Scaling Dimethyl Ether Applications in Global Energy Markets

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Tech Evolution

Dimethyl ether (DME) has undergone significant technological evolution since its initial discovery in the 19th century. The journey of DME as a potential energy source began in earnest during the 1990s when researchers recognized its potential as a clean-burning alternative fuel. The early stages of DME technology focused primarily on its synthesis from various feedstocks, with methanol dehydration emerging as the most common production method.

In the early 2000s, the technological focus shifted towards optimizing DME production processes to improve efficiency and reduce costs. This period saw the development of advanced catalysts and reactor designs, enabling higher conversion rates and purer DME output. Simultaneously, research into direct DME synthesis from syngas gained momentum, promising a more streamlined production pathway.

The mid-2000s marked a crucial phase in DME's technological evolution, with increased attention on its applications in the energy sector. Engine manufacturers began developing and testing DME-compatible engines, particularly for heavy-duty vehicles. This period also saw the first large-scale DME production plants coming online, demonstrating the technology's readiness for commercial deployment.

From 2010 onwards, DME technology entered a phase of refinement and diversification. Researchers explored novel production methods, including biomass-to-DME processes, aiming to enhance the fuel's sustainability credentials. Concurrently, advancements in DME handling and storage technologies addressed some of the practical challenges associated with its widespread adoption.

Recent years have witnessed a growing interest in DME as a potential solution for decarbonizing hard-to-abate sectors. This has led to innovations in DME blending technologies, exploring its use in combination with other fuels like propane. Additionally, research into DME as a hydrogen carrier has gained traction, positioning it as a potential player in the emerging hydrogen economy.

The technological evolution of DME has also seen significant progress in standardization and regulatory frameworks. International collaborations have resulted in the development of DME fuel standards, facilitating its integration into existing energy infrastructures. This standardization has been crucial in building confidence among potential adopters and investors.

Looking ahead, the technological trajectory of DME is likely to focus on further improving production efficiencies, expanding feedstock options, and enhancing its compatibility with existing and future energy systems. Emerging areas of research include the use of renewable electricity for DME production, potentially linking it to the growing renewable energy sector and providing a solution for energy storage and transport.

In the early 2000s, the technological focus shifted towards optimizing DME production processes to improve efficiency and reduce costs. This period saw the development of advanced catalysts and reactor designs, enabling higher conversion rates and purer DME output. Simultaneously, research into direct DME synthesis from syngas gained momentum, promising a more streamlined production pathway.

The mid-2000s marked a crucial phase in DME's technological evolution, with increased attention on its applications in the energy sector. Engine manufacturers began developing and testing DME-compatible engines, particularly for heavy-duty vehicles. This period also saw the first large-scale DME production plants coming online, demonstrating the technology's readiness for commercial deployment.

From 2010 onwards, DME technology entered a phase of refinement and diversification. Researchers explored novel production methods, including biomass-to-DME processes, aiming to enhance the fuel's sustainability credentials. Concurrently, advancements in DME handling and storage technologies addressed some of the practical challenges associated with its widespread adoption.

Recent years have witnessed a growing interest in DME as a potential solution for decarbonizing hard-to-abate sectors. This has led to innovations in DME blending technologies, exploring its use in combination with other fuels like propane. Additionally, research into DME as a hydrogen carrier has gained traction, positioning it as a potential player in the emerging hydrogen economy.

The technological evolution of DME has also seen significant progress in standardization and regulatory frameworks. International collaborations have resulted in the development of DME fuel standards, facilitating its integration into existing energy infrastructures. This standardization has been crucial in building confidence among potential adopters and investors.

Looking ahead, the technological trajectory of DME is likely to focus on further improving production efficiencies, expanding feedstock options, and enhancing its compatibility with existing and future energy systems. Emerging areas of research include the use of renewable electricity for DME production, potentially linking it to the growing renewable energy sector and providing a solution for energy storage and transport.

Global DME Demand

The global demand for dimethyl ether (DME) has been steadily increasing, driven by its versatile applications in various sectors of the energy market. As a clean-burning, non-toxic fuel with properties similar to liquefied petroleum gas (LPG), DME has gained significant attention as an alternative energy source. The market demand for DME is primarily concentrated in the Asia-Pacific region, with China leading the consumption, followed by Japan and South Korea.

In the transportation sector, DME has shown promising potential as a diesel substitute, particularly for heavy-duty vehicles. Its high cetane number and clean combustion characteristics make it an attractive option for reducing emissions and improving air quality in urban areas. Several countries, including Sweden, Japan, and China, have conducted extensive trials and pilot projects to evaluate the feasibility of DME as a transportation fuel.

The industrial sector represents another significant area of DME demand. It is widely used as an aerosol propellant in various consumer products, replacing chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) due to environmental concerns. Additionally, DME serves as a crucial intermediate in the production of dimethyl sulfate, methyl acetate, and other chemicals, further driving its demand in the chemical industry.

In the residential and commercial sectors, DME is gaining traction as a cooking fuel and heating source, particularly in regions with limited access to natural gas infrastructure. Its properties make it a suitable replacement for LPG, offering similar performance with reduced emissions. This application has seen significant growth in developing countries, where traditional biomass fuels are being phased out in favor of cleaner alternatives.

The power generation sector is also exploring the potential of DME as a fuel for gas turbines and combined cycle power plants. Its clean-burning properties and compatibility with existing infrastructure make it an attractive option for reducing carbon emissions in electricity production. However, this application is still in the early stages of development and requires further research and investment to become commercially viable on a large scale.

Despite the growing demand, the global DME market faces several challenges. The availability of low-cost natural gas and the established infrastructure for conventional fuels pose significant competition. Additionally, the lack of widespread distribution networks and the need for specialized equipment for handling and storage limit the rapid adoption of DME in some regions.

Looking ahead, the global demand for DME is expected to continue its upward trajectory, driven by increasing environmental regulations, the push for cleaner energy sources, and ongoing research and development efforts to expand its applications. The Asia-Pacific region is projected to remain the largest market, with emerging economies in Southeast Asia and India presenting new growth opportunities. As technology advances and production costs decrease, DME is likely to play an increasingly important role in the global energy mix, contributing to the transition towards a more sustainable and diversified energy landscape.

In the transportation sector, DME has shown promising potential as a diesel substitute, particularly for heavy-duty vehicles. Its high cetane number and clean combustion characteristics make it an attractive option for reducing emissions and improving air quality in urban areas. Several countries, including Sweden, Japan, and China, have conducted extensive trials and pilot projects to evaluate the feasibility of DME as a transportation fuel.

The industrial sector represents another significant area of DME demand. It is widely used as an aerosol propellant in various consumer products, replacing chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) due to environmental concerns. Additionally, DME serves as a crucial intermediate in the production of dimethyl sulfate, methyl acetate, and other chemicals, further driving its demand in the chemical industry.

In the residential and commercial sectors, DME is gaining traction as a cooking fuel and heating source, particularly in regions with limited access to natural gas infrastructure. Its properties make it a suitable replacement for LPG, offering similar performance with reduced emissions. This application has seen significant growth in developing countries, where traditional biomass fuels are being phased out in favor of cleaner alternatives.

The power generation sector is also exploring the potential of DME as a fuel for gas turbines and combined cycle power plants. Its clean-burning properties and compatibility with existing infrastructure make it an attractive option for reducing carbon emissions in electricity production. However, this application is still in the early stages of development and requires further research and investment to become commercially viable on a large scale.

Despite the growing demand, the global DME market faces several challenges. The availability of low-cost natural gas and the established infrastructure for conventional fuels pose significant competition. Additionally, the lack of widespread distribution networks and the need for specialized equipment for handling and storage limit the rapid adoption of DME in some regions.

Looking ahead, the global demand for DME is expected to continue its upward trajectory, driven by increasing environmental regulations, the push for cleaner energy sources, and ongoing research and development efforts to expand its applications. The Asia-Pacific region is projected to remain the largest market, with emerging economies in Southeast Asia and India presenting new growth opportunities. As technology advances and production costs decrease, DME is likely to play an increasingly important role in the global energy mix, contributing to the transition towards a more sustainable and diversified energy landscape.

DME Tech Challenges

Despite the promising potential of dimethyl ether (DME) as a clean alternative fuel, several technical challenges hinder its widespread adoption in global energy markets. One of the primary obstacles is the lack of dedicated infrastructure for DME production, storage, and distribution. Unlike established fuels such as gasoline or diesel, DME requires specialized handling equipment and storage facilities due to its unique physical properties.

The production of DME at scale presents another significant challenge. While the synthesis process from methanol or syngas is well-understood, optimizing large-scale production to achieve cost-effectiveness remains a hurdle. Current production methods often struggle to match the economies of scale enjoyed by conventional fuels, making DME less competitive in the market.

Engine compatibility is a crucial technical issue that needs addressing. Although DME can be used in modified diesel engines, widespread adoption would require significant redesigns of existing engine technologies. This includes developing new fuel injection systems, addressing potential material compatibility issues, and optimizing combustion processes for DME's specific characteristics.

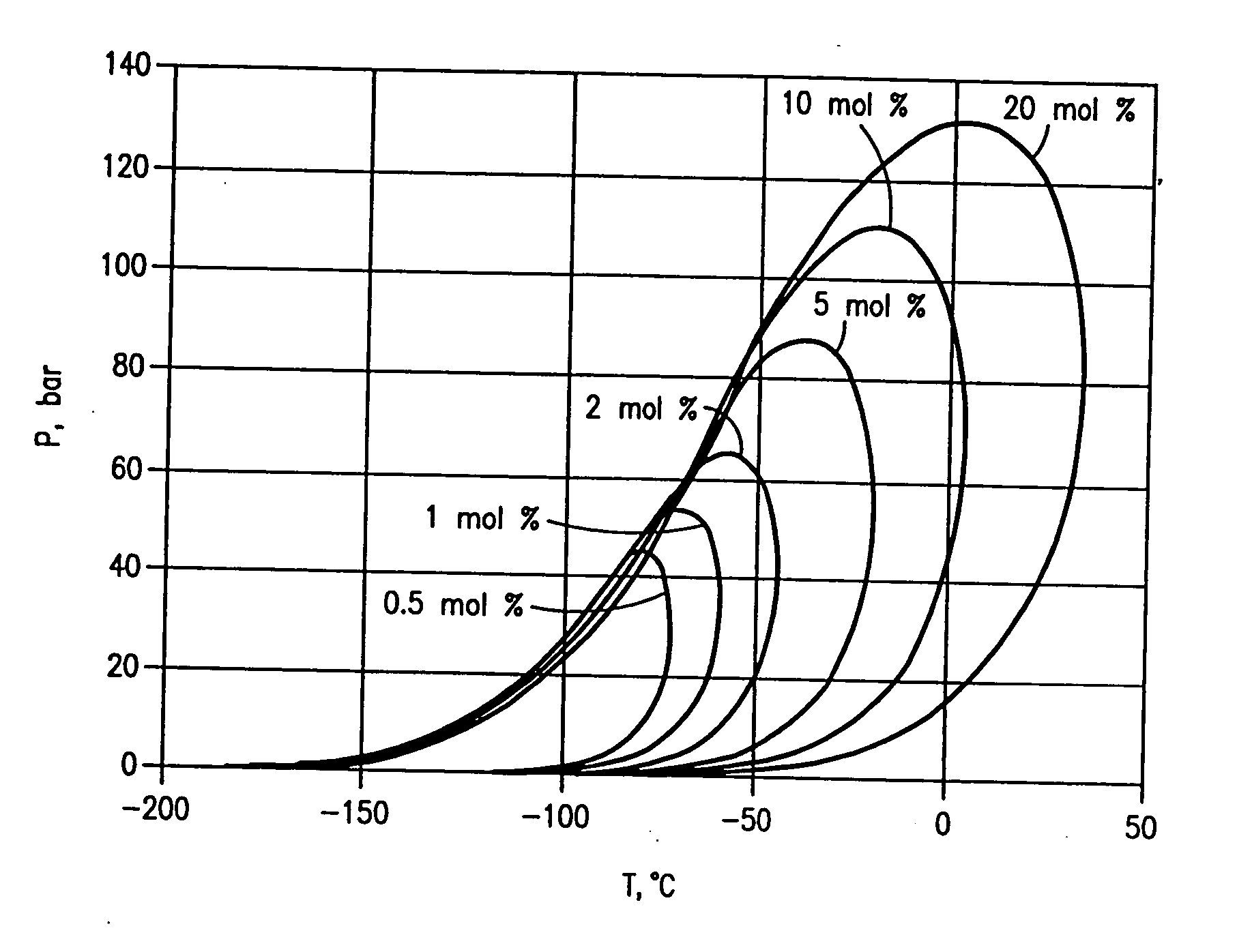

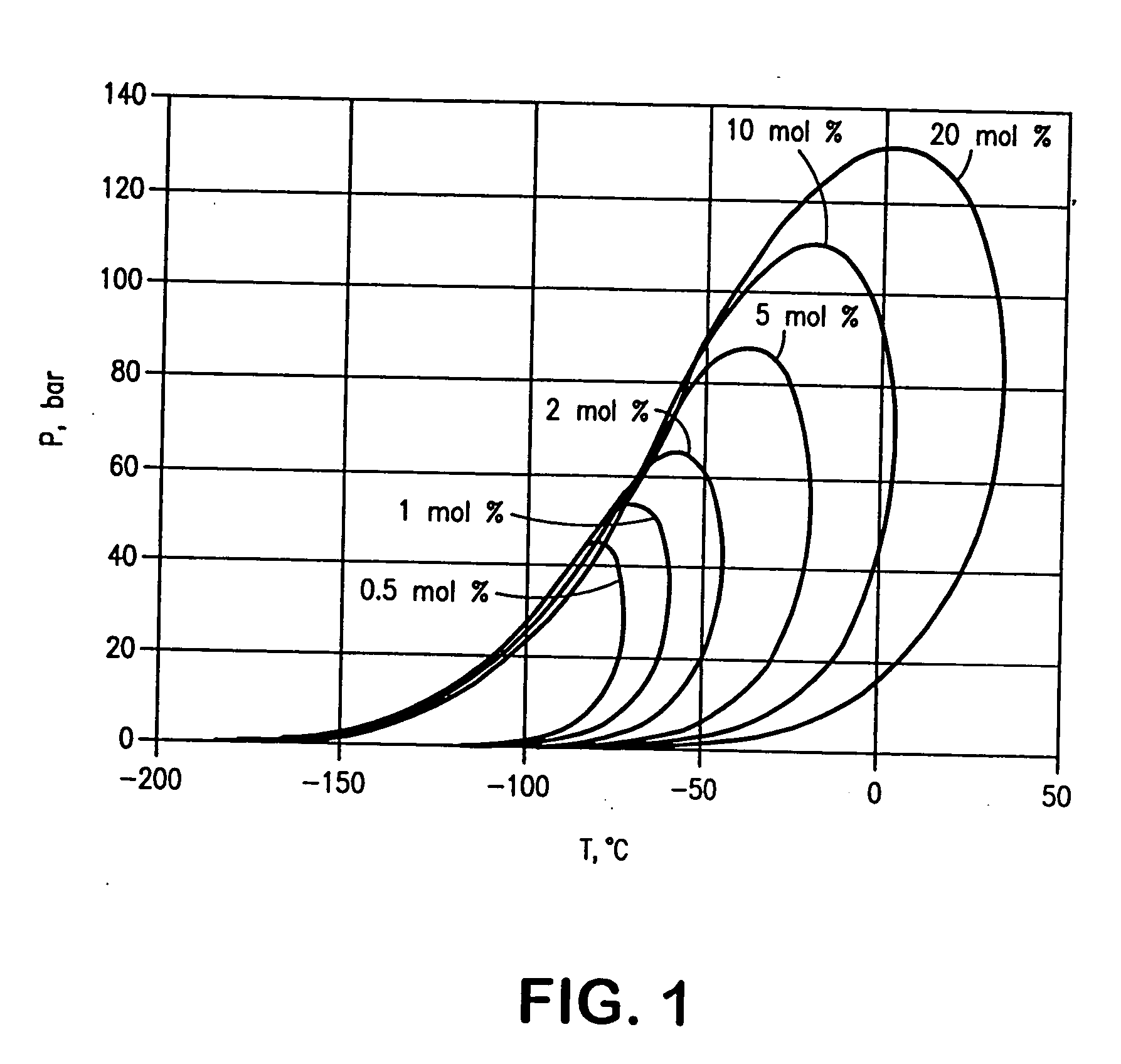

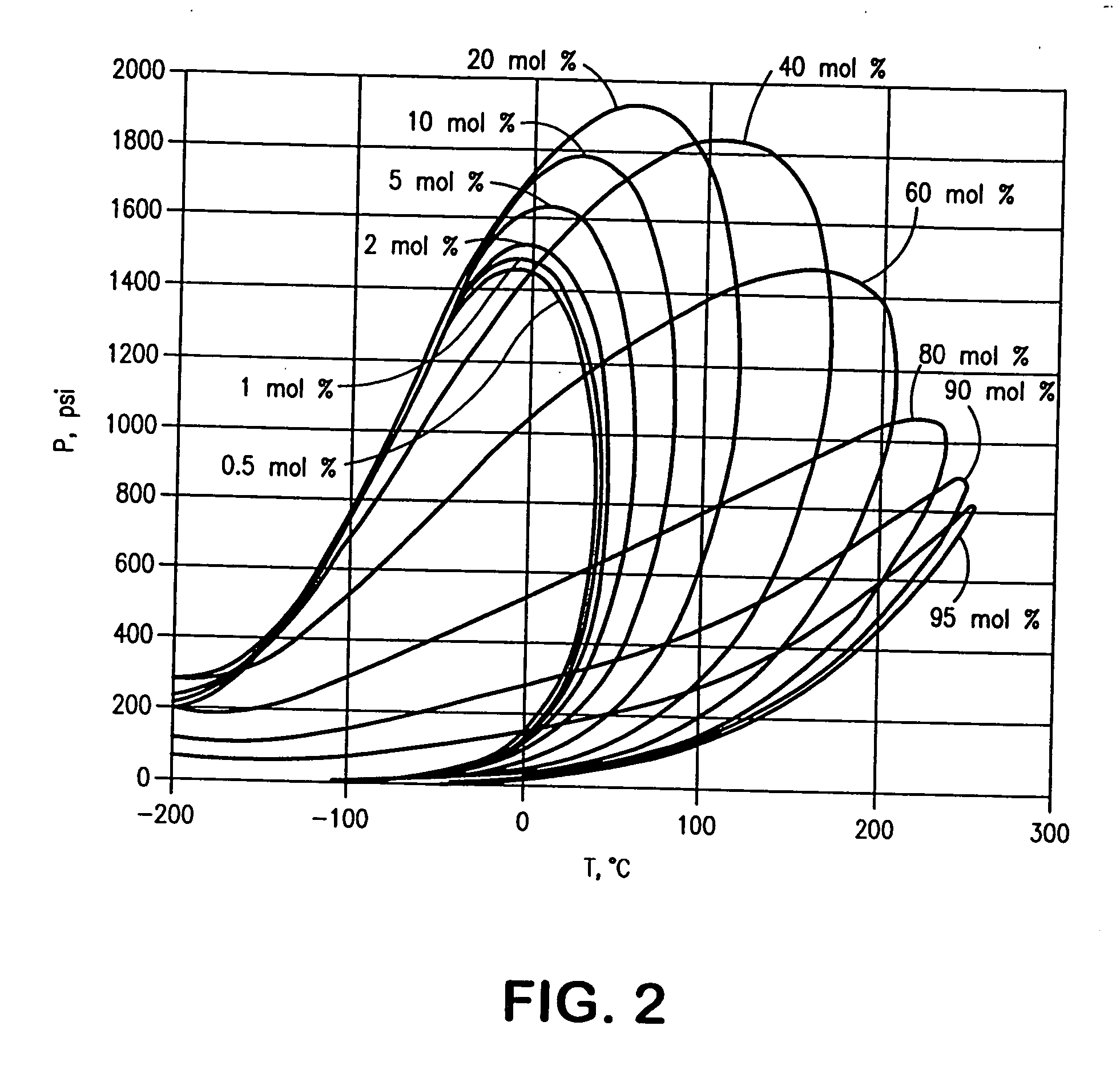

The storage and transportation of DME pose additional challenges due to its low boiling point and high vapor pressure. These properties necessitate pressurized containers and specialized handling procedures, which can increase logistical complexities and costs throughout the supply chain.

Another technical hurdle is the need for improved catalysts in DME production. Current catalysts used in the synthesis process may suffer from deactivation or selectivity issues, impacting the efficiency and economics of large-scale production. Research into more robust and efficient catalysts is crucial for enhancing DME's viability as a fuel alternative.

Environmental considerations also present technical challenges. While DME combustion produces lower emissions compared to conventional fuels, the entire lifecycle assessment, including production and distribution, needs to be optimized to maximize its environmental benefits. This involves developing more energy-efficient production processes and reducing the carbon footprint of the entire DME supply chain.

Lastly, the integration of DME into existing energy systems poses technical challenges. This includes developing blending strategies with conventional fuels, adapting current fueling stations, and ensuring compatibility with existing storage and transportation infrastructure. Overcoming these integration challenges is crucial for the seamless incorporation of DME into the global energy market.

The production of DME at scale presents another significant challenge. While the synthesis process from methanol or syngas is well-understood, optimizing large-scale production to achieve cost-effectiveness remains a hurdle. Current production methods often struggle to match the economies of scale enjoyed by conventional fuels, making DME less competitive in the market.

Engine compatibility is a crucial technical issue that needs addressing. Although DME can be used in modified diesel engines, widespread adoption would require significant redesigns of existing engine technologies. This includes developing new fuel injection systems, addressing potential material compatibility issues, and optimizing combustion processes for DME's specific characteristics.

The storage and transportation of DME pose additional challenges due to its low boiling point and high vapor pressure. These properties necessitate pressurized containers and specialized handling procedures, which can increase logistical complexities and costs throughout the supply chain.

Another technical hurdle is the need for improved catalysts in DME production. Current catalysts used in the synthesis process may suffer from deactivation or selectivity issues, impacting the efficiency and economics of large-scale production. Research into more robust and efficient catalysts is crucial for enhancing DME's viability as a fuel alternative.

Environmental considerations also present technical challenges. While DME combustion produces lower emissions compared to conventional fuels, the entire lifecycle assessment, including production and distribution, needs to be optimized to maximize its environmental benefits. This involves developing more energy-efficient production processes and reducing the carbon footprint of the entire DME supply chain.

Lastly, the integration of DME into existing energy systems poses technical challenges. This includes developing blending strategies with conventional fuels, adapting current fueling stations, and ensuring compatibility with existing storage and transportation infrastructure. Overcoming these integration challenges is crucial for the seamless incorporation of DME into the global energy market.

Current DME Solutions

01 Production of dimethyl ether

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.- Production of dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

- Catalysts for dimethyl ether synthesis: Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.

- Applications of dimethyl ether: Dimethyl ether has various applications, including use as a fuel substitute, propellant, refrigerant, and chemical intermediate. Its properties make it suitable for use in diesel engines, aerosol products, and as a feedstock for other chemical processes.

- Purification and separation of dimethyl ether: Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes may involve distillation, adsorption, or membrane separation techniques to obtain high-purity dimethyl ether.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of dimethyl ether production and use is conducted. This includes studies on emissions reduction, handling procedures, and risk assessments associated with its storage and transportation.

02 Catalysts for dimethyl ether synthesis

Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst can significantly affect the reaction efficiency, product selectivity, and overall process economics.Expand Specific Solutions03 Applications of dimethyl ether

Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as a potential alternative fuel for diesel engines due to its clean-burning properties and high cetane number.Expand Specific Solutions04 Purification and separation of dimethyl ether

Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes often involve distillation, adsorption, or membrane separation techniques to achieve high-purity dimethyl ether for various applications.Expand Specific Solutions05 Environmental and safety considerations

Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and storage requirements to ensure safe and sustainable utilization of dimethyl ether in various applications.Expand Specific Solutions

DME Industry Players

The global market for dimethyl ether (DME) applications is in a growth phase, driven by increasing demand for clean energy alternatives. The market size is expanding, particularly in Asia-Pacific regions, with projections indicating significant growth potential. Technologically, DME production and application processes are maturing, with key players like China Petroleum & Chemical Corp., SK Energy, and BP Corporation North America leading research and development efforts. These companies, along with academic institutions such as the University of Southern California and research centers like the Centre National de la Recherche Scientifique, are advancing DME technology across various applications, from fuel to chemical feedstock. The competitive landscape is characterized by a mix of established energy giants and specialized chemical companies, indicating a diverse and dynamic market environment.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been at the forefront of dimethyl ether (DME) research and application in global energy markets. The company has developed a proprietary technology for large-scale DME production from coal and natural gas. Their process involves syngas generation, methanol synthesis, and methanol dehydration to DME. Sinopec has successfully implemented this technology in multiple plants across China, with production capacities ranging from 100,000 to 1,000,000 tons per year[1][3]. The company has also been exploring the use of DME as a clean alternative fuel for vehicles and household cooking, conducting extensive field trials and demonstrations[2].

Strengths: Established large-scale production technology, extensive experience in DME applications, strong domestic market presence. Weaknesses: Heavy reliance on coal-based feedstock, which may face environmental challenges in the long term.

BP Corporation North America, Inc.

Technical Solution: BP has been actively involved in scaling DME applications in global energy markets through its innovative approach to DME production and utilization. The company has developed a novel process for direct DME synthesis from syngas, bypassing the methanol intermediate step. This technology, known as the BP/JM DME process, offers significant advantages in terms of efficiency and cost-effectiveness[4]. BP has also been exploring the potential of DME as a low-carbon fuel for heavy-duty vehicles and marine applications. In collaboration with various partners, BP has conducted successful trials of DME-powered trucks and ships, demonstrating the fuel's potential to reduce greenhouse gas emissions by up to 85% compared to conventional diesel[5][6].

Strengths: Advanced direct DME synthesis technology, strong focus on sustainable transportation applications. Weaknesses: Limited commercial-scale implementation of DME technology compared to some competitors.

DME Tech Innovations

Energy supply method and system

PatentWO2006004140A1

Innovation

- The introduction of Dimethyl Ether (DME) as a versatile energy circulation medium, which can be derived from biomass, waste, and petroleum residues, and used for power generation, transportation, and heating, allowing for efficient energy storage and distribution without relying on pipelines, and enabling the conversion of waste heat into usable energy.

Method for transporting synthetic products

PatentInactiveUS20060058564A1

Innovation

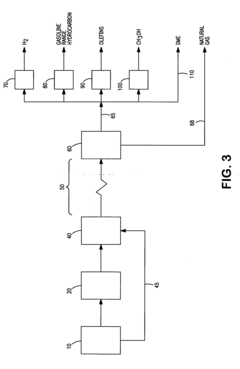

- A method involving the conversion of these products into a dense phase state, allowing for their transportation via pipeline by mixing with natural gas, maintaining the dense phase state during transit, and then converting back at the delivery point for separation and further processing.

DME Policy Landscape

The global policy landscape for dimethyl ether (DME) applications in energy markets is characterized by a complex interplay of environmental regulations, energy security concerns, and economic incentives. Many countries have implemented policies to promote the use of DME as a cleaner alternative to conventional fuels, particularly in the transportation and industrial sectors.

In the European Union, the Renewable Energy Directive (RED II) has set ambitious targets for renewable energy use in transport, creating opportunities for DME as a low-carbon fuel. The directive encourages the use of advanced biofuels, including those derived from waste and residues, which aligns with DME production from sustainable feedstocks.

China has been at the forefront of DME adoption, with policies supporting its use as a cooking fuel and diesel substitute. The government has implemented subsidies and tax incentives to encourage DME production and consumption, particularly in rural areas where it can replace coal and improve air quality.

In the United States, the Environmental Protection Agency (EPA) has approved DME as a renewable fuel under the Renewable Fuel Standard (RFS) program. This classification allows DME producers to generate Renewable Identification Numbers (RINs), providing economic incentives for production and blending.

Japan has also shown interest in DME as part of its energy diversification strategy. The country's Strategic Energy Plan includes provisions for DME research and development, focusing on its potential as a hydrogen carrier and clean fuel for power generation.

Several developing countries, particularly in Southeast Asia, have implemented policies to promote DME as a cooking fuel alternative to liquefied petroleum gas (LPG). These initiatives aim to reduce dependence on imported fossil fuels and improve energy access in remote areas.

Despite these supportive policies, challenges remain in scaling DME applications globally. Inconsistent regulatory frameworks across regions, limited infrastructure for distribution, and competition from other alternative fuels have hindered widespread adoption.

To address these challenges, policymakers are increasingly focusing on harmonizing standards and regulations for DME across borders. International collaborations, such as the International DME Association, are working to promote knowledge sharing and policy alignment to create a more favorable environment for DME market growth.

As the world transitions towards cleaner energy sources, the policy landscape for DME is likely to evolve further. Future policies may focus on integrating DME into broader decarbonization strategies, such as sector coupling and renewable energy storage solutions, to maximize its potential in the global energy market.

In the European Union, the Renewable Energy Directive (RED II) has set ambitious targets for renewable energy use in transport, creating opportunities for DME as a low-carbon fuel. The directive encourages the use of advanced biofuels, including those derived from waste and residues, which aligns with DME production from sustainable feedstocks.

China has been at the forefront of DME adoption, with policies supporting its use as a cooking fuel and diesel substitute. The government has implemented subsidies and tax incentives to encourage DME production and consumption, particularly in rural areas where it can replace coal and improve air quality.

In the United States, the Environmental Protection Agency (EPA) has approved DME as a renewable fuel under the Renewable Fuel Standard (RFS) program. This classification allows DME producers to generate Renewable Identification Numbers (RINs), providing economic incentives for production and blending.

Japan has also shown interest in DME as part of its energy diversification strategy. The country's Strategic Energy Plan includes provisions for DME research and development, focusing on its potential as a hydrogen carrier and clean fuel for power generation.

Several developing countries, particularly in Southeast Asia, have implemented policies to promote DME as a cooking fuel alternative to liquefied petroleum gas (LPG). These initiatives aim to reduce dependence on imported fossil fuels and improve energy access in remote areas.

Despite these supportive policies, challenges remain in scaling DME applications globally. Inconsistent regulatory frameworks across regions, limited infrastructure for distribution, and competition from other alternative fuels have hindered widespread adoption.

To address these challenges, policymakers are increasingly focusing on harmonizing standards and regulations for DME across borders. International collaborations, such as the International DME Association, are working to promote knowledge sharing and policy alignment to create a more favorable environment for DME market growth.

As the world transitions towards cleaner energy sources, the policy landscape for DME is likely to evolve further. Future policies may focus on integrating DME into broader decarbonization strategies, such as sector coupling and renewable energy storage solutions, to maximize its potential in the global energy market.

DME Environmental Impact

Dimethyl ether (DME) has gained attention as a potential alternative fuel due to its favorable environmental characteristics compared to conventional fossil fuels. When considering the environmental impact of scaling DME applications in global energy markets, several key factors come into play.

DME combustion produces significantly lower emissions of particulate matter, nitrogen oxides, and sulfur oxides compared to diesel fuel. This reduction in harmful pollutants can lead to improved air quality, particularly in urban areas where vehicle emissions are a major concern. The lower soot formation during DME combustion also contributes to reduced black carbon emissions, which have been linked to climate change and adverse health effects.

From a greenhouse gas perspective, DME offers potential advantages over traditional fossil fuels. When produced from renewable sources such as biomass or captured carbon dioxide, DME can have a substantially lower carbon footprint throughout its lifecycle. However, the environmental benefits of DME are highly dependent on the production pathway, with fossil fuel-based production methods potentially negating some of the advantages.

Water consumption and land use are important considerations in scaling DME production. While DME itself does not pose significant risks to water resources, the production process may require substantial water inputs, particularly if biomass feedstocks are used. Land use changes associated with feedstock cultivation could also have ecological implications, potentially affecting biodiversity and ecosystem services.

The storage and transportation of DME present fewer environmental risks compared to some other fuels. DME is non-toxic and biodegradable, reducing the potential for long-term environmental contamination in case of spills or leaks. Its properties also allow for easier handling and storage compared to liquefied natural gas (LNG) or liquefied petroleum gas (LPG).

As DME can be used as a drop-in replacement for certain applications, it may leverage existing infrastructure to some extent, potentially reducing the environmental impact associated with new infrastructure development. However, widespread adoption would still require significant investments in production facilities and distribution networks.

The end-use efficiency of DME in various applications, such as power generation or transportation, is another crucial factor in its overall environmental impact. Higher efficiency can lead to reduced fuel consumption and, consequently, lower emissions per unit of energy delivered.

DME combustion produces significantly lower emissions of particulate matter, nitrogen oxides, and sulfur oxides compared to diesel fuel. This reduction in harmful pollutants can lead to improved air quality, particularly in urban areas where vehicle emissions are a major concern. The lower soot formation during DME combustion also contributes to reduced black carbon emissions, which have been linked to climate change and adverse health effects.

From a greenhouse gas perspective, DME offers potential advantages over traditional fossil fuels. When produced from renewable sources such as biomass or captured carbon dioxide, DME can have a substantially lower carbon footprint throughout its lifecycle. However, the environmental benefits of DME are highly dependent on the production pathway, with fossil fuel-based production methods potentially negating some of the advantages.

Water consumption and land use are important considerations in scaling DME production. While DME itself does not pose significant risks to water resources, the production process may require substantial water inputs, particularly if biomass feedstocks are used. Land use changes associated with feedstock cultivation could also have ecological implications, potentially affecting biodiversity and ecosystem services.

The storage and transportation of DME present fewer environmental risks compared to some other fuels. DME is non-toxic and biodegradable, reducing the potential for long-term environmental contamination in case of spills or leaks. Its properties also allow for easier handling and storage compared to liquefied natural gas (LNG) or liquefied petroleum gas (LPG).

As DME can be used as a drop-in replacement for certain applications, it may leverage existing infrastructure to some extent, potentially reducing the environmental impact associated with new infrastructure development. However, widespread adoption would still require significant investments in production facilities and distribution networks.

The end-use efficiency of DME in various applications, such as power generation or transportation, is another crucial factor in its overall environmental impact. Higher efficiency can lead to reduced fuel consumption and, consequently, lower emissions per unit of energy delivered.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!