Research on solvent-free or green gel permeation chromatography systems

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Green GPC Technology Background and Objectives

Gel Permeation Chromatography (GPC) has been a cornerstone analytical technique in polymer science since its development in the 1960s. This separation method, based on molecular size differences, has traditionally relied on organic solvents such as tetrahydrofuran (THF), chloroform, and toluene as mobile phases. These conventional solvents present significant environmental and health concerns due to their toxicity, flammability, and contribution to volatile organic compound (VOC) emissions.

The evolution of GPC technology has been marked by incremental improvements in column technology, detection methods, and data analysis. However, the fundamental reliance on environmentally harmful solvents has remained largely unchanged until recent years. The growing global emphasis on sustainable chemistry, embodied in principles of green chemistry established in the 1990s, has created momentum for reimagining this essential analytical technique.

Current environmental regulations, including REACH in Europe and similar frameworks globally, are increasingly restricting the use of hazardous solvents in laboratory and industrial settings. This regulatory landscape, combined with corporate sustainability initiatives and the rising costs of solvent procurement and disposal, has accelerated interest in developing greener alternatives for GPC analysis.

The concept of green GPC encompasses several approaches: the replacement of traditional organic solvents with environmentally benign alternatives, the development of solvent-free systems, and the creation of more efficient systems that minimize solvent consumption. Recent technological advances in supercritical fluid chromatography (SFC), aqueous GPC systems, and novel stationary phases have opened promising pathways toward these goals.

The primary technical objectives for green GPC development include creating systems that maintain or exceed the analytical performance of conventional GPC while eliminating or significantly reducing environmental impact. This involves developing compatible stationary phases, optimizing separation conditions, ensuring broad polymer solubility in green mobile phases, and maintaining detection sensitivity across diverse polymer types.

Additionally, the field aims to establish standardized methodologies that facilitate industry adoption, reduce analysis costs through decreased solvent consumption and waste management, and enable high-throughput capabilities to meet industrial demands. The ultimate goal is to transform GPC from an environmentally problematic technique into a sustainable analytical method aligned with circular economy principles.

The trajectory of green GPC development reflects broader trends in analytical chemistry toward miniaturization, automation, and sustainability. As polymer materials become increasingly complex and ubiquitous in modern society, the need for environmentally responsible characterization methods grows correspondingly urgent, positioning green GPC as a critical enabling technology for sustainable materials development.

The evolution of GPC technology has been marked by incremental improvements in column technology, detection methods, and data analysis. However, the fundamental reliance on environmentally harmful solvents has remained largely unchanged until recent years. The growing global emphasis on sustainable chemistry, embodied in principles of green chemistry established in the 1990s, has created momentum for reimagining this essential analytical technique.

Current environmental regulations, including REACH in Europe and similar frameworks globally, are increasingly restricting the use of hazardous solvents in laboratory and industrial settings. This regulatory landscape, combined with corporate sustainability initiatives and the rising costs of solvent procurement and disposal, has accelerated interest in developing greener alternatives for GPC analysis.

The concept of green GPC encompasses several approaches: the replacement of traditional organic solvents with environmentally benign alternatives, the development of solvent-free systems, and the creation of more efficient systems that minimize solvent consumption. Recent technological advances in supercritical fluid chromatography (SFC), aqueous GPC systems, and novel stationary phases have opened promising pathways toward these goals.

The primary technical objectives for green GPC development include creating systems that maintain or exceed the analytical performance of conventional GPC while eliminating or significantly reducing environmental impact. This involves developing compatible stationary phases, optimizing separation conditions, ensuring broad polymer solubility in green mobile phases, and maintaining detection sensitivity across diverse polymer types.

Additionally, the field aims to establish standardized methodologies that facilitate industry adoption, reduce analysis costs through decreased solvent consumption and waste management, and enable high-throughput capabilities to meet industrial demands. The ultimate goal is to transform GPC from an environmentally problematic technique into a sustainable analytical method aligned with circular economy principles.

The trajectory of green GPC development reflects broader trends in analytical chemistry toward miniaturization, automation, and sustainability. As polymer materials become increasingly complex and ubiquitous in modern society, the need for environmentally responsible characterization methods grows correspondingly urgent, positioning green GPC as a critical enabling technology for sustainable materials development.

Market Analysis for Solvent-Free Chromatography

The global market for solvent-free or green gel permeation chromatography (GPC) systems is experiencing significant growth driven by increasing environmental regulations and sustainability initiatives across industries. The current market size for green chromatography technologies is estimated at $1.2 billion, with projections indicating a compound annual growth rate of 8.7% over the next five years.

Key market drivers include stringent environmental regulations limiting the use of hazardous organic solvents, particularly in pharmaceutical and food industries where regulatory bodies like FDA and EMA have implemented guidelines promoting green chemistry principles. The pharmaceutical sector represents the largest market segment, accounting for approximately 40% of the total market share, followed by environmental testing (25%) and food safety analysis (20%).

Regional analysis reveals North America as the dominant market with 38% share, attributed to early adoption of green technologies and presence of major chromatography equipment manufacturers. Europe follows closely at 35%, driven by strict environmental regulations and sustainability mandates. The Asia-Pacific region, while currently representing 22% of the market, is expected to witness the fastest growth rate of 12.3% annually, primarily due to expanding pharmaceutical manufacturing and increasing environmental concerns in China and India.

From an end-user perspective, research institutions and pharmaceutical companies demonstrate the highest demand for solvent-free GPC systems, collectively accounting for over 60% of market consumption. This trend is reinforced by increasing research funding directed specifically toward sustainable analytical technologies.

Market challenges include the higher initial investment costs for green chromatography systems compared to conventional systems, with price premiums averaging 15-25%. Additionally, performance limitations in certain applications and resistance to change from established methodologies present adoption barriers.

Consumer behavior analysis indicates growing preference for integrated systems that offer both environmental benefits and operational efficiency. Market surveys show that 78% of potential buyers consider environmental impact as a "very important" factor in purchasing decisions, representing a significant shift from just 45% five years ago.

The competitive landscape features established analytical instrument manufacturers expanding their green chromatography portfolios alongside innovative startups focusing exclusively on sustainable separation technologies. Strategic partnerships between equipment manufacturers and consumables providers are increasingly common, creating comprehensive eco-friendly chromatography solutions.

Future market projections suggest accelerated growth as technological advancements address current performance limitations and economies of scale reduce cost barriers. The development of novel stationary phases compatible with water-based mobile phases represents a particularly promising market segment with projected annual growth exceeding 15%.

Key market drivers include stringent environmental regulations limiting the use of hazardous organic solvents, particularly in pharmaceutical and food industries where regulatory bodies like FDA and EMA have implemented guidelines promoting green chemistry principles. The pharmaceutical sector represents the largest market segment, accounting for approximately 40% of the total market share, followed by environmental testing (25%) and food safety analysis (20%).

Regional analysis reveals North America as the dominant market with 38% share, attributed to early adoption of green technologies and presence of major chromatography equipment manufacturers. Europe follows closely at 35%, driven by strict environmental regulations and sustainability mandates. The Asia-Pacific region, while currently representing 22% of the market, is expected to witness the fastest growth rate of 12.3% annually, primarily due to expanding pharmaceutical manufacturing and increasing environmental concerns in China and India.

From an end-user perspective, research institutions and pharmaceutical companies demonstrate the highest demand for solvent-free GPC systems, collectively accounting for over 60% of market consumption. This trend is reinforced by increasing research funding directed specifically toward sustainable analytical technologies.

Market challenges include the higher initial investment costs for green chromatography systems compared to conventional systems, with price premiums averaging 15-25%. Additionally, performance limitations in certain applications and resistance to change from established methodologies present adoption barriers.

Consumer behavior analysis indicates growing preference for integrated systems that offer both environmental benefits and operational efficiency. Market surveys show that 78% of potential buyers consider environmental impact as a "very important" factor in purchasing decisions, representing a significant shift from just 45% five years ago.

The competitive landscape features established analytical instrument manufacturers expanding their green chromatography portfolios alongside innovative startups focusing exclusively on sustainable separation technologies. Strategic partnerships between equipment manufacturers and consumables providers are increasingly common, creating comprehensive eco-friendly chromatography solutions.

Future market projections suggest accelerated growth as technological advancements address current performance limitations and economies of scale reduce cost barriers. The development of novel stationary phases compatible with water-based mobile phases represents a particularly promising market segment with projected annual growth exceeding 15%.

Current Challenges in Eco-Friendly GPC Systems

Despite significant advancements in analytical chemistry, conventional gel permeation chromatography (GPC) systems continue to rely heavily on environmentally harmful organic solvents. The primary challenge facing eco-friendly GPC development is the fundamental dependence on these solvents as mobile phases, with tetrahydrofuran (THF), chloroform, and toluene being particularly problematic due to their toxicity, volatility, and environmental persistence. These solvents pose significant health risks to laboratory personnel through inhalation and skin contact while contributing substantially to laboratory waste streams.

Technical limitations present another major obstacle, as many green solvents exhibit incompatibility with existing GPC column materials. Conventional stationary phases designed for organic solvents often demonstrate poor separation efficiency, reduced column lifetime, or complete incompatibility when used with aqueous or bio-based alternatives. This necessitates complete redesign of column chemistry rather than simple solvent substitution.

Detector sensitivity represents a critical challenge, as many alternative solvents possess optical properties that interfere with traditional detection methods. Refractive index (RI) and UV detectors frequently demonstrate reduced sensitivity or increased baseline noise when operating with green solvents, compromising analytical precision and reliability. This technical limitation has significantly slowed adoption of environmentally friendly alternatives in precision analytical applications.

Economic barriers further complicate the transition to green GPC systems. The established infrastructure for conventional solvent-based systems represents significant capital investment for laboratories, creating resistance to adoption of new technologies that might require substantial equipment modifications or replacements. Additionally, many green solvents and compatible column materials currently command premium prices due to limited production scale and specialized manufacturing requirements.

Regulatory frameworks present a complex landscape that simultaneously drives and hinders eco-friendly GPC development. While environmental regulations increasingly restrict conventional solvent usage, the validation requirements for analytical methods in regulated industries create significant barriers to adopting novel green technologies. Pharmaceutical and food safety applications, in particular, require extensive validation of any methodological changes, creating institutional resistance to adopting unproven green alternatives.

Performance standardization remains underdeveloped for green GPC systems, with limited consensus on calibration standards, method validation protocols, and performance metrics specifically designed for eco-friendly alternatives. This lack of standardization complicates cross-laboratory comparisons and hinders widespread adoption in quality-critical applications.

Technical limitations present another major obstacle, as many green solvents exhibit incompatibility with existing GPC column materials. Conventional stationary phases designed for organic solvents often demonstrate poor separation efficiency, reduced column lifetime, or complete incompatibility when used with aqueous or bio-based alternatives. This necessitates complete redesign of column chemistry rather than simple solvent substitution.

Detector sensitivity represents a critical challenge, as many alternative solvents possess optical properties that interfere with traditional detection methods. Refractive index (RI) and UV detectors frequently demonstrate reduced sensitivity or increased baseline noise when operating with green solvents, compromising analytical precision and reliability. This technical limitation has significantly slowed adoption of environmentally friendly alternatives in precision analytical applications.

Economic barriers further complicate the transition to green GPC systems. The established infrastructure for conventional solvent-based systems represents significant capital investment for laboratories, creating resistance to adoption of new technologies that might require substantial equipment modifications or replacements. Additionally, many green solvents and compatible column materials currently command premium prices due to limited production scale and specialized manufacturing requirements.

Regulatory frameworks present a complex landscape that simultaneously drives and hinders eco-friendly GPC development. While environmental regulations increasingly restrict conventional solvent usage, the validation requirements for analytical methods in regulated industries create significant barriers to adopting novel green technologies. Pharmaceutical and food safety applications, in particular, require extensive validation of any methodological changes, creating institutional resistance to adopting unproven green alternatives.

Performance standardization remains underdeveloped for green GPC systems, with limited consensus on calibration standards, method validation protocols, and performance metrics specifically designed for eco-friendly alternatives. This lack of standardization complicates cross-laboratory comparisons and hinders widespread adoption in quality-critical applications.

Current Solvent-Free GPC Methodologies

01 Solvent-free gel permeation chromatography systems

Development of gel permeation chromatography systems that operate without traditional organic solvents, eliminating the need for hazardous chemicals in the separation process. These systems utilize alternative mechanisms for polymer separation and analysis, reducing environmental impact and safety concerns associated with conventional GPC methods. The solvent-free approach also minimizes waste generation and disposal issues while maintaining analytical performance.- Green solvents for gel permeation chromatography: Environmentally friendly solvents can be used in gel permeation chromatography systems to reduce environmental impact. These green solvents include water-based systems, bio-derived solvents, and other environmentally benign alternatives that replace traditional toxic organic solvents. These systems maintain separation efficiency while significantly reducing hazardous waste generation and environmental footprint.

- Solvent-free gel permeation chromatography techniques: Innovative approaches to gel permeation chromatography that eliminate or drastically reduce solvent usage have been developed. These techniques include dry-state analysis methods, solid-phase extraction principles adapted to size exclusion, and novel stationary phases that enable separation without traditional mobile phases. These solvent-free systems offer advantages in cost reduction, safety improvement, and environmental protection.

- Supercritical fluid chromatography for polymer analysis: Supercritical fluid chromatography represents an alternative to traditional solvent-based gel permeation chromatography. Using supercritical CO2 or other environmentally friendly supercritical fluids as the mobile phase eliminates the need for organic solvents. This technique provides efficient separation of polymers and macromolecules while offering advantages in terms of speed, resolution, and environmental impact.

- Recycling systems for chromatography solvents: Solvent recycling systems integrated with gel permeation chromatography equipment allow for the capture, purification, and reuse of solvents. These systems incorporate distillation units, membrane filtration, or adsorption technologies to purify used solvents for subsequent chromatographic runs. By implementing solvent recycling, laboratories can significantly reduce solvent consumption and waste generation while maintaining analytical performance.

- Miniaturized and microfluidic GPC systems: Miniaturized and microfluidic gel permeation chromatography systems dramatically reduce solvent consumption through scaled-down operations. These systems utilize microchannels, nanoliter flow rates, and highly efficient stationary phases to achieve separation with minimal solvent usage. The miniaturization approach maintains analytical performance while offering significant reductions in environmental impact, cost, and analysis time.

02 Green solvents for gel permeation chromatography

Implementation of environmentally friendly solvents in gel permeation chromatography systems as alternatives to traditional toxic or petroleum-based solvents. These green solvents include bio-based materials, supercritical CO2, and other environmentally benign fluids that reduce the ecological footprint of chromatographic analyses. The use of such solvents maintains separation efficiency while significantly decreasing environmental hazards and improving laboratory safety conditions.Expand Specific Solutions03 Sustainable materials for chromatography columns

Development of chromatography columns using sustainable and biodegradable materials for gel permeation applications. These columns incorporate eco-friendly stationary phases derived from renewable resources, reducing dependence on petroleum-based polymers. The sustainable materials provide comparable separation performance to conventional columns while offering improved environmental credentials and potentially lower toxicity profiles.Expand Specific Solutions04 Energy-efficient gel permeation chromatography systems

Design of energy-efficient gel permeation chromatography systems that reduce power consumption during operation. These systems incorporate optimized pumping mechanisms, improved thermal management, and advanced electronics to minimize energy requirements. Some designs utilize renewable energy sources or energy recovery systems to further reduce the carbon footprint of analytical procedures while maintaining or improving analytical performance.Expand Specific Solutions05 Miniaturized and waste-reducing GPC technologies

Development of miniaturized gel permeation chromatography systems that significantly reduce solvent consumption and waste generation. These compact systems utilize microfluidic technologies and advanced detection methods to achieve comparable analytical results with substantially smaller sample and solvent volumes. The miniaturization approach addresses both environmental concerns and cost efficiency by minimizing resource requirements and waste disposal needs.Expand Specific Solutions

Leading Companies in Green Separation Science

The green gel permeation chromatography (GPC) market is in its growth phase, with increasing demand for environmentally friendly analytical techniques driving innovation. The global market for sustainable chromatography systems is expanding rapidly as regulatory pressures and sustainability initiatives push laboratories toward solvent-free alternatives. Waters Technology Corp. leads the commercial space with established GPC platforms, while academic institutions like Nanjing University, University of Tokyo, and Vanderbilt University are advancing fundamental research in green separation technologies. Companies including Purolite LLC and Roche Diagnostics GmbH are developing specialized applications, with research institutes such as ITRI and CSIR contributing to technological advancements. The technology is approaching early maturity in specialized applications but remains in development for broader implementation, with collaborative efforts between industry and academia accelerating progress toward commercially viable solvent-free systems.

Waters Technology Corp.

Technical Solution: Waters Technology has pioneered significant advancements in green gel permeation chromatography through their ACQUITY Advanced Polymer Chromatography (APC) system. This technology utilizes ultra-high performance columns with sub-2μm particles that dramatically reduce solvent consumption by up to 96% compared to traditional GPC systems. Their approach incorporates recyclable columns and minimal waste generation protocols. Waters has also developed eco-friendly mobile phases that replace traditional toxic solvents like THF with more environmentally benign alternatives. Their GPC systems feature intelligent solvent management with automated recycling capabilities and low-flow technology that maintains analytical precision while minimizing environmental impact. The company has integrated their green GPC systems with sophisticated software that optimizes separation parameters to further reduce solvent usage while maintaining or improving analytical performance.

Strengths: Industry-leading reduction in solvent consumption; comprehensive integration of hardware and software solutions; established global support infrastructure. Weaknesses: Higher initial investment costs compared to conventional systems; requires specialized training for optimal operation; some applications still require adaptation from traditional methods.

Nanjing University

Technical Solution: Nanjing University has pioneered innovative approaches to green gel permeation chromatography through the development of ionic liquid-based separation systems. Their technology replaces conventional organic solvents with designer ionic liquids that offer tunable selectivity while eliminating volatile organic compounds. The university's research team has synthesized novel stationary phases with controlled porosity and surface functionality specifically optimized for ionic liquid mobile phases. Their approach incorporates microfluidic separation channels that dramatically reduce mobile phase consumption while maintaining separation efficiency. Nanjing University has developed temperature-responsive polymer matrices that enable solvent-free separations through controlled changes in polymer conformation in response to thermal stimuli. Their systems feature integrated recycling technology that recovers and purifies ionic liquids, creating sustainable separation processes with minimal waste generation. The university has also pioneered the use of deep eutectic solvents as environmentally benign alternatives to traditional GPC solvents, offering comparable separation performance with significantly reduced environmental impact.

Strengths: Highly innovative approaches to solvent elimination; excellent separation performance for specialized applications; significant reduction in hazardous waste. Weaknesses: Technology still primarily at research scale; requires specialized equipment not widely available; higher complexity in method development compared to traditional systems.

Key Innovations in Green Chromatography

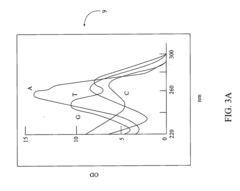

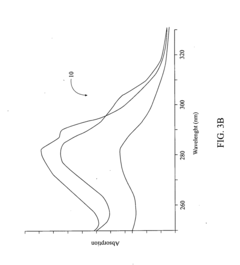

System and method for determining the presence or absence of adsorbed biomolecules or biomolecular structures on a surface

PatentInactiveUS20190056389A1

Innovation

- The use of ultraviolet wavelengths to excite surface plasmons on a photonic surface with a diffraction grating, coinciding with native molecular absorption lines, and a thin aluminum layer with protective dielectric layers to enhance sensitivity and refractive index changes detection.

Environmental Impact Assessment of GPC Systems

Traditional gel permeation chromatography (GPC) systems rely heavily on organic solvents that pose significant environmental concerns. These systems typically consume large volumes of solvents such as tetrahydrofuran (THF), chloroform, and toluene, which are classified as hazardous substances with detrimental effects on both environmental and human health. The environmental footprint of conventional GPC extends beyond mere solvent usage to include energy consumption, waste generation, and potential ecological contamination.

The production, transportation, and disposal of organic solvents contribute substantially to greenhouse gas emissions. Studies indicate that analytical laboratories generate approximately 5-10 times more waste by weight than the samples they analyze, with solvents accounting for up to 80% of this waste. Traditional GPC systems can consume between 100-500 mL of solvent per hour during operation, translating to significant annual volumes for facilities running multiple analyses daily.

Solvent waste from GPC systems often contains dissolved polymers and additives that complicate treatment processes. Improper disposal can lead to soil contamination, groundwater pollution, and disruption of aquatic ecosystems. Volatile organic compounds (VOCs) released during GPC operations contribute to air quality degradation and potential ozone depletion, while also presenting workplace health hazards through inhalation and dermal exposure.

Green and solvent-free GPC alternatives demonstrate remarkable environmental advantages. Water-based systems reduce toxic waste by 95% compared to organic solvent-based methods. Supercritical fluid chromatography using CO2 as the mobile phase offers a particularly promising approach, with a carbon footprint approximately 60% lower than conventional systems. These sustainable alternatives also typically require less energy for solvent recycling and waste management.

Life cycle assessments of emerging green GPC technologies reveal significant reductions in environmental impact categories including global warming potential, acidification, and resource depletion. For instance, the implementation of solvent recycling systems can recover up to 90% of used solvents, dramatically reducing fresh solvent requirements and associated environmental burdens.

Regulatory frameworks worldwide are increasingly restricting the use of hazardous solvents, with the European Union's REACH regulation and similar initiatives in North America and Asia driving the transition toward greener analytical methods. Organizations adopting environmentally responsible GPC systems not only achieve compliance with these regulations but also realize cost savings through reduced solvent procurement, waste disposal, and workplace safety measures.

The production, transportation, and disposal of organic solvents contribute substantially to greenhouse gas emissions. Studies indicate that analytical laboratories generate approximately 5-10 times more waste by weight than the samples they analyze, with solvents accounting for up to 80% of this waste. Traditional GPC systems can consume between 100-500 mL of solvent per hour during operation, translating to significant annual volumes for facilities running multiple analyses daily.

Solvent waste from GPC systems often contains dissolved polymers and additives that complicate treatment processes. Improper disposal can lead to soil contamination, groundwater pollution, and disruption of aquatic ecosystems. Volatile organic compounds (VOCs) released during GPC operations contribute to air quality degradation and potential ozone depletion, while also presenting workplace health hazards through inhalation and dermal exposure.

Green and solvent-free GPC alternatives demonstrate remarkable environmental advantages. Water-based systems reduce toxic waste by 95% compared to organic solvent-based methods. Supercritical fluid chromatography using CO2 as the mobile phase offers a particularly promising approach, with a carbon footprint approximately 60% lower than conventional systems. These sustainable alternatives also typically require less energy for solvent recycling and waste management.

Life cycle assessments of emerging green GPC technologies reveal significant reductions in environmental impact categories including global warming potential, acidification, and resource depletion. For instance, the implementation of solvent recycling systems can recover up to 90% of used solvents, dramatically reducing fresh solvent requirements and associated environmental burdens.

Regulatory frameworks worldwide are increasingly restricting the use of hazardous solvents, with the European Union's REACH regulation and similar initiatives in North America and Asia driving the transition toward greener analytical methods. Organizations adopting environmentally responsible GPC systems not only achieve compliance with these regulations but also realize cost savings through reduced solvent procurement, waste disposal, and workplace safety measures.

Regulatory Framework for Green Analytical Methods

The regulatory landscape for green analytical methods has evolved significantly in response to growing environmental concerns and sustainability initiatives. Major regulatory bodies including the Environmental Protection Agency (EPA), the European Chemicals Agency (ECHA), and the International Organization for Standardization (ISO) have established frameworks that increasingly favor environmentally benign analytical techniques such as solvent-free gel permeation chromatography (GPC) systems.

The EPA's Green Chemistry Program, established in the 1990s, provides guidelines that prioritize the reduction or elimination of hazardous substances in chemical processes, directly impacting chromatographic methods. These guidelines have been instrumental in driving research toward solvent-free GPC systems, as traditional methods often rely on toxic organic solvents like tetrahydrofuran (THF) and chloroform.

In Europe, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation has imposed stringent requirements on chemical usage, creating regulatory pressure to develop greener analytical alternatives. The regulation specifically addresses solvent waste management and encourages the adoption of techniques that minimize environmental impact, making solvent-free GPC systems increasingly attractive from a compliance perspective.

ISO 14000 series standards for environmental management systems provide another layer of regulatory guidance, establishing frameworks for organizations to systematically improve their environmental performance. These standards have prompted analytical laboratories to reassess their methodologies, with many now implementing green chemistry metrics to evaluate and reduce the environmental footprint of their analytical procedures.

The pharmaceutical industry faces particularly rigorous regulatory oversight through Good Manufacturing Practices (GMP) and International Conference on Harmonisation (ICH) guidelines. The ICH Q3C guideline on residual solvents classifies solvents based on their toxicity, creating a regulatory incentive to develop solvent-free or green solvent alternatives for GPC applications in pharmaceutical analysis.

Recent regulatory trends indicate a move toward lifecycle assessment approaches for analytical methods, considering environmental impacts from reagent production through waste disposal. This holistic perspective has accelerated interest in green GPC technologies that utilize supercritical fluids, ionic liquids, or water-based systems as environmentally preferable alternatives to traditional organic solvents.

Academic and industrial researchers must navigate this complex regulatory landscape when developing new green GPC methodologies, ensuring compliance while simultaneously advancing analytical capabilities. The successful commercialization of these technologies increasingly depends on their alignment with global sustainability regulations and standards.

The EPA's Green Chemistry Program, established in the 1990s, provides guidelines that prioritize the reduction or elimination of hazardous substances in chemical processes, directly impacting chromatographic methods. These guidelines have been instrumental in driving research toward solvent-free GPC systems, as traditional methods often rely on toxic organic solvents like tetrahydrofuran (THF) and chloroform.

In Europe, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation has imposed stringent requirements on chemical usage, creating regulatory pressure to develop greener analytical alternatives. The regulation specifically addresses solvent waste management and encourages the adoption of techniques that minimize environmental impact, making solvent-free GPC systems increasingly attractive from a compliance perspective.

ISO 14000 series standards for environmental management systems provide another layer of regulatory guidance, establishing frameworks for organizations to systematically improve their environmental performance. These standards have prompted analytical laboratories to reassess their methodologies, with many now implementing green chemistry metrics to evaluate and reduce the environmental footprint of their analytical procedures.

The pharmaceutical industry faces particularly rigorous regulatory oversight through Good Manufacturing Practices (GMP) and International Conference on Harmonisation (ICH) guidelines. The ICH Q3C guideline on residual solvents classifies solvents based on their toxicity, creating a regulatory incentive to develop solvent-free or green solvent alternatives for GPC applications in pharmaceutical analysis.

Recent regulatory trends indicate a move toward lifecycle assessment approaches for analytical methods, considering environmental impacts from reagent production through waste disposal. This holistic perspective has accelerated interest in green GPC technologies that utilize supercritical fluids, ionic liquids, or water-based systems as environmentally preferable alternatives to traditional organic solvents.

Academic and industrial researchers must navigate this complex regulatory landscape when developing new green GPC methodologies, ensuring compliance while simultaneously advancing analytical capabilities. The successful commercialization of these technologies increasingly depends on their alignment with global sustainability regulations and standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!