Enhancing CMOS Battery Durability for Next-Gen Devices

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMOS Battery Evolution and Objectives

CMOS (Complementary Metal-Oxide-Semiconductor) batteries have been a critical component in electronic devices for decades, serving as the power source for maintaining system settings and real-time clocks when the main power is off. The evolution of CMOS batteries has been closely tied to the advancement of portable electronics and the increasing demand for longer-lasting, more efficient power solutions.

In the early days of personal computing, CMOS batteries were primarily used in desktop computers to maintain BIOS settings and system time. These batteries were typically large, non-rechargeable lithium cells with a lifespan of several years. As technology progressed, the need for smaller, more durable CMOS batteries grew, particularly with the rise of laptops and mobile devices.

The miniaturization of electronic components led to the development of smaller CMOS batteries, often in the form of coin cells or button batteries. These compact power sources allowed for slimmer device designs while still providing the necessary backup power. However, as devices became more sophisticated and energy-demanding, the limitations of traditional CMOS batteries became apparent.

Recent years have seen a shift towards more advanced CMOS battery technologies. Manufacturers have explored various chemistries and designs to enhance durability and longevity. Lithium-ion and lithium polymer batteries have gained popularity due to their higher energy density and rechargeability. Some devices now incorporate supercapacitors or hybrid systems that combine traditional batteries with energy harvesting technologies.

The primary objective in enhancing CMOS battery durability for next-generation devices is to address several key challenges. First, there is a need to increase the overall lifespan of these batteries to match or exceed the expected lifetime of the devices they power. This involves improving the chemical stability of the battery components and reducing self-discharge rates.

Another crucial goal is to develop CMOS batteries that can withstand a wider range of environmental conditions. As devices are used in increasingly diverse settings, from extreme temperatures to high-humidity environments, the power source must remain stable and functional. This objective necessitates research into new materials and protective encapsulations.

Furthermore, the integration of smart power management systems is becoming a priority. These systems aim to optimize battery usage, implement more efficient charging cycles, and provide accurate state-of-charge information. By intelligently managing power consumption, next-generation CMOS batteries can significantly extend their operational life.

Lastly, there is a growing emphasis on sustainability and environmental responsibility. The development of eco-friendly CMOS batteries that use less toxic materials and are easier to recycle aligns with global efforts to reduce electronic waste. This objective not only addresses environmental concerns but also anticipates future regulations on battery composition and disposal.

In the early days of personal computing, CMOS batteries were primarily used in desktop computers to maintain BIOS settings and system time. These batteries were typically large, non-rechargeable lithium cells with a lifespan of several years. As technology progressed, the need for smaller, more durable CMOS batteries grew, particularly with the rise of laptops and mobile devices.

The miniaturization of electronic components led to the development of smaller CMOS batteries, often in the form of coin cells or button batteries. These compact power sources allowed for slimmer device designs while still providing the necessary backup power. However, as devices became more sophisticated and energy-demanding, the limitations of traditional CMOS batteries became apparent.

Recent years have seen a shift towards more advanced CMOS battery technologies. Manufacturers have explored various chemistries and designs to enhance durability and longevity. Lithium-ion and lithium polymer batteries have gained popularity due to their higher energy density and rechargeability. Some devices now incorporate supercapacitors or hybrid systems that combine traditional batteries with energy harvesting technologies.

The primary objective in enhancing CMOS battery durability for next-generation devices is to address several key challenges. First, there is a need to increase the overall lifespan of these batteries to match or exceed the expected lifetime of the devices they power. This involves improving the chemical stability of the battery components and reducing self-discharge rates.

Another crucial goal is to develop CMOS batteries that can withstand a wider range of environmental conditions. As devices are used in increasingly diverse settings, from extreme temperatures to high-humidity environments, the power source must remain stable and functional. This objective necessitates research into new materials and protective encapsulations.

Furthermore, the integration of smart power management systems is becoming a priority. These systems aim to optimize battery usage, implement more efficient charging cycles, and provide accurate state-of-charge information. By intelligently managing power consumption, next-generation CMOS batteries can significantly extend their operational life.

Lastly, there is a growing emphasis on sustainability and environmental responsibility. The development of eco-friendly CMOS batteries that use less toxic materials and are easier to recycle aligns with global efforts to reduce electronic waste. This objective not only addresses environmental concerns but also anticipates future regulations on battery composition and disposal.

Market Demand Analysis for Long-Lasting CMOS Batteries

The market demand for long-lasting CMOS batteries in next-generation devices has been steadily increasing, driven by the growing need for extended device uptime and improved user experience. As consumer electronics, IoT devices, and wearable technologies continue to evolve, the requirement for more durable and efficient power sources has become paramount.

In the smartphone sector, which represents a significant portion of the CMOS battery market, consumers consistently rank battery life as one of the top factors influencing their purchasing decisions. This trend has led manufacturers to prioritize battery performance improvements, with a focus on both capacity and longevity. The demand for smartphones with multi-day battery life has created a competitive landscape where enhanced CMOS battery technology can provide a significant market advantage.

The wearable technology market, including smartwatches and fitness trackers, has also seen a surge in demand for improved battery performance. Users expect these devices to operate continuously for extended periods without frequent charging, making battery durability a critical factor in product success. This has led to increased investment in research and development of advanced CMOS battery technologies tailored for wearable applications.

In the automotive industry, the shift towards electric and hybrid vehicles has amplified the need for high-performance, long-lasting battery solutions. While lithium-ion batteries currently dominate this space, there is growing interest in CMOS battery technology for auxiliary systems and sensors within vehicles, where size constraints and longevity requirements align well with CMOS capabilities.

The Internet of Things (IoT) sector presents another significant market opportunity for enhanced CMOS batteries. As the number of connected devices continues to grow exponentially, the demand for power-efficient, long-lasting batteries has become critical. Many IoT applications require batteries that can operate for years without replacement, making improved CMOS battery durability an essential factor in enabling widespread IoT adoption.

In the medical device industry, the need for reliable, long-lasting power sources is particularly acute. Implantable medical devices, such as pacemakers and neurostimulators, require batteries that can function safely and effectively for extended periods. Enhanced CMOS battery technology has the potential to significantly improve patient outcomes by reducing the frequency of battery replacement procedures.

Market analysis indicates that the global CMOS battery market is poised for substantial growth in the coming years. This growth is expected to be driven by advancements in battery technology, increasing adoption of portable electronic devices, and the expanding IoT ecosystem. The demand for enhanced CMOS battery durability is likely to be particularly strong in regions with high technology adoption rates, such as North America, Europe, and parts of Asia.

In the smartphone sector, which represents a significant portion of the CMOS battery market, consumers consistently rank battery life as one of the top factors influencing their purchasing decisions. This trend has led manufacturers to prioritize battery performance improvements, with a focus on both capacity and longevity. The demand for smartphones with multi-day battery life has created a competitive landscape where enhanced CMOS battery technology can provide a significant market advantage.

The wearable technology market, including smartwatches and fitness trackers, has also seen a surge in demand for improved battery performance. Users expect these devices to operate continuously for extended periods without frequent charging, making battery durability a critical factor in product success. This has led to increased investment in research and development of advanced CMOS battery technologies tailored for wearable applications.

In the automotive industry, the shift towards electric and hybrid vehicles has amplified the need for high-performance, long-lasting battery solutions. While lithium-ion batteries currently dominate this space, there is growing interest in CMOS battery technology for auxiliary systems and sensors within vehicles, where size constraints and longevity requirements align well with CMOS capabilities.

The Internet of Things (IoT) sector presents another significant market opportunity for enhanced CMOS batteries. As the number of connected devices continues to grow exponentially, the demand for power-efficient, long-lasting batteries has become critical. Many IoT applications require batteries that can operate for years without replacement, making improved CMOS battery durability an essential factor in enabling widespread IoT adoption.

In the medical device industry, the need for reliable, long-lasting power sources is particularly acute. Implantable medical devices, such as pacemakers and neurostimulators, require batteries that can function safely and effectively for extended periods. Enhanced CMOS battery technology has the potential to significantly improve patient outcomes by reducing the frequency of battery replacement procedures.

Market analysis indicates that the global CMOS battery market is poised for substantial growth in the coming years. This growth is expected to be driven by advancements in battery technology, increasing adoption of portable electronic devices, and the expanding IoT ecosystem. The demand for enhanced CMOS battery durability is likely to be particularly strong in regions with high technology adoption rates, such as North America, Europe, and parts of Asia.

Current CMOS Battery Technology Challenges

CMOS battery technology, while widely used in various electronic devices, faces several significant challenges that hinder its performance and longevity in next-generation devices. One of the primary issues is the limited energy density of current CMOS batteries. As devices become more compact and feature-rich, the demand for higher energy storage capacity within the same or smaller footprint increases. This constraint poses a significant challenge for designers and engineers striving to create longer-lasting, more powerful devices.

Another critical challenge is the degradation of battery performance over time. CMOS batteries are susceptible to capacity loss and increased internal resistance due to repeated charge-discharge cycles and environmental factors such as temperature fluctuations. This degradation not only shortens the overall lifespan of the battery but also impacts the reliability of the device it powers, potentially leading to data loss or system failures in critical applications.

The charging speed of CMOS batteries is another area of concern. With the fast-paced nature of modern technology use, there is a growing demand for batteries that can be charged rapidly without compromising safety or long-term performance. Current CMOS battery technology often falls short in this aspect, leading to user frustration and limiting the practical usability of devices in certain scenarios.

Safety issues also present a significant challenge in CMOS battery technology. While generally considered safer than some other battery types, CMOS batteries are not immune to risks such as overheating, swelling, or even rare cases of fire or explosion. These safety concerns become more pronounced as manufacturers push the boundaries of battery capacity and charging speeds to meet consumer demands.

Environmental impact and sustainability are increasingly important considerations in battery technology. The production and disposal of CMOS batteries involve materials and processes that can have negative environmental consequences. There is a growing need for more eco-friendly battery solutions that reduce reliance on rare or toxic materials and improve recyclability.

Lastly, the integration of CMOS batteries with advanced power management systems and emerging technologies like Internet of Things (IoT) devices presents both opportunities and challenges. Optimizing battery performance in diverse and often unpredictable usage scenarios requires sophisticated power management algorithms and hardware designs, which add complexity to device development and manufacturing processes.

Addressing these challenges is crucial for the continued evolution of CMOS battery technology. Innovations in materials science, manufacturing processes, and battery management systems are needed to overcome these limitations and meet the demands of next-generation devices. The industry must focus on developing solutions that not only enhance energy density and longevity but also prioritize safety, sustainability, and seamless integration with emerging technologies.

Another critical challenge is the degradation of battery performance over time. CMOS batteries are susceptible to capacity loss and increased internal resistance due to repeated charge-discharge cycles and environmental factors such as temperature fluctuations. This degradation not only shortens the overall lifespan of the battery but also impacts the reliability of the device it powers, potentially leading to data loss or system failures in critical applications.

The charging speed of CMOS batteries is another area of concern. With the fast-paced nature of modern technology use, there is a growing demand for batteries that can be charged rapidly without compromising safety or long-term performance. Current CMOS battery technology often falls short in this aspect, leading to user frustration and limiting the practical usability of devices in certain scenarios.

Safety issues also present a significant challenge in CMOS battery technology. While generally considered safer than some other battery types, CMOS batteries are not immune to risks such as overheating, swelling, or even rare cases of fire or explosion. These safety concerns become more pronounced as manufacturers push the boundaries of battery capacity and charging speeds to meet consumer demands.

Environmental impact and sustainability are increasingly important considerations in battery technology. The production and disposal of CMOS batteries involve materials and processes that can have negative environmental consequences. There is a growing need for more eco-friendly battery solutions that reduce reliance on rare or toxic materials and improve recyclability.

Lastly, the integration of CMOS batteries with advanced power management systems and emerging technologies like Internet of Things (IoT) devices presents both opportunities and challenges. Optimizing battery performance in diverse and often unpredictable usage scenarios requires sophisticated power management algorithms and hardware designs, which add complexity to device development and manufacturing processes.

Addressing these challenges is crucial for the continued evolution of CMOS battery technology. Innovations in materials science, manufacturing processes, and battery management systems are needed to overcome these limitations and meet the demands of next-generation devices. The industry must focus on developing solutions that not only enhance energy density and longevity but also prioritize safety, sustainability, and seamless integration with emerging technologies.

Existing CMOS Battery Enhancement Solutions

01 Power management techniques for CMOS battery

Various power management techniques are employed to extend CMOS battery life. These include implementing low-power modes, optimizing power consumption during standby, and utilizing intelligent power distribution systems. Such techniques help reduce the overall power drain on the CMOS battery, thereby increasing its durability and lifespan.- Power management techniques for CMOS battery longevity: Various power management techniques are employed to extend CMOS battery life. These include implementing low-power modes, optimizing power consumption during standby, and utilizing intelligent power distribution systems. Such techniques help reduce the drain on the CMOS battery, thereby increasing its overall durability and lifespan.

- Advanced battery technologies for CMOS applications: Developments in battery technology specifically tailored for CMOS applications focus on improving energy density, reducing self-discharge rates, and enhancing overall performance. These advancements include new materials, improved cell designs, and innovative manufacturing processes that contribute to longer-lasting CMOS batteries.

- Circuit design optimization for reduced battery drain: Optimizing circuit designs in CMOS systems can significantly reduce battery drain. This includes implementing efficient voltage regulators, using low-leakage transistors, and designing circuits that minimize standby current. Such optimizations help extend the life of the CMOS battery by reducing unnecessary power consumption.

- Temperature compensation and environmental protection: Implementing temperature compensation mechanisms and environmental protection features can enhance CMOS battery durability. This includes designing circuits that adjust power consumption based on temperature variations and incorporating protective measures against environmental factors such as humidity and electromagnetic interference.

- Smart charging and battery management systems: Incorporating smart charging algorithms and advanced battery management systems can significantly improve CMOS battery durability. These systems can monitor battery health, optimize charging cycles, and implement predictive maintenance strategies to extend battery life and improve overall system reliability.

02 Battery monitoring and replacement systems

Advanced monitoring systems are developed to track CMOS battery health and performance. These systems can provide early warnings for battery replacement, ensuring uninterrupted operation of CMOS-dependent functions. Some designs incorporate automatic switchover mechanisms to backup power sources when the primary CMOS battery is depleted.Expand Specific Solutions03 Enhanced battery chemistry and construction

Improvements in battery chemistry and physical construction contribute to increased CMOS battery durability. This includes the development of new electrolyte compositions, advanced electrode materials, and optimized cell designs that reduce self-discharge rates and extend overall battery life.Expand Specific Solutions04 Integration of energy harvesting technologies

Some designs incorporate energy harvesting technologies to supplement or recharge the CMOS battery. These may include solar cells, thermal energy harvesters, or kinetic energy capture systems, which can help maintain battery charge levels and extend overall durability.Expand Specific Solutions05 Circuit design optimization for reduced power consumption

Advancements in circuit design focus on reducing the power consumption of CMOS-dependent components. This includes the development of more efficient memory retention circuits, low-leakage transistors, and adaptive power gating techniques that minimize unnecessary power draw from the CMOS battery.Expand Specific Solutions

Key Players in CMOS Battery Industry

The competition landscape for enhancing CMOS battery durability in next-generation devices is characterized by a mature market with significant growth potential. Major players like Taiwan Semiconductor Manufacturing Co., GLOBALFOUNDRIES, and United Microelectronics Corp. are at the forefront of CMOS technology development. The market is driven by increasing demand for longer-lasting batteries in portable electronics and IoT devices. Technological advancements focus on improving energy efficiency and reducing power consumption. Emerging players like Contemporary Amperex Technology and Samsung SDI are also making strides in battery technology, potentially disrupting the established market dynamics.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed advanced CMOS processes specifically tailored for battery management systems (BMS) in next-generation devices. Their 22nm ultra-low power (22ULP) and 12nm FinFET Compact (12FFC) technologies offer significant improvements in power efficiency and integration density[1]. These processes enable the production of highly efficient power management ICs (PMICs) that can extend battery life in portable devices. TSMC's BMS solutions incorporate advanced features such as high-precision voltage and current sensing, adaptive power management algorithms, and integrated security features to protect against unauthorized access and tampering[2].

Strengths: Industry-leading process technology, high integration capabilities, and extensive ecosystem support. Weaknesses: Higher production costs compared to older processes, potential supply chain constraints due to high demand.

QUALCOMM, Inc.

Technical Solution: Qualcomm has introduced its Quick Charge 5 technology, which is designed to enhance CMOS battery durability in next-gen devices. This technology utilizes advanced power management ICs (PMICs) and incorporates smart battery management algorithms. Quick Charge 5 supports 100W+ charging speeds while maintaining battery longevity through features like real-time thermal management and voltage regulation[3]. Qualcomm's solution also includes a custom CMOS-based fuel gauge IC that provides highly accurate battery state-of-charge (SoC) and state-of-health (SoH) measurements, enabling more efficient charging cycles and prolonged battery life[4].

Strengths: Widespread adoption in mobile devices, comprehensive ecosystem support, and advanced power management features. Weaknesses: Primarily focused on mobile applications, may have limited applicability in other device categories.

Innovative CMOS Battery Materials Research

Method and apparatus for predicting service life of CMOS device, electronic device, and medium

PatentWO2024045351A1

Innovation

- By obtaining the electrical parameter time series sample data of CMOS devices under accelerated stress testing, a training set is established and a long short-term memory model is used for life prediction and device failure time.

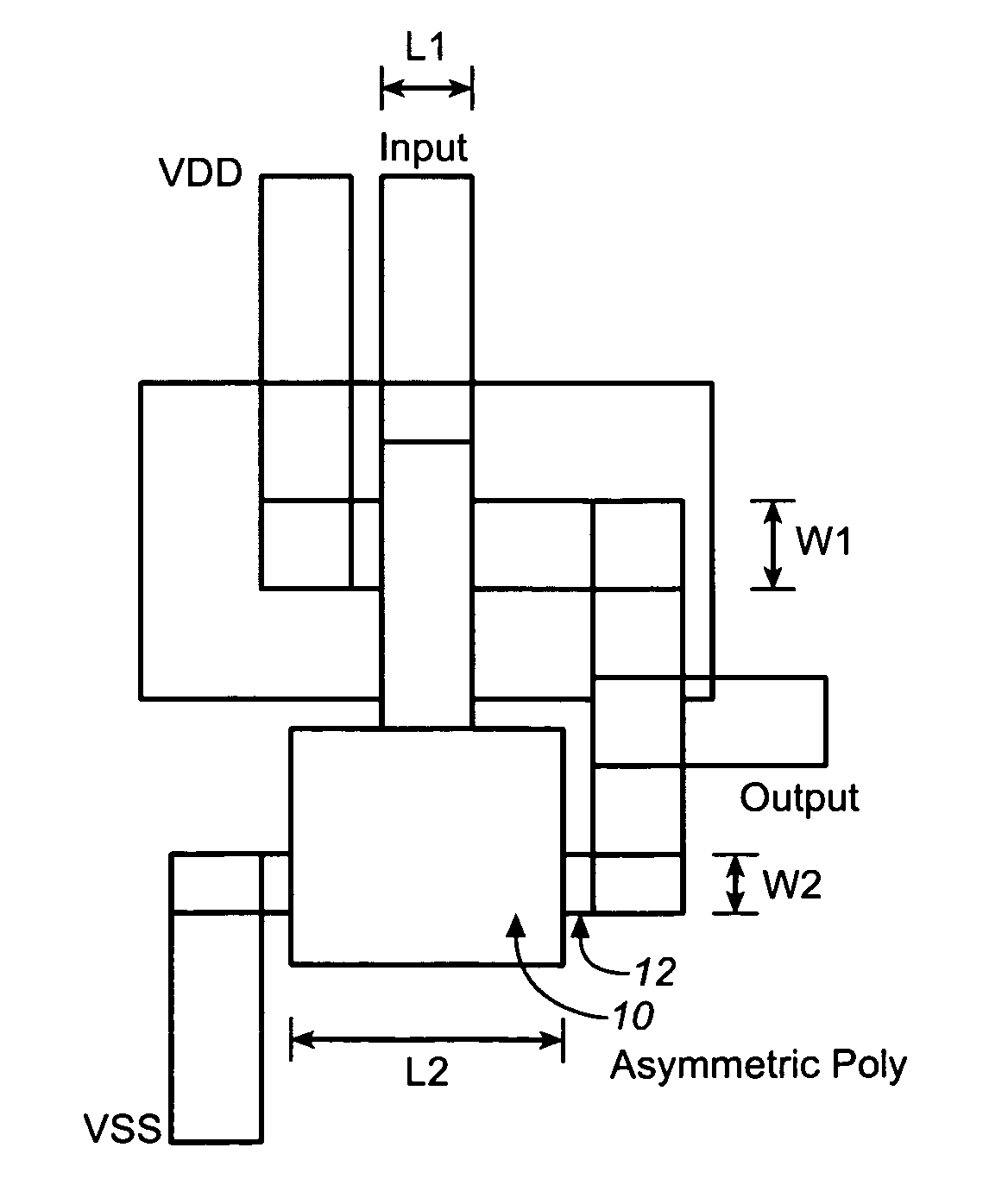

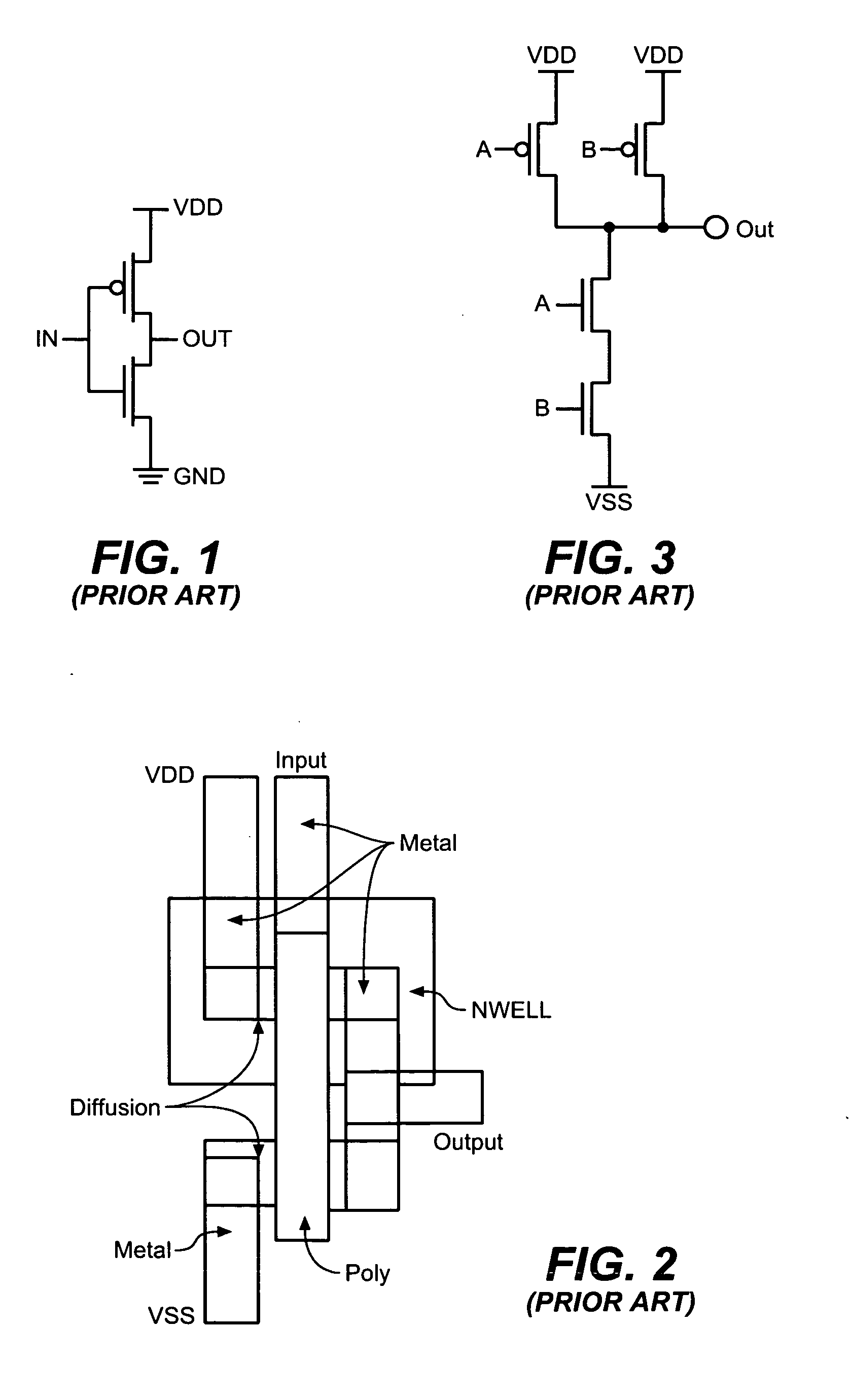

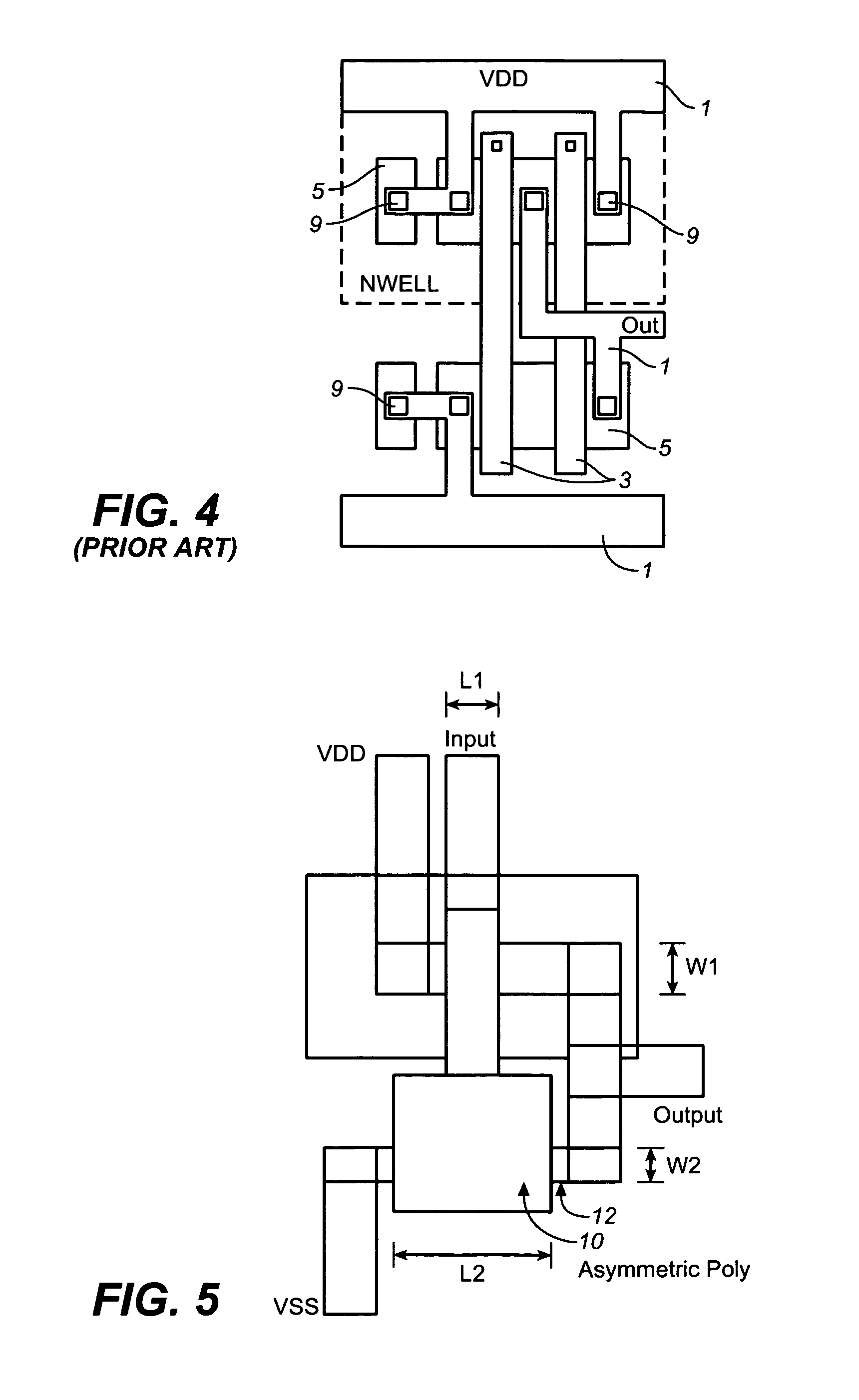

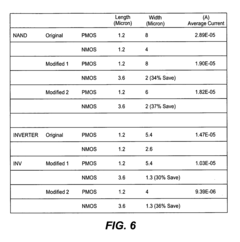

Asymmetrical layout for complementary metal-oxide-semiconductor integrated circuit to reduce power consumption

PatentInactiveUS20090072320A1

Innovation

- The implementation of an asymmetrical polysilicon gate and diffusion layout in CMOS integrated circuits, where the polysilicon gate and diffusion dimensions are asymmetrical, causing P-type and N-type transistors to switch at different times, thereby reducing short circuit current and power consumption.

Environmental Impact of CMOS Battery Production

The production of CMOS batteries for next-generation devices has significant environmental implications that must be carefully considered. The manufacturing process involves the use of various materials and chemicals, some of which can have detrimental effects on the environment if not properly managed.

One of the primary environmental concerns is the extraction and processing of raw materials used in CMOS battery production. These materials often include lithium, cobalt, nickel, and other rare earth elements. Mining operations for these resources can lead to habitat destruction, soil erosion, and water pollution. Additionally, the energy-intensive refining processes contribute to increased carbon emissions and greenhouse gas production.

The manufacturing phase of CMOS batteries also presents environmental challenges. The production facilities require substantial energy consumption, often relying on fossil fuels, which further exacerbates carbon emissions. Moreover, the use of toxic chemicals and solvents in the manufacturing process can result in hazardous waste that requires careful disposal to prevent soil and water contamination.

Water usage is another critical environmental factor in CMOS battery production. The manufacturing process demands large quantities of water for cooling, cleaning, and other purposes. This can strain local water resources, particularly in water-scarce regions, and may lead to conflicts with other water users in the area.

The disposal and recycling of CMOS batteries at the end of their lifecycle also pose environmental risks. Improper disposal can result in the leaching of harmful chemicals into soil and groundwater. While recycling efforts are increasing, the process itself can be energy-intensive and may generate additional waste products that require careful management.

To mitigate these environmental impacts, manufacturers are exploring more sustainable production methods. These include developing cleaner extraction techniques for raw materials, implementing closed-loop manufacturing systems to reduce waste and water consumption, and investing in renewable energy sources to power production facilities. Additionally, advancements in battery technology are focusing on the use of more abundant and less environmentally harmful materials.

Efforts to improve the recyclability of CMOS batteries are also underway, with research into design modifications that facilitate easier disassembly and material recovery. Furthermore, the development of more durable batteries with longer lifespans can reduce the overall environmental impact by decreasing the frequency of battery replacement and disposal.

As the demand for next-generation devices continues to grow, addressing the environmental impact of CMOS battery production becomes increasingly crucial. Balancing technological advancement with environmental stewardship will require ongoing innovation, stringent regulations, and a commitment to sustainable practices throughout the entire battery lifecycle.

One of the primary environmental concerns is the extraction and processing of raw materials used in CMOS battery production. These materials often include lithium, cobalt, nickel, and other rare earth elements. Mining operations for these resources can lead to habitat destruction, soil erosion, and water pollution. Additionally, the energy-intensive refining processes contribute to increased carbon emissions and greenhouse gas production.

The manufacturing phase of CMOS batteries also presents environmental challenges. The production facilities require substantial energy consumption, often relying on fossil fuels, which further exacerbates carbon emissions. Moreover, the use of toxic chemicals and solvents in the manufacturing process can result in hazardous waste that requires careful disposal to prevent soil and water contamination.

Water usage is another critical environmental factor in CMOS battery production. The manufacturing process demands large quantities of water for cooling, cleaning, and other purposes. This can strain local water resources, particularly in water-scarce regions, and may lead to conflicts with other water users in the area.

The disposal and recycling of CMOS batteries at the end of their lifecycle also pose environmental risks. Improper disposal can result in the leaching of harmful chemicals into soil and groundwater. While recycling efforts are increasing, the process itself can be energy-intensive and may generate additional waste products that require careful management.

To mitigate these environmental impacts, manufacturers are exploring more sustainable production methods. These include developing cleaner extraction techniques for raw materials, implementing closed-loop manufacturing systems to reduce waste and water consumption, and investing in renewable energy sources to power production facilities. Additionally, advancements in battery technology are focusing on the use of more abundant and less environmentally harmful materials.

Efforts to improve the recyclability of CMOS batteries are also underway, with research into design modifications that facilitate easier disassembly and material recovery. Furthermore, the development of more durable batteries with longer lifespans can reduce the overall environmental impact by decreasing the frequency of battery replacement and disposal.

As the demand for next-generation devices continues to grow, addressing the environmental impact of CMOS battery production becomes increasingly crucial. Balancing technological advancement with environmental stewardship will require ongoing innovation, stringent regulations, and a commitment to sustainable practices throughout the entire battery lifecycle.

Cost-Benefit Analysis of Enhanced CMOS Batteries

The cost-benefit analysis of enhanced CMOS batteries for next-generation devices reveals a complex interplay of economic factors and technological advancements. Initial investment in research and development for improved CMOS battery technology is substantial, requiring significant capital expenditure in materials science, manufacturing processes, and testing facilities. However, the long-term benefits of enhanced battery durability can potentially outweigh these upfront costs.

From a manufacturing perspective, the implementation of advanced CMOS battery technology may necessitate retooling production lines and updating quality control measures. This could lead to temporary increases in production costs and potential disruptions in supply chains. Nevertheless, as production scales up and processes are optimized, economies of scale are likely to reduce per-unit costs over time.

For device manufacturers, the integration of enhanced CMOS batteries offers several advantages. Improved battery life can be a key differentiator in the competitive consumer electronics market, potentially leading to increased market share and customer loyalty. Additionally, devices with longer-lasting batteries may command premium pricing, boosting profit margins.

From a consumer perspective, the benefits of enhanced battery durability are clear. Longer battery life translates to improved user experience, reduced need for frequent charging, and potentially lower replacement costs over the device's lifetime. This increased satisfaction could drive higher sales volumes and brand loyalty, indirectly benefiting manufacturers and retailers.

Environmental considerations also play a role in the cost-benefit analysis. Enhanced CMOS batteries with longer lifespans can reduce electronic waste, aligning with growing consumer demand for sustainable products. This eco-friendly aspect can contribute to positive brand image and potentially offset some of the higher production costs through increased sales or premium pricing.

However, the analysis must also account for potential risks. Rapid advancements in competing battery technologies could render investments in CMOS battery enhancements obsolete. Moreover, unforeseen issues with new battery formulations, such as safety concerns or performance degradation over time, could lead to costly recalls or damage to brand reputation.

In conclusion, while the initial costs of enhancing CMOS battery durability are significant, the potential long-term benefits in terms of market competitiveness, consumer satisfaction, and environmental sustainability present a compelling case for investment. The key to maximizing the benefit-to-cost ratio lies in strategic R&D focus, efficient manufacturing processes, and effective marketing to highlight the value proposition of enhanced battery life in next-generation devices.

From a manufacturing perspective, the implementation of advanced CMOS battery technology may necessitate retooling production lines and updating quality control measures. This could lead to temporary increases in production costs and potential disruptions in supply chains. Nevertheless, as production scales up and processes are optimized, economies of scale are likely to reduce per-unit costs over time.

For device manufacturers, the integration of enhanced CMOS batteries offers several advantages. Improved battery life can be a key differentiator in the competitive consumer electronics market, potentially leading to increased market share and customer loyalty. Additionally, devices with longer-lasting batteries may command premium pricing, boosting profit margins.

From a consumer perspective, the benefits of enhanced battery durability are clear. Longer battery life translates to improved user experience, reduced need for frequent charging, and potentially lower replacement costs over the device's lifetime. This increased satisfaction could drive higher sales volumes and brand loyalty, indirectly benefiting manufacturers and retailers.

Environmental considerations also play a role in the cost-benefit analysis. Enhanced CMOS batteries with longer lifespans can reduce electronic waste, aligning with growing consumer demand for sustainable products. This eco-friendly aspect can contribute to positive brand image and potentially offset some of the higher production costs through increased sales or premium pricing.

However, the analysis must also account for potential risks. Rapid advancements in competing battery technologies could render investments in CMOS battery enhancements obsolete. Moreover, unforeseen issues with new battery formulations, such as safety concerns or performance degradation over time, could lead to costly recalls or damage to brand reputation.

In conclusion, while the initial costs of enhancing CMOS battery durability are significant, the potential long-term benefits in terms of market competitiveness, consumer satisfaction, and environmental sustainability present a compelling case for investment. The key to maximizing the benefit-to-cost ratio lies in strategic R&D focus, efficient manufacturing processes, and effective marketing to highlight the value proposition of enhanced battery life in next-generation devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!