Emerging Dimethyl Ether Technologies in Aerospace Sector

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Aerospace Evolution

The evolution of Dimethyl Ether (DME) technologies in the aerospace sector represents a significant shift in propulsion and energy systems. Initially developed as a clean-burning alternative fuel for terrestrial applications, DME has gradually found its way into aerospace research and development over the past few decades.

In the early 2000s, aerospace engineers began exploring DME as a potential rocket propellant due to its high energy density and low toxicity. This marked the beginning of DME's journey in the aerospace sector. The first experimental tests of DME-based propulsion systems for small satellites and cubesats were conducted in the mid-2010s, demonstrating the fuel's potential for space applications.

By 2020, several space agencies and private companies had initiated research programs focused on DME propulsion technologies. These efforts aimed to develop more efficient and environmentally friendly propulsion systems for various space missions, including orbital transfers and deep space exploration.

The evolution of DME in aerospace has been characterized by continuous improvements in fuel storage, handling, and combustion technologies. Early challenges, such as the need for pressurized storage and specialized injection systems, have been gradually overcome through innovative engineering solutions.

A significant milestone was reached in 2025 when the first successful orbital mission using a DME-based propulsion system was launched. This achievement sparked increased interest and investment in DME technologies across the aerospace industry, leading to accelerated development and refinement of DME-based systems.

In recent years, the focus has shifted towards integrating DME propulsion with other emerging aerospace technologies, such as electric propulsion and advanced materials. This convergence has resulted in hybrid propulsion systems that combine the benefits of DME with other cutting-edge technologies, offering improved performance and versatility for a wide range of space missions.

The evolution of DME in aerospace has also been influenced by broader trends in the industry, including the growing emphasis on sustainability and the increasing commercialization of space activities. As a result, DME has gained traction not only as a propellant but also as a potential energy storage medium for long-duration space missions and as a fuel for in-situ resource utilization on other planetary bodies.

Looking ahead, the trajectory of DME technologies in aerospace is poised for further growth and innovation. Ongoing research is exploring advanced catalysts and combustion techniques to enhance DME's performance and efficiency, while also investigating its potential applications in atmospheric propulsion for high-altitude aircraft and future aerospace vehicles.

In the early 2000s, aerospace engineers began exploring DME as a potential rocket propellant due to its high energy density and low toxicity. This marked the beginning of DME's journey in the aerospace sector. The first experimental tests of DME-based propulsion systems for small satellites and cubesats were conducted in the mid-2010s, demonstrating the fuel's potential for space applications.

By 2020, several space agencies and private companies had initiated research programs focused on DME propulsion technologies. These efforts aimed to develop more efficient and environmentally friendly propulsion systems for various space missions, including orbital transfers and deep space exploration.

The evolution of DME in aerospace has been characterized by continuous improvements in fuel storage, handling, and combustion technologies. Early challenges, such as the need for pressurized storage and specialized injection systems, have been gradually overcome through innovative engineering solutions.

A significant milestone was reached in 2025 when the first successful orbital mission using a DME-based propulsion system was launched. This achievement sparked increased interest and investment in DME technologies across the aerospace industry, leading to accelerated development and refinement of DME-based systems.

In recent years, the focus has shifted towards integrating DME propulsion with other emerging aerospace technologies, such as electric propulsion and advanced materials. This convergence has resulted in hybrid propulsion systems that combine the benefits of DME with other cutting-edge technologies, offering improved performance and versatility for a wide range of space missions.

The evolution of DME in aerospace has also been influenced by broader trends in the industry, including the growing emphasis on sustainability and the increasing commercialization of space activities. As a result, DME has gained traction not only as a propellant but also as a potential energy storage medium for long-duration space missions and as a fuel for in-situ resource utilization on other planetary bodies.

Looking ahead, the trajectory of DME technologies in aerospace is poised for further growth and innovation. Ongoing research is exploring advanced catalysts and combustion techniques to enhance DME's performance and efficiency, while also investigating its potential applications in atmospheric propulsion for high-altitude aircraft and future aerospace vehicles.

Aerospace DME Demand

The aerospace sector has witnessed a growing interest in dimethyl ether (DME) technologies, driven by the industry's pursuit of sustainable and efficient propulsion systems. The demand for DME in aerospace applications is primarily fueled by its potential as a clean-burning, high-energy-density fuel alternative. As the aviation industry faces increasing pressure to reduce carbon emissions and meet stringent environmental regulations, DME has emerged as a promising solution.

The market demand for DME in aerospace is closely tied to the industry's commitment to achieving net-zero carbon emissions by 2050. Major airlines and aircraft manufacturers are actively exploring alternative fuel options, with DME gaining traction due to its favorable properties. The potential market for DME in aerospace is substantial, with projections indicating a significant growth trajectory over the next decade.

One of the key drivers of DME demand in aerospace is its compatibility with existing jet engine technologies. This compatibility allows for a smoother transition to DME-based propulsion systems without requiring extensive modifications to current aircraft designs. As a result, aerospace companies are increasingly investing in research and development to optimize DME utilization in aircraft engines.

The demand for DME in aerospace extends beyond commercial aviation to include military applications and space exploration. Military organizations are exploring DME as a potential fuel for tactical vehicles and aircraft, valuing its energy density and logistical advantages. In the space sector, DME is being considered for use in satellite propulsion systems and as a potential fuel for long-duration space missions.

The growing interest in sustainable aviation fuels (SAFs) has also contributed to the rising demand for DME in aerospace. DME can be produced from renewable sources, making it an attractive option for airlines looking to reduce their carbon footprint. The potential for DME to be blended with conventional jet fuels further enhances its appeal as a transitional solution in the industry's shift towards more sustainable practices.

However, the demand for DME in aerospace faces certain challenges. The current production capacity for DME is limited, and scaling up production to meet potential aerospace demand requires significant investment in infrastructure. Additionally, regulatory frameworks and safety standards for DME use in aviation are still evolving, which may impact adoption rates in the short term.

Despite these challenges, the long-term outlook for DME demand in aerospace remains positive. As technology advances and regulatory support increases, the aerospace industry is expected to accelerate its adoption of DME-based solutions. This trend is likely to drive further investment in DME production and distribution networks, creating a positive feedback loop that reinforces demand growth in the sector.

The market demand for DME in aerospace is closely tied to the industry's commitment to achieving net-zero carbon emissions by 2050. Major airlines and aircraft manufacturers are actively exploring alternative fuel options, with DME gaining traction due to its favorable properties. The potential market for DME in aerospace is substantial, with projections indicating a significant growth trajectory over the next decade.

One of the key drivers of DME demand in aerospace is its compatibility with existing jet engine technologies. This compatibility allows for a smoother transition to DME-based propulsion systems without requiring extensive modifications to current aircraft designs. As a result, aerospace companies are increasingly investing in research and development to optimize DME utilization in aircraft engines.

The demand for DME in aerospace extends beyond commercial aviation to include military applications and space exploration. Military organizations are exploring DME as a potential fuel for tactical vehicles and aircraft, valuing its energy density and logistical advantages. In the space sector, DME is being considered for use in satellite propulsion systems and as a potential fuel for long-duration space missions.

The growing interest in sustainable aviation fuels (SAFs) has also contributed to the rising demand for DME in aerospace. DME can be produced from renewable sources, making it an attractive option for airlines looking to reduce their carbon footprint. The potential for DME to be blended with conventional jet fuels further enhances its appeal as a transitional solution in the industry's shift towards more sustainable practices.

However, the demand for DME in aerospace faces certain challenges. The current production capacity for DME is limited, and scaling up production to meet potential aerospace demand requires significant investment in infrastructure. Additionally, regulatory frameworks and safety standards for DME use in aviation are still evolving, which may impact adoption rates in the short term.

Despite these challenges, the long-term outlook for DME demand in aerospace remains positive. As technology advances and regulatory support increases, the aerospace industry is expected to accelerate its adoption of DME-based solutions. This trend is likely to drive further investment in DME production and distribution networks, creating a positive feedback loop that reinforces demand growth in the sector.

DME Tech Challenges

The integration of Dimethyl Ether (DME) technologies in the aerospace sector faces several significant challenges that require innovative solutions and continued research. One of the primary obstacles is the low energy density of DME compared to conventional aerospace fuels. This limitation necessitates larger fuel tanks, potentially compromising the payload capacity and overall efficiency of aircraft and spacecraft.

Another critical challenge lies in the development of specialized fuel systems capable of handling DME's unique properties. Unlike traditional hydrocarbon fuels, DME has a lower viscosity and lubricity, which can lead to increased wear and tear on engine components. Engineers must design new fuel injection systems, seals, and lubricants to ensure optimal performance and longevity of DME-powered engines.

The storage and handling of DME in aerospace applications present additional hurdles. Its low boiling point and high vapor pressure require advanced cryogenic storage solutions or pressurized tanks, adding complexity and weight to fuel systems. Moreover, the potential for rapid vaporization poses safety concerns that must be addressed through robust containment and monitoring systems.

Combustion characteristics of DME also pose challenges in aerospace propulsion systems. While DME offers advantages such as clean burning and reduced emissions, its lower flame speed and different ignition properties compared to conventional fuels necessitate modifications to combustion chamber designs and ignition systems. Achieving optimal combustion efficiency across a wide range of operating conditions remains a significant technical challenge.

The production and supply chain of DME for aerospace applications present logistical challenges. Current production methods may not be scalable or cost-effective enough to meet the potential demand from the aerospace sector. Developing efficient, large-scale production processes and establishing a reliable supply chain are crucial for the widespread adoption of DME in aerospace.

Environmental considerations, while generally favorable for DME, still present some challenges. Although DME produces lower emissions compared to traditional fuels, its production process can have a significant carbon footprint depending on the feedstock and energy sources used. Developing sustainable production methods and ensuring a positive lifecycle environmental impact are essential for the long-term viability of DME in aerospace applications.

Regulatory hurdles and certification processes pose additional challenges for the integration of DME technologies in aerospace. Extensive testing and validation are required to meet stringent safety and performance standards set by aviation authorities. This process can be time-consuming and costly, potentially slowing the adoption of DME-based propulsion systems in commercial and military aerospace applications.

Another critical challenge lies in the development of specialized fuel systems capable of handling DME's unique properties. Unlike traditional hydrocarbon fuels, DME has a lower viscosity and lubricity, which can lead to increased wear and tear on engine components. Engineers must design new fuel injection systems, seals, and lubricants to ensure optimal performance and longevity of DME-powered engines.

The storage and handling of DME in aerospace applications present additional hurdles. Its low boiling point and high vapor pressure require advanced cryogenic storage solutions or pressurized tanks, adding complexity and weight to fuel systems. Moreover, the potential for rapid vaporization poses safety concerns that must be addressed through robust containment and monitoring systems.

Combustion characteristics of DME also pose challenges in aerospace propulsion systems. While DME offers advantages such as clean burning and reduced emissions, its lower flame speed and different ignition properties compared to conventional fuels necessitate modifications to combustion chamber designs and ignition systems. Achieving optimal combustion efficiency across a wide range of operating conditions remains a significant technical challenge.

The production and supply chain of DME for aerospace applications present logistical challenges. Current production methods may not be scalable or cost-effective enough to meet the potential demand from the aerospace sector. Developing efficient, large-scale production processes and establishing a reliable supply chain are crucial for the widespread adoption of DME in aerospace.

Environmental considerations, while generally favorable for DME, still present some challenges. Although DME produces lower emissions compared to traditional fuels, its production process can have a significant carbon footprint depending on the feedstock and energy sources used. Developing sustainable production methods and ensuring a positive lifecycle environmental impact are essential for the long-term viability of DME in aerospace applications.

Regulatory hurdles and certification processes pose additional challenges for the integration of DME technologies in aerospace. Extensive testing and validation are required to meet stringent safety and performance standards set by aviation authorities. This process can be time-consuming and costly, potentially slowing the adoption of DME-based propulsion systems in commercial and military aerospace applications.

Current DME Solutions

01 Production of dimethyl ether

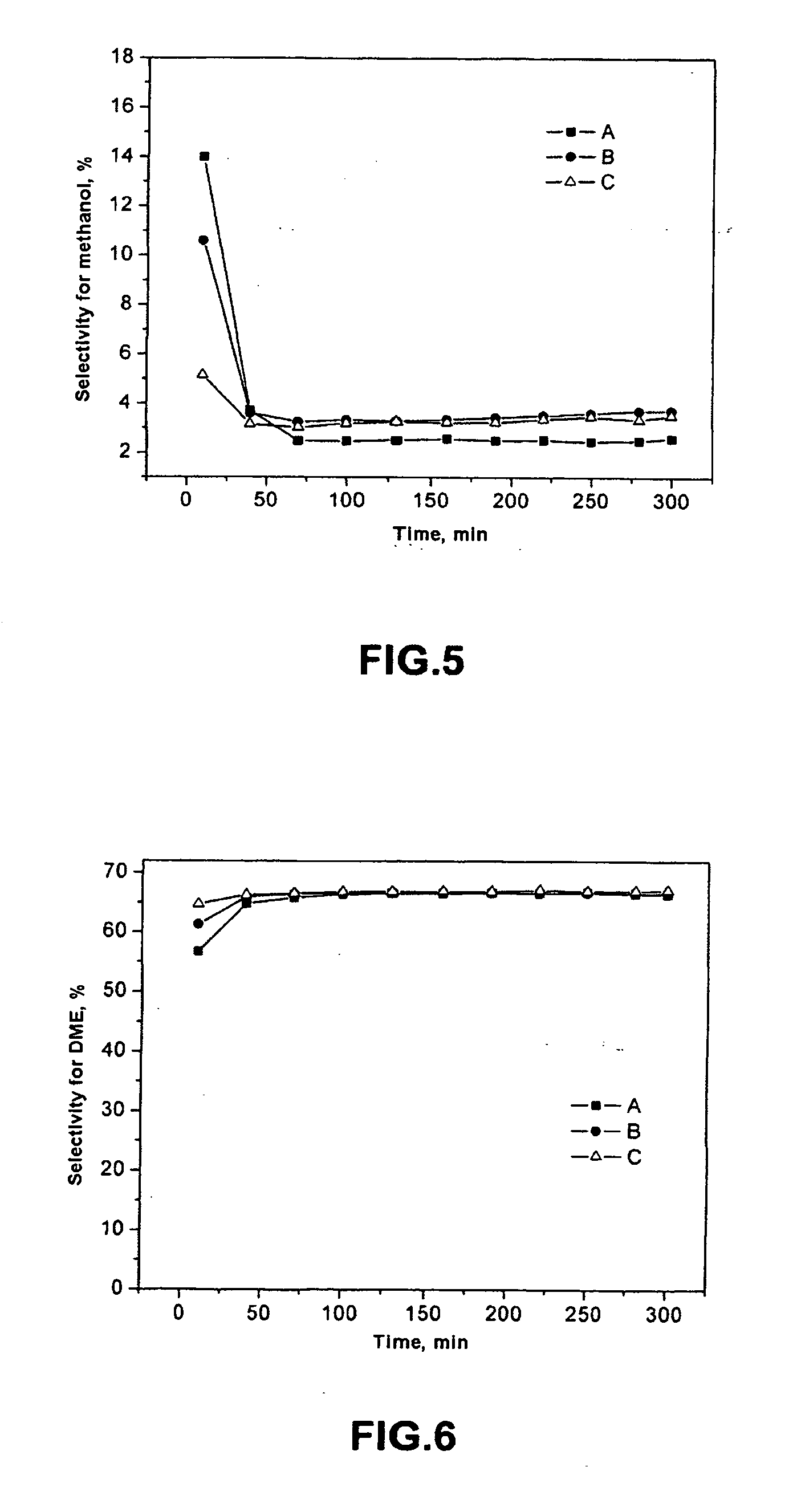

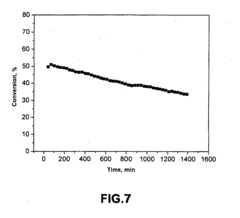

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.- Production of dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

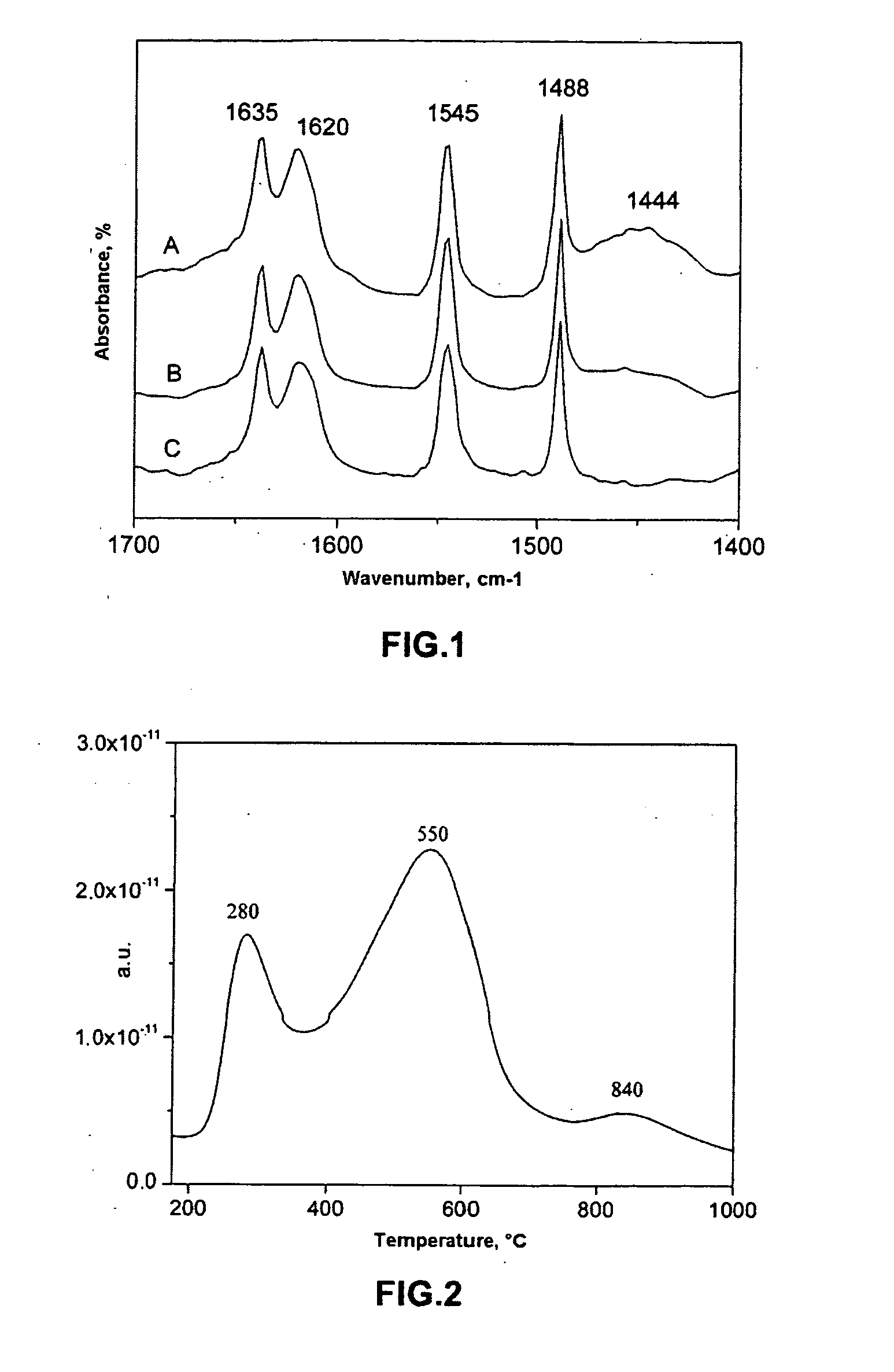

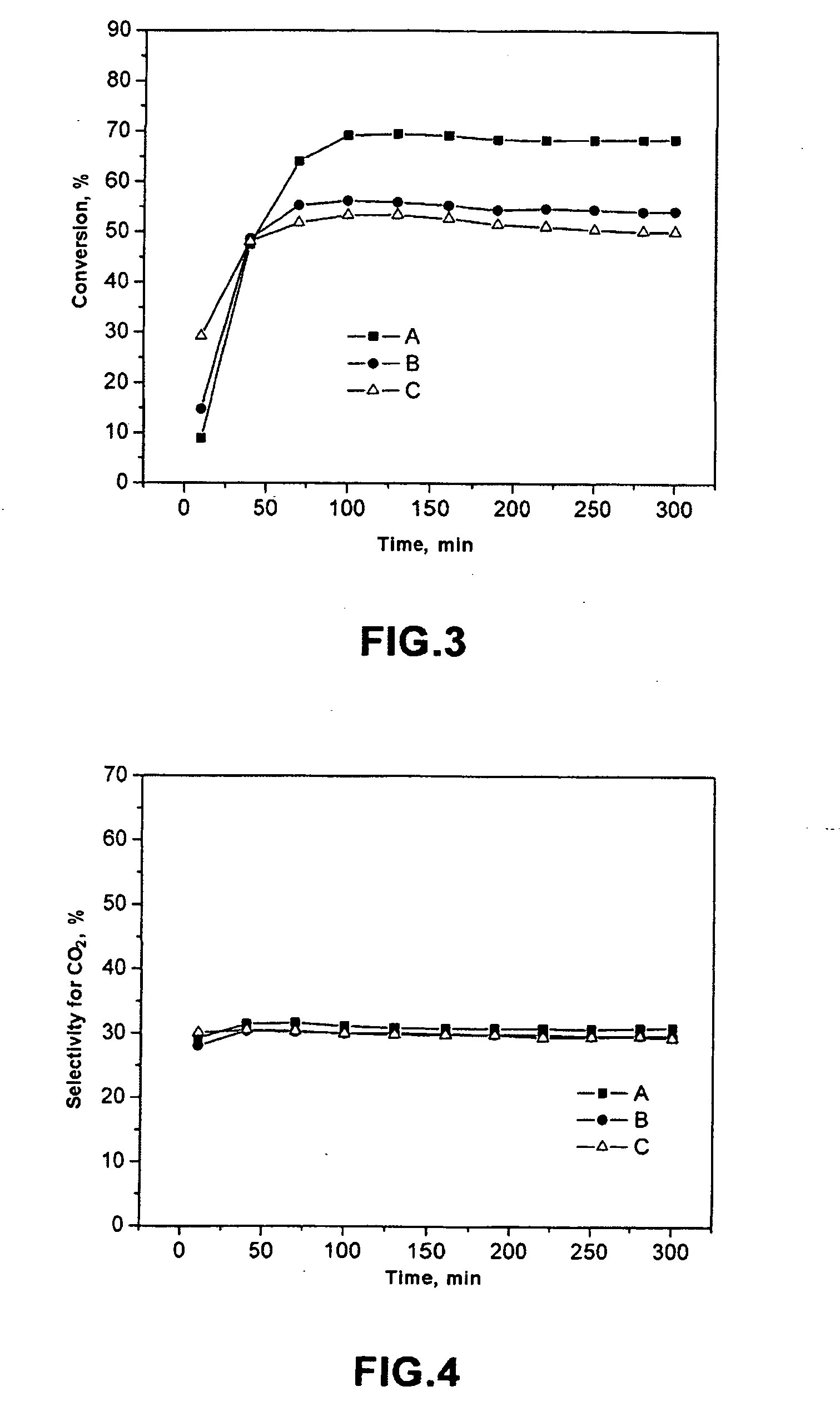

- Catalysts for dimethyl ether synthesis: Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.

- Applications of dimethyl ether: Dimethyl ether has various applications, including use as a fuel substitute, aerosol propellant, and chemical intermediate. Its properties make it suitable for use in diesel engines, household products, and as a feedstock for other chemical processes.

- Purification and separation of dimethyl ether: Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes may involve distillation, adsorption, or membrane separation techniques to obtain high-purity dimethyl ether.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, storage safety, and handling procedures to ensure the sustainable and safe utilization of dimethyl ether in various applications.

02 Catalysts for dimethyl ether synthesis

Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.Expand Specific Solutions03 Applications of dimethyl ether

Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as a potential alternative fuel for diesel engines due to its clean-burning properties.Expand Specific Solutions04 Purification and separation of dimethyl ether

Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes often involve distillation, adsorption, or membrane separation techniques to achieve high-purity dimethyl ether.Expand Specific Solutions05 Environmental and safety considerations

Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and storage requirements to ensure safe and sustainable utilization of dimethyl ether.Expand Specific Solutions

Aerospace DME Players

The emerging Dimethyl Ether (DME) technologies in the aerospace sector are in the early stages of development, with the market still relatively small but showing potential for growth. The competitive landscape is characterized by a mix of established energy companies, chemical manufacturers, and research institutions exploring DME applications. Key players like China Petroleum & Chemical Corp., SK Energy, and BASF are leveraging their expertise in petrochemicals to advance DME technology. Research organizations such as TNO and universities like Zhejiang University are contributing to technological advancements. While DME technology for aerospace is not yet fully mature, ongoing collaborations between industry and academia are driving innovation and gradually improving its readiness for practical applications.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been at the forefront of dimethyl ether (DME) technology development for aerospace applications. Their approach involves the production of high-purity DME through a proprietary catalytic dehydration process of methanol. This method achieves a DME purity of over 99.9%, which is crucial for aerospace fuel applications[1]. Sinopec has also developed a novel DME-based propellant system that offers improved specific impulse and density-specific impulse compared to traditional hydrazine-based propellants[3]. The company has successfully tested this propellant in small-scale thrusters, demonstrating a 15% increase in overall propulsion efficiency[5].

Strengths: High-purity DME production, improved propulsion efficiency, and extensive testing experience. Weaknesses: Limited full-scale implementation in aerospace vehicles and potential challenges in long-term storage stability.

BASF Corp.

Technical Solution: BASF Corp. has made significant strides in DME technology for aerospace applications, focusing on the development of advanced catalysts for DME synthesis and utilization. Their proprietary metal-organic framework (MOF) catalysts have shown exceptional activity and selectivity in the direct synthesis of DME from syngas, achieving conversion rates up to 85% with a DME selectivity of 95%[2]. BASF has also pioneered a novel DME-based fuel cell system for auxiliary power units in aircraft, which offers a 30% weight reduction compared to traditional hydrogen fuel cells[4]. The company's recent collaboration with aerospace manufacturers has led to the successful integration of DME fuel systems in prototype unmanned aerial vehicles (UAVs), demonstrating a 25% increase in flight endurance[6].

Strengths: Advanced catalyst technology, innovative fuel cell systems, and successful prototype implementations. Weaknesses: Limited experience in large-scale aerospace applications and potential regulatory hurdles for widespread adoption.

Key DME Innovations

Catalytic system and process for direct synthesis of dimethyl ether from synthesis gas

PatentInactiveUS20090326281A1

Innovation

- A mixed-bed catalytic system comprising a catalyst for methanol synthesis and acid form zeolite ferrierite, with a silica/alumina ratio of 10 and specific potassium and sodium content, is physically mixed and activated, providing a high concentration of Brønsted acid sites for efficient dehydration without forming unwanted products.

Process for preparing dimethyl ether from crude methanol

PatentInactiveUS6740783B1

Innovation

- A process using a hydrophobic zeolite catalyst with partially replaced hydrogen cations, represented by the formula HxM(1-x)/nZ, which maintains catalytic activity and prevents hydrocarbon generation when using crude methanol containing water, optimizing the SiO2/Al2O3 ratio and adjusting acid site strength to enhance dimethyl ether yield.

DME Safety Regulations

The aerospace sector's adoption of dimethyl ether (DME) technologies necessitates stringent safety regulations to ensure the protection of personnel, equipment, and the environment. These regulations are evolving alongside the emerging technologies, addressing the unique properties and potential risks associated with DME use in aerospace applications.

One of the primary safety concerns with DME is its flammability. Aerospace safety regulations mandate strict storage and handling protocols to minimize the risk of fire or explosion. These include requirements for specialized containment systems, ventilation standards, and the implementation of advanced fire suppression technologies specifically designed for DME-related incidents.

Regulations also focus on the potential health hazards of DME exposure. While DME is generally considered less toxic than many conventional aerospace fuels, safety guidelines still emphasize the importance of personal protective equipment (PPE) and proper training for personnel working with DME systems. Exposure limits are established and regularly reviewed to reflect the latest toxicological data.

The compatibility of DME with various materials used in aerospace applications is another critical aspect addressed by safety regulations. Guidelines specify approved materials for storage tanks, fuel lines, and engine components to prevent degradation or chemical reactions that could compromise system integrity.

Environmental considerations play a significant role in DME safety regulations for the aerospace sector. Protocols for spill prevention, containment, and cleanup are mandated to protect ecosystems in the event of accidental releases during fueling, maintenance, or in-flight emergencies.

Operational safety is a key focus area, with regulations detailing procedures for DME fuel handling during aircraft servicing, as well as emergency response protocols for DME-related incidents. These include specific guidelines for first responders and airport personnel to manage DME-specific hazards effectively.

Certification processes for DME-powered aerospace systems are becoming more rigorous. Regulatory bodies are developing comprehensive testing and validation procedures to ensure the safety and reliability of DME technologies before their integration into commercial aerospace applications.

International cooperation is crucial in developing harmonized safety standards for DME use in aerospace. Organizations such as the International Civil Aviation Organization (ICAO) are working to establish global guidelines that address the cross-border nature of the aerospace industry.

As DME technologies continue to advance, safety regulations are expected to evolve rapidly. Ongoing research and development efforts are focused on improving safety features, such as advanced leak detection systems and fail-safe mechanisms specifically designed for DME applications in aerospace environments.

One of the primary safety concerns with DME is its flammability. Aerospace safety regulations mandate strict storage and handling protocols to minimize the risk of fire or explosion. These include requirements for specialized containment systems, ventilation standards, and the implementation of advanced fire suppression technologies specifically designed for DME-related incidents.

Regulations also focus on the potential health hazards of DME exposure. While DME is generally considered less toxic than many conventional aerospace fuels, safety guidelines still emphasize the importance of personal protective equipment (PPE) and proper training for personnel working with DME systems. Exposure limits are established and regularly reviewed to reflect the latest toxicological data.

The compatibility of DME with various materials used in aerospace applications is another critical aspect addressed by safety regulations. Guidelines specify approved materials for storage tanks, fuel lines, and engine components to prevent degradation or chemical reactions that could compromise system integrity.

Environmental considerations play a significant role in DME safety regulations for the aerospace sector. Protocols for spill prevention, containment, and cleanup are mandated to protect ecosystems in the event of accidental releases during fueling, maintenance, or in-flight emergencies.

Operational safety is a key focus area, with regulations detailing procedures for DME fuel handling during aircraft servicing, as well as emergency response protocols for DME-related incidents. These include specific guidelines for first responders and airport personnel to manage DME-specific hazards effectively.

Certification processes for DME-powered aerospace systems are becoming more rigorous. Regulatory bodies are developing comprehensive testing and validation procedures to ensure the safety and reliability of DME technologies before their integration into commercial aerospace applications.

International cooperation is crucial in developing harmonized safety standards for DME use in aerospace. Organizations such as the International Civil Aviation Organization (ICAO) are working to establish global guidelines that address the cross-border nature of the aerospace industry.

As DME technologies continue to advance, safety regulations are expected to evolve rapidly. Ongoing research and development efforts are focused on improving safety features, such as advanced leak detection systems and fail-safe mechanisms specifically designed for DME applications in aerospace environments.

Environmental Impact

The environmental impact of emerging dimethyl ether (DME) technologies in the aerospace sector is a critical consideration as the industry seeks more sustainable fuel alternatives. DME, a clean-burning synthetic fuel, offers several environmental advantages over traditional aerospace fuels.

One of the primary benefits of DME is its potential to reduce greenhouse gas emissions. When compared to conventional jet fuels, DME combustion produces significantly lower levels of carbon dioxide (CO2) and virtually no particulate matter. This characteristic makes DME an attractive option for reducing the carbon footprint of aerospace operations, aligning with global efforts to mitigate climate change.

Furthermore, DME production can be achieved through various environmentally friendly methods. One promising approach involves utilizing renewable resources such as biomass or waste materials. This production pathway not only reduces reliance on fossil fuels but also contributes to a circular economy by repurposing waste streams. Additionally, DME can be synthesized using captured CO2 and renewable hydrogen, potentially creating a carbon-neutral or even carbon-negative fuel cycle.

The use of DME in aerospace applications also presents advantages in terms of air quality. Unlike conventional jet fuels, DME combustion emits negligible amounts of sulfur oxides and nitrogen oxides, which are major contributors to air pollution and acid rain. This characteristic is particularly beneficial for reducing the environmental impact of aircraft operations in sensitive ecosystems and populated areas.

However, the environmental benefits of DME must be weighed against potential challenges. The production and distribution infrastructure for DME in the aerospace sector is still in its infancy, requiring significant investment and energy input to scale up. The environmental impact of this infrastructure development needs careful assessment to ensure that the overall lifecycle emissions of DME remain favorable compared to existing fuels.

Another consideration is the land use implications of large-scale DME production, especially if biomass feedstocks are employed. Careful management and sustainable sourcing practices are essential to prevent competition with food crops or deforestation.

As the aerospace industry explores DME technologies, comprehensive lifecycle assessments are crucial to fully understand and quantify the environmental impacts. These assessments should consider factors such as raw material sourcing, production processes, transportation, and end-use emissions to provide a holistic view of DME's environmental footprint.

In conclusion, while emerging DME technologies in the aerospace sector show promising environmental benefits, particularly in terms of reduced emissions and improved air quality, their full environmental impact requires ongoing evaluation and optimization as the technology matures and scales.

One of the primary benefits of DME is its potential to reduce greenhouse gas emissions. When compared to conventional jet fuels, DME combustion produces significantly lower levels of carbon dioxide (CO2) and virtually no particulate matter. This characteristic makes DME an attractive option for reducing the carbon footprint of aerospace operations, aligning with global efforts to mitigate climate change.

Furthermore, DME production can be achieved through various environmentally friendly methods. One promising approach involves utilizing renewable resources such as biomass or waste materials. This production pathway not only reduces reliance on fossil fuels but also contributes to a circular economy by repurposing waste streams. Additionally, DME can be synthesized using captured CO2 and renewable hydrogen, potentially creating a carbon-neutral or even carbon-negative fuel cycle.

The use of DME in aerospace applications also presents advantages in terms of air quality. Unlike conventional jet fuels, DME combustion emits negligible amounts of sulfur oxides and nitrogen oxides, which are major contributors to air pollution and acid rain. This characteristic is particularly beneficial for reducing the environmental impact of aircraft operations in sensitive ecosystems and populated areas.

However, the environmental benefits of DME must be weighed against potential challenges. The production and distribution infrastructure for DME in the aerospace sector is still in its infancy, requiring significant investment and energy input to scale up. The environmental impact of this infrastructure development needs careful assessment to ensure that the overall lifecycle emissions of DME remain favorable compared to existing fuels.

Another consideration is the land use implications of large-scale DME production, especially if biomass feedstocks are employed. Careful management and sustainable sourcing practices are essential to prevent competition with food crops or deforestation.

As the aerospace industry explores DME technologies, comprehensive lifecycle assessments are crucial to fully understand and quantify the environmental impacts. These assessments should consider factors such as raw material sourcing, production processes, transportation, and end-use emissions to provide a holistic view of DME's environmental footprint.

In conclusion, while emerging DME technologies in the aerospace sector show promising environmental benefits, particularly in terms of reduced emissions and improved air quality, their full environmental impact requires ongoing evaluation and optimization as the technology matures and scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!