Gel permeation chromatography in additive manufacturing polymer analysis

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GPC Technology Evolution in Polymer Analysis

Gel Permeation Chromatography (GPC) has undergone significant evolution since its inception in the 1960s, transforming from a rudimentary separation technique to a sophisticated analytical tool essential for polymer characterization in additive manufacturing. The initial development phase focused on basic size exclusion principles with limited detector capabilities and column technology, primarily serving research laboratories for fundamental polymer studies.

The 1980s marked a pivotal transition with the introduction of improved column materials featuring controlled pore sizes and enhanced stationary phases, enabling more precise molecular weight distribution analysis. This period also witnessed the integration of multiple detection systems, including refractive index (RI) detectors and ultraviolet (UV) absorption detectors, expanding the analytical capabilities beyond simple molecular weight determination.

By the 1990s, GPC technology experienced significant advancement with the development of multi-angle light scattering (MALS) detectors, which revolutionized absolute molecular weight measurements without reliance on calibration standards. This innovation proved particularly valuable for analyzing complex polymers used in emerging additive manufacturing processes, where traditional calibration methods often proved inadequate.

The early 2000s brought automation and computerization to GPC systems, with sophisticated software packages enabling complex data analysis, peak deconvolution, and comprehensive polymer characterization. These developments coincided with the growing interest in additive manufacturing technologies, creating a synergistic relationship between polymer analysis needs and analytical capabilities.

The most recent decade has witnessed the miniaturization of GPC systems, development of ultra-high-performance liquid chromatography (UHPLC) platforms for GPC applications, and integration with other analytical techniques such as mass spectrometry and vibrational spectroscopy. These advancements have enabled comprehensive characterization of polymers used in additive manufacturing, including detailed analysis of molecular architecture, branching, and chemical composition.

Current state-of-the-art GPC systems feature multi-detector arrays combining RI, viscometry, light scattering, and mass spectrometry, providing unprecedented insights into polymer structure-property relationships critical for additive manufacturing applications. The evolution of column technology now includes sub-2μm particles and monolithic columns, offering superior resolution and faster analysis times essential for high-throughput quality control in industrial settings.

The trajectory of GPC technology continues toward greater sensitivity, higher resolution, faster analysis, and more comprehensive characterization capabilities, directly addressing the complex analytical challenges presented by advanced polymers in additive manufacturing processes. This evolution reflects the growing sophistication of polymer materials and the increasing demands for precise characterization in advanced manufacturing applications.

The 1980s marked a pivotal transition with the introduction of improved column materials featuring controlled pore sizes and enhanced stationary phases, enabling more precise molecular weight distribution analysis. This period also witnessed the integration of multiple detection systems, including refractive index (RI) detectors and ultraviolet (UV) absorption detectors, expanding the analytical capabilities beyond simple molecular weight determination.

By the 1990s, GPC technology experienced significant advancement with the development of multi-angle light scattering (MALS) detectors, which revolutionized absolute molecular weight measurements without reliance on calibration standards. This innovation proved particularly valuable for analyzing complex polymers used in emerging additive manufacturing processes, where traditional calibration methods often proved inadequate.

The early 2000s brought automation and computerization to GPC systems, with sophisticated software packages enabling complex data analysis, peak deconvolution, and comprehensive polymer characterization. These developments coincided with the growing interest in additive manufacturing technologies, creating a synergistic relationship between polymer analysis needs and analytical capabilities.

The most recent decade has witnessed the miniaturization of GPC systems, development of ultra-high-performance liquid chromatography (UHPLC) platforms for GPC applications, and integration with other analytical techniques such as mass spectrometry and vibrational spectroscopy. These advancements have enabled comprehensive characterization of polymers used in additive manufacturing, including detailed analysis of molecular architecture, branching, and chemical composition.

Current state-of-the-art GPC systems feature multi-detector arrays combining RI, viscometry, light scattering, and mass spectrometry, providing unprecedented insights into polymer structure-property relationships critical for additive manufacturing applications. The evolution of column technology now includes sub-2μm particles and monolithic columns, offering superior resolution and faster analysis times essential for high-throughput quality control in industrial settings.

The trajectory of GPC technology continues toward greater sensitivity, higher resolution, faster analysis, and more comprehensive characterization capabilities, directly addressing the complex analytical challenges presented by advanced polymers in additive manufacturing processes. This evolution reflects the growing sophistication of polymer materials and the increasing demands for precise characterization in advanced manufacturing applications.

Market Demand for Advanced Polymer Characterization

The polymer additive manufacturing market has witnessed substantial growth in recent years, driving an increasing demand for advanced polymer characterization techniques. Gel permeation chromatography (GPC) has emerged as a critical analytical method in this space, with market research indicating a compound annual growth rate of 8.2% for polymer analysis instrumentation between 2021 and 2026. This growth is primarily fueled by the expanding adoption of 3D printing technologies across various industries, including aerospace, automotive, healthcare, and consumer goods.

The demand for GPC in additive manufacturing polymer analysis stems from several key market needs. Manufacturers require precise molecular weight distribution data to ensure consistent print quality and mechanical properties. Research indicates that variations in molecular weight can significantly impact flow behavior during printing, resulting in defects and compromised structural integrity. A recent industry survey revealed that 78% of additive manufacturing companies consider polymer characterization essential for quality control processes.

Material development represents another significant market driver. As the industry moves toward more specialized applications, there is growing demand for custom-formulated polymers with specific properties. GPC enables researchers to correlate molecular characteristics with performance attributes, accelerating the development cycle. The market for specialized 3D printing materials is projected to grow at 23% annually, creating substantial opportunities for advanced characterization technologies.

Regulatory compliance further amplifies market demand for GPC analysis. Industries such as medical device manufacturing and aerospace require comprehensive material documentation, including detailed polymer characterization data. This trend is particularly evident in markets with stringent quality standards, where GPC serves as a critical tool for material validation and certification.

The shift toward sustainable materials in additive manufacturing has created additional market opportunities for polymer characterization. As manufacturers explore bio-based and recyclable polymers, GPC analysis becomes essential for understanding degradation mechanisms and ensuring consistent performance across recycling cycles. Market research indicates that sustainability considerations influence purchasing decisions for 65% of industrial 3D printing users.

Regional analysis reveals particularly strong demand growth in Asia-Pacific markets, where rapid industrialization and increasing adoption of advanced manufacturing technologies drive investment in analytical instrumentation. North American and European markets show steady growth, primarily driven by research institutions and high-tech manufacturing sectors seeking to optimize material performance and processing parameters.

The demand for GPC in additive manufacturing polymer analysis stems from several key market needs. Manufacturers require precise molecular weight distribution data to ensure consistent print quality and mechanical properties. Research indicates that variations in molecular weight can significantly impact flow behavior during printing, resulting in defects and compromised structural integrity. A recent industry survey revealed that 78% of additive manufacturing companies consider polymer characterization essential for quality control processes.

Material development represents another significant market driver. As the industry moves toward more specialized applications, there is growing demand for custom-formulated polymers with specific properties. GPC enables researchers to correlate molecular characteristics with performance attributes, accelerating the development cycle. The market for specialized 3D printing materials is projected to grow at 23% annually, creating substantial opportunities for advanced characterization technologies.

Regulatory compliance further amplifies market demand for GPC analysis. Industries such as medical device manufacturing and aerospace require comprehensive material documentation, including detailed polymer characterization data. This trend is particularly evident in markets with stringent quality standards, where GPC serves as a critical tool for material validation and certification.

The shift toward sustainable materials in additive manufacturing has created additional market opportunities for polymer characterization. As manufacturers explore bio-based and recyclable polymers, GPC analysis becomes essential for understanding degradation mechanisms and ensuring consistent performance across recycling cycles. Market research indicates that sustainability considerations influence purchasing decisions for 65% of industrial 3D printing users.

Regional analysis reveals particularly strong demand growth in Asia-Pacific markets, where rapid industrialization and increasing adoption of advanced manufacturing technologies drive investment in analytical instrumentation. North American and European markets show steady growth, primarily driven by research institutions and high-tech manufacturing sectors seeking to optimize material performance and processing parameters.

Current GPC Capabilities and Limitations in AM

Gel permeation chromatography (GPC) currently serves as a fundamental analytical technique in additive manufacturing (AM) polymer characterization, offering valuable insights into molecular weight distribution and polymer structure. Modern GPC systems employed in AM research typically achieve resolution capabilities down to 1,000-2,000 g/mol, enabling differentiation between polymer chains of varying lengths. The technique excels at quantifying number-average molecular weight (Mn), weight-average molecular weight (Mw), and polydispersity index (PDI), critical parameters that directly influence mechanical properties and processing behavior of AM polymers.

Standard GPC configurations in AM laboratories commonly utilize refractive index (RI) detectors, which provide adequate sensitivity for most commercial polymers. Advanced setups incorporate multi-angle light scattering (MALS) or viscometry detectors, enhancing accuracy for complex polymer architectures frequently encountered in high-performance AM materials. Automated sampling systems have significantly improved throughput, allowing characterization of multiple formulations within reasonable timeframes.

Despite these capabilities, GPC faces several limitations when applied to AM polymer analysis. Sample preparation remains labor-intensive, requiring dissolution in appropriate solvents that may not fully solubilize crosslinked or partially cured resins common in stereolithography (SLA) or digital light processing (DLP) processes. This creates blind spots in understanding network formation during printing and post-processing stages.

Temperature-dependent analysis presents another challenge, as standard GPC typically operates at ambient conditions, whereas AM processes often subject polymers to extreme thermal cycles. This discrepancy limits direct correlation between GPC data and actual printing behavior. Additionally, GPC struggles with characterizing branched structures and copolymers with varying solubility characteristics, both increasingly common in advanced AM formulations designed for specific mechanical or thermal properties.

Calibration dependencies represent a significant limitation, as most GPC systems rely on polystyrene standards that may not accurately represent the hydrodynamic behavior of specialized AM polymers. This introduces systematic errors in molecular weight determination, particularly for novel materials with unique chain conformations or functional groups. The technique also provides limited information about chemical composition and functionality distribution, necessitating complementary analytical methods.

Time resolution constraints further limit GPC's utility in studying rapid polymerization kinetics during AM processes. The technique typically requires 30-60 minutes per analysis, making it unsuitable for real-time monitoring of molecular weight evolution during printing. This temporal disconnect complicates efforts to optimize process parameters based on polymer structure development.

Standard GPC configurations in AM laboratories commonly utilize refractive index (RI) detectors, which provide adequate sensitivity for most commercial polymers. Advanced setups incorporate multi-angle light scattering (MALS) or viscometry detectors, enhancing accuracy for complex polymer architectures frequently encountered in high-performance AM materials. Automated sampling systems have significantly improved throughput, allowing characterization of multiple formulations within reasonable timeframes.

Despite these capabilities, GPC faces several limitations when applied to AM polymer analysis. Sample preparation remains labor-intensive, requiring dissolution in appropriate solvents that may not fully solubilize crosslinked or partially cured resins common in stereolithography (SLA) or digital light processing (DLP) processes. This creates blind spots in understanding network formation during printing and post-processing stages.

Temperature-dependent analysis presents another challenge, as standard GPC typically operates at ambient conditions, whereas AM processes often subject polymers to extreme thermal cycles. This discrepancy limits direct correlation between GPC data and actual printing behavior. Additionally, GPC struggles with characterizing branched structures and copolymers with varying solubility characteristics, both increasingly common in advanced AM formulations designed for specific mechanical or thermal properties.

Calibration dependencies represent a significant limitation, as most GPC systems rely on polystyrene standards that may not accurately represent the hydrodynamic behavior of specialized AM polymers. This introduces systematic errors in molecular weight determination, particularly for novel materials with unique chain conformations or functional groups. The technique also provides limited information about chemical composition and functionality distribution, necessitating complementary analytical methods.

Time resolution constraints further limit GPC's utility in studying rapid polymerization kinetics during AM processes. The technique typically requires 30-60 minutes per analysis, making it unsuitable for real-time monitoring of molecular weight evolution during printing. This temporal disconnect complicates efforts to optimize process parameters based on polymer structure development.

Established GPC Protocols for AM Polymers

01 Principles and applications of gel permeation chromatography

Gel permeation chromatography (GPC) is a type of size exclusion chromatography that separates molecules based on their size. It is widely used for the analysis of polymers and macromolecules. The technique involves passing a solution through a column packed with porous beads, where larger molecules elute faster than smaller ones. This method allows for the determination of molecular weight distributions, polymer characterization, and quality control in various industries.- Principles and applications of gel permeation chromatography: Gel permeation chromatography (GPC) is a type of size exclusion chromatography that separates molecules based on their size. It is widely used for the analysis of polymers and macromolecules. The technique involves passing a solution through a column packed with porous beads, where larger molecules elute faster than smaller ones. This method allows for the determination of molecular weight distribution, average molecular weights, and polydispersity of polymers.

- Instrumentation and equipment for gel permeation chromatography: Various specialized equipment and instruments have been developed for gel permeation chromatography analysis. These include automated sample preparation systems, high-performance liquid chromatography systems modified for GPC, specialized columns with controlled pore sizes, detectors (such as refractive index, UV-vis, and light scattering detectors), and data analysis software. Innovations in instrumentation have improved the accuracy, reproducibility, and throughput of GPC analyses.

- Method improvements and optimization techniques: Researchers have developed various improvements to traditional gel permeation chromatography methods to enhance separation efficiency, resolution, and analysis speed. These include the use of different mobile phases, temperature control systems, gradient elution techniques, and multi-detector approaches. Optimization of flow rates, column selection, and sample preparation protocols have also been developed to address specific analytical challenges and improve the accuracy of molecular weight determinations.

- Specialized applications in polymer analysis: Gel permeation chromatography has been adapted for specialized applications in polymer science and industry. These include the characterization of synthetic polymers, biopolymers, copolymers, and polymer blends. The technique has been used to analyze polymerization kinetics, monitor polymer degradation, evaluate polymer modifications, and quality control in polymer production. Specific methods have been developed for challenging polymer systems such as water-soluble polymers, high-temperature polymers, and ultra-high molecular weight materials.

- Integration with other analytical techniques: Modern gel permeation chromatography systems are often integrated with other analytical techniques to provide comprehensive characterization of complex materials. These hyphenated techniques include GPC coupled with mass spectrometry, infrared spectroscopy, nuclear magnetic resonance, and multi-angle light scattering. Such combinations allow for simultaneous determination of molecular weight distribution and chemical composition or structure. Advanced data processing algorithms and computational methods have been developed to interpret the complex data generated by these integrated analytical systems.

02 Instrumentation and equipment for gel permeation chromatography

Specialized equipment and instrumentation are essential for gel permeation chromatography analysis. These systems typically include pumps, columns, detectors, and data processing software. Advanced GPC systems may incorporate multiple detectors such as refractive index, UV-visible, light scattering, and viscometric detectors for comprehensive polymer characterization. Innovations in instrumentation focus on improving resolution, sensitivity, automation, and throughput for more efficient analyses.Expand Specific Solutions03 Column materials and stationary phases

The choice of column materials and stationary phases is crucial for effective gel permeation chromatography separation. Various porous materials are used as stationary phases, including cross-linked polystyrene, agarose, silica, and specialized polymeric materials. These materials are designed with specific pore size distributions to effectively separate molecules within particular molecular weight ranges. Developments in column technology focus on improving separation efficiency, resolution, and compatibility with different solvents and sample types.Expand Specific Solutions04 Method development and optimization techniques

Developing and optimizing gel permeation chromatography methods involves selecting appropriate mobile phases, flow rates, column temperatures, and detection parameters. Method optimization aims to achieve better resolution, accuracy, and reproducibility in molecular weight determination. Advanced techniques include multi-detector calibration, universal calibration approaches, and the use of computational algorithms for data analysis. These optimization strategies are essential for addressing complex sample matrices and achieving reliable characterization results.Expand Specific Solutions05 Specialized applications in polymer and biomolecule analysis

Gel permeation chromatography has specialized applications in the analysis of synthetic polymers, biopolymers, and complex macromolecular systems. It is used for characterizing polymer blends, copolymers, protein aggregates, and other complex molecular systems. In pharmaceutical and biomedical fields, GPC is employed for analyzing drug delivery systems, protein formulations, and biomaterials. Industrial applications include quality control in polymer manufacturing, monitoring polymerization reactions, and analyzing recycled materials.Expand Specific Solutions

Leading Companies in GPC and AM Polymer Analysis

Gel permeation chromatography (GPC) in additive manufacturing polymer analysis is currently in a growth phase, with the market expanding as additive manufacturing adoption increases globally. The technology has reached moderate maturity, with established players like Waters Technology Corp. and Agilent Technologies offering sophisticated analytical solutions. Leading chemical companies including Dow Global Technologies, Merck Patent GmbH, and ExxonMobil Chemical Patents are actively developing specialized polymer formulations requiring precise characterization. The competitive landscape features both analytical instrument manufacturers and chemical companies investing in R&D to address challenges in polymer quality control and material development. 3M Innovative Properties and Evonik Operations are focusing on proprietary polymer systems, while academic institutions like Rutgers University contribute fundamental research advancing the field's technical capabilities.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed proprietary GPC methodologies specifically for analyzing their extensive portfolio of polymers used in additive manufacturing. Their approach integrates GPC with infrared spectroscopy and thermal analysis to create a comprehensive characterization platform for AM materials. Dow's system employs specialized high-temperature GPC capabilities essential for analyzing engineering polymers like polyamides and polycarbonates commonly used in industrial 3D printing. Their methodology includes proprietary column technologies optimized for separating complex polymer blends and detecting subtle changes in molecular architecture that impact printing performance. Dow has pioneered correlation models between GPC-derived molecular weight distributions and key AM processing parameters, enabling prediction of warpage, layer adhesion strength, and dimensional accuracy in printed parts. Their research has established critical molecular weight thresholds for different AM technologies (FDM, SLS, SLA), providing valuable design guidelines for new AM materials.

Strengths: Extensive polymer chemistry expertise applied to AM materials analysis; integrated multi-analytical approach provides comprehensive characterization; established correlations between molecular properties and printing performance. Weaknesses: Systems primarily optimized for Dow's own polymer portfolio; less accessible to broader industry; requires significant expertise in polymer science for effective utilization.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed specialized GPC methodologies for analyzing polyolefin-based materials used in additive manufacturing. Their approach focuses on characterizing the complex branching structures and molecular weight distributions that significantly impact the processing and performance of polyolefin materials in AM applications. ExxonMobil's GPC systems incorporate multi-angle light scattering (MALS) and viscometry detection alongside traditional refractive index detection to provide detailed information about molecular architecture. Their proprietary column technologies are specifically optimized for separating complex polyolefin structures across a wide molecular weight range (10³ to 10⁷ g/mol). ExxonMobil has pioneered the use of high-temperature GPC for analyzing semi-crystalline polyolefins, with systems capable of operating at temperatures up to 160°C to ensure complete polymer dissolution. Their research has established critical relationships between molecular weight distribution, branching frequency, and key AM processing parameters including melt flow behavior, crystallization kinetics, and interlayer adhesion strength.

Strengths: Unparalleled expertise in polyolefin characterization; specialized high-temperature capabilities essential for semi-crystalline polymer analysis; established correlations between molecular architecture and AM processing behavior. Weaknesses: Primarily focused on polyolefin materials with less emphasis on other polymer classes; requires specialized high-temperature equipment; complex methodology requiring significant expertise in polyolefin chemistry.

Key Technical Innovations in GPC for Complex Polymers

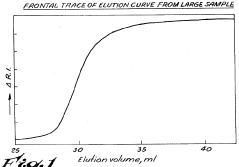

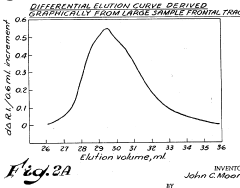

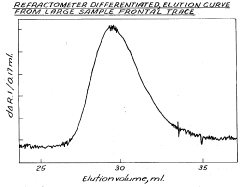

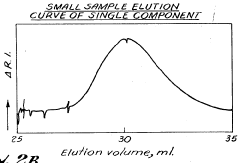

Method for analysis of large polymer molecules

PatentInactiveUS3649200A

Innovation

- The method involves introducing a large dilute polymer solution into a GPC column filled with the same solvent, allowing the solution to displace the solvent, creating a transition zone where polymer concentration rises, thereby eliminating 'viscous fingering' and accounting for 'viscous delay' through mathematical corrections, enabling more accurate molecular size distribution analysis.

New polymer and its preparation method

PatentWO2023247784A1

Innovation

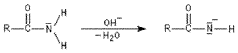

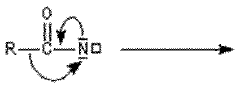

- A polyvinylamine polymer is synthesized through a method involving a base polymer with cationic and non-ionic monomers, structuring systems, and a specific Hofmann degradation process, which increases molecular weight without affecting viscosity, enhancing dry strength and drainage properties.

Quality Control Standards for AM Polymers

Quality control standards for additive manufacturing (AM) polymers have evolved significantly with the integration of gel permeation chromatography (GPC) as a critical analytical technique. These standards establish comprehensive frameworks for ensuring consistent polymer quality throughout the AM process chain, from raw material characterization to final part validation.

The International Organization for Standardization (ISO) and ASTM International have developed key standards specifically addressing polymer characterization in AM, including ISO/ASTM 52900 and ASTM F2921, which incorporate molecular weight distribution analysis via GPC as a fundamental quality parameter. These standards recognize that molecular weight variations directly impact mechanical properties, processability, and long-term performance of printed parts.

Quality control protocols typically mandate GPC analysis at multiple stages: incoming raw material inspection, in-process monitoring during printing, and final part validation. For incoming materials, standards specify acceptable molecular weight ranges (Mn, Mw) and polydispersity indices (PDI) for different AM technologies. For example, selective laser sintering (SLS) polymers generally require narrower molecular weight distributions (PDI < 2.5) compared to fused filament fabrication (FFF) materials.

Standards also address GPC methodology standardization, prescribing specific solvent systems, column configurations, and calibration procedures to ensure reproducible results across different laboratories. For instance, tetrahydrofuran (THF) with polystyrene standards is commonly specified for analyzing ABS and PLA, while hexafluoroisopropanol (HFIP) is mandated for polyamides and some engineering thermoplastics.

Recycling considerations feature prominently in modern AM polymer standards, with GPC-based metrics defining acceptable degradation thresholds. Many standards now specify maximum allowable decreases in weight-average molecular weight (typically 5-15% depending on polymer class) and increases in polydispersity before recycled powder must be refreshed with virgin material.

Traceability requirements constitute another critical component, mandating documentation of GPC results throughout the material lifecycle. This includes retention of chromatograms, calibration data, and molecular weight calculations to support quality audits and failure investigations.

Advanced standards are beginning to incorporate correlations between GPC data and mechanical properties, establishing predictive models that link molecular characteristics to performance metrics. These models enable manufacturers to predict part performance based on molecular weight profiles, potentially reducing physical testing requirements.

As AM applications expand into regulated industries like aerospace and medical devices, GPC-based quality standards continue to evolve, with increasing emphasis on statistical process control methodologies and uncertainty quantification in molecular weight determinations.

The International Organization for Standardization (ISO) and ASTM International have developed key standards specifically addressing polymer characterization in AM, including ISO/ASTM 52900 and ASTM F2921, which incorporate molecular weight distribution analysis via GPC as a fundamental quality parameter. These standards recognize that molecular weight variations directly impact mechanical properties, processability, and long-term performance of printed parts.

Quality control protocols typically mandate GPC analysis at multiple stages: incoming raw material inspection, in-process monitoring during printing, and final part validation. For incoming materials, standards specify acceptable molecular weight ranges (Mn, Mw) and polydispersity indices (PDI) for different AM technologies. For example, selective laser sintering (SLS) polymers generally require narrower molecular weight distributions (PDI < 2.5) compared to fused filament fabrication (FFF) materials.

Standards also address GPC methodology standardization, prescribing specific solvent systems, column configurations, and calibration procedures to ensure reproducible results across different laboratories. For instance, tetrahydrofuran (THF) with polystyrene standards is commonly specified for analyzing ABS and PLA, while hexafluoroisopropanol (HFIP) is mandated for polyamides and some engineering thermoplastics.

Recycling considerations feature prominently in modern AM polymer standards, with GPC-based metrics defining acceptable degradation thresholds. Many standards now specify maximum allowable decreases in weight-average molecular weight (typically 5-15% depending on polymer class) and increases in polydispersity before recycled powder must be refreshed with virgin material.

Traceability requirements constitute another critical component, mandating documentation of GPC results throughout the material lifecycle. This includes retention of chromatograms, calibration data, and molecular weight calculations to support quality audits and failure investigations.

Advanced standards are beginning to incorporate correlations between GPC data and mechanical properties, establishing predictive models that link molecular characteristics to performance metrics. These models enable manufacturers to predict part performance based on molecular weight profiles, potentially reducing physical testing requirements.

As AM applications expand into regulated industries like aerospace and medical devices, GPC-based quality standards continue to evolve, with increasing emphasis on statistical process control methodologies and uncertainty quantification in molecular weight determinations.

Material Sustainability and Recyclability Assessment

The sustainability and recyclability of polymers used in additive manufacturing (AM) represent critical considerations in the context of circular economy principles. Gel Permeation Chromatography (GPC) offers valuable insights into polymer degradation during recycling processes, enabling quantitative assessment of molecular weight changes and distribution shifts that directly impact material performance in subsequent manufacturing cycles.

GPC analysis reveals that most thermoplastics used in AM experience chain scission during recycling, resulting in decreased molecular weight and narrower polydispersity. For instance, studies on recycled PLA show approximately 15-20% reduction in weight-average molecular weight after each processing cycle, correlating directly with diminished mechanical properties. This degradation pathway can be precisely tracked through GPC measurements, allowing for predictive models of material lifespan.

The recyclability assessment of AM polymers through GPC enables the development of standardized protocols for determining maximum recycling iterations before material properties fall below acceptable thresholds. Current research indicates that most AM-grade polymers maintain adequate performance for 3-5 recycling cycles when properly characterized and managed, with GPC serving as the primary analytical tool for quality assurance.

Material sustainability metrics derived from GPC data include degradation rate coefficients, chain scission indices, and molecular weight retention percentages. These parameters, when integrated into lifecycle assessment models, provide quantitative measures of polymer circularity potential. Polymers exhibiting higher molecular stability during reprocessing, as evidenced by minimal changes in GPC elution profiles, demonstrate superior sustainability credentials.

The integration of GPC analysis into recycling workflows enables the strategic blending of virgin and recycled materials based on precise molecular characteristics rather than arbitrary ratios. This approach has demonstrated up to 40% improvement in resource efficiency while maintaining performance specifications. Furthermore, GPC data supports the development of stabilizing additives specifically designed to counteract degradation mechanisms identified through molecular weight analysis.

Recent innovations in high-temperature GPC techniques have expanded analysis capabilities to engineering polymers like PEEK and PEI used in high-performance AM applications, addressing previous limitations in recyclability assessment for these materials. This advancement enables comprehensive sustainability evaluation across the full spectrum of AM polymers, from commodity thermoplastics to specialized engineering resins.

The correlation between GPC-measured molecular characteristics and mechanical performance of recycled AM parts provides essential data for predictive quality models, supporting informed decision-making regarding material reuse strategies and end-of-life management options.

GPC analysis reveals that most thermoplastics used in AM experience chain scission during recycling, resulting in decreased molecular weight and narrower polydispersity. For instance, studies on recycled PLA show approximately 15-20% reduction in weight-average molecular weight after each processing cycle, correlating directly with diminished mechanical properties. This degradation pathway can be precisely tracked through GPC measurements, allowing for predictive models of material lifespan.

The recyclability assessment of AM polymers through GPC enables the development of standardized protocols for determining maximum recycling iterations before material properties fall below acceptable thresholds. Current research indicates that most AM-grade polymers maintain adequate performance for 3-5 recycling cycles when properly characterized and managed, with GPC serving as the primary analytical tool for quality assurance.

Material sustainability metrics derived from GPC data include degradation rate coefficients, chain scission indices, and molecular weight retention percentages. These parameters, when integrated into lifecycle assessment models, provide quantitative measures of polymer circularity potential. Polymers exhibiting higher molecular stability during reprocessing, as evidenced by minimal changes in GPC elution profiles, demonstrate superior sustainability credentials.

The integration of GPC analysis into recycling workflows enables the strategic blending of virgin and recycled materials based on precise molecular characteristics rather than arbitrary ratios. This approach has demonstrated up to 40% improvement in resource efficiency while maintaining performance specifications. Furthermore, GPC data supports the development of stabilizing additives specifically designed to counteract degradation mechanisms identified through molecular weight analysis.

Recent innovations in high-temperature GPC techniques have expanded analysis capabilities to engineering polymers like PEEK and PEI used in high-performance AM applications, addressing previous limitations in recyclability assessment for these materials. This advancement enables comprehensive sustainability evaluation across the full spectrum of AM polymers, from commodity thermoplastics to specialized engineering resins.

The correlation between GPC-measured molecular characteristics and mechanical performance of recycled AM parts provides essential data for predictive quality models, supporting informed decision-making regarding material reuse strategies and end-of-life management options.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!