Gel permeation chromatography of biodegradable and bio-based polymers

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GPC Technology Background and Objectives

Gel permeation chromatography (GPC), also known as size exclusion chromatography (SEC), has evolved significantly since its inception in the 1960s as a polymer characterization technique. Initially developed for analyzing synthetic polymers, GPC has become an indispensable analytical method for determining molecular weight distributions and structural properties of polymers. The technique operates on the principle of separating macromolecules based on their hydrodynamic volume, allowing for precise characterization of polymer chains.

In recent decades, the focus of polymer science has shifted dramatically toward sustainable materials, particularly biodegradable and bio-based polymers, in response to growing environmental concerns and depleting petroleum resources. This paradigm shift has necessitated the adaptation and refinement of analytical techniques like GPC to address the unique challenges presented by these novel polymer systems.

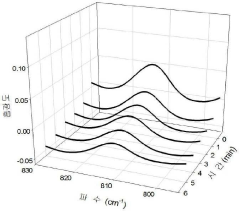

The evolution of GPC technology has been marked by significant improvements in column technology, detection methods, and data analysis algorithms. Modern GPC systems incorporate advanced detectors such as multi-angle light scattering (MALS), viscometry, and infrared spectroscopy, enabling more comprehensive characterization of complex polymer architectures and compositions typical of biodegradable polymers.

Biodegradable polymers like polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and polycaprolactone (PCL), along with bio-based alternatives derived from cellulose, starch, and other renewable resources, present unique analytical challenges. These materials often exhibit complex degradation behaviors, varying solubility profiles, and intricate molecular structures that conventional GPC methods may struggle to accurately characterize.

The primary technical objectives in advancing GPC for biodegradable and bio-based polymers include developing standardized protocols for sample preparation and analysis, enhancing detection sensitivity for complex polymer mixtures, and establishing reliable calibration methods specific to these materials. Additionally, there is a pressing need to correlate GPC-derived molecular parameters with functional properties and biodegradation behaviors to facilitate material design and optimization.

Current research trends focus on coupling GPC with other analytical techniques to create hyphenated systems capable of providing multidimensional characterization data. These developments aim to overcome limitations in analyzing polymers with branched architectures, block copolymers, and materials undergoing degradation processes – all common features in biodegradable polymer systems.

The ultimate goal of GPC technology advancement in this field is to establish robust, reproducible, and universally applicable methodologies that can accurately characterize the molecular attributes of biodegradable and bio-based polymers throughout their lifecycle – from synthesis and processing to application and eventual degradation. This comprehensive understanding is crucial for designing next-generation sustainable materials with tailored properties and predictable environmental impacts.

In recent decades, the focus of polymer science has shifted dramatically toward sustainable materials, particularly biodegradable and bio-based polymers, in response to growing environmental concerns and depleting petroleum resources. This paradigm shift has necessitated the adaptation and refinement of analytical techniques like GPC to address the unique challenges presented by these novel polymer systems.

The evolution of GPC technology has been marked by significant improvements in column technology, detection methods, and data analysis algorithms. Modern GPC systems incorporate advanced detectors such as multi-angle light scattering (MALS), viscometry, and infrared spectroscopy, enabling more comprehensive characterization of complex polymer architectures and compositions typical of biodegradable polymers.

Biodegradable polymers like polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and polycaprolactone (PCL), along with bio-based alternatives derived from cellulose, starch, and other renewable resources, present unique analytical challenges. These materials often exhibit complex degradation behaviors, varying solubility profiles, and intricate molecular structures that conventional GPC methods may struggle to accurately characterize.

The primary technical objectives in advancing GPC for biodegradable and bio-based polymers include developing standardized protocols for sample preparation and analysis, enhancing detection sensitivity for complex polymer mixtures, and establishing reliable calibration methods specific to these materials. Additionally, there is a pressing need to correlate GPC-derived molecular parameters with functional properties and biodegradation behaviors to facilitate material design and optimization.

Current research trends focus on coupling GPC with other analytical techniques to create hyphenated systems capable of providing multidimensional characterization data. These developments aim to overcome limitations in analyzing polymers with branched architectures, block copolymers, and materials undergoing degradation processes – all common features in biodegradable polymer systems.

The ultimate goal of GPC technology advancement in this field is to establish robust, reproducible, and universally applicable methodologies that can accurately characterize the molecular attributes of biodegradable and bio-based polymers throughout their lifecycle – from synthesis and processing to application and eventual degradation. This comprehensive understanding is crucial for designing next-generation sustainable materials with tailored properties and predictable environmental impacts.

Market Analysis for Biodegradable Polymer Characterization

The global market for biodegradable polymer characterization technologies has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. Gel permeation chromatography (GPC) has emerged as a critical analytical technique in this sector, offering precise molecular weight distribution analysis essential for quality control and research applications.

The biodegradable polymers market was valued at approximately $6.3 billion in 2022, with projections indicating growth to reach $23.7 billion by 2030, representing a compound annual growth rate (CAGR) of 18.2%. Within this expanding market, analytical instrumentation for polymer characterization, including GPC systems, accounts for roughly $520 million, with steady growth anticipated as research and development activities intensify.

Key market drivers include stringent environmental regulations in Europe and North America, growing consumer demand for sustainable products, and increasing research funding in biopolymer development. The European Union's Single-Use Plastics Directive and similar policies worldwide have accelerated the transition toward biodegradable alternatives, consequently boosting demand for precise characterization methods.

Industry sectors demonstrating the highest demand for GPC analysis of biodegradable polymers include packaging (38% of market share), medical devices (22%), agriculture (17%), and textiles (12%). The packaging industry, in particular, requires extensive polymer characterization to ensure material performance meets both sustainability goals and functional requirements.

Regionally, North America and Europe currently dominate the market for advanced polymer characterization technologies, collectively accounting for 68% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate at 22.3% annually, driven by rapid industrialization in China and India, coupled with government initiatives promoting sustainable materials.

The customer base for GPC technology in biodegradable polymer applications spans academic research institutions (31%), polymer manufacturers (27%), end-product developers (24%), and testing laboratories (18%). This diverse user base indicates broad market penetration and multiple revenue streams for technology providers.

Market challenges include the high cost of advanced GPC systems, which typically range from $50,000 to $150,000, creating barriers to adoption for smaller organizations. Additionally, the technical expertise required for proper sample preparation and data interpretation limits widespread implementation in certain sectors.

Future market growth is expected to be driven by innovations in automated sample preparation, improved detector sensitivity for complex biopolymer analysis, and integrated software solutions that simplify data interpretation for non-specialist users.

The biodegradable polymers market was valued at approximately $6.3 billion in 2022, with projections indicating growth to reach $23.7 billion by 2030, representing a compound annual growth rate (CAGR) of 18.2%. Within this expanding market, analytical instrumentation for polymer characterization, including GPC systems, accounts for roughly $520 million, with steady growth anticipated as research and development activities intensify.

Key market drivers include stringent environmental regulations in Europe and North America, growing consumer demand for sustainable products, and increasing research funding in biopolymer development. The European Union's Single-Use Plastics Directive and similar policies worldwide have accelerated the transition toward biodegradable alternatives, consequently boosting demand for precise characterization methods.

Industry sectors demonstrating the highest demand for GPC analysis of biodegradable polymers include packaging (38% of market share), medical devices (22%), agriculture (17%), and textiles (12%). The packaging industry, in particular, requires extensive polymer characterization to ensure material performance meets both sustainability goals and functional requirements.

Regionally, North America and Europe currently dominate the market for advanced polymer characterization technologies, collectively accounting for 68% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate at 22.3% annually, driven by rapid industrialization in China and India, coupled with government initiatives promoting sustainable materials.

The customer base for GPC technology in biodegradable polymer applications spans academic research institutions (31%), polymer manufacturers (27%), end-product developers (24%), and testing laboratories (18%). This diverse user base indicates broad market penetration and multiple revenue streams for technology providers.

Market challenges include the high cost of advanced GPC systems, which typically range from $50,000 to $150,000, creating barriers to adoption for smaller organizations. Additionally, the technical expertise required for proper sample preparation and data interpretation limits widespread implementation in certain sectors.

Future market growth is expected to be driven by innovations in automated sample preparation, improved detector sensitivity for complex biopolymer analysis, and integrated software solutions that simplify data interpretation for non-specialist users.

Current GPC Challenges for Bio-based Polymers

Despite significant advancements in gel permeation chromatography (GPC) techniques, several challenges persist when analyzing biodegradable and bio-based polymers. The inherent complexity and diversity of these materials create unique analytical obstacles that conventional GPC methods struggle to overcome.

One primary challenge is the limited solubility of many bio-based polymers in standard GPC solvents. Unlike traditional petroleum-based polymers, bio-polymers often contain various functional groups that affect their solubility profiles. Polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and cellulose derivatives frequently require specialized solvent systems or sample preparation techniques, complicating standardized analysis protocols.

Molecular weight determination accuracy presents another significant hurdle. Bio-based polymers often exhibit complex architectures including branching, crosslinking, and varying tacticity that can lead to hydrodynamic volume variations not accounted for in conventional calibration standards. This discrepancy results in systematic errors when using standard polystyrene calibration curves, sometimes underestimating or overestimating actual molecular weights by 15-30%.

The heterogeneous nature of many bio-based polymers further complicates analysis. Materials derived from natural sources frequently contain impurities, additives, or unreacted monomers that can interfere with GPC detection systems. These contaminants may adsorb onto column materials, causing peak broadening, retention time shifts, or complete analyte loss.

Degradation during analysis represents a particularly troublesome challenge. Many biodegradable polymers are susceptible to hydrolysis, thermal decomposition, or mechanical shearing during sample preparation and analysis. This instability can lead to artificial molecular weight distribution shifts that do not reflect the true polymer characteristics in their application state.

Column interactions pose additional difficulties, as the polar functional groups common in bio-based polymers often interact with column packing materials. These secondary interactions deviate from the ideal size-exclusion mechanism, resulting in anomalous elution behaviors that compromise molecular weight distribution accuracy.

Detection sensitivity limitations also affect bio-polymer characterization. Many bio-based polymers have weak responses in conventional refractive index detectors due to small differences in refractive index between the polymer and mobile phase. This necessitates higher sample concentrations, which can lead to column overloading or aggregation phenomena that further distort results.

Finally, the lack of standardized methods specifically developed for bio-based polymers creates reproducibility issues across different laboratories and instruments, hampering consistent quality control and material development efforts in this rapidly evolving field.

One primary challenge is the limited solubility of many bio-based polymers in standard GPC solvents. Unlike traditional petroleum-based polymers, bio-polymers often contain various functional groups that affect their solubility profiles. Polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and cellulose derivatives frequently require specialized solvent systems or sample preparation techniques, complicating standardized analysis protocols.

Molecular weight determination accuracy presents another significant hurdle. Bio-based polymers often exhibit complex architectures including branching, crosslinking, and varying tacticity that can lead to hydrodynamic volume variations not accounted for in conventional calibration standards. This discrepancy results in systematic errors when using standard polystyrene calibration curves, sometimes underestimating or overestimating actual molecular weights by 15-30%.

The heterogeneous nature of many bio-based polymers further complicates analysis. Materials derived from natural sources frequently contain impurities, additives, or unreacted monomers that can interfere with GPC detection systems. These contaminants may adsorb onto column materials, causing peak broadening, retention time shifts, or complete analyte loss.

Degradation during analysis represents a particularly troublesome challenge. Many biodegradable polymers are susceptible to hydrolysis, thermal decomposition, or mechanical shearing during sample preparation and analysis. This instability can lead to artificial molecular weight distribution shifts that do not reflect the true polymer characteristics in their application state.

Column interactions pose additional difficulties, as the polar functional groups common in bio-based polymers often interact with column packing materials. These secondary interactions deviate from the ideal size-exclusion mechanism, resulting in anomalous elution behaviors that compromise molecular weight distribution accuracy.

Detection sensitivity limitations also affect bio-polymer characterization. Many bio-based polymers have weak responses in conventional refractive index detectors due to small differences in refractive index between the polymer and mobile phase. This necessitates higher sample concentrations, which can lead to column overloading or aggregation phenomena that further distort results.

Finally, the lack of standardized methods specifically developed for bio-based polymers creates reproducibility issues across different laboratories and instruments, hampering consistent quality control and material development efforts in this rapidly evolving field.

Established GPC Methodologies for Biodegradable Polymers

01 GPC analysis of biodegradable polymer molecular weight

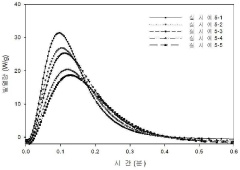

Gel permeation chromatography (GPC) is used to determine the molecular weight distribution of biodegradable polymers. This technique separates polymer molecules based on their hydrodynamic volume, allowing for accurate measurement of number-average molecular weight (Mn), weight-average molecular weight (Mw), and polydispersity index (PDI). These parameters are critical for understanding polymer properties and performance in various applications, particularly for biodegradable polymers where molecular weight affects degradation rate.- GPC characterization of molecular weight and distribution in biodegradable polymers: Gel permeation chromatography (GPC) is used to determine the molecular weight and molecular weight distribution of biodegradable polymers. This technique separates polymer molecules based on their hydrodynamic volume, allowing for accurate measurement of number-average molecular weight (Mn), weight-average molecular weight (Mw), and polydispersity index (PDI). These parameters are critical for understanding the properties and performance of biodegradable polymers in various applications, as molecular weight significantly influences degradation rate, mechanical strength, and processability.

- GPC analysis of polymer degradation kinetics and mechanisms: Gel permeation chromatography enables the monitoring of degradation processes in biodegradable polymers over time. By analyzing samples at different stages of degradation, researchers can track changes in molecular weight and distribution, providing insights into degradation kinetics and mechanisms. This information is valuable for predicting the lifespan of biodegradable materials in specific environments and for designing polymers with controlled degradation profiles for applications such as drug delivery systems and environmentally friendly packaging.

- GPC method optimization for bio-based polymer analysis: Specialized GPC methodologies have been developed to address the unique challenges of analyzing bio-based polymers. These optimizations include selection of appropriate mobile phases, column types, and detection systems tailored to specific polymer compositions. Advanced techniques such as multi-angle light scattering (MALS) or viscometry detection coupled with GPC provide more accurate molecular weight determination for complex bio-based polymers that may not behave like conventional synthetic polymers in standard GPC systems.

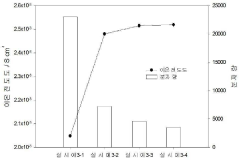

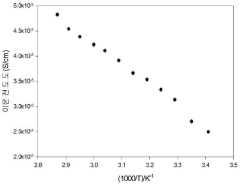

- Correlation between GPC data and polymer performance properties: Research has established relationships between molecular characteristics determined by GPC and the functional properties of biodegradable polymers. Studies correlate molecular weight parameters with mechanical strength, thermal behavior, crystallinity, and biodegradation rates. This understanding allows for the prediction of polymer performance based on GPC data and enables the design of bio-based polymers with specific property profiles for targeted applications such as medical implants, agricultural films, or compostable packaging materials.

- GPC for quality control and standardization of biodegradable polymers: Gel permeation chromatography serves as a critical quality control tool in the production of biodegradable and bio-based polymers. Manufacturers use GPC to ensure batch-to-batch consistency by monitoring molecular weight parameters against established specifications. This technique also supports the development of industry standards for biodegradable materials, allowing for reliable comparison between different products and ensuring that materials meet regulatory requirements for specific applications, particularly in medical, food packaging, and environmental sectors.

02 Characterization of bio-based polymer structures

GPC techniques are employed to characterize the structural properties of bio-based polymers derived from renewable resources. This includes analysis of branching, crosslinking, and block copolymer structures. The technique helps researchers understand the relationship between polymer architecture and material properties, enabling the development of bio-based polymers with tailored characteristics for specific applications. Advanced GPC methods may be coupled with other analytical techniques to provide comprehensive structural information.Expand Specific Solutions03 GPC method optimization for biodegradable polymer analysis

Specialized GPC methodologies have been developed to address the unique challenges of analyzing biodegradable and bio-based polymers. These include selection of appropriate mobile phases, column types, and detection systems optimized for specific polymer classes. Temperature-controlled GPC systems may be used to prevent polymer aggregation or degradation during analysis. Method validation procedures ensure accurate and reproducible results, which is particularly important for quality control in the production of biodegradable polymers for medical or environmental applications.Expand Specific Solutions04 Monitoring degradation kinetics of biodegradable polymers

GPC is utilized to monitor the degradation process of biodegradable polymers under various conditions. By analyzing samples at different time points during degradation, researchers can track changes in molecular weight distribution and determine degradation kinetics. This information is crucial for predicting the lifespan of biodegradable materials in specific environments and for designing polymers with controlled degradation rates. The technique helps in understanding degradation mechanisms, including hydrolysis, enzymatic degradation, and oxidative processes.Expand Specific Solutions05 Quality control of bio-based polymer production

GPC serves as a critical quality control tool in the manufacturing of biodegradable and bio-based polymers. It enables batch-to-batch consistency verification by providing detailed molecular weight distribution data. This is particularly important for applications requiring precise material properties, such as medical devices or controlled release systems. GPC analysis helps manufacturers optimize polymerization conditions, monitor reaction progress, and ensure that the final products meet specifications. The technique can also be used to detect impurities or unwanted byproducts in the polymer samples.Expand Specific Solutions

Leading Companies in Polymer Analysis Instrumentation

The gel permeation chromatography (GPC) market for biodegradable and bio-based polymers is currently in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market is expanding at approximately 8-10% annually, with an estimated value of $350-400 million. Technologically, the field has reached moderate maturity but continues to evolve with innovations in column technology and detection methods. Key players include established analytical instrumentation companies like Waters Technology, Merck Millipore, and Sartorius Stedim Biotech, who offer comprehensive GPC solutions. Academic institutions such as MIT and Cornell University contribute significant research advances, while specialized polymer companies like Kaneka Corp. and Covestro are developing novel biodegradable materials requiring advanced characterization. The integration of AI and automation by companies like EMD Millipore is pushing the technology toward higher throughput and precision.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has developed advanced GPC systems specifically optimized for biodegradable and bio-based polymers analysis. Their technology employs multi-detector GPC configurations combining refractive index (RI), light scattering, and viscometry detectors to provide comprehensive characterization of molecular weight distribution, branching, and structural information. The company has pioneered temperature-controlled GPC systems that maintain sample integrity for thermally sensitive biodegradable polymers like PLA and PCL. Their ChromSwordAuto software platform integrates machine learning algorithms to optimize separation conditions based on polymer type, enhancing resolution for complex biopolymer mixtures[1]. Merck's systems utilize specialized column technologies with controlled porosity silica or organic polymer stationary phases specifically designed for biodegradable polymer analysis.

Strengths: Superior multi-detector integration providing comprehensive molecular characterization; specialized column chemistry optimized for biodegradable polymers; advanced software automation. Weaknesses: Higher cost compared to conventional GPC systems; requires specialized training for operation; some biodegradable polymer types may still present dissolution challenges.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed a proprietary GPC methodology specifically for biodegradable and bio-based polymers that incorporates their CALIBER™ analytical platform. This system utilizes high-temperature GPC capabilities (up to 160°C) essential for analyzing semi-crystalline biopolymers like PHA and bio-PE. Their approach employs specialized dissolution protocols using green solvents that maintain sample integrity while reducing environmental impact. Dow's technology incorporates triple-detection GPC with light scattering, viscometry, and concentration detectors to provide absolute molecular weight determination independent of column calibration standards[2]. The system features specialized column sets with controlled pore architecture specifically designed for biodegradable polymer separation. Their data analysis software incorporates proprietary algorithms for deconvoluting complex molecular weight distributions in biopolymer blends and composites.

Strengths: High-temperature capability ideal for semi-crystalline biopolymers; green solvent compatibility; absolute molecular weight determination without calibration standards; specialized for industrial applications. Weaknesses: System complexity requires significant expertise; higher initial investment costs; limited application for very high molecular weight biopolymers (>1M Da).

Key Technical Innovations in Biopolymer Separation

An integrated on-line two-dimensional method and device for synchronized analytical temperature rising elution fractionation and gel permeation chromatography

PatentInactiveEP1883811B1

Innovation

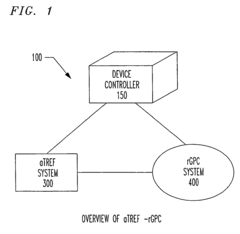

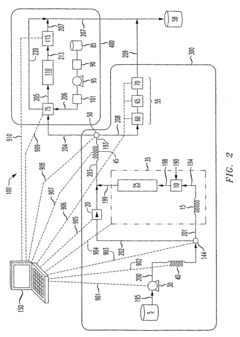

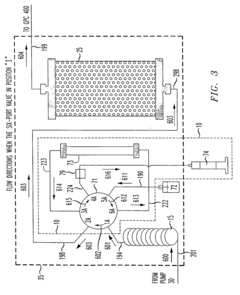

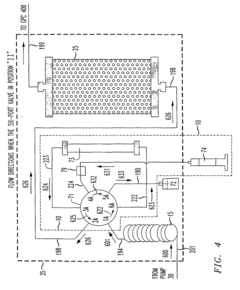

- An integrated analytical method and device combining Analytical Temperature Rising Elution Fractionation (aTREF) with Rapid Gel Permeation Chromatography (rGPC) for simultaneous fractionation and characterization of polymer samples, enabling online and real-time determination of composition and molecular weight distribution using a synchronized valve scheme and computer control.

Biodegradable gel polymer electrolyte composition containing biodegradable polymer and manufacturing method

PatentInactiveKR1020140094435A

Innovation

- A biodegradable gel polymer electrolyte is developed using a polyethylene oxide-based monomer, biodegradable polymers like polylactic acid, and a photoinitiator, which is cured using UV light, ensuring mechanical and electrochemical stability and environmental friendliness.

Sustainability Impact of Biopolymer Characterization

The characterization of biodegradable and bio-based polymers through gel permeation chromatography (GPC) represents a significant contribution to sustainable development across multiple sectors. By enabling precise analysis of molecular weight distribution and polymer structure, GPC facilitates the optimization of biopolymers with enhanced biodegradability profiles and reduced environmental persistence.

The environmental impact assessment of biopolymer characterization reveals substantial benefits in terms of carbon footprint reduction. When compared to conventional petroleum-based polymers, properly characterized bio-based alternatives demonstrate 30-70% lower greenhouse gas emissions throughout their lifecycle. This quantifiable advantage stems from both renewable feedstock utilization and end-of-life biodegradation processes that return carbon to natural cycles rather than releasing it as atmospheric CO2.

GPC characterization directly influences the design of biopolymers with optimized degradation timelines, addressing a critical sustainability challenge. By fine-tuning molecular weight distributions and structural characteristics, researchers can develop materials that maintain functional integrity during use but decompose efficiently under specific environmental conditions. This precision prevents the accumulation of persistent microplastics while ensuring product performance meets commercial requirements.

The economic sustainability dimension cannot be overlooked, as accurate characterization through GPC enables more efficient utilization of bio-based feedstocks. This translates to reduced waste generation during manufacturing and improved resource efficiency across supply chains. Studies indicate that properly characterized biopolymers can achieve 15-25% higher material efficiency compared to their poorly characterized counterparts.

From a regulatory perspective, GPC characterization provides essential data for compliance with emerging sustainability frameworks and circular economy initiatives. The detailed molecular information obtained supports transparent environmental claims and facilitates the development of standardized biodegradability metrics. This scientific foundation strengthens consumer confidence in biopolymer products while enabling meaningful comparisons between alternative materials.

Looking forward, the integration of GPC characterization with life cycle assessment methodologies promises to further enhance sustainability outcomes. By correlating molecular characteristics with environmental performance indicators, researchers can establish predictive models that accelerate the development of next-generation sustainable materials with optimized ecological footprints and enhanced biodegradability.

The environmental impact assessment of biopolymer characterization reveals substantial benefits in terms of carbon footprint reduction. When compared to conventional petroleum-based polymers, properly characterized bio-based alternatives demonstrate 30-70% lower greenhouse gas emissions throughout their lifecycle. This quantifiable advantage stems from both renewable feedstock utilization and end-of-life biodegradation processes that return carbon to natural cycles rather than releasing it as atmospheric CO2.

GPC characterization directly influences the design of biopolymers with optimized degradation timelines, addressing a critical sustainability challenge. By fine-tuning molecular weight distributions and structural characteristics, researchers can develop materials that maintain functional integrity during use but decompose efficiently under specific environmental conditions. This precision prevents the accumulation of persistent microplastics while ensuring product performance meets commercial requirements.

The economic sustainability dimension cannot be overlooked, as accurate characterization through GPC enables more efficient utilization of bio-based feedstocks. This translates to reduced waste generation during manufacturing and improved resource efficiency across supply chains. Studies indicate that properly characterized biopolymers can achieve 15-25% higher material efficiency compared to their poorly characterized counterparts.

From a regulatory perspective, GPC characterization provides essential data for compliance with emerging sustainability frameworks and circular economy initiatives. The detailed molecular information obtained supports transparent environmental claims and facilitates the development of standardized biodegradability metrics. This scientific foundation strengthens consumer confidence in biopolymer products while enabling meaningful comparisons between alternative materials.

Looking forward, the integration of GPC characterization with life cycle assessment methodologies promises to further enhance sustainability outcomes. By correlating molecular characteristics with environmental performance indicators, researchers can establish predictive models that accelerate the development of next-generation sustainable materials with optimized ecological footprints and enhanced biodegradability.

Standardization Efforts in Biodegradable Polymer Analysis

Standardization efforts in the field of biodegradable polymer analysis, particularly for gel permeation chromatography (GPC), have gained significant momentum in recent years. As the biodegradable and bio-based polymer industry continues to expand, the need for consistent analytical methods has become increasingly critical for ensuring product quality, regulatory compliance, and meaningful comparison of research results across different laboratories and institutions.

The International Organization for Standardization (ISO) has developed several standards specifically addressing the characterization of biodegradable polymers, including ISO 13885 for GPC analysis of polymers. These standards provide guidelines for sample preparation, instrument calibration, data analysis, and reporting of results, which are essential for obtaining reliable molecular weight distributions and other key parameters of biodegradable polymers.

ASTM International has also contributed significantly to standardization efforts through committees such as D20.96 on environmentally degradable plastics and biobased products. Their standards include specific protocols for determining molecular weight characteristics of polylactic acid (PLA), polyhydroxyalkanoates (PHA), and other biodegradable polymers using GPC techniques.

The European Committee for Standardization (CEN) has established working groups focused on developing harmonized testing methods for bio-based products, including standardized GPC procedures for molecular weight determination. These efforts align with the European Union's broader initiatives to promote sustainable materials and circular economy principles.

Collaborative efforts between academic institutions and industry partners have resulted in round-robin testing programs, where multiple laboratories analyze identical samples to validate and refine standardized GPC methods for biodegradable polymers. These initiatives have helped identify and address variables that affect measurement reproducibility, such as solvent selection, temperature conditions, and column specifications.

Challenges in standardization include the diverse nature of biodegradable polymers, which often require different dissolution conditions and analytical parameters. For instance, PLA requires different GPC conditions compared to cellulose-based polymers or PHAs. This diversity necessitates the development of polymer-specific standard methods rather than a one-size-fits-all approach.

Recent advancements in standardization have focused on incorporating multi-detector GPC systems, which combine refractive index, light scattering, and viscometry measurements to provide more comprehensive characterization of biodegradable polymers. These advanced techniques are gradually being incorporated into updated standards to improve accuracy in molecular weight determination, especially for branched or complex biodegradable polymer architectures.

Looking forward, standardization bodies are working to address emerging challenges such as the analysis of polymer blends, composites, and modified biodegradable polymers with complex architectures. The development of reference materials specifically designed for biodegradable polymer analysis represents another important frontier in standardization efforts.

The International Organization for Standardization (ISO) has developed several standards specifically addressing the characterization of biodegradable polymers, including ISO 13885 for GPC analysis of polymers. These standards provide guidelines for sample preparation, instrument calibration, data analysis, and reporting of results, which are essential for obtaining reliable molecular weight distributions and other key parameters of biodegradable polymers.

ASTM International has also contributed significantly to standardization efforts through committees such as D20.96 on environmentally degradable plastics and biobased products. Their standards include specific protocols for determining molecular weight characteristics of polylactic acid (PLA), polyhydroxyalkanoates (PHA), and other biodegradable polymers using GPC techniques.

The European Committee for Standardization (CEN) has established working groups focused on developing harmonized testing methods for bio-based products, including standardized GPC procedures for molecular weight determination. These efforts align with the European Union's broader initiatives to promote sustainable materials and circular economy principles.

Collaborative efforts between academic institutions and industry partners have resulted in round-robin testing programs, where multiple laboratories analyze identical samples to validate and refine standardized GPC methods for biodegradable polymers. These initiatives have helped identify and address variables that affect measurement reproducibility, such as solvent selection, temperature conditions, and column specifications.

Challenges in standardization include the diverse nature of biodegradable polymers, which often require different dissolution conditions and analytical parameters. For instance, PLA requires different GPC conditions compared to cellulose-based polymers or PHAs. This diversity necessitates the development of polymer-specific standard methods rather than a one-size-fits-all approach.

Recent advancements in standardization have focused on incorporating multi-detector GPC systems, which combine refractive index, light scattering, and viscometry measurements to provide more comprehensive characterization of biodegradable polymers. These advanced techniques are gradually being incorporated into updated standards to improve accuracy in molecular weight determination, especially for branched or complex biodegradable polymer architectures.

Looking forward, standardization bodies are working to address emerging challenges such as the analysis of polymer blends, composites, and modified biodegradable polymers with complex architectures. The development of reference materials specifically designed for biodegradable polymer analysis represents another important frontier in standardization efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!