the need for significant infrastructure investments to support widespread DME adoption may slow its market growth in some regions.

Despite these challenges, the overall market outlook for DME remains positive. As environmental regulations become more stringent and the focus on sustainable energy solutions intensifies, DME's unique properties and versatility position it well for future growth across multiple industries and applications.

Current DME Tech Challenges

Despite the promising potential of dimethyl ether (DME) as a clean and efficient energy carrier, several significant technical challenges currently hinder its widespread adoption and advancement in energy routes. One of the primary obstacles is the production cost of DME, which remains relatively high compared to conventional fuels. The current production methods, primarily through methanol dehydration or direct synthesis from syngas, require substantial energy inputs and expensive catalysts, limiting the economic viability of large-scale DME production.

Another critical challenge lies in the storage and transportation infrastructure for DME. As a liquefied gas at ambient temperature and moderate pressure, DME requires specialized handling and storage facilities. The existing infrastructure for petroleum-based fuels is not readily compatible with DME, necessitating significant investments in new or modified storage tanks, pipelines, and distribution systems.

The development of efficient and durable DME-compatible engines presents another hurdle. While DME can be used in modified diesel engines, optimizing engine performance, reducing emissions, and ensuring long-term reliability remain ongoing challenges. The unique properties of DME, such as its lower viscosity and lubricity compared to diesel fuel, require specialized fuel injection systems and engine components.

Furthermore, the production of DME from renewable sources faces technical barriers. While bio-based DME production shows promise for sustainability, current processes struggle with feedstock variability, low conversion efficiencies, and the need for extensive pre-treatment of biomass. Developing robust and scalable technologies for converting diverse biomass feedstocks into DME efficiently is crucial for its role in renewable energy advancement.

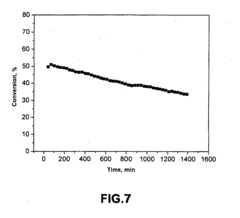

Catalyst development remains a critical area of focus. Current catalysts used in DME synthesis and dehydration processes often suffer from deactivation, selectivity issues, and sensitivity to impurities in the feedstock. Improving catalyst performance, longevity, and resistance to poisoning is essential for enhancing the overall efficiency and economics of DME production.

Lastly, the integration of DME production with carbon capture and utilization (CCU) technologies presents both an opportunity and a challenge. While DME synthesis can potentially serve as a CO2 utilization pathway, developing efficient and economically viable processes for CO2-to-DME conversion at scale remains a significant technical hurdle. Overcoming these challenges is crucial for positioning DME as a key player in future low-carbon energy systems.

Another critical challenge lies in the storage and transportation infrastructure for DME. As a liquefied gas at ambient temperature and moderate pressure, DME requires specialized handling and storage facilities. The existing infrastructure for petroleum-based fuels is not readily compatible with DME, necessitating significant investments in new or modified storage tanks, pipelines, and distribution systems.

The development of efficient and durable DME-compatible engines presents another hurdle. While DME can be used in modified diesel engines, optimizing engine performance, reducing emissions, and ensuring long-term reliability remain ongoing challenges. The unique properties of DME, such as its lower viscosity and lubricity compared to diesel fuel, require specialized fuel injection systems and engine components.

Furthermore, the production of DME from renewable sources faces technical barriers. While bio-based DME production shows promise for sustainability, current processes struggle with feedstock variability, low conversion efficiencies, and the need for extensive pre-treatment of biomass. Developing robust and scalable technologies for converting diverse biomass feedstocks into DME efficiently is crucial for its role in renewable energy advancement.

Catalyst development remains a critical area of focus. Current catalysts used in DME synthesis and dehydration processes often suffer from deactivation, selectivity issues, and sensitivity to impurities in the feedstock. Improving catalyst performance, longevity, and resistance to poisoning is essential for enhancing the overall efficiency and economics of DME production.

Lastly, the integration of DME production with carbon capture and utilization (CCU) technologies presents both an opportunity and a challenge. While DME synthesis can potentially serve as a CO2 utilization pathway, developing efficient and economically viable processes for CO2-to-DME conversion at scale remains a significant technical hurdle. Overcoming these challenges is crucial for positioning DME as a key player in future low-carbon energy systems.

Current DME Production Methods

01 Production methods for dimethyl ether

Various methods for producing dimethyl ether (DME) have been developed, including direct synthesis from syngas and dehydration of methanol. These processes aim to improve efficiency and reduce production costs, making DME a more viable alternative fuel.- Production methods for dimethyl ether: Various methods for producing dimethyl ether (DME) have been developed, including direct synthesis from syngas and dehydration of methanol. These processes aim to improve efficiency and reduce production costs, making DME a more viable alternative fuel.

- DME as a clean alternative fuel: Dimethyl ether is being explored as a clean-burning alternative fuel for various applications, including diesel engines and power generation. Its properties make it an attractive option for reducing emissions and improving energy efficiency in transportation and industrial sectors.

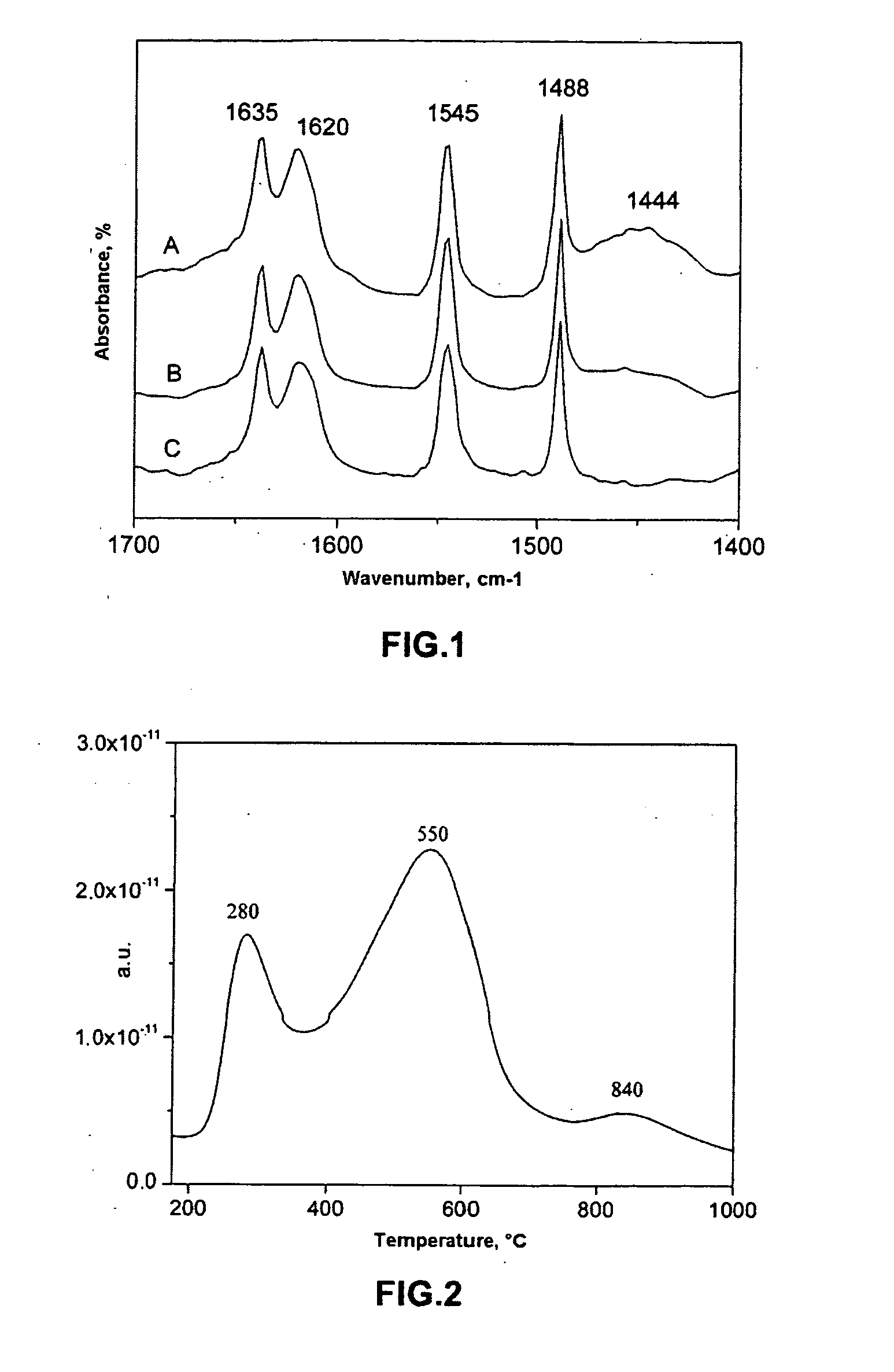

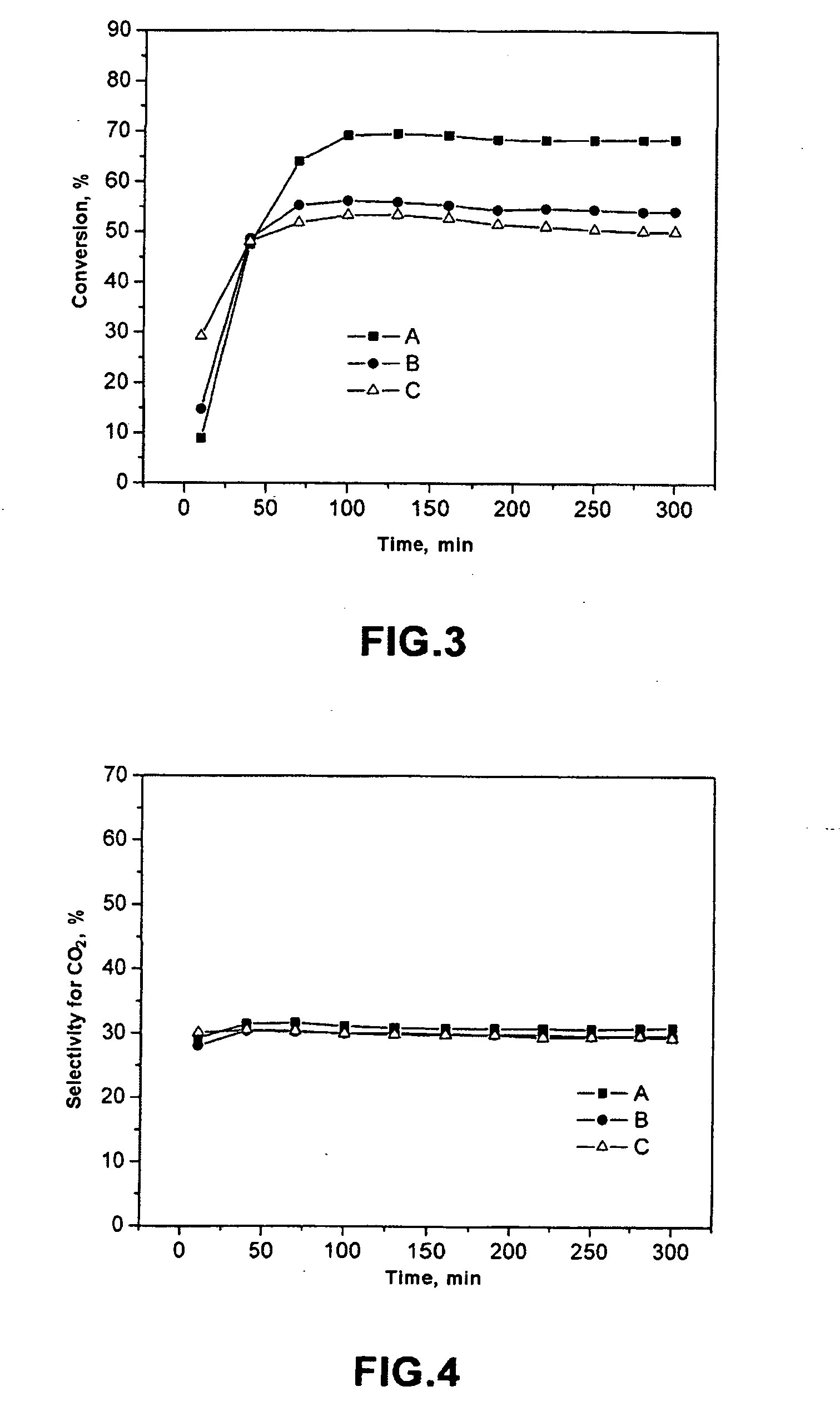

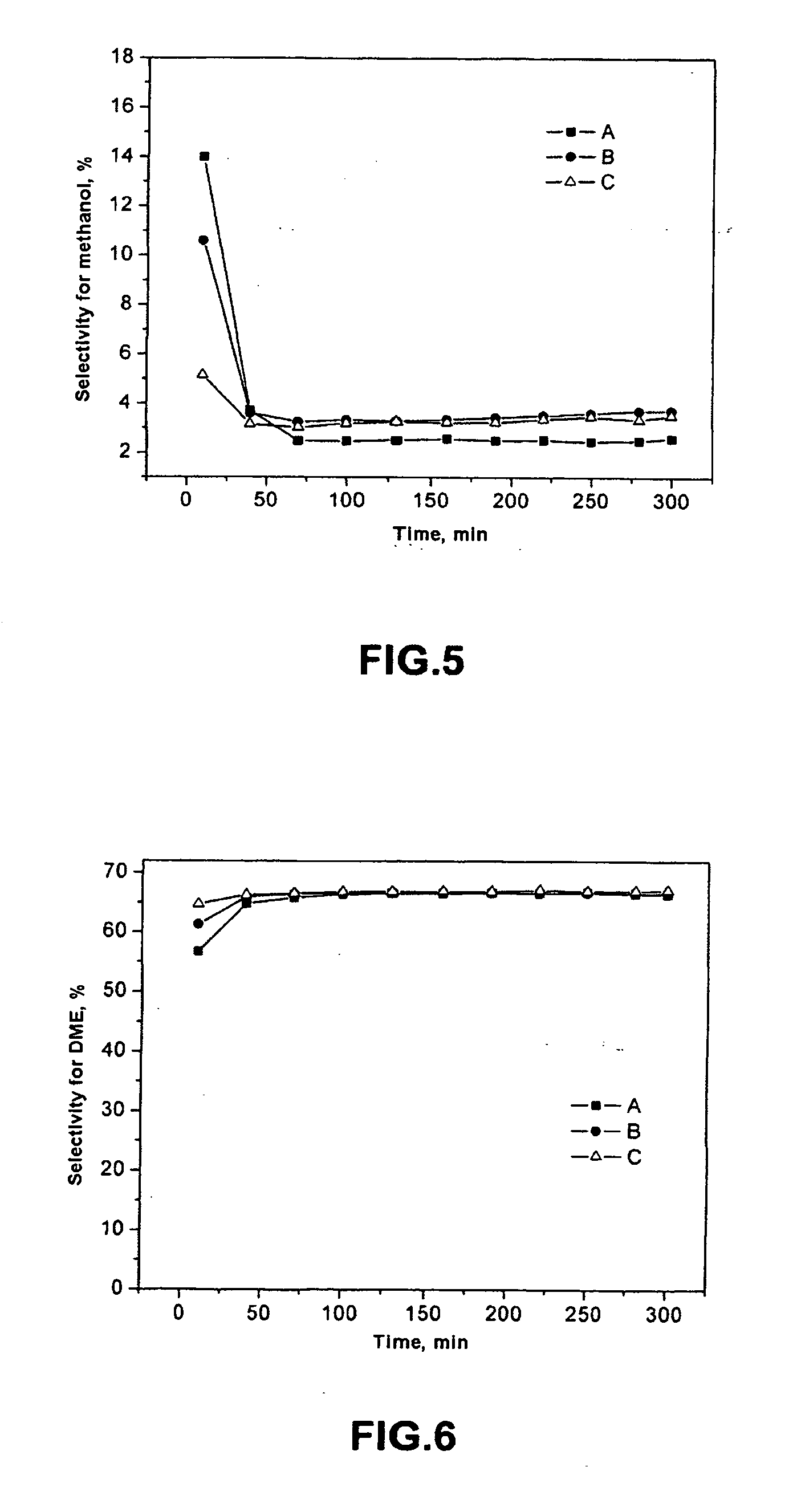

- Catalysts for DME synthesis: Research on catalysts plays a crucial role in advancing DME production technology. Novel catalysts are being developed to enhance conversion rates, selectivity, and stability in DME synthesis processes, contributing to more efficient and economical production methods.

- DME storage and transportation systems: Advancements in DME storage and transportation systems are essential for its widespread adoption as an energy source. Innovations in this area focus on improving safety, efficiency, and cost-effectiveness of DME handling throughout the supply chain.

- DME utilization in fuel cells: Exploring the potential of DME in fuel cell applications is an emerging area of research. This includes developing DME-compatible fuel cell systems and investigating the feasibility of using DME as a hydrogen carrier for fuel cell technology.

02 DME as a clean alternative fuel

Dimethyl ether is being explored as a clean-burning alternative fuel for various applications, including diesel engines and power generation. Its properties make it an attractive option for reducing emissions and improving energy efficiency in transportation and industrial sectors.Expand Specific Solutions03 Catalysts for DME synthesis

Research on catalysts plays a crucial role in advancing DME production technology. Novel catalysts are being developed to enhance conversion rates, selectivity, and stability in DME synthesis processes, contributing to more efficient and cost-effective production methods.Expand Specific Solutions04 DME storage and transportation systems

Advancements in DME storage and transportation systems are essential for its widespread adoption as an energy source. Innovations in this area focus on improving safety, efficiency, and compatibility with existing infrastructure to facilitate the use of DME in various applications.Expand Specific Solutions05 DME-based power generation

The use of dimethyl ether in power generation systems is being explored to provide cleaner and more efficient energy solutions. This includes the development of DME-fueled turbines, combined heat and power systems, and other innovative power generation technologies.Expand Specific Solutions

Key Players in DME Industry

The dimethyl ether (DME) energy advancement sector is in a growth phase, with increasing market size and technological maturity. Major players like China Petroleum & Chemical Corp., SK Energy, and Indian Oil Corp. are driving innovation and commercialization efforts. The global DME market is projected to expand significantly due to its potential as a clean alternative fuel. Technological advancements are focused on improving production efficiency and expanding applications. Research institutions such as the University of Southern California and Fraunhofer-Gesellschaft are contributing to the development of novel DME production methods and applications, indicating a collaborative ecosystem between industry and academia in pushing the technology forward.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has made significant strides in dimethyl ether (DME) production and utilization. They have developed a proprietary one-step synthesis process for DME production from syngas, which has improved efficiency by up to 20% compared to traditional two-step processes[1]. This technology integrates methanol synthesis and dehydration into a single reactor, reducing capital and operating costs. Sinopec has also pioneered the use of DME as a clean-burning alternative fuel for diesel engines, with pilot projects demonstrating a reduction in particulate matter emissions by up to 90%[2]. Their research extends to using DME as a hydrogen carrier for fuel cells, potentially revolutionizing energy storage and transportation[3].

Strengths: Integrated production process, reduced costs, and versatile applications in transportation and energy storage. Weaknesses: Dependence on syngas availability and potential competition from other alternative fuels.

Sinopec Research Institute of Petroleum Processing

Technical Solution: The Sinopec Research Institute of Petroleum Processing has been at the forefront of DME technology advancement. They have developed a novel catalyst system for DME synthesis that increases conversion rates by up to 15% while reducing byproduct formation[4]. Their research has also focused on optimizing DME production from various feedstocks, including coal, natural gas, and biomass, enhancing the flexibility of DME as an energy source. The institute has made breakthroughs in DME purification techniques, achieving 99.9% purity levels suitable for high-end applications[5]. Additionally, they have conducted extensive studies on DME's potential as a green refrigerant, demonstrating its superior thermodynamic properties and lower global warming potential compared to traditional hydrofluorocarbons[6].

Strengths: Advanced catalyst technology, feedstock flexibility, and high-purity DME production. Weaknesses: Potential scalability challenges and competition from established energy technologies.

DME Catalysis Innovations

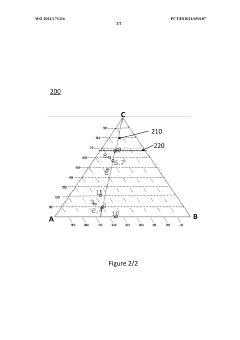

Catalytic system and process for direct synthesis of dimethyl ether from synthesis gas

PatentInactiveUS20090326281A1

Innovation

- A mixed-bed catalytic system comprising a catalyst for methanol synthesis and acid form zeolite ferrierite, with a silica/alumina ratio of 10 and specific potassium and sodium content, is physically mixed and activated, providing a high concentration of Brønsted acid sites for efficient dehydration without forming unwanted products.

Fixed bed reactor with layered dimethyl ether synthesis catalysts

PatentWO2021171316A1

Innovation

- A fixed bed reactor with multiple layers of catalysts, where a methanol synthesis catalyst with a spinel structure alternates with a methanol dehydration catalyst, reducing copper content and using nanoparticles to enhance dispersion and stability, and separating the catalysts to prevent deactivation.

Environmental Impact of DME

Dimethyl ether (DME) has emerged as a promising alternative fuel with significant environmental benefits compared to conventional fossil fuels. As a clean-burning, non-toxic, and biodegradable compound, DME offers several advantages in terms of reducing environmental impact across various sectors.

One of the primary environmental benefits of DME is its potential to reduce greenhouse gas emissions. When used as a fuel in internal combustion engines or power generation, DME produces lower carbon dioxide emissions compared to diesel or gasoline. This reduction in CO2 emissions can contribute to mitigating climate change and meeting global carbon reduction targets.

Furthermore, DME combustion results in near-zero particulate matter emissions, addressing a major concern associated with traditional diesel engines. The reduction in particulate matter can lead to improved air quality, particularly in urban areas where vehicle emissions are a significant contributor to air pollution.

DME also exhibits lower nitrogen oxide (NOx) emissions compared to conventional fuels. NOx is a major contributor to smog formation and acid rain, and its reduction can have positive impacts on both human health and ecosystem integrity. The lower NOx emissions from DME combustion can help in meeting increasingly stringent air quality regulations.

In terms of its production, DME can be synthesized from various feedstocks, including renewable sources such as biomass and waste materials. This flexibility in production pathways offers the potential for a more sustainable fuel lifecycle, particularly when derived from renewable resources. The use of waste materials or biomass for DME production can contribute to waste reduction and circular economy principles.

DME's properties also make it less harmful to soil and water resources in case of accidental spills or leaks. Unlike petroleum-based fuels, DME is highly biodegradable and does not persist in the environment, reducing the risk of long-term contamination of ecosystems.

The adoption of DME as a fuel can also indirectly contribute to reducing the environmental impact of oil exploration and extraction activities. By diversifying the energy mix and potentially reducing dependence on conventional petroleum products, DME can help mitigate the ecological disruptions associated with fossil fuel extraction.

However, it is important to note that the overall environmental impact of DME depends on its production methods and feedstock sources. While DME itself offers environmental advantages, the sustainability of its production process must be carefully considered to ensure a net positive environmental impact throughout its lifecycle.

One of the primary environmental benefits of DME is its potential to reduce greenhouse gas emissions. When used as a fuel in internal combustion engines or power generation, DME produces lower carbon dioxide emissions compared to diesel or gasoline. This reduction in CO2 emissions can contribute to mitigating climate change and meeting global carbon reduction targets.

Furthermore, DME combustion results in near-zero particulate matter emissions, addressing a major concern associated with traditional diesel engines. The reduction in particulate matter can lead to improved air quality, particularly in urban areas where vehicle emissions are a significant contributor to air pollution.

DME also exhibits lower nitrogen oxide (NOx) emissions compared to conventional fuels. NOx is a major contributor to smog formation and acid rain, and its reduction can have positive impacts on both human health and ecosystem integrity. The lower NOx emissions from DME combustion can help in meeting increasingly stringent air quality regulations.

In terms of its production, DME can be synthesized from various feedstocks, including renewable sources such as biomass and waste materials. This flexibility in production pathways offers the potential for a more sustainable fuel lifecycle, particularly when derived from renewable resources. The use of waste materials or biomass for DME production can contribute to waste reduction and circular economy principles.

DME's properties also make it less harmful to soil and water resources in case of accidental spills or leaks. Unlike petroleum-based fuels, DME is highly biodegradable and does not persist in the environment, reducing the risk of long-term contamination of ecosystems.

The adoption of DME as a fuel can also indirectly contribute to reducing the environmental impact of oil exploration and extraction activities. By diversifying the energy mix and potentially reducing dependence on conventional petroleum products, DME can help mitigate the ecological disruptions associated with fossil fuel extraction.

However, it is important to note that the overall environmental impact of DME depends on its production methods and feedstock sources. While DME itself offers environmental advantages, the sustainability of its production process must be carefully considered to ensure a net positive environmental impact throughout its lifecycle.

DME Policy and Regulations

The regulatory landscape for dimethyl ether (DME) as an alternative fuel is evolving rapidly across the globe. In the United States, the Environmental Protection Agency (EPA) has approved DME as a renewable fuel under the Renewable Fuel Standard program, recognizing its potential to reduce greenhouse gas emissions. This classification allows DME producers to generate Renewable Identification Numbers (RINs), providing economic incentives for production and use.

The European Union has also taken steps to promote DME as part of its renewable energy directive. The EU's Fuel Quality Directive includes DME as a clean fuel option, encouraging member states to incorporate it into their national energy strategies. Several European countries, including Sweden and Denmark, have implemented tax incentives and subsidies to support DME production and infrastructure development.

In Asia, China has been at the forefront of DME policy implementation. The Chinese government has included DME in its national energy strategy, providing subsidies for production facilities and mandating its use in certain sectors. Japan has also shown interest, with the Ministry of Economy, Trade and Industry (METI) funding research and development projects focused on DME technology.

Globally, the International DME Association (IDA) plays a crucial role in advocating for supportive policies and regulations. The IDA works with governments and industry stakeholders to develop standards and best practices for DME production, distribution, and use. These efforts have led to the creation of international standards, such as ISO 16861:2015, which specifies the requirements for DME used as fuel.

Safety regulations surrounding DME are also being developed and refined. Many countries are adapting existing LPG regulations to accommodate DME, given their similar properties. This includes storage, handling, and transportation guidelines to ensure safe use across the supply chain.

As DME gains traction as a clean energy solution, policymakers are increasingly focusing on lifecycle assessments to evaluate its environmental impact. This has led to the development of sustainability criteria for DME production, particularly when derived from biomass or waste streams. These criteria are becoming integral to regulatory frameworks, ensuring that DME contributes positively to climate change mitigation efforts.

The regulatory landscape for DME is expected to continue evolving as more countries recognize its potential in energy transition strategies. Future policy developments are likely to focus on harmonizing international standards, addressing infrastructure challenges, and creating more robust incentive structures to accelerate DME adoption across various sectors.

The European Union has also taken steps to promote DME as part of its renewable energy directive. The EU's Fuel Quality Directive includes DME as a clean fuel option, encouraging member states to incorporate it into their national energy strategies. Several European countries, including Sweden and Denmark, have implemented tax incentives and subsidies to support DME production and infrastructure development.

In Asia, China has been at the forefront of DME policy implementation. The Chinese government has included DME in its national energy strategy, providing subsidies for production facilities and mandating its use in certain sectors. Japan has also shown interest, with the Ministry of Economy, Trade and Industry (METI) funding research and development projects focused on DME technology.

Globally, the International DME Association (IDA) plays a crucial role in advocating for supportive policies and regulations. The IDA works with governments and industry stakeholders to develop standards and best practices for DME production, distribution, and use. These efforts have led to the creation of international standards, such as ISO 16861:2015, which specifies the requirements for DME used as fuel.

Safety regulations surrounding DME are also being developed and refined. Many countries are adapting existing LPG regulations to accommodate DME, given their similar properties. This includes storage, handling, and transportation guidelines to ensure safe use across the supply chain.

As DME gains traction as a clean energy solution, policymakers are increasingly focusing on lifecycle assessments to evaluate its environmental impact. This has led to the development of sustainability criteria for DME production, particularly when derived from biomass or waste streams. These criteria are becoming integral to regulatory frameworks, ensuring that DME contributes positively to climate change mitigation efforts.

The regulatory landscape for DME is expected to continue evolving as more countries recognize its potential in energy transition strategies. Future policy developments are likely to focus on harmonizing international standards, addressing infrastructure challenges, and creating more robust incentive structures to accelerate DME adoption across various sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!