Dodecane in Advanced Composites: A Comprehensive Guide

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dodecane in Composites: Background and Objectives

Dodecane, a versatile hydrocarbon compound, has emerged as a significant player in the field of advanced composites. This long-chain alkane, with its unique properties, has garnered attention from researchers and industry professionals alike, paving the way for innovative applications in composite materials. The journey of dodecane in composites began with the recognition of its potential as a phase change material (PCM) due to its favorable melting point and latent heat characteristics.

The evolution of dodecane's role in composites has been driven by the increasing demand for materials with enhanced thermal management capabilities, particularly in aerospace, automotive, and construction industries. As global energy concerns and sustainability issues have come to the forefront, the development of composites incorporating dodecane has accelerated, aiming to create more energy-efficient and environmentally friendly materials.

The primary objective of integrating dodecane into advanced composites is to harness its thermal energy storage capabilities. By encapsulating dodecane within the composite matrix, researchers aim to create materials that can absorb, store, and release thermal energy effectively. This property is particularly valuable in applications where temperature regulation is crucial, such as in building materials for improved energy efficiency or in electronic components for thermal management.

Another key goal is to enhance the mechanical properties of composites through the incorporation of dodecane. The interaction between dodecane and various matrix materials has shown promise in improving flexibility, impact resistance, and overall durability of composite structures. This synergy between thermal functionality and mechanical enhancement makes dodecane-based composites particularly attractive for multifunctional applications.

The research landscape surrounding dodecane in composites has expanded to include various encapsulation techniques, matrix compatibility studies, and performance optimization strategies. Scientists are exploring novel methods to effectively integrate dodecane into different composite systems, ranging from polymer-based to ceramic-based matrices. The aim is to develop composites that not only exhibit superior thermal properties but also maintain or improve their structural integrity and longevity.

As the field progresses, there is a growing focus on understanding the long-term behavior of dodecane-infused composites, including their stability, cycling performance, and potential environmental impacts. This comprehensive approach to research and development is essential for realizing the full potential of dodecane in advanced composite applications and addressing any challenges that may arise during practical implementation.

The evolution of dodecane's role in composites has been driven by the increasing demand for materials with enhanced thermal management capabilities, particularly in aerospace, automotive, and construction industries. As global energy concerns and sustainability issues have come to the forefront, the development of composites incorporating dodecane has accelerated, aiming to create more energy-efficient and environmentally friendly materials.

The primary objective of integrating dodecane into advanced composites is to harness its thermal energy storage capabilities. By encapsulating dodecane within the composite matrix, researchers aim to create materials that can absorb, store, and release thermal energy effectively. This property is particularly valuable in applications where temperature regulation is crucial, such as in building materials for improved energy efficiency or in electronic components for thermal management.

Another key goal is to enhance the mechanical properties of composites through the incorporation of dodecane. The interaction between dodecane and various matrix materials has shown promise in improving flexibility, impact resistance, and overall durability of composite structures. This synergy between thermal functionality and mechanical enhancement makes dodecane-based composites particularly attractive for multifunctional applications.

The research landscape surrounding dodecane in composites has expanded to include various encapsulation techniques, matrix compatibility studies, and performance optimization strategies. Scientists are exploring novel methods to effectively integrate dodecane into different composite systems, ranging from polymer-based to ceramic-based matrices. The aim is to develop composites that not only exhibit superior thermal properties but also maintain or improve their structural integrity and longevity.

As the field progresses, there is a growing focus on understanding the long-term behavior of dodecane-infused composites, including their stability, cycling performance, and potential environmental impacts. This comprehensive approach to research and development is essential for realizing the full potential of dodecane in advanced composite applications and addressing any challenges that may arise during practical implementation.

Market Analysis for Dodecane-Enhanced Composites

The market for dodecane-enhanced composites is experiencing significant growth, driven by the increasing demand for high-performance materials in various industries. Dodecane, a saturated hydrocarbon, has emerged as a valuable additive in advanced composite materials, offering unique properties that enhance their overall performance and versatility.

In the aerospace sector, dodecane-enhanced composites are gaining traction due to their lightweight nature and improved mechanical properties. These materials contribute to fuel efficiency and reduced emissions in aircraft manufacturing, aligning with the industry's sustainability goals. The automotive industry is also adopting these composites for similar reasons, particularly in electric vehicle production where weight reduction is crucial for extending battery range.

The construction industry represents another significant market for dodecane-enhanced composites. These materials offer superior strength-to-weight ratios, corrosion resistance, and durability, making them ideal for infrastructure projects, especially in harsh environments. The growing focus on sustainable building practices further drives the adoption of these advanced composites.

In the renewable energy sector, dodecane-enhanced composites are finding applications in wind turbine blades and solar panel components. The materials' resistance to environmental factors and improved longevity contribute to the overall efficiency and lifespan of renewable energy installations.

The electronics industry is exploring the use of dodecane-enhanced composites in the production of lightweight, durable casings for devices and components. This trend is particularly evident in the rapidly expanding market for wearable technology and portable electronics.

Market analysts project a compound annual growth rate (CAGR) for dodecane-enhanced composites that outpaces traditional composite materials. This growth is attributed to the increasing awareness of their benefits and the expanding range of applications across industries.

However, challenges remain in the widespread adoption of these materials. The higher initial costs associated with dodecane-enhanced composites compared to conventional materials pose a barrier to entry for some manufacturers. Additionally, the need for specialized manufacturing processes and equipment may limit immediate adoption in certain sectors.

Despite these challenges, the long-term benefits of dodecane-enhanced composites, including improved performance, longevity, and potential cost savings over the product lifecycle, are expected to drive continued market expansion. As research and development efforts intensify, and production processes become more efficient, the market for these advanced materials is poised for sustained growth in the coming years.

In the aerospace sector, dodecane-enhanced composites are gaining traction due to their lightweight nature and improved mechanical properties. These materials contribute to fuel efficiency and reduced emissions in aircraft manufacturing, aligning with the industry's sustainability goals. The automotive industry is also adopting these composites for similar reasons, particularly in electric vehicle production where weight reduction is crucial for extending battery range.

The construction industry represents another significant market for dodecane-enhanced composites. These materials offer superior strength-to-weight ratios, corrosion resistance, and durability, making them ideal for infrastructure projects, especially in harsh environments. The growing focus on sustainable building practices further drives the adoption of these advanced composites.

In the renewable energy sector, dodecane-enhanced composites are finding applications in wind turbine blades and solar panel components. The materials' resistance to environmental factors and improved longevity contribute to the overall efficiency and lifespan of renewable energy installations.

The electronics industry is exploring the use of dodecane-enhanced composites in the production of lightweight, durable casings for devices and components. This trend is particularly evident in the rapidly expanding market for wearable technology and portable electronics.

Market analysts project a compound annual growth rate (CAGR) for dodecane-enhanced composites that outpaces traditional composite materials. This growth is attributed to the increasing awareness of their benefits and the expanding range of applications across industries.

However, challenges remain in the widespread adoption of these materials. The higher initial costs associated with dodecane-enhanced composites compared to conventional materials pose a barrier to entry for some manufacturers. Additionally, the need for specialized manufacturing processes and equipment may limit immediate adoption in certain sectors.

Despite these challenges, the long-term benefits of dodecane-enhanced composites, including improved performance, longevity, and potential cost savings over the product lifecycle, are expected to drive continued market expansion. As research and development efforts intensify, and production processes become more efficient, the market for these advanced materials is poised for sustained growth in the coming years.

Current Challenges in Dodecane Integration

The integration of dodecane into advanced composites presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is achieving uniform dispersion of dodecane within the composite matrix. Due to its non-polar nature, dodecane tends to form aggregates or clusters, leading to inconsistent distribution throughout the material. This inhomogeneity can result in localized areas of weakness, compromising the overall mechanical properties of the composite.

Another major challenge lies in maintaining the structural integrity of the composite during the incorporation of dodecane. The introduction of this hydrocarbon can potentially disrupt the bonding between the matrix and reinforcing fibers, leading to reduced interfacial adhesion. This weakened interface can result in premature failure of the composite under stress, limiting its load-bearing capacity and overall performance.

The volatility of dodecane poses yet another hurdle in its integration into advanced composites. Its relatively low boiling point (216.2°C) can cause issues during high-temperature processing or in applications where the composite may be exposed to elevated temperatures. This volatility can lead to the formation of voids or micro-cracks within the composite structure, further compromising its mechanical and thermal properties.

Compatibility with different matrix materials is also a significant concern. While dodecane may integrate well with certain polymer matrices, it may exhibit poor compatibility with others, leading to phase separation or degradation of the matrix properties. This challenge necessitates careful selection of matrix materials and potentially the development of new formulations specifically designed to accommodate dodecane.

Furthermore, the long-term stability of dodecane-integrated composites remains a subject of ongoing research. There are concerns about the potential leaching or migration of dodecane over time, especially under various environmental conditions. This could lead to a gradual deterioration of the composite's properties and potentially impact its service life.

Lastly, the environmental and health implications of incorporating dodecane into advanced composites are still not fully understood. As regulations around chemical usage become more stringent, there is a growing need to assess the potential environmental impact and toxicity of dodecane-containing composites throughout their lifecycle, from manufacturing to disposal.

Another major challenge lies in maintaining the structural integrity of the composite during the incorporation of dodecane. The introduction of this hydrocarbon can potentially disrupt the bonding between the matrix and reinforcing fibers, leading to reduced interfacial adhesion. This weakened interface can result in premature failure of the composite under stress, limiting its load-bearing capacity and overall performance.

The volatility of dodecane poses yet another hurdle in its integration into advanced composites. Its relatively low boiling point (216.2°C) can cause issues during high-temperature processing or in applications where the composite may be exposed to elevated temperatures. This volatility can lead to the formation of voids or micro-cracks within the composite structure, further compromising its mechanical and thermal properties.

Compatibility with different matrix materials is also a significant concern. While dodecane may integrate well with certain polymer matrices, it may exhibit poor compatibility with others, leading to phase separation or degradation of the matrix properties. This challenge necessitates careful selection of matrix materials and potentially the development of new formulations specifically designed to accommodate dodecane.

Furthermore, the long-term stability of dodecane-integrated composites remains a subject of ongoing research. There are concerns about the potential leaching or migration of dodecane over time, especially under various environmental conditions. This could lead to a gradual deterioration of the composite's properties and potentially impact its service life.

Lastly, the environmental and health implications of incorporating dodecane into advanced composites are still not fully understood. As regulations around chemical usage become more stringent, there is a growing need to assess the potential environmental impact and toxicity of dodecane-containing composites throughout their lifecycle, from manufacturing to disposal.

Existing Dodecane Incorporation Techniques

01 Synthesis and production of dodecane

Dodecane can be synthesized through various chemical processes, including the hydrogenation of long-chain alkenes or the Fischer-Tropsch process. It can also be produced from renewable resources such as plant oils or biomass. The synthesis methods often involve catalytic reactions and may require specific reaction conditions to optimize yield and purity.- Synthesis and production of dodecane: Various methods for synthesizing and producing dodecane are described, including catalytic processes, hydrogenation reactions, and chemical transformations of precursor molecules. These techniques aim to improve the efficiency and yield of dodecane production for industrial applications.

- Use of dodecane in cosmetic and personal care products: Dodecane is utilized as an ingredient in cosmetic and personal care formulations, serving as a solvent, emollient, or carrier for active ingredients. It can enhance the texture, spreadability, and overall performance of various beauty and skincare products.

- Application of dodecane in fuel and energy systems: Dodecane finds applications in fuel and energy systems, including its use as a component in jet fuels, diesel fuels, and other hydrocarbon-based energy sources. Research focuses on optimizing its properties for improved combustion efficiency and environmental performance.

- Dodecane as a solvent and extraction medium: The use of dodecane as a solvent and extraction medium in various industrial processes is explored. It is employed in the extraction of organic compounds, separation of mixtures, and as a reaction medium for chemical syntheses due to its favorable physicochemical properties.

- Dodecane in polymer and material science applications: Dodecane is utilized in polymer and material science applications, including its role in the synthesis of polymers, as a plasticizer, and in the development of advanced materials with specific properties. Research focuses on incorporating dodecane to enhance material performance and functionality.

02 Applications in cosmetics and personal care products

Dodecane is used in various cosmetic and personal care formulations due to its emollient properties and ability to enhance the spreadability of products. It can be found in skincare products, hair care formulations, and makeup items. Dodecane helps improve the texture and feel of these products while also acting as a solvent for other ingredients.Expand Specific Solutions03 Use in industrial and chemical processes

Dodecane finds applications in various industrial and chemical processes. It can be used as a solvent, a component in lubricants, or as a raw material for the production of other chemicals. In some cases, it is employed in the manufacturing of plastics, rubber, and other synthetic materials. Dodecane's properties make it suitable for use in heat transfer fluids and as a standard in gas chromatography.Expand Specific Solutions04 Environmental and fuel applications

Dodecane has potential applications in environmental remediation and as a component in alternative fuels. It can be used in bioremediation processes for cleaning up oil spills or contaminated soils. In the field of renewable energy, dodecane and its derivatives are being explored as potential biofuels or additives to improve the properties of existing fuels.Expand Specific Solutions05 Analytical and research applications

Dodecane is utilized in various analytical and research applications. It serves as a reference compound in chromatography and spectroscopy, helping to calibrate instruments and develop new analytical methods. In research settings, dodecane is used to study molecular interactions, surface phenomena, and as a model compound for understanding the behavior of hydrocarbons in different environments.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The market for advanced composites incorporating dodecane is in a growth phase, driven by increasing demand for high-performance materials across industries. The global market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing rapidly, with companies like BASF, Evonik, and Arkema leading innovation in composite formulations and manufacturing processes. These industry leaders are investing heavily in R&D to enhance dodecane-based composites' properties and applications. Emerging players such as Wanhua Chemical and Shandong Guangtong New Materials are also contributing to technological advancements, particularly in specialized applications. The competitive landscape is characterized by a mix of established chemical giants and innovative startups, fostering a dynamic environment for further development and commercialization of dodecane-enhanced advanced composites.

Evonik Operations GmbH

Technical Solution: Evonik has developed a novel approach to incorporating dodecane in advanced composites through their ROHACELL® foam technology. This innovative process uses dodecane as a blowing agent and structural modifier in high-performance structural foams[7]. The company's patented technique allows for precise control of cell structure and density, resulting in lightweight composites with exceptional mechanical properties. Evonik's dodecane-based foams have shown a 40% reduction in weight while maintaining comparable strength to solid materials, making them ideal for applications in automotive, aerospace, and wind energy sectors[8].

Strengths: Significant weight reduction, customizable properties, and broad application potential. Weaknesses: Potential limitations in extreme temperature environments and higher production costs.

Chevron Phillips Chemical Co. LP

Technical Solution: Chevron Phillips Chemical has focused on the synthesis and modification of dodecane for use in advanced composites. Their approach involves the development of functionalized dodecane derivatives that can be directly incorporated into polymer matrices, enhancing compatibility and performance[9]. The company's proprietary process allows for the creation of dodecane-based monomers and oligomers that can be polymerized to form high-performance thermoplastic and thermoset composites. These materials have demonstrated improved chemical resistance, thermal stability, and mechanical properties, with up to 35% increase in flexural strength compared to conventional composites[10].

Strengths: Enhanced material properties, versatile integration options, and potential for custom-tailored solutions. Weaknesses: Complex synthesis processes and potential regulatory challenges for novel materials.

Innovative Approaches in Dodecane-Composite Synergy

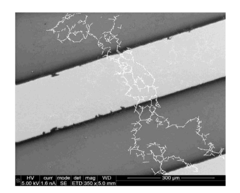

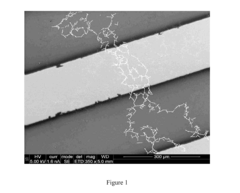

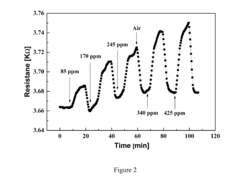

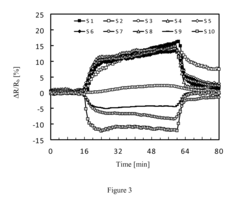

Carbon nanotube structures in sensor apparatuses for analyzing biomarkers in breath samples

PatentActiveUS20110098591A1

Innovation

- A system comprising an array of chemically sensitive sensors made from single-walled carbon nanotubes (SWCNTs) coated with non-polar small organic molecules, in conjunction with learning and pattern recognition algorithms, is used to measure breath analytes. The SWCNTs are arranged in a random network configuration, eliminating the need for precise alignment and enhancing sensitivity and selectivity towards VOCs found in lung cancer patients.

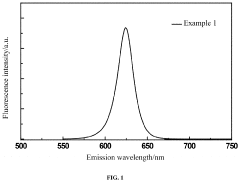

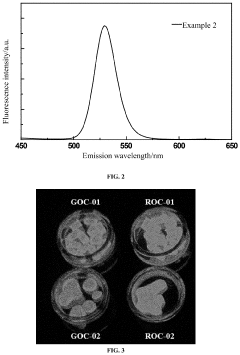

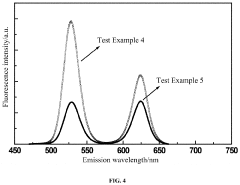

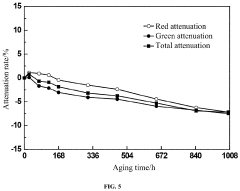

Quantum dot (QD) and QD composite, and preparation methods thereof

PatentActiveUS20230303916A1

Innovation

- A QD with a core-shell structure of CdZnSeS/CdZnSe/CdZnS/ZnS and a metal halide ligand between the shell layers, combined with a QD composite using an organic polymer, which enhances stability and optical performance, and a method involving specific precursor ratios and reactions to form the QDs and composites.

Environmental Impact of Dodecane in Composites

The environmental impact of dodecane in composites is a critical consideration in the development and application of advanced composite materials. Dodecane, a hydrocarbon compound, plays a significant role in the manufacturing process and performance of these composites, but its use also raises important environmental concerns.

One of the primary environmental issues associated with dodecane in composites is its potential for volatile organic compound (VOC) emissions. During the production, curing, and even the lifecycle of composite materials containing dodecane, there is a risk of these compounds being released into the atmosphere. VOCs contribute to air pollution and can have adverse effects on both human health and the environment, particularly in terms of ground-level ozone formation and smog.

The production of dodecane itself, typically derived from petroleum sources, also carries environmental implications. The extraction and refining processes contribute to greenhouse gas emissions and can lead to other forms of environmental degradation associated with fossil fuel industries. This upstream impact is an important factor when considering the overall environmental footprint of composites utilizing dodecane.

In terms of waste management, composites containing dodecane present challenges for recycling and disposal. The complex nature of these materials often makes them difficult to separate into their constituent components, potentially leading to increased landfill waste or the need for specialized recycling processes. This aspect of the lifecycle can contribute to long-term environmental impacts if not properly addressed.

However, it's important to note that the use of dodecane in advanced composites can also have positive environmental implications. These materials often contribute to weight reduction in various applications, particularly in the automotive and aerospace industries. Lighter vehicles and aircraft consume less fuel, potentially offsetting some of the environmental impacts associated with dodecane's production and use.

Researchers and industry professionals are actively working on mitigating the environmental impacts of dodecane in composites. This includes developing more efficient production methods to reduce VOC emissions, exploring bio-based alternatives to petroleum-derived dodecane, and improving end-of-life recycling technologies for composite materials.

The regulatory landscape surrounding the use of dodecane and similar compounds in composites is evolving, with increasing focus on environmental protection. Manufacturers are facing stricter emissions standards and waste management requirements, driving innovation in both material composition and production processes.

In conclusion, while dodecane plays a crucial role in the performance of advanced composites, its environmental impact is a complex issue that requires careful consideration. Balancing the benefits of improved material properties against potential environmental risks remains a key challenge for the industry, necessitating ongoing research and development efforts to create more sustainable composite solutions.

One of the primary environmental issues associated with dodecane in composites is its potential for volatile organic compound (VOC) emissions. During the production, curing, and even the lifecycle of composite materials containing dodecane, there is a risk of these compounds being released into the atmosphere. VOCs contribute to air pollution and can have adverse effects on both human health and the environment, particularly in terms of ground-level ozone formation and smog.

The production of dodecane itself, typically derived from petroleum sources, also carries environmental implications. The extraction and refining processes contribute to greenhouse gas emissions and can lead to other forms of environmental degradation associated with fossil fuel industries. This upstream impact is an important factor when considering the overall environmental footprint of composites utilizing dodecane.

In terms of waste management, composites containing dodecane present challenges for recycling and disposal. The complex nature of these materials often makes them difficult to separate into their constituent components, potentially leading to increased landfill waste or the need for specialized recycling processes. This aspect of the lifecycle can contribute to long-term environmental impacts if not properly addressed.

However, it's important to note that the use of dodecane in advanced composites can also have positive environmental implications. These materials often contribute to weight reduction in various applications, particularly in the automotive and aerospace industries. Lighter vehicles and aircraft consume less fuel, potentially offsetting some of the environmental impacts associated with dodecane's production and use.

Researchers and industry professionals are actively working on mitigating the environmental impacts of dodecane in composites. This includes developing more efficient production methods to reduce VOC emissions, exploring bio-based alternatives to petroleum-derived dodecane, and improving end-of-life recycling technologies for composite materials.

The regulatory landscape surrounding the use of dodecane and similar compounds in composites is evolving, with increasing focus on environmental protection. Manufacturers are facing stricter emissions standards and waste management requirements, driving innovation in both material composition and production processes.

In conclusion, while dodecane plays a crucial role in the performance of advanced composites, its environmental impact is a complex issue that requires careful consideration. Balancing the benefits of improved material properties against potential environmental risks remains a key challenge for the industry, necessitating ongoing research and development efforts to create more sustainable composite solutions.

Regulatory Framework for Advanced Composite Materials

The regulatory framework for advanced composite materials incorporating dodecane is a complex and evolving landscape. Governments and international bodies have established guidelines to ensure the safe development, production, and use of these materials across various industries.

In the United States, the Federal Aviation Administration (FAA) plays a crucial role in regulating composite materials used in aerospace applications. The FAA's Advisory Circular 20-107B provides guidance on the certification of composite aircraft structures. This document outlines the requirements for design, testing, and maintenance of composite components, including those potentially incorporating dodecane as a constituent.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which impacts the use of dodecane in advanced composites. Under REACH, manufacturers must register chemicals used in their products and provide safety data. This regulation aims to protect human health and the environment while promoting innovation in the chemical industry.

For automotive applications, the National Highway Traffic Safety Administration (NHTSA) in the United States has established standards for the use of composite materials in vehicle construction. These regulations focus on crash safety and structural integrity, which are critical considerations when incorporating dodecane-based composites in automotive design.

In the construction sector, building codes and standards such as those developed by the International Code Council (ICC) govern the use of advanced composite materials. These codes ensure that composite materials, including those containing dodecane, meet fire safety, structural performance, and durability requirements for use in buildings and infrastructure.

The Occupational Safety and Health Administration (OSHA) in the United States has established guidelines for worker safety when handling and processing advanced composite materials. These regulations cover exposure limits, personal protective equipment, and proper handling procedures for chemicals like dodecane used in composite manufacturing.

Environmental regulations also play a significant role in the development and use of dodecane-based composites. The Environmental Protection Agency (EPA) in the United States and similar agencies worldwide have established guidelines for emissions control, waste management, and environmental impact assessments related to the production and disposal of advanced composite materials.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed specific standards for testing and characterizing advanced composite materials. These standards ensure consistency and reliability in material properties and performance across different manufacturers and applications.

As the field of advanced composites continues to evolve, regulatory bodies are working to keep pace with technological advancements. This includes developing new standards and guidelines for emerging applications of dodecane-based composites in areas such as renewable energy, medical devices, and smart materials.

In the United States, the Federal Aviation Administration (FAA) plays a crucial role in regulating composite materials used in aerospace applications. The FAA's Advisory Circular 20-107B provides guidance on the certification of composite aircraft structures. This document outlines the requirements for design, testing, and maintenance of composite components, including those potentially incorporating dodecane as a constituent.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which impacts the use of dodecane in advanced composites. Under REACH, manufacturers must register chemicals used in their products and provide safety data. This regulation aims to protect human health and the environment while promoting innovation in the chemical industry.

For automotive applications, the National Highway Traffic Safety Administration (NHTSA) in the United States has established standards for the use of composite materials in vehicle construction. These regulations focus on crash safety and structural integrity, which are critical considerations when incorporating dodecane-based composites in automotive design.

In the construction sector, building codes and standards such as those developed by the International Code Council (ICC) govern the use of advanced composite materials. These codes ensure that composite materials, including those containing dodecane, meet fire safety, structural performance, and durability requirements for use in buildings and infrastructure.

The Occupational Safety and Health Administration (OSHA) in the United States has established guidelines for worker safety when handling and processing advanced composite materials. These regulations cover exposure limits, personal protective equipment, and proper handling procedures for chemicals like dodecane used in composite manufacturing.

Environmental regulations also play a significant role in the development and use of dodecane-based composites. The Environmental Protection Agency (EPA) in the United States and similar agencies worldwide have established guidelines for emissions control, waste management, and environmental impact assessments related to the production and disposal of advanced composite materials.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed specific standards for testing and characterizing advanced composite materials. These standards ensure consistency and reliability in material properties and performance across different manufacturers and applications.

As the field of advanced composites continues to evolve, regulatory bodies are working to keep pace with technological advancements. This includes developing new standards and guidelines for emerging applications of dodecane-based composites in areas such as renewable energy, medical devices, and smart materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!