Research on temperature-controlled gel permeation chromatography

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Temperature-Controlled GPC Background and Objectives

Gel permeation chromatography (GPC) has evolved significantly since its inception in the 1960s, becoming a cornerstone analytical technique for polymer characterization. The integration of temperature control capabilities represents a critical advancement in this field, enabling more precise separation and analysis of complex polymer systems. Temperature-controlled GPC addresses the fundamental limitations of conventional GPC by allowing for the manipulation of sample viscosity, solubility, and molecular interactions during the separation process.

The historical trajectory of GPC technology reveals a consistent trend toward enhanced precision and versatility. Early systems operated primarily at ambient temperatures, which significantly restricted their application scope, particularly for thermosensitive polymers or those with complex phase behaviors. The introduction of temperature control mechanisms in the 1980s marked a pivotal shift, expanding the analytical capabilities to encompass a broader range of polymer materials and conditions.

Current technological objectives in temperature-controlled GPC research center on achieving unprecedented levels of separation efficiency and analytical accuracy. Researchers aim to develop systems capable of maintaining ultra-stable temperature profiles across the entire chromatographic pathway, minimizing thermal gradients that can distort separation profiles. Additionally, there is a growing emphasis on extending the operational temperature range, with particular interest in both cryogenic conditions for thermally labile compounds and elevated temperatures for high-melting polymers.

The evolution of temperature-controlled GPC aligns with broader trends in analytical chemistry toward multi-parameter, adaptive methodologies. Modern research increasingly focuses on integrating temperature modulation with other separation parameters, creating dynamic chromatographic environments that can be optimized in real-time based on sample characteristics. This approach represents a paradigm shift from static to responsive analytical systems.

From a technological perspective, the field is witnessing convergence with advanced materials science, particularly in the development of column materials with enhanced thermal stability and separation efficiency across wide temperature ranges. Concurrently, computational advances are enabling more sophisticated data interpretation models that can account for temperature-dependent changes in polymer behavior during analysis.

The ultimate objective of current temperature-controlled GPC research extends beyond mere analytical improvement to establishing comprehensive polymer characterization platforms. These systems aim to provide multidimensional insights into polymer properties, including molecular weight distribution, branching characteristics, and conformational dynamics, all as functions of temperature. This holistic approach promises to bridge the gap between molecular structure and macroscopic material properties, facilitating more rational polymer design and application development.

The historical trajectory of GPC technology reveals a consistent trend toward enhanced precision and versatility. Early systems operated primarily at ambient temperatures, which significantly restricted their application scope, particularly for thermosensitive polymers or those with complex phase behaviors. The introduction of temperature control mechanisms in the 1980s marked a pivotal shift, expanding the analytical capabilities to encompass a broader range of polymer materials and conditions.

Current technological objectives in temperature-controlled GPC research center on achieving unprecedented levels of separation efficiency and analytical accuracy. Researchers aim to develop systems capable of maintaining ultra-stable temperature profiles across the entire chromatographic pathway, minimizing thermal gradients that can distort separation profiles. Additionally, there is a growing emphasis on extending the operational temperature range, with particular interest in both cryogenic conditions for thermally labile compounds and elevated temperatures for high-melting polymers.

The evolution of temperature-controlled GPC aligns with broader trends in analytical chemistry toward multi-parameter, adaptive methodologies. Modern research increasingly focuses on integrating temperature modulation with other separation parameters, creating dynamic chromatographic environments that can be optimized in real-time based on sample characteristics. This approach represents a paradigm shift from static to responsive analytical systems.

From a technological perspective, the field is witnessing convergence with advanced materials science, particularly in the development of column materials with enhanced thermal stability and separation efficiency across wide temperature ranges. Concurrently, computational advances are enabling more sophisticated data interpretation models that can account for temperature-dependent changes in polymer behavior during analysis.

The ultimate objective of current temperature-controlled GPC research extends beyond mere analytical improvement to establishing comprehensive polymer characterization platforms. These systems aim to provide multidimensional insights into polymer properties, including molecular weight distribution, branching characteristics, and conformational dynamics, all as functions of temperature. This holistic approach promises to bridge the gap between molecular structure and macroscopic material properties, facilitating more rational polymer design and application development.

Market Analysis for Temperature-Controlled GPC Systems

The global market for temperature-controlled gel permeation chromatography (GPC) systems has experienced significant growth in recent years, driven by increasing demand for precise polymer analysis across various industries. The current market size is estimated to reach several hundred million dollars, with a compound annual growth rate projected between 5-7% over the next five years. This growth trajectory is supported by expanding applications in pharmaceutical research, material science, and industrial polymer manufacturing.

North America currently dominates the temperature-controlled GPC systems market, accounting for approximately one-third of global revenue. This dominance stems from the region's robust pharmaceutical and biotechnology sectors, coupled with substantial R&D investments. Europe follows closely as the second-largest market, particularly strong in chemical and polymer industries. The Asia-Pacific region, however, is emerging as the fastest-growing market, with China, Japan, and India leading regional adoption due to rapid industrialization and increasing research activities.

From an end-user perspective, pharmaceutical and biotechnology companies represent the largest segment, utilizing temperature-controlled GPC systems for drug development, quality control, and research applications. Academic and research institutions constitute another significant market segment, particularly for advanced polymer science research. The industrial polymer manufacturing sector shows steady demand growth as manufacturers seek more precise characterization methods for product development and quality assurance.

Key market drivers include the growing complexity of polymer formulations requiring more sophisticated analysis techniques, increasing regulatory requirements for pharmaceutical and material characterization, and technological advancements improving system accuracy and efficiency. The trend toward miniaturization and automation in analytical instruments is reshaping customer expectations, with demand rising for systems offering higher throughput, reduced sample volumes, and enhanced temperature control precision.

Market challenges include the high initial investment cost for temperature-controlled GPC systems, which can limit adoption among smaller organizations and academic institutions. Technical complexity requiring specialized training and maintenance represents another barrier to market expansion. Additionally, competition from alternative polymer characterization techniques creates pressure on manufacturers to continuously innovate and demonstrate superior value.

The service and consumables segment associated with temperature-controlled GPC systems presents a lucrative revenue stream, with recurring sales of columns, standards, and maintenance services generating substantial after-market value. This segment is projected to grow at a faster rate than the instrument market itself, reflecting the increasing installed base and operational requirements of existing systems.

North America currently dominates the temperature-controlled GPC systems market, accounting for approximately one-third of global revenue. This dominance stems from the region's robust pharmaceutical and biotechnology sectors, coupled with substantial R&D investments. Europe follows closely as the second-largest market, particularly strong in chemical and polymer industries. The Asia-Pacific region, however, is emerging as the fastest-growing market, with China, Japan, and India leading regional adoption due to rapid industrialization and increasing research activities.

From an end-user perspective, pharmaceutical and biotechnology companies represent the largest segment, utilizing temperature-controlled GPC systems for drug development, quality control, and research applications. Academic and research institutions constitute another significant market segment, particularly for advanced polymer science research. The industrial polymer manufacturing sector shows steady demand growth as manufacturers seek more precise characterization methods for product development and quality assurance.

Key market drivers include the growing complexity of polymer formulations requiring more sophisticated analysis techniques, increasing regulatory requirements for pharmaceutical and material characterization, and technological advancements improving system accuracy and efficiency. The trend toward miniaturization and automation in analytical instruments is reshaping customer expectations, with demand rising for systems offering higher throughput, reduced sample volumes, and enhanced temperature control precision.

Market challenges include the high initial investment cost for temperature-controlled GPC systems, which can limit adoption among smaller organizations and academic institutions. Technical complexity requiring specialized training and maintenance represents another barrier to market expansion. Additionally, competition from alternative polymer characterization techniques creates pressure on manufacturers to continuously innovate and demonstrate superior value.

The service and consumables segment associated with temperature-controlled GPC systems presents a lucrative revenue stream, with recurring sales of columns, standards, and maintenance services generating substantial after-market value. This segment is projected to grow at a faster rate than the instrument market itself, reflecting the increasing installed base and operational requirements of existing systems.

Current Challenges in Temperature-Controlled GPC Technology

Despite significant advancements in temperature-controlled gel permeation chromatography (GPC) technology, several critical challenges continue to impede its optimal performance and widespread application. One of the primary obstacles remains the achievement of precise temperature stability throughout the entire chromatographic system. Even minor temperature fluctuations of 0.1-0.2°C can significantly impact retention times and peak resolution, particularly when analyzing temperature-sensitive polymers or biomolecules.

The thermal equilibration time presents another substantial challenge. Current systems often require extended periods (30-60 minutes) to reach stable temperature conditions after adjustment, limiting throughput and efficiency in analytical laboratories. This delay becomes particularly problematic when analyzing multiple samples requiring different temperature conditions or when conducting temperature-gradient experiments.

Column temperature homogeneity represents a persistent technical hurdle. Temperature gradients within the column can lead to band broadening and reduced separation efficiency. Current column oven designs struggle to maintain uniform temperature distribution, especially at the column ends where connections to external components create thermal interfaces that are difficult to control precisely.

Solvent viscosity changes with temperature significantly impact separation performance but remain inadequately addressed in current systems. As temperature increases, solvent viscosity typically decreases, altering flow characteristics and potentially changing the effective pore size of the stationary phase. These effects can complicate data interpretation and compromise the accuracy of molecular weight determinations.

The integration of temperature control with other analytical techniques presents compatibility challenges. When GPC is coupled with detectors such as light scattering, viscometry, or mass spectrometry, maintaining consistent temperature across all system components becomes increasingly complex. Temperature differentials between the separation column and detection systems can introduce artifacts and measurement errors.

Energy efficiency and environmental considerations pose growing concerns. Traditional column ovens consume substantial power, particularly when operating at elevated temperatures or when rapid temperature changes are required. This energy consumption contradicts the increasing emphasis on sustainable laboratory practices and green analytical chemistry principles.

Calibration and validation procedures for temperature-controlled GPC systems lack standardization across the industry. Different manufacturers employ varying approaches to temperature measurement and control, making cross-platform comparisons challenging and potentially affecting the reproducibility of results between laboratories using different instrumentation.

The thermal equilibration time presents another substantial challenge. Current systems often require extended periods (30-60 minutes) to reach stable temperature conditions after adjustment, limiting throughput and efficiency in analytical laboratories. This delay becomes particularly problematic when analyzing multiple samples requiring different temperature conditions or when conducting temperature-gradient experiments.

Column temperature homogeneity represents a persistent technical hurdle. Temperature gradients within the column can lead to band broadening and reduced separation efficiency. Current column oven designs struggle to maintain uniform temperature distribution, especially at the column ends where connections to external components create thermal interfaces that are difficult to control precisely.

Solvent viscosity changes with temperature significantly impact separation performance but remain inadequately addressed in current systems. As temperature increases, solvent viscosity typically decreases, altering flow characteristics and potentially changing the effective pore size of the stationary phase. These effects can complicate data interpretation and compromise the accuracy of molecular weight determinations.

The integration of temperature control with other analytical techniques presents compatibility challenges. When GPC is coupled with detectors such as light scattering, viscometry, or mass spectrometry, maintaining consistent temperature across all system components becomes increasingly complex. Temperature differentials between the separation column and detection systems can introduce artifacts and measurement errors.

Energy efficiency and environmental considerations pose growing concerns. Traditional column ovens consume substantial power, particularly when operating at elevated temperatures or when rapid temperature changes are required. This energy consumption contradicts the increasing emphasis on sustainable laboratory practices and green analytical chemistry principles.

Calibration and validation procedures for temperature-controlled GPC systems lack standardization across the industry. Different manufacturers employ varying approaches to temperature measurement and control, making cross-platform comparisons challenging and potentially affecting the reproducibility of results between laboratories using different instrumentation.

Current Technical Solutions for Temperature-Controlled GPC

01 Temperature control systems for GPC columns

Temperature control systems are essential for gel permeation chromatography (GPC) to ensure accurate and reproducible results. These systems typically include heating elements, temperature sensors, and control mechanisms that maintain the column at a specific temperature. Precise temperature control helps to stabilize the separation process by reducing viscosity variations in the mobile phase and minimizing thermal fluctuations that could affect retention times and peak resolution.- Temperature control systems for GPC: Temperature control systems are essential for gel permeation chromatography to maintain consistent and accurate results. These systems typically include heating/cooling elements, temperature sensors, and control units that regulate the temperature of the column and mobile phase. Precise temperature control helps to ensure reproducible retention times and accurate molecular weight determinations by minimizing variations in polymer chain conformations and solvent viscosity.

- Column temperature regulation methods: Various methods are employed to regulate column temperature in gel permeation chromatography. These include water jacket systems, air circulation chambers, and direct contact heating elements. Some advanced systems incorporate multiple temperature zones to create controlled temperature gradients along the column. Effective column temperature regulation minimizes band broadening and improves separation efficiency, particularly for temperature-sensitive polymers.

- Temperature effects on separation performance: Temperature significantly affects separation performance in gel permeation chromatography by influencing solvent viscosity, diffusion rates, and polymer-solvent interactions. Higher temperatures generally reduce viscosity and improve diffusion, potentially enhancing resolution and reducing analysis time. However, excessive temperatures may cause sample degradation or column damage. Understanding these temperature effects is crucial for optimizing separation conditions for different polymer types.

- Automated temperature control algorithms: Advanced GPC systems incorporate automated temperature control algorithms that dynamically adjust temperature parameters based on sample characteristics and separation requirements. These algorithms may include predictive models, feedback control mechanisms, and self-calibration features. Some systems allow for programmed temperature gradients or temperature cycling to enhance separation of complex polymer mixtures with different temperature-dependent behaviors.

- Temperature calibration and validation methods: Accurate temperature calibration and validation are essential for reliable GPC analysis. Methods include the use of temperature reference standards, multi-point calibration procedures, and regular verification protocols. Some systems incorporate built-in temperature verification tools that monitor and document temperature stability throughout the analysis. Proper temperature calibration ensures consistent performance across different instruments and laboratories, facilitating data comparability and method transfer.

02 Temperature effects on polymer characterization in GPC

Temperature significantly impacts polymer characterization in gel permeation chromatography. Higher temperatures generally reduce the viscosity of the mobile phase and polymer solutions, affecting elution behavior and separation efficiency. Temperature control is particularly critical when analyzing temperature-sensitive polymers or when studying temperature-dependent properties such as molecular weight distribution. Consistent temperature conditions ensure that changes in chromatographic behavior are due to sample characteristics rather than environmental variations.Expand Specific Solutions03 Thermostatted GPC column compartments

Specialized column compartments with thermostatting capabilities are designed to maintain stable temperatures during gel permeation chromatography analysis. These compartments often feature insulation, circulation systems for temperature-controlled fluids, and precise electronic controls. Some advanced designs incorporate multiple heating zones or gradient temperature capabilities to optimize separation conditions for complex polymer mixtures or to simulate specific environmental conditions during analysis.Expand Specific Solutions04 Temperature calibration and validation methods for GPC

Accurate temperature calibration and validation are essential for reliable gel permeation chromatography results. Methods include using certified reference materials to verify temperature effects on retention behavior, implementing temperature mapping across the column, and regular verification of temperature sensor accuracy. Validation protocols often require demonstrating temperature stability over extended periods and across the operational range of the instrument to ensure consistent chromatographic performance.Expand Specific Solutions05 Temperature-controlled sample preparation for GPC

Sample preparation under controlled temperature conditions is crucial for accurate gel permeation chromatography analysis. This includes dissolution of polymers at specific temperatures, filtration of samples under temperature-controlled conditions, and maintaining sample stability prior to injection. Temperature-controlled autosamplers and sample handling systems help prevent precipitation, aggregation, or degradation of temperature-sensitive polymers before analysis, ensuring that the chromatographic results accurately represent the original sample characteristics.Expand Specific Solutions

Leading Manufacturers and Research Institutions in GPC

Temperature-controlled gel permeation chromatography (GPC) is currently in a growth phase, with the market expanding due to increasing applications in polymer analysis and pharmaceutical research. The global market size is estimated to be approaching $1 billion, driven by demand for precise molecular weight distribution analysis. Leading players include Waters Technology Corp., which dominates with advanced GPC systems, and Shimadzu Corp., offering integrated temperature control solutions. Dow Global Technologies contributes significant innovations in polymer analysis applications, while academic institutions like California Institute of Technology and Seoul National University provide fundamental research advancements. Hitachi High-Tech America and Merck Millipore are expanding their presence with specialized columns and detection systems. The technology has reached moderate maturity but continues to evolve with improvements in temperature stability, column technology, and detection sensitivity.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed proprietary temperature-controlled GPC systems specifically optimized for polyolefin and industrial polymer characterization. Their technology incorporates high-temperature GPC capabilities (up to 220°C) essential for analyzing crystalline polymers that require complete dissolution at elevated temperatures. Dow's approach features specialized sample preparation modules with nitrogen-purged environments to prevent oxidative degradation during high-temperature dissolution and analysis. Their systems employ custom-designed column ovens with multi-point temperature sensing and zone-specific heating elements that eliminate temperature gradients across column banks, critical for analyzing complex polymer blends. Dow has pioneered the integration of multiple detection methods (IR, viscometry, light scattering) in high-temperature environments, enabling comprehensive polymer characterization without compromising thermal stability. Their technology includes automated viscosity correction algorithms that account for temperature-dependent changes in mobile phase properties, ensuring accurate molecular weight calculations across different operating temperatures. Dow's research has established industry standards for temperature-dependent calibration of GPC systems for specific polymer classes.

Strengths: Exceptional high-temperature capabilities (up to 220°C) ideal for polyolefin analysis; integrated oxidation prevention systems extend column life; comprehensive multi-detection capabilities provide detailed polymer characterization. Weaknesses: Systems optimized primarily for industrial polymers rather than biomolecules; significant energy requirements for high-temperature operation; specialized training needed for proper operation and maintenance of high-temperature components.

Waters Technology Corp.

Technical Solution: Waters Technology has pioneered advanced temperature-controlled gel permeation chromatography (TC-GPC) systems that integrate precise temperature regulation throughout the entire chromatographic process. Their ACQUITY Advanced Polymer Chromatography (APC) system incorporates multi-detector technology with temperature control ranging from ambient to 90°C, enabling high-resolution polymer analysis with minimal band broadening. The system features column compartments with active pre-heating and cooling capabilities that maintain temperature stability within ±0.1°C, critical for analyzing temperature-sensitive polymers. Waters' approach combines their patented sub-2μm particle columns with temperature-controlled sample handling to prevent on-column precipitation and degradation of sensitive samples. Their technology allows for the separation of complex polymer mixtures with molecular weight differences as small as 10%, significantly outperforming traditional GPC methods that typically require 30% differences for effective separation.

Strengths: Superior resolution with temperature precision of ±0.1°C allows for analysis of thermally sensitive polymers; integrated multi-detector capability provides comprehensive characterization; reduced analysis time compared to conventional GPC. Weaknesses: Higher initial investment cost; requires specialized training for operation; limited to maximum temperature of 90°C which may not be sufficient for some high-temperature polymer applications.

Key Patents and Innovations in Temperature-Controlled GPC

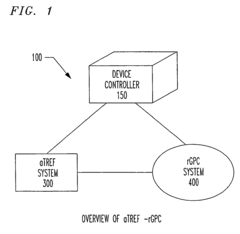

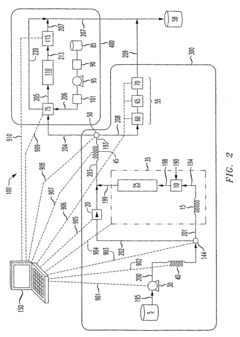

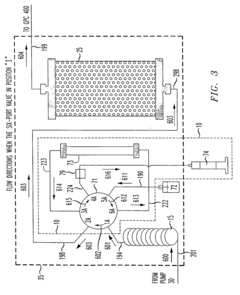

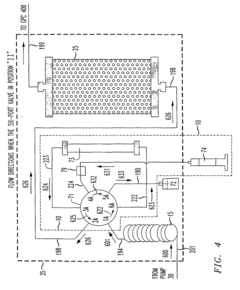

An integrated on-line two-dimensional method and device for synchronized analytical temperature rising elution fractionation and gel permeation chromatography

PatentInactiveEP1883811B1

Innovation

- An integrated analytical method and device combining Analytical Temperature Rising Elution Fractionation (aTREF) with Rapid Gel Permeation Chromatography (rGPC) for simultaneous fractionation and characterization of polymer samples, enabling online and real-time determination of composition and molecular weight distribution using a synchronized valve scheme and computer control.

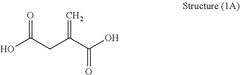

Aqueous composition comprising multi-stage latex polymer particles

PatentActiveUS12116440B2

Innovation

- An aqueous composition containing multi-stage latex polymer particles, comprising a first-stage polymer with an ethylenically unsaturated acid monomer and a vinyl monomer, and a second-stage polymer with an ethylenically unsaturated monomer and an epoxy group, which are bound together to provide improved crosslinking without the need for external agents.

Validation and Standardization Protocols for GPC Analysis

Establishing robust validation and standardization protocols is essential for ensuring the reliability and reproducibility of temperature-controlled gel permeation chromatography (GPC) analyses. These protocols must address multiple aspects of the analytical process, from instrument qualification to method validation and quality control procedures.

The validation process for temperature-controlled GPC systems should begin with installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ). IQ verifies that the instrument is properly installed according to manufacturer specifications, with particular attention to temperature control components. OQ confirms that all system functions, especially temperature regulation mechanisms, operate within specified parameters. PQ demonstrates that the system consistently performs as intended under actual operating conditions across the required temperature range.

Method validation for temperature-controlled GPC analysis requires assessment of several critical performance characteristics. Accuracy should be evaluated using reference materials with known molecular weight distributions at different temperatures. Precision must be demonstrated through repeatability (intra-day) and intermediate precision (inter-day) studies at various temperatures. Linearity of detector response across the molecular weight range of interest should be established at each operating temperature.

Robustness testing is particularly important for temperature-controlled GPC, as it evaluates the method's reliability when faced with small but deliberate variations in analytical parameters. This includes testing stability at temperature extremes and during temperature transitions. Specificity testing ensures that the presence of potential interferents does not affect molecular weight determination at different temperatures.

System suitability tests (SSTs) should be incorporated into routine analysis protocols. These typically include injections of molecular weight standards at the beginning of each analytical sequence to verify proper system performance. For temperature-controlled applications, SSTs should be performed at each temperature setting used in the analysis to confirm consistent performance across the temperature range.

Quality control procedures must include regular calibration of both the chromatographic system and its temperature control components. Temperature verification using external calibrated devices is recommended at defined intervals. Control charts should be maintained to monitor system performance over time, with particular attention to any drift in retention times or peak resolution that might indicate temperature control issues.

Standardized documentation practices are essential for maintaining compliance with regulatory requirements. This includes detailed standard operating procedures (SOPs) for instrument operation, method execution, data analysis, and troubleshooting. All temperature-related parameters must be clearly specified in these documents, along with acceptable ranges and corrective actions when deviations occur.

The validation process for temperature-controlled GPC systems should begin with installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ). IQ verifies that the instrument is properly installed according to manufacturer specifications, with particular attention to temperature control components. OQ confirms that all system functions, especially temperature regulation mechanisms, operate within specified parameters. PQ demonstrates that the system consistently performs as intended under actual operating conditions across the required temperature range.

Method validation for temperature-controlled GPC analysis requires assessment of several critical performance characteristics. Accuracy should be evaluated using reference materials with known molecular weight distributions at different temperatures. Precision must be demonstrated through repeatability (intra-day) and intermediate precision (inter-day) studies at various temperatures. Linearity of detector response across the molecular weight range of interest should be established at each operating temperature.

Robustness testing is particularly important for temperature-controlled GPC, as it evaluates the method's reliability when faced with small but deliberate variations in analytical parameters. This includes testing stability at temperature extremes and during temperature transitions. Specificity testing ensures that the presence of potential interferents does not affect molecular weight determination at different temperatures.

System suitability tests (SSTs) should be incorporated into routine analysis protocols. These typically include injections of molecular weight standards at the beginning of each analytical sequence to verify proper system performance. For temperature-controlled applications, SSTs should be performed at each temperature setting used in the analysis to confirm consistent performance across the temperature range.

Quality control procedures must include regular calibration of both the chromatographic system and its temperature control components. Temperature verification using external calibrated devices is recommended at defined intervals. Control charts should be maintained to monitor system performance over time, with particular attention to any drift in retention times or peak resolution that might indicate temperature control issues.

Standardized documentation practices are essential for maintaining compliance with regulatory requirements. This includes detailed standard operating procedures (SOPs) for instrument operation, method execution, data analysis, and troubleshooting. All temperature-related parameters must be clearly specified in these documents, along with acceptable ranges and corrective actions when deviations occur.

Environmental Impact and Sustainability Considerations

Temperature-controlled gel permeation chromatography (GPC) systems, while offering significant analytical advantages, present several environmental and sustainability challenges that warrant careful consideration. The operation of these systems typically requires substantial energy consumption, primarily due to the precise temperature control mechanisms that must maintain stable conditions throughout analytical processes. This energy demand contributes to the carbon footprint of laboratories and research facilities, particularly when analyses are conducted continuously or at extreme temperature ranges.

Solvent usage represents another significant environmental concern. Traditional GPC methods rely heavily on organic solvents such as tetrahydrofuran (THF), chloroform, and toluene, which are known for their toxicity and environmental persistence. The temperature-controlled aspect often necessitates greater solvent volumes to maintain system stability, further exacerbating waste generation. Modern sustainable laboratory practices must address the proper disposal or recycling of these solvents to minimize environmental contamination.

Recent advancements in green chemistry have begun to address these challenges through the development of alternative solvent systems. Water-based mobile phases and bio-derived solvents show promise for certain applications, potentially reducing the environmental impact of temperature-controlled GPC operations. Additionally, solvent recycling systems specifically designed for chromatography laboratories can recover up to 90% of used solvents, significantly reducing waste output and operational costs.

Equipment lifecycle considerations also factor into the sustainability equation. Temperature-controlled GPC systems contain specialized components including heating elements, cooling systems, and precision electronics that may contain rare earth elements or hazardous materials. Manufacturers are increasingly adopting design for environment (DfE) principles, creating modular systems that facilitate repairs, upgrades, and eventual recycling of components rather than complete system replacement.

Laboratory efficiency improvements offer another pathway toward sustainability. Integration of temperature-controlled GPC systems with laboratory automation reduces sample and solvent requirements while maximizing analytical throughput. Advanced software algorithms optimize temperature programs and solvent usage based on specific analytical needs, further reducing resource consumption without compromising analytical quality.

Regulatory frameworks worldwide are evolving to address laboratory sustainability concerns. The implementation of ISO 14001 environmental management systems in analytical laboratories has demonstrated measurable reductions in waste generation and energy consumption. Furthermore, initiatives like My Green Lab certification provide standardized metrics for evaluating and improving the environmental performance of analytical procedures including temperature-controlled GPC methods.

Solvent usage represents another significant environmental concern. Traditional GPC methods rely heavily on organic solvents such as tetrahydrofuran (THF), chloroform, and toluene, which are known for their toxicity and environmental persistence. The temperature-controlled aspect often necessitates greater solvent volumes to maintain system stability, further exacerbating waste generation. Modern sustainable laboratory practices must address the proper disposal or recycling of these solvents to minimize environmental contamination.

Recent advancements in green chemistry have begun to address these challenges through the development of alternative solvent systems. Water-based mobile phases and bio-derived solvents show promise for certain applications, potentially reducing the environmental impact of temperature-controlled GPC operations. Additionally, solvent recycling systems specifically designed for chromatography laboratories can recover up to 90% of used solvents, significantly reducing waste output and operational costs.

Equipment lifecycle considerations also factor into the sustainability equation. Temperature-controlled GPC systems contain specialized components including heating elements, cooling systems, and precision electronics that may contain rare earth elements or hazardous materials. Manufacturers are increasingly adopting design for environment (DfE) principles, creating modular systems that facilitate repairs, upgrades, and eventual recycling of components rather than complete system replacement.

Laboratory efficiency improvements offer another pathway toward sustainability. Integration of temperature-controlled GPC systems with laboratory automation reduces sample and solvent requirements while maximizing analytical throughput. Advanced software algorithms optimize temperature programs and solvent usage based on specific analytical needs, further reducing resource consumption without compromising analytical quality.

Regulatory frameworks worldwide are evolving to address laboratory sustainability concerns. The implementation of ISO 14001 environmental management systems in analytical laboratories has demonstrated measurable reductions in waste generation and energy consumption. Furthermore, initiatives like My Green Lab certification provide standardized metrics for evaluating and improving the environmental performance of analytical procedures including temperature-controlled GPC methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!