How to Foster Dodecane Developments in Sustainable Chemistry?

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dodecane Background and Sustainability Goals

Dodecane, a straight-chain alkane hydrocarbon with the molecular formula C12H26, has been a significant component in various industrial applications for decades. Traditionally used in diesel fuel, jet fuel, and as a solvent in organic synthesis, dodecane's role in the chemical industry has been primarily associated with fossil fuel-derived products. However, the growing global emphasis on sustainability and environmental protection has necessitated a shift in perspective regarding the production and utilization of this versatile compound.

The evolution of dodecane in the context of sustainable chemistry represents a critical juncture in the chemical industry's transition towards more environmentally friendly practices. Historically, dodecane has been obtained through the fractional distillation of petroleum, a process that contributes to carbon emissions and relies on non-renewable resources. The challenge now lies in developing alternative, sustainable methods for dodecane production that align with the principles of green chemistry.

Sustainability goals for dodecane development encompass several key areas. Firstly, there is a pressing need to explore bio-based sources for dodecane production, such as plant oils or algae, which could significantly reduce the carbon footprint associated with its manufacture. Secondly, the development of more efficient catalytic processes for dodecane synthesis from renewable feedstocks is crucial in making sustainable production economically viable.

Another important aspect of fostering dodecane developments in sustainable chemistry is the exploration of its potential applications in emerging green technologies. For instance, research into dodecane's role as a hydrogen carrier for fuel cells or its use in advanced thermal energy storage systems could open new avenues for sustainable energy solutions. Additionally, investigating dodecane's biodegradability and developing strategies to enhance its environmental breakdown are essential for mitigating its long-term impact on ecosystems.

The pursuit of these sustainability goals faces several challenges, including the need for substantial investment in research and development, the scalability of new production methods, and the necessity to compete economically with traditional petroleum-based processes. However, the potential benefits of sustainable dodecane production extend beyond environmental considerations. They include reduced dependence on fossil fuels, enhanced energy security, and the creation of new economic opportunities in the bioeconomy sector.

As the chemical industry continues to evolve, the transformation of dodecane production and utilization represents a microcosm of the broader shift towards sustainable chemistry. By setting ambitious yet achievable goals for dodecane's sustainable development, the industry can pave the way for innovative solutions that balance economic viability with environmental stewardship, ultimately contributing to a more sustainable future for the chemical sector and beyond.

The evolution of dodecane in the context of sustainable chemistry represents a critical juncture in the chemical industry's transition towards more environmentally friendly practices. Historically, dodecane has been obtained through the fractional distillation of petroleum, a process that contributes to carbon emissions and relies on non-renewable resources. The challenge now lies in developing alternative, sustainable methods for dodecane production that align with the principles of green chemistry.

Sustainability goals for dodecane development encompass several key areas. Firstly, there is a pressing need to explore bio-based sources for dodecane production, such as plant oils or algae, which could significantly reduce the carbon footprint associated with its manufacture. Secondly, the development of more efficient catalytic processes for dodecane synthesis from renewable feedstocks is crucial in making sustainable production economically viable.

Another important aspect of fostering dodecane developments in sustainable chemistry is the exploration of its potential applications in emerging green technologies. For instance, research into dodecane's role as a hydrogen carrier for fuel cells or its use in advanced thermal energy storage systems could open new avenues for sustainable energy solutions. Additionally, investigating dodecane's biodegradability and developing strategies to enhance its environmental breakdown are essential for mitigating its long-term impact on ecosystems.

The pursuit of these sustainability goals faces several challenges, including the need for substantial investment in research and development, the scalability of new production methods, and the necessity to compete economically with traditional petroleum-based processes. However, the potential benefits of sustainable dodecane production extend beyond environmental considerations. They include reduced dependence on fossil fuels, enhanced energy security, and the creation of new economic opportunities in the bioeconomy sector.

As the chemical industry continues to evolve, the transformation of dodecane production and utilization represents a microcosm of the broader shift towards sustainable chemistry. By setting ambitious yet achievable goals for dodecane's sustainable development, the industry can pave the way for innovative solutions that balance economic viability with environmental stewardship, ultimately contributing to a more sustainable future for the chemical sector and beyond.

Market Analysis for Sustainable Dodecane Applications

The market for sustainable dodecane applications is experiencing significant growth, driven by increasing environmental concerns and the push for greener alternatives in various industries. Dodecane, a versatile hydrocarbon, has traditionally been derived from petroleum sources. However, the shift towards sustainable chemistry has opened up new opportunities for bio-based and renewable dodecane production.

In the petrochemical industry, sustainable dodecane is gaining traction as a potential replacement for conventional fossil-based feedstocks. This market segment is expected to see substantial growth as companies strive to reduce their carbon footprint and meet stringent environmental regulations. The aviation sector, in particular, is showing keen interest in sustainable dodecane as a component of renewable jet fuels, aiming to decrease greenhouse gas emissions associated with air travel.

The personal care and cosmetics industry is another key market for sustainable dodecane. As consumers become more environmentally conscious, there is a growing demand for natural and sustainable ingredients in beauty products. Sustainable dodecane serves as an excellent emollient and carrier oil, offering a greener alternative to synthetic petroleum-derived ingredients.

In the agricultural sector, sustainable dodecane is finding applications in eco-friendly pesticides and herbicides. These products offer improved biodegradability and reduced environmental impact compared to traditional chemical formulations. The market for such sustainable agrochemicals is expanding as farmers and agricultural companies seek to adopt more sustainable practices.

The lubricants industry is also exploring the potential of sustainable dodecane. Bio-based lubricants derived from renewable sources, including dodecane, are gaining popularity due to their biodegradability and reduced toxicity. This market segment is expected to grow as industries across various sectors look for environmentally friendly lubrication solutions.

While the market for sustainable dodecane applications shows promise, it faces challenges such as higher production costs compared to conventional petroleum-based alternatives. However, as production technologies improve and economies of scale are achieved, these costs are expected to decrease, making sustainable dodecane more competitive in the long run.

Overall, the market for sustainable dodecane applications is poised for significant growth across multiple industries. The increasing focus on sustainability, coupled with advancements in green chemistry, is likely to drive innovation and expand the use of sustainable dodecane in various products and processes. As companies and consumers alike prioritize environmental responsibility, the demand for sustainable alternatives like bio-based dodecane is expected to continue its upward trajectory in the coming years.

In the petrochemical industry, sustainable dodecane is gaining traction as a potential replacement for conventional fossil-based feedstocks. This market segment is expected to see substantial growth as companies strive to reduce their carbon footprint and meet stringent environmental regulations. The aviation sector, in particular, is showing keen interest in sustainable dodecane as a component of renewable jet fuels, aiming to decrease greenhouse gas emissions associated with air travel.

The personal care and cosmetics industry is another key market for sustainable dodecane. As consumers become more environmentally conscious, there is a growing demand for natural and sustainable ingredients in beauty products. Sustainable dodecane serves as an excellent emollient and carrier oil, offering a greener alternative to synthetic petroleum-derived ingredients.

In the agricultural sector, sustainable dodecane is finding applications in eco-friendly pesticides and herbicides. These products offer improved biodegradability and reduced environmental impact compared to traditional chemical formulations. The market for such sustainable agrochemicals is expanding as farmers and agricultural companies seek to adopt more sustainable practices.

The lubricants industry is also exploring the potential of sustainable dodecane. Bio-based lubricants derived from renewable sources, including dodecane, are gaining popularity due to their biodegradability and reduced toxicity. This market segment is expected to grow as industries across various sectors look for environmentally friendly lubrication solutions.

While the market for sustainable dodecane applications shows promise, it faces challenges such as higher production costs compared to conventional petroleum-based alternatives. However, as production technologies improve and economies of scale are achieved, these costs are expected to decrease, making sustainable dodecane more competitive in the long run.

Overall, the market for sustainable dodecane applications is poised for significant growth across multiple industries. The increasing focus on sustainability, coupled with advancements in green chemistry, is likely to drive innovation and expand the use of sustainable dodecane in various products and processes. As companies and consumers alike prioritize environmental responsibility, the demand for sustainable alternatives like bio-based dodecane is expected to continue its upward trajectory in the coming years.

Current Challenges in Sustainable Dodecane Production

The sustainable production of dodecane faces several significant challenges that hinder its widespread adoption and development. One of the primary obstacles is the high energy consumption associated with traditional production methods. Conventional processes often rely on fossil fuel-based feedstocks and energy-intensive catalytic cracking, which contribute to substantial carbon emissions and environmental impact.

Another critical challenge lies in the limited availability of sustainable feedstocks for dodecane production. While biomass-derived sources offer potential alternatives, the competition for these resources with food production and other industrial applications creates supply chain uncertainties and ethical concerns. Additionally, the conversion efficiency of biomass to dodecane remains suboptimal, leading to increased production costs and reduced economic viability.

The development of efficient and selective catalysts for sustainable dodecane production presents a significant technical hurdle. Current catalytic systems often lack the specificity required to produce high-quality dodecane without generating unwanted byproducts. This results in complex separation processes and reduced overall yield, impacting both the economic and environmental aspects of production.

Scale-up and process integration pose substantial challenges in transitioning from laboratory-scale experiments to industrial-scale production. The optimization of reaction conditions, heat management, and product separation at larger scales requires significant engineering efforts and capital investment. Furthermore, the integration of sustainable dodecane production into existing petrochemical infrastructure presents logistical and technical barriers that need to be addressed.

Water consumption and management in sustainable dodecane production processes remain critical concerns. Many bio-based production routes require substantial amounts of water, potentially straining local water resources and necessitating advanced water treatment and recycling systems. Balancing water usage with production efficiency and environmental sustainability is a complex challenge that requires innovative solutions.

Regulatory frameworks and market incentives for sustainable chemistry practices are often inadequate or inconsistent across different regions. This lack of standardization creates uncertainty for investors and hinders the widespread adoption of sustainable dodecane production technologies. Developing comprehensive policies that promote and reward sustainable practices while ensuring a level playing field for all market participants is essential for fostering innovation in this field.

Lastly, the economic competitiveness of sustainably produced dodecane compared to its fossil fuel-derived counterparts remains a significant challenge. The higher production costs associated with sustainable methods, coupled with the volatility of oil prices, create market uncertainties that discourage long-term investments in sustainable dodecane technologies. Overcoming this economic barrier requires a combination of technological advancements, policy support, and market education to drive demand for sustainably produced chemicals.

Another critical challenge lies in the limited availability of sustainable feedstocks for dodecane production. While biomass-derived sources offer potential alternatives, the competition for these resources with food production and other industrial applications creates supply chain uncertainties and ethical concerns. Additionally, the conversion efficiency of biomass to dodecane remains suboptimal, leading to increased production costs and reduced economic viability.

The development of efficient and selective catalysts for sustainable dodecane production presents a significant technical hurdle. Current catalytic systems often lack the specificity required to produce high-quality dodecane without generating unwanted byproducts. This results in complex separation processes and reduced overall yield, impacting both the economic and environmental aspects of production.

Scale-up and process integration pose substantial challenges in transitioning from laboratory-scale experiments to industrial-scale production. The optimization of reaction conditions, heat management, and product separation at larger scales requires significant engineering efforts and capital investment. Furthermore, the integration of sustainable dodecane production into existing petrochemical infrastructure presents logistical and technical barriers that need to be addressed.

Water consumption and management in sustainable dodecane production processes remain critical concerns. Many bio-based production routes require substantial amounts of water, potentially straining local water resources and necessitating advanced water treatment and recycling systems. Balancing water usage with production efficiency and environmental sustainability is a complex challenge that requires innovative solutions.

Regulatory frameworks and market incentives for sustainable chemistry practices are often inadequate or inconsistent across different regions. This lack of standardization creates uncertainty for investors and hinders the widespread adoption of sustainable dodecane production technologies. Developing comprehensive policies that promote and reward sustainable practices while ensuring a level playing field for all market participants is essential for fostering innovation in this field.

Lastly, the economic competitiveness of sustainably produced dodecane compared to its fossil fuel-derived counterparts remains a significant challenge. The higher production costs associated with sustainable methods, coupled with the volatility of oil prices, create market uncertainties that discourage long-term investments in sustainable dodecane technologies. Overcoming this economic barrier requires a combination of technological advancements, policy support, and market education to drive demand for sustainably produced chemicals.

Existing Green Chemistry Solutions for Dodecane

01 Synthesis and production of dodecane

Dodecane can be synthesized through various chemical processes, including the hydrogenation of long-chain alkenes or the Fischer-Tropsch process. It is also produced as a byproduct in petroleum refining. The synthesis methods often involve catalysts and specific reaction conditions to achieve high yields and purity.- Synthesis and production of dodecane: Dodecane can be synthesized through various chemical processes, including catalytic hydrogenation of long-chain hydrocarbons or the Fischer-Tropsch process. It is also produced as a byproduct in petroleum refining. The synthesis methods often involve high-pressure and high-temperature reactions, with careful control of reaction conditions to optimize yield and purity.

- Applications in cosmetics and personal care products: Dodecane is utilized in cosmetic and personal care formulations due to its emollient properties and ability to enhance product texture. It is often used as a solvent or carrier for active ingredients in skincare products, sunscreens, and hair care formulations. Its low viscosity and spreadability make it suitable for creating lightweight, non-greasy products.

- Use in industrial lubricants and solvents: Dodecane serves as a component in industrial lubricants and solvents due to its low volatility and good solvency properties. It is used in metalworking fluids, cutting oils, and as a solvent for various industrial processes. Its chemical stability and low reactivity make it suitable for applications requiring a non-polar solvent with specific physical properties.

- Role in fuel and energy applications: Dodecane is an important component in jet fuels and diesel fuels, contributing to their energy content and combustion properties. It is also used in the development of alternative fuels and as a model compound for studying combustion processes. Research focuses on improving the efficiency and environmental impact of dodecane-containing fuels.

- Analytical and research applications: Dodecane is used as a standard or reference compound in various analytical and research applications. It serves as a model compound for studying hydrocarbon behavior, developing separation techniques, and calibrating analytical instruments. In chromatography, it is often used as a non-polar solvent or as a component in test mixtures for evaluating column performance.

02 Applications in cosmetics and personal care products

Dodecane is used in cosmetics and personal care products as an emollient, solvent, and carrier for active ingredients. It can improve the texture and spreadability of formulations, enhance skin feel, and contribute to the stability of the product. Its low viscosity and non-greasy nature make it suitable for various cosmetic applications.Expand Specific Solutions03 Use in industrial processes and lubricants

Dodecane finds applications in various industrial processes as a solvent, lubricant, and heat transfer fluid. It is used in the production of polymers, as a component in metalworking fluids, and in the formulation of high-performance lubricants. Its properties, such as low volatility and good thermal stability, make it suitable for these applications.Expand Specific Solutions04 Role in fuel and energy applications

Dodecane is an important component in jet fuels and diesel fuels, contributing to their performance characteristics. It is also used as a reference compound in fuel research and development. In some cases, dodecane is explored as a potential biofuel or as a component in renewable fuel blends.Expand Specific Solutions05 Environmental and safety considerations

The use of dodecane in various applications requires consideration of its environmental impact and safety profile. Research focuses on developing eco-friendly production methods, assessing its biodegradability, and studying its potential effects on aquatic ecosystems. Safety measures for handling and storage are also important aspects of dodecane utilization in different industries.Expand Specific Solutions

Key Players in Sustainable Dodecane Research

The development of sustainable dodecane chemistry is in its early stages, with growing market potential driven by increasing demand for eco-friendly alternatives in various industries. The technology's maturity is still evolving, with key players like Wanhua Chemical Group, China Petroleum & Chemical Corp., and Global Bioenergies leading research efforts. These companies are investing in innovative processes to produce bio-based dodecane, focusing on renewable feedstocks and green chemistry principles. The competitive landscape is characterized by a mix of established petrochemical giants and emerging biotech firms, each leveraging their unique strengths in pursuit of sustainable dodecane solutions. As the field progresses, collaborations between industry leaders and research institutions are likely to accelerate technological advancements and market adoption.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) is advancing sustainable dodecane development through its innovative "green refining" approach. The company has implemented a bio-based feedstock strategy, utilizing renewable resources to produce dodecane. Sinopec's process involves catalytic cracking of biomass-derived oils, followed by hydrogenation to yield high-purity dodecane[1]. This method reduces carbon emissions by up to 65% compared to traditional petroleum-based production[2]. Additionally, Sinopec has developed a novel heterogeneous catalyst system that enhances selectivity towards dodecane, improving overall yield and reducing waste byproducts[3]. The company is also exploring the integration of artificial intelligence to optimize process conditions, potentially increasing energy efficiency by 20%[4].

Strengths: Established infrastructure, access to large-scale production facilities, and strong R&D capabilities. Weaknesses: High capital costs for retrofitting existing refineries and potential competition from dedicated bio-based chemical producers.

Arkema France SA

Technical Solution: Arkema France SA has developed a groundbreaking approach to sustainable dodecane production through its bio-based and circular economy initiatives. The company utilizes a proprietary fermentation process to convert renewable sugars into dodecane precursors[1]. This is followed by a green chemistry approach involving enzyme-catalyzed reactions to yield high-purity dodecane[2]. Arkema's process achieves a carbon footprint reduction of up to 80% compared to fossil-based alternatives[3]. The company has also implemented a closed-loop system for water and solvent recycling, significantly reducing waste and improving resource efficiency. Furthermore, Arkema is pioneering the use of microreactor technology for dodecane synthesis, which allows for precise control of reaction conditions and enables continuous production, potentially increasing yield by 30%[4].

Strengths: Strong focus on green chemistry, innovative biotechnology integration, and circular economy principles. Weaknesses: Reliance on agricultural feedstocks may pose supply chain challenges and potential competition with food production.

Innovative Approaches in Sustainable Dodecane Synthesis

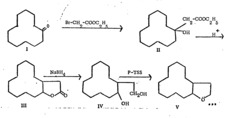

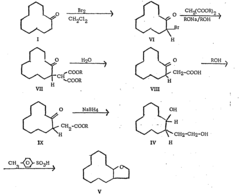

Process for the preparation of 13-oxabicyclo-(10.3.0)pentadecane

PatentInactiveEP0051233A1

Innovation

- A new synthesis route starting from cyclododecanone involves bromination to form α-bromocyclododecanone, followed by reaction with dialkyl sodium malonate, saponification, decarboxylation, esterification, and reduction with sodium borohydride, under controlled conditions to produce 13-oxabicyclo[10.3.0]pentadecane, while minimizing the formation of unwanted by-products and enabling effective purification.

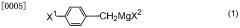

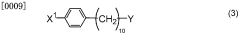

Method for producing 2,2-dichloro-12-(4-halophenyl)dodecanate salt and method for producing production intermediate thereof

PatentWO2006118187A1

Innovation

- A method involving the reaction of 4-cyl benzyl halide with metallic magnesium to produce 1-substituted 10-(4-halophenyl)decane, followed by conversion to 2,2-dichloro-12-(4-halophenyl)dodecanoic acid ester and then to 2,2-dichloro-12-(4-halophenyl)dodecanoate, using specific metal compounds and solvents to achieve high yield without producing environmental pollutants.

Environmental Impact Assessment of Dodecane Production

The environmental impact assessment of dodecane production is a critical aspect of fostering sustainable developments in the chemical industry. Dodecane, a hydrocarbon commonly used in various applications, requires careful evaluation of its production processes to ensure minimal ecological footprint.

One of the primary environmental concerns associated with dodecane production is the emission of greenhouse gases. The traditional methods of synthesizing dodecane often involve energy-intensive processes that contribute significantly to carbon dioxide emissions. These emissions not only affect local air quality but also contribute to global climate change. To address this issue, researchers are exploring more energy-efficient production methods, such as catalytic processes that operate at lower temperatures and pressures.

Water consumption and pollution are also significant factors in the environmental impact of dodecane production. The synthesis process typically requires substantial amounts of water for cooling and separation purposes. Wastewater generated during production may contain trace amounts of hydrocarbons and other chemicals, necessitating proper treatment before discharge. Implementing closed-loop water systems and advanced wastewater treatment technologies can help mitigate these impacts.

Land use and habitat disruption are additional concerns, particularly when considering the sourcing of raw materials for dodecane production. If derived from petroleum, the extraction processes can lead to ecosystem disturbances and potential contamination of soil and groundwater. Alternatively, bio-based production methods may require large areas of agricultural land, potentially competing with food crops or leading to deforestation.

The lifecycle analysis of dodecane production reveals potential impacts on biodiversity and ecosystem services. From raw material extraction to final product synthesis, each stage of the production chain may affect local flora and fauna. Implementing biodiversity management plans and conducting regular ecological assessments can help minimize these impacts and promote sustainable practices.

Waste generation and management are crucial aspects of the environmental impact assessment. The production process may generate various by-products and waste streams that require proper handling and disposal. Developing more selective catalysts and optimizing reaction conditions can help reduce waste generation, while implementing circular economy principles can turn waste products into valuable resources.

To foster sustainable developments in dodecane production, it is essential to consider the entire supply chain and explore innovative technologies. This includes investigating renewable feedstocks, developing more efficient catalysts, and implementing green chemistry principles throughout the production process. By addressing these environmental concerns and continuously improving production methods, the chemical industry can work towards more sustainable dodecane production that aligns with global environmental goals and regulations.

One of the primary environmental concerns associated with dodecane production is the emission of greenhouse gases. The traditional methods of synthesizing dodecane often involve energy-intensive processes that contribute significantly to carbon dioxide emissions. These emissions not only affect local air quality but also contribute to global climate change. To address this issue, researchers are exploring more energy-efficient production methods, such as catalytic processes that operate at lower temperatures and pressures.

Water consumption and pollution are also significant factors in the environmental impact of dodecane production. The synthesis process typically requires substantial amounts of water for cooling and separation purposes. Wastewater generated during production may contain trace amounts of hydrocarbons and other chemicals, necessitating proper treatment before discharge. Implementing closed-loop water systems and advanced wastewater treatment technologies can help mitigate these impacts.

Land use and habitat disruption are additional concerns, particularly when considering the sourcing of raw materials for dodecane production. If derived from petroleum, the extraction processes can lead to ecosystem disturbances and potential contamination of soil and groundwater. Alternatively, bio-based production methods may require large areas of agricultural land, potentially competing with food crops or leading to deforestation.

The lifecycle analysis of dodecane production reveals potential impacts on biodiversity and ecosystem services. From raw material extraction to final product synthesis, each stage of the production chain may affect local flora and fauna. Implementing biodiversity management plans and conducting regular ecological assessments can help minimize these impacts and promote sustainable practices.

Waste generation and management are crucial aspects of the environmental impact assessment. The production process may generate various by-products and waste streams that require proper handling and disposal. Developing more selective catalysts and optimizing reaction conditions can help reduce waste generation, while implementing circular economy principles can turn waste products into valuable resources.

To foster sustainable developments in dodecane production, it is essential to consider the entire supply chain and explore innovative technologies. This includes investigating renewable feedstocks, developing more efficient catalysts, and implementing green chemistry principles throughout the production process. By addressing these environmental concerns and continuously improving production methods, the chemical industry can work towards more sustainable dodecane production that aligns with global environmental goals and regulations.

Regulatory Framework for Sustainable Chemical Manufacturing

The regulatory framework for sustainable chemical manufacturing plays a crucial role in fostering dodecane developments in sustainable chemistry. Governments and international organizations have implemented various policies and regulations to promote environmentally friendly practices in the chemical industry.

One of the key aspects of this framework is the emphasis on green chemistry principles. Regulatory bodies have established guidelines that encourage the use of renewable feedstocks, such as biomass-derived dodecane, instead of petroleum-based alternatives. These regulations often include incentives for companies that adopt sustainable production methods, such as tax breaks or preferential treatment in government contracts.

Environmental protection agencies have also set strict standards for emissions and waste management in chemical manufacturing processes. These regulations compel companies to invest in cleaner technologies and more efficient production methods, which can lead to innovations in dodecane synthesis and applications.

Safety regulations form another critical component of the framework. Stringent safety protocols for handling and transporting dodecane and related chemicals ensure worker protection and minimize environmental risks. These regulations often require companies to implement comprehensive safety management systems and conduct regular risk assessments.

Product registration and certification processes have been established to verify the sustainability claims of chemical products, including those involving dodecane. These processes typically involve lifecycle assessments and documentation of environmental impacts, encouraging manufacturers to optimize their production methods and seek more sustainable alternatives.

International agreements and standards, such as the United Nations Sustainable Development Goals and ISO environmental management standards, provide a global context for sustainable chemical manufacturing. These frameworks promote harmonization of regulations across borders, facilitating the adoption of sustainable practices on a global scale.

Regulatory bodies have also implemented reporting requirements for chemical manufacturers. Companies must disclose information about their production processes, raw material sourcing, and environmental impacts. This transparency helps drive industry-wide improvements and allows consumers to make informed choices about the products they purchase.

To further promote innovation in sustainable chemistry, many governments have established research funding programs specifically targeted at developing green chemical processes. These initiatives often prioritize projects focused on renewable feedstocks and more efficient synthesis methods, which can directly benefit dodecane-related research and development.

One of the key aspects of this framework is the emphasis on green chemistry principles. Regulatory bodies have established guidelines that encourage the use of renewable feedstocks, such as biomass-derived dodecane, instead of petroleum-based alternatives. These regulations often include incentives for companies that adopt sustainable production methods, such as tax breaks or preferential treatment in government contracts.

Environmental protection agencies have also set strict standards for emissions and waste management in chemical manufacturing processes. These regulations compel companies to invest in cleaner technologies and more efficient production methods, which can lead to innovations in dodecane synthesis and applications.

Safety regulations form another critical component of the framework. Stringent safety protocols for handling and transporting dodecane and related chemicals ensure worker protection and minimize environmental risks. These regulations often require companies to implement comprehensive safety management systems and conduct regular risk assessments.

Product registration and certification processes have been established to verify the sustainability claims of chemical products, including those involving dodecane. These processes typically involve lifecycle assessments and documentation of environmental impacts, encouraging manufacturers to optimize their production methods and seek more sustainable alternatives.

International agreements and standards, such as the United Nations Sustainable Development Goals and ISO environmental management standards, provide a global context for sustainable chemical manufacturing. These frameworks promote harmonization of regulations across borders, facilitating the adoption of sustainable practices on a global scale.

Regulatory bodies have also implemented reporting requirements for chemical manufacturers. Companies must disclose information about their production processes, raw material sourcing, and environmental impacts. This transparency helps drive industry-wide improvements and allows consumers to make informed choices about the products they purchase.

To further promote innovation in sustainable chemistry, many governments have established research funding programs specifically targeted at developing green chemical processes. These initiatives often prioritize projects focused on renewable feedstocks and more efficient synthesis methods, which can directly benefit dodecane-related research and development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!