How to Harness Dodecane in Advanced Emulsion Techniques?

JUL 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dodecane Emulsion Background and Objectives

Dodecane, a versatile hydrocarbon compound, has emerged as a key player in advanced emulsion techniques, revolutionizing various industries from cosmetics to pharmaceuticals. The evolution of dodecane-based emulsions traces back to the early 20th century, with significant advancements occurring in recent decades due to improved understanding of interfacial phenomena and molecular interactions.

The primary objective of harnessing dodecane in advanced emulsion techniques is to create stable, controllable, and functional emulsion systems with enhanced properties. These emulsions aim to overcome traditional limitations such as instability, poor encapsulation efficiency, and limited functionality. By leveraging dodecane's unique physicochemical properties, researchers and industry professionals seek to develop novel formulations with improved performance characteristics.

One of the key trends in dodecane emulsion technology is the development of nanoemulsions, which offer superior stability and bioavailability compared to conventional emulsions. These nanoscale systems have shown promise in drug delivery, nutraceuticals, and personal care products. Another emerging trend is the use of dodecane in stimuli-responsive emulsions, capable of changing their properties in response to external triggers such as temperature, pH, or light.

The technological evolution in this field has been driven by advancements in emulsification techniques, including high-pressure homogenization, microfluidics, and ultrasonic emulsification. These methods allow for precise control over droplet size and distribution, leading to more stable and functional emulsions. Additionally, the development of novel surfactants and co-emulsifiers specifically designed for dodecane-based systems has further expanded the possibilities for emulsion formulation.

As we look towards the future, the objectives for dodecane emulsion technology are multifaceted. There is a growing focus on developing environmentally friendly and sustainable emulsion systems, aligning with global trends towards green chemistry. Researchers are also exploring the potential of dodecane emulsions in advanced materials science, including the creation of smart materials with self-healing or self-cleaning properties.

Furthermore, the integration of dodecane emulsions with other cutting-edge technologies, such as microencapsulation and 3D printing, presents exciting opportunities for innovation. These synergies could lead to the development of novel drug delivery systems, advanced cosmetic formulations, and high-performance industrial materials.

In conclusion, the background and objectives of dodecane emulsion technology reflect a dynamic and rapidly evolving field with significant potential for transformative applications across multiple industries. As research continues to push the boundaries of what is possible with dodecane-based emulsions, we can anticipate groundbreaking developments that will shape the future of emulsion science and technology.

The primary objective of harnessing dodecane in advanced emulsion techniques is to create stable, controllable, and functional emulsion systems with enhanced properties. These emulsions aim to overcome traditional limitations such as instability, poor encapsulation efficiency, and limited functionality. By leveraging dodecane's unique physicochemical properties, researchers and industry professionals seek to develop novel formulations with improved performance characteristics.

One of the key trends in dodecane emulsion technology is the development of nanoemulsions, which offer superior stability and bioavailability compared to conventional emulsions. These nanoscale systems have shown promise in drug delivery, nutraceuticals, and personal care products. Another emerging trend is the use of dodecane in stimuli-responsive emulsions, capable of changing their properties in response to external triggers such as temperature, pH, or light.

The technological evolution in this field has been driven by advancements in emulsification techniques, including high-pressure homogenization, microfluidics, and ultrasonic emulsification. These methods allow for precise control over droplet size and distribution, leading to more stable and functional emulsions. Additionally, the development of novel surfactants and co-emulsifiers specifically designed for dodecane-based systems has further expanded the possibilities for emulsion formulation.

As we look towards the future, the objectives for dodecane emulsion technology are multifaceted. There is a growing focus on developing environmentally friendly and sustainable emulsion systems, aligning with global trends towards green chemistry. Researchers are also exploring the potential of dodecane emulsions in advanced materials science, including the creation of smart materials with self-healing or self-cleaning properties.

Furthermore, the integration of dodecane emulsions with other cutting-edge technologies, such as microencapsulation and 3D printing, presents exciting opportunities for innovation. These synergies could lead to the development of novel drug delivery systems, advanced cosmetic formulations, and high-performance industrial materials.

In conclusion, the background and objectives of dodecane emulsion technology reflect a dynamic and rapidly evolving field with significant potential for transformative applications across multiple industries. As research continues to push the boundaries of what is possible with dodecane-based emulsions, we can anticipate groundbreaking developments that will shape the future of emulsion science and technology.

Market Analysis for Dodecane-based Emulsions

The market for dodecane-based emulsions has shown significant growth potential in recent years, driven by increasing demand across various industries. The global emulsion market, which includes dodecane-based formulations, is expected to reach substantial value by 2025, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is primarily attributed to the expanding applications of dodecane emulsions in sectors such as cosmetics, pharmaceuticals, and advanced materials.

In the cosmetics industry, dodecane-based emulsions are gaining traction due to their excellent stability and skin-feel properties. These emulsions are increasingly used in high-performance skincare products, sunscreens, and color cosmetics. The natural and synthetic cosmetics market, which heavily utilizes emulsion technology, has been experiencing robust growth, particularly in regions like Asia-Pacific and North America.

The pharmaceutical sector represents another significant market for dodecane-based emulsions. These formulations are utilized in drug delivery systems, enhancing the bioavailability and efficacy of certain medications. With the increasing focus on personalized medicine and targeted drug delivery, the demand for advanced emulsion techniques incorporating dodecane is expected to rise.

In the field of advanced materials, dodecane emulsions are finding applications in the production of specialty coatings, adhesives, and polymer composites. The construction and automotive industries, in particular, are driving demand for these high-performance materials, seeking improved durability, weather resistance, and environmental sustainability.

The food and beverage industry is also exploring the potential of dodecane-based emulsions for encapsulation and flavor delivery systems. This sector's interest is fueled by consumer demand for clean label products and enhanced nutritional profiles, where stable emulsions play a crucial role.

Geographically, North America and Europe currently lead the market for dodecane-based emulsions, owing to their well-established industrial base and research capabilities. However, the Asia-Pacific region is emerging as a key growth market, driven by rapid industrialization, increasing consumer spending power, and growing awareness of advanced materials.

Key market challenges include regulatory hurdles, particularly in the food and pharmaceutical sectors, and the need for sustainable and eco-friendly formulations. These challenges are also driving innovation, with companies investing in research and development to create bio-based alternatives and improve the environmental profile of dodecane emulsions.

In the cosmetics industry, dodecane-based emulsions are gaining traction due to their excellent stability and skin-feel properties. These emulsions are increasingly used in high-performance skincare products, sunscreens, and color cosmetics. The natural and synthetic cosmetics market, which heavily utilizes emulsion technology, has been experiencing robust growth, particularly in regions like Asia-Pacific and North America.

The pharmaceutical sector represents another significant market for dodecane-based emulsions. These formulations are utilized in drug delivery systems, enhancing the bioavailability and efficacy of certain medications. With the increasing focus on personalized medicine and targeted drug delivery, the demand for advanced emulsion techniques incorporating dodecane is expected to rise.

In the field of advanced materials, dodecane emulsions are finding applications in the production of specialty coatings, adhesives, and polymer composites. The construction and automotive industries, in particular, are driving demand for these high-performance materials, seeking improved durability, weather resistance, and environmental sustainability.

The food and beverage industry is also exploring the potential of dodecane-based emulsions for encapsulation and flavor delivery systems. This sector's interest is fueled by consumer demand for clean label products and enhanced nutritional profiles, where stable emulsions play a crucial role.

Geographically, North America and Europe currently lead the market for dodecane-based emulsions, owing to their well-established industrial base and research capabilities. However, the Asia-Pacific region is emerging as a key growth market, driven by rapid industrialization, increasing consumer spending power, and growing awareness of advanced materials.

Key market challenges include regulatory hurdles, particularly in the food and pharmaceutical sectors, and the need for sustainable and eco-friendly formulations. These challenges are also driving innovation, with companies investing in research and development to create bio-based alternatives and improve the environmental profile of dodecane emulsions.

Current Challenges in Dodecane Emulsion Technology

Despite the widespread use of dodecane in emulsion technology, several challenges persist in harnessing its full potential for advanced applications. One of the primary obstacles is the inherent instability of dodecane-based emulsions over extended periods. This instability often leads to phase separation, coalescence, and Ostwald ripening, compromising the emulsion's integrity and functionality.

Another significant challenge lies in controlling the droplet size distribution of dodecane emulsions. Achieving a uniform and consistent droplet size is crucial for many applications, particularly in the pharmaceutical and cosmetic industries. However, current emulsification techniques often struggle to produce monodisperse droplets, resulting in reduced efficacy and performance variability.

The interfacial tension between dodecane and water poses additional difficulties in emulsion formation and stabilization. While surfactants are commonly used to address this issue, finding the optimal surfactant system that balances emulsion stability, biocompatibility, and cost-effectiveness remains a complex task. Moreover, the interaction between dodecane and various surfactants is not fully understood, leading to unpredictable emulsion behaviors in different environmental conditions.

Environmental concerns and regulatory pressures present another set of challenges for dodecane emulsion technology. As a petroleum-derived compound, dodecane faces scrutiny regarding its sustainability and potential environmental impact. Developing eco-friendly alternatives or improving the biodegradability of dodecane-based emulsions without compromising performance is a pressing issue for researchers and industry professionals.

The scalability of dodecane emulsion production also presents significant hurdles. While laboratory-scale emulsification processes can achieve desired results, translating these successes to industrial-scale production often encounters difficulties in maintaining emulsion quality and consistency. This scale-up challenge is particularly evident in continuous emulsification processes, where maintaining precise control over process parameters becomes increasingly complex.

Furthermore, the limited solubility of certain active ingredients in dodecane restricts its application in some fields. Enhancing the solubilizing capacity of dodecane-based emulsions without compromising stability or introducing additional complexities remains an active area of research. This challenge is particularly relevant in the development of drug delivery systems and advanced cosmetic formulations.

Lastly, the characterization and quality control of dodecane emulsions present ongoing challenges. Current analytical techniques often struggle to provide real-time, in-situ measurements of emulsion properties, making it difficult to monitor and adjust emulsion characteristics during production or application. Developing more sophisticated, non-invasive analytical methods is crucial for advancing dodecane emulsion technology and ensuring consistent product quality.

Another significant challenge lies in controlling the droplet size distribution of dodecane emulsions. Achieving a uniform and consistent droplet size is crucial for many applications, particularly in the pharmaceutical and cosmetic industries. However, current emulsification techniques often struggle to produce monodisperse droplets, resulting in reduced efficacy and performance variability.

The interfacial tension between dodecane and water poses additional difficulties in emulsion formation and stabilization. While surfactants are commonly used to address this issue, finding the optimal surfactant system that balances emulsion stability, biocompatibility, and cost-effectiveness remains a complex task. Moreover, the interaction between dodecane and various surfactants is not fully understood, leading to unpredictable emulsion behaviors in different environmental conditions.

Environmental concerns and regulatory pressures present another set of challenges for dodecane emulsion technology. As a petroleum-derived compound, dodecane faces scrutiny regarding its sustainability and potential environmental impact. Developing eco-friendly alternatives or improving the biodegradability of dodecane-based emulsions without compromising performance is a pressing issue for researchers and industry professionals.

The scalability of dodecane emulsion production also presents significant hurdles. While laboratory-scale emulsification processes can achieve desired results, translating these successes to industrial-scale production often encounters difficulties in maintaining emulsion quality and consistency. This scale-up challenge is particularly evident in continuous emulsification processes, where maintaining precise control over process parameters becomes increasingly complex.

Furthermore, the limited solubility of certain active ingredients in dodecane restricts its application in some fields. Enhancing the solubilizing capacity of dodecane-based emulsions without compromising stability or introducing additional complexities remains an active area of research. This challenge is particularly relevant in the development of drug delivery systems and advanced cosmetic formulations.

Lastly, the characterization and quality control of dodecane emulsions present ongoing challenges. Current analytical techniques often struggle to provide real-time, in-situ measurements of emulsion properties, making it difficult to monitor and adjust emulsion characteristics during production or application. Developing more sophisticated, non-invasive analytical methods is crucial for advancing dodecane emulsion technology and ensuring consistent product quality.

Existing Dodecane Emulsion Formulations

01 Emulsion stability testing methods

Various methods are employed to test the stability of dodecane emulsions. These include centrifugation, temperature cycling, and long-term storage tests. Advanced techniques such as light scattering and microscopy are also used to assess particle size distribution and emulsion structure over time.- Emulsion stabilization techniques: Various techniques are employed to enhance the stability of dodecane emulsions. These may include the use of specific emulsifiers, surfactants, or stabilizers that are compatible with dodecane. The choice of stabilization method depends on the intended application and desired properties of the emulsion.

- Particle size control in dodecane emulsions: Controlling the particle size distribution in dodecane emulsions is crucial for maintaining stability. Techniques such as high-pressure homogenization or ultrasonic emulsification may be used to achieve desired particle sizes. Smaller and more uniform droplet sizes generally contribute to improved emulsion stability.

- Temperature effects on dodecane emulsion stability: The stability of dodecane emulsions can be significantly influenced by temperature variations. Research focuses on developing formulations that maintain stability across a wide temperature range, considering factors such as viscosity changes and phase separation tendencies at different temperatures.

- pH adjustment for dodecane emulsion stability: Adjusting the pH of dodecane emulsions can play a crucial role in their stability. The optimal pH range depends on the specific emulsion system and the properties of the emulsifiers used. Careful pH control can help prevent coalescence and improve overall emulsion stability.

- Novel emulsifiers for dodecane emulsions: Research is ongoing to develop novel emulsifiers specifically designed for dodecane emulsions. These may include custom-synthesized surfactants or naturally derived compounds that exhibit superior stabilizing properties for dodecane-based systems, potentially offering improved performance over traditional emulsifiers.

02 Surfactant selection for dodecane emulsions

The choice of surfactants plays a crucial role in stabilizing dodecane emulsions. Non-ionic surfactants, such as ethoxylated alcohols or sorbitan esters, are often preferred due to their compatibility with a wide range of pH values and their resistance to electrolytes. The HLB (Hydrophilic-Lipophilic Balance) of the surfactant is carefully considered to match the oil phase properties.Expand Specific Solutions03 Emulsion stabilization through viscosity modification

Increasing the viscosity of the continuous phase can enhance the stability of dodecane emulsions. This is achieved by adding thickening agents such as cellulose derivatives, xanthan gum, or synthetic polymers. The increased viscosity helps to prevent droplet coalescence and sedimentation, thereby improving long-term stability.Expand Specific Solutions04 Use of co-emulsifiers and stabilizers

Co-emulsifiers and stabilizers are often incorporated to enhance the stability of dodecane emulsions. These additives can include long-chain alcohols, fatty acids, or polymeric stabilizers. They work in synergy with the primary emulsifier to create a more robust interfacial film around the oil droplets, preventing coalescence and Ostwald ripening.Expand Specific Solutions05 Emulsion preparation techniques

The method of emulsion preparation significantly impacts its stability. High-pressure homogenization, microfluidization, and ultrasonic emulsification are techniques used to create fine, uniform droplets in dodecane emulsions. The processing parameters, such as temperature, pressure, and duration, are optimized to achieve the desired droplet size distribution and enhance overall stability.Expand Specific Solutions

Key Players in Advanced Emulsion Industry

The competitive landscape for advanced emulsion techniques using dodecane is evolving rapidly, reflecting the technology's growing importance across multiple industries. The market is in an early growth stage, with significant potential for expansion as applications in sectors like petrochemicals, materials science, and pharmaceuticals continue to develop. Key players such as BASF Corp., Arkema France SA, and Wanhua Chemical Group are investing heavily in research and development, driving innovation in this field. The technology's maturity is progressing, with companies like PetroChina Co., Ltd. and China Petroleum & Chemical Corp. leveraging their extensive resources to scale up production and improve efficiency. Academic institutions, including Zhejiang University and Nanjing University, are also contributing to advancements through collaborative research efforts with industry partners.

BASF Corp.

Technical Solution: BASF has developed advanced emulsion techniques utilizing dodecane as a key component in their formulations. Their approach involves creating stable oil-in-water emulsions where dodecane serves as the oil phase. BASF's method employs a combination of specially designed surfactants and emulsifiers that effectively stabilize the dodecane droplets within the aqueous continuous phase. This technique allows for the creation of emulsions with controlled droplet sizes, typically ranging from 100 nm to 10 μm [1]. BASF has also implemented a high-pressure homogenization process to achieve uniform droplet distribution and enhance emulsion stability. Their research has shown that these dodecane-based emulsions exhibit improved shelf life and can be tailored for various applications in personal care, agrochemicals, and industrial coatings [3].

Strengths: Highly stable emulsions, versatile application range, and precise control over droplet size. Weaknesses: May require specialized equipment for production and potential higher costs compared to conventional emulsion techniques.

Arkema France SA

Technical Solution: Arkema has pioneered a novel approach to harnessing dodecane in advanced emulsion techniques through their proprietary "Controlled Polymerization" technology. This method involves the use of dodecane as both a solvent and a co-stabilizer in the emulsion polymerization process. Arkema's technique utilizes specially designed amphiphilic block copolymers that act as reactive surfactants, facilitating the formation of stable dodecane-containing nanoemulsions. The process allows for the creation of core-shell nanoparticles with a dodecane-rich core and a polymer shell, resulting in emulsions with enhanced stability and unique properties. Arkema's research has demonstrated that these dodecane-based emulsions exhibit improved thermal stability and can be used to create high-performance materials for applications in adhesives, coatings, and specialty polymers [2][5].

Strengths: Unique core-shell nanoparticle structure, enhanced thermal stability, and potential for high-performance materials. Weaknesses: Complex synthesis process and potential limitations in scaling up production.

Innovative Approaches in Dodecane Emulsification

Particles for electrophoretic displays comprising a core and a random - copolymer coating

PatentWO2013149714A1

Innovation

- The development of electrophoretic fluids comprising particles with a core and a polymeric shell, where the polymeric shell is a random copolymer with a charged or chargeable structural unit and a hydrocarbon soluble structural unit, allowing for controlled charging and steric stabilization of the particles, enabling flexible modification of particle charge and dispersibility.

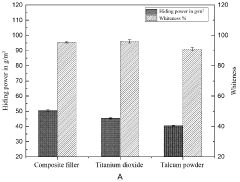

Method for preparing titanium dioxide/talcum powder composite filler by microemulsion method

PatentActiveZA202200133A

Innovation

- A microemulsion method using zirconia beads as a grinding medium, sodium hexametaphosphate as a dispersing agent, sodium dodecyl benzene sulfonate as a surfactant, Span 80 as an emulsifier, acetic acid as a catalyst, and tetrabutyl titanate as a titanium source, to create a titanium dioxide/talcum powder composite filler with improved coating strength and dispersibility, reducing agglomeration and production costs while maintaining high purity.

Environmental Impact of Dodecane Emulsions

The environmental impact of dodecane emulsions is a critical consideration in the development and application of advanced emulsion techniques. Dodecane, a hydrocarbon compound, has been widely used in various industries due to its unique properties. However, its potential environmental consequences must be carefully evaluated and mitigated.

One of the primary concerns associated with dodecane emulsions is their potential for water pollution. When released into aquatic environments, these emulsions can form a thin film on the water surface, disrupting gas exchange and potentially harming aquatic life. This film can also interfere with the photosynthesis of aquatic plants, leading to ecosystem imbalances.

Soil contamination is another significant environmental issue related to dodecane emulsions. Accidental spills or improper disposal can result in the infiltration of dodecane into soil layers, affecting soil quality and potentially contaminating groundwater resources. This contamination can persist for extended periods, posing long-term risks to both terrestrial and aquatic ecosystems.

The volatility of dodecane also raises concerns about air pollution. When exposed to the atmosphere, dodecane can evaporate and contribute to the formation of ground-level ozone and other air pollutants. This can have adverse effects on air quality, particularly in urban and industrial areas where emissions are more concentrated.

Biodegradation of dodecane emulsions is a crucial factor in assessing their environmental impact. While dodecane is generally considered biodegradable, the rate of degradation can vary depending on environmental conditions. In some cases, the presence of emulsifiers or other additives may slow down the biodegradation process, prolonging the environmental persistence of these compounds.

The potential for bioaccumulation in aquatic organisms is another environmental concern associated with dodecane emulsions. Some marine species may absorb and concentrate these compounds in their tissues, potentially leading to biomagnification up the food chain. This can have far-reaching consequences for ecosystem health and potentially impact human food sources.

To address these environmental challenges, researchers and industry professionals are exploring various mitigation strategies. These include the development of more environmentally friendly emulsifiers, improved containment and disposal methods, and the use of bioremediation techniques to accelerate the breakdown of dodecane in contaminated environments.

Regulatory frameworks and industry standards play a crucial role in managing the environmental impact of dodecane emulsions. Stricter guidelines for handling, storage, and disposal of these materials are being implemented in many jurisdictions to minimize their environmental footprint. Additionally, ongoing research into alternative compounds and emulsion techniques aims to reduce reliance on potentially harmful substances like dodecane.

One of the primary concerns associated with dodecane emulsions is their potential for water pollution. When released into aquatic environments, these emulsions can form a thin film on the water surface, disrupting gas exchange and potentially harming aquatic life. This film can also interfere with the photosynthesis of aquatic plants, leading to ecosystem imbalances.

Soil contamination is another significant environmental issue related to dodecane emulsions. Accidental spills or improper disposal can result in the infiltration of dodecane into soil layers, affecting soil quality and potentially contaminating groundwater resources. This contamination can persist for extended periods, posing long-term risks to both terrestrial and aquatic ecosystems.

The volatility of dodecane also raises concerns about air pollution. When exposed to the atmosphere, dodecane can evaporate and contribute to the formation of ground-level ozone and other air pollutants. This can have adverse effects on air quality, particularly in urban and industrial areas where emissions are more concentrated.

Biodegradation of dodecane emulsions is a crucial factor in assessing their environmental impact. While dodecane is generally considered biodegradable, the rate of degradation can vary depending on environmental conditions. In some cases, the presence of emulsifiers or other additives may slow down the biodegradation process, prolonging the environmental persistence of these compounds.

The potential for bioaccumulation in aquatic organisms is another environmental concern associated with dodecane emulsions. Some marine species may absorb and concentrate these compounds in their tissues, potentially leading to biomagnification up the food chain. This can have far-reaching consequences for ecosystem health and potentially impact human food sources.

To address these environmental challenges, researchers and industry professionals are exploring various mitigation strategies. These include the development of more environmentally friendly emulsifiers, improved containment and disposal methods, and the use of bioremediation techniques to accelerate the breakdown of dodecane in contaminated environments.

Regulatory frameworks and industry standards play a crucial role in managing the environmental impact of dodecane emulsions. Stricter guidelines for handling, storage, and disposal of these materials are being implemented in many jurisdictions to minimize their environmental footprint. Additionally, ongoing research into alternative compounds and emulsion techniques aims to reduce reliance on potentially harmful substances like dodecane.

Regulatory Framework for Emulsion Technologies

The regulatory framework for emulsion technologies involving dodecane is a complex and evolving landscape that requires careful navigation by industry stakeholders. At the international level, organizations such as the International Organization for Standardization (ISO) and the World Health Organization (WHO) provide guidelines and standards for the safe use of emulsions in various applications. These standards often serve as a basis for national and regional regulations.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating emulsion technologies, particularly those used in food, pharmaceuticals, and cosmetics. The FDA's Generally Recognized as Safe (GRAS) status is a key consideration for dodecane and other emulsion components. The Environmental Protection Agency (EPA) also has oversight on the environmental impact of emulsion technologies, especially concerning potential releases into water bodies or soil.

The European Union has established the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of dodecane and other chemicals in emulsion technologies. REACH requires manufacturers and importers to register substances and provide safety data, ensuring a high level of protection for human health and the environment.

In Asia, countries like Japan and South Korea have their own regulatory bodies and frameworks. Japan's Ministry of Health, Labour and Welfare oversees the use of emulsions in food and cosmetics, while the Korean Food and Drug Administration (KFDA) regulates similar applications in South Korea.

Specific regulations often depend on the intended application of the emulsion technology. For instance, emulsions used in pharmaceuticals must adhere to Good Manufacturing Practice (GMP) guidelines, which are more stringent than those for industrial applications. Similarly, emulsions used in food products must comply with food safety regulations, which vary by country but often include labeling requirements and restrictions on certain ingredients.

As environmental concerns grow, many jurisdictions are implementing stricter regulations on the disposal and environmental impact of emulsions. This includes requirements for biodegradability and limitations on volatile organic compound (VOC) emissions, which can affect the formulation of dodecane-based emulsions.

Compliance with these diverse regulatory frameworks requires ongoing vigilance and adaptation from companies working with advanced emulsion techniques. As research continues to uncover new applications and potential risks associated with emulsion technologies, regulatory bodies are likely to update their guidelines and restrictions accordingly. This dynamic regulatory environment necessitates that companies maintain robust compliance programs and stay informed about emerging regulatory trends across different markets and applications.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating emulsion technologies, particularly those used in food, pharmaceuticals, and cosmetics. The FDA's Generally Recognized as Safe (GRAS) status is a key consideration for dodecane and other emulsion components. The Environmental Protection Agency (EPA) also has oversight on the environmental impact of emulsion technologies, especially concerning potential releases into water bodies or soil.

The European Union has established the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of dodecane and other chemicals in emulsion technologies. REACH requires manufacturers and importers to register substances and provide safety data, ensuring a high level of protection for human health and the environment.

In Asia, countries like Japan and South Korea have their own regulatory bodies and frameworks. Japan's Ministry of Health, Labour and Welfare oversees the use of emulsions in food and cosmetics, while the Korean Food and Drug Administration (KFDA) regulates similar applications in South Korea.

Specific regulations often depend on the intended application of the emulsion technology. For instance, emulsions used in pharmaceuticals must adhere to Good Manufacturing Practice (GMP) guidelines, which are more stringent than those for industrial applications. Similarly, emulsions used in food products must comply with food safety regulations, which vary by country but often include labeling requirements and restrictions on certain ingredients.

As environmental concerns grow, many jurisdictions are implementing stricter regulations on the disposal and environmental impact of emulsions. This includes requirements for biodegradability and limitations on volatile organic compound (VOC) emissions, which can affect the formulation of dodecane-based emulsions.

Compliance with these diverse regulatory frameworks requires ongoing vigilance and adaptation from companies working with advanced emulsion techniques. As research continues to uncover new applications and potential risks associated with emulsion technologies, regulatory bodies are likely to update their guidelines and restrictions accordingly. This dynamic regulatory environment necessitates that companies maintain robust compliance programs and stay informed about emerging regulatory trends across different markets and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!