Glycerol's Impact on Flavor Development in Fermented Foods

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glycerol in Fermentation

Glycerol, a key byproduct of alcoholic fermentation, plays a crucial role in the development of flavors in fermented foods. This three-carbon polyol is produced by yeast during the fermentation process as a response to osmotic stress and redox imbalance. Its presence significantly influences the sensory characteristics of various fermented products, including wines, beers, and fermented dairy products.

In alcoholic beverages, glycerol contributes to the mouthfeel and perceived sweetness, enhancing the overall sensory experience. It imparts a smooth, viscous texture that is often described as "fullness" or "body" in wines. The concentration of glycerol in wines typically ranges from 4 to 10 g/L, with higher levels generally found in red wines compared to white wines. In beer, glycerol levels are usually lower, ranging from 1 to 3 g/L, but still contribute to the overall flavor profile.

The impact of glycerol on flavor development extends beyond its direct sensory effects. It serves as a precursor for various flavor compounds, participating in complex chemical reactions during fermentation and aging processes. For instance, glycerol can undergo esterification with organic acids, forming glycerol esters that contribute fruity and floral notes to fermented beverages. Additionally, it can be metabolized by certain microorganisms to produce compounds like acrolein, which can impart undesirable flavors if present in high concentrations.

In fermented dairy products, such as yogurt and kefir, glycerol production by lactic acid bacteria contributes to the characteristic flavor profile. It enhances the perception of sweetness and can mask some of the sourness associated with lactic acid production. The interaction between glycerol and milk proteins also influences the texture and mouthfeel of these products.

The production of glycerol during fermentation is influenced by various factors, including yeast strain, fermentation temperature, sugar concentration, and nitrogen availability. Winemakers and brewers can manipulate these parameters to optimize glycerol production and, consequently, the flavor profile of their products. Some yeast strains, particularly those of Saccharomyces cerevisiae, are known for their high glycerol production, making them valuable in the production of full-bodied wines.

Recent research has focused on understanding the genetic and metabolic pathways involved in glycerol production during fermentation. This knowledge has led to the development of genetically modified yeast strains with enhanced glycerol production capabilities, offering new possibilities for flavor modulation in fermented foods. However, the use of such strains remains controversial and is subject to regulatory restrictions in many countries.

In alcoholic beverages, glycerol contributes to the mouthfeel and perceived sweetness, enhancing the overall sensory experience. It imparts a smooth, viscous texture that is often described as "fullness" or "body" in wines. The concentration of glycerol in wines typically ranges from 4 to 10 g/L, with higher levels generally found in red wines compared to white wines. In beer, glycerol levels are usually lower, ranging from 1 to 3 g/L, but still contribute to the overall flavor profile.

The impact of glycerol on flavor development extends beyond its direct sensory effects. It serves as a precursor for various flavor compounds, participating in complex chemical reactions during fermentation and aging processes. For instance, glycerol can undergo esterification with organic acids, forming glycerol esters that contribute fruity and floral notes to fermented beverages. Additionally, it can be metabolized by certain microorganisms to produce compounds like acrolein, which can impart undesirable flavors if present in high concentrations.

In fermented dairy products, such as yogurt and kefir, glycerol production by lactic acid bacteria contributes to the characteristic flavor profile. It enhances the perception of sweetness and can mask some of the sourness associated with lactic acid production. The interaction between glycerol and milk proteins also influences the texture and mouthfeel of these products.

The production of glycerol during fermentation is influenced by various factors, including yeast strain, fermentation temperature, sugar concentration, and nitrogen availability. Winemakers and brewers can manipulate these parameters to optimize glycerol production and, consequently, the flavor profile of their products. Some yeast strains, particularly those of Saccharomyces cerevisiae, are known for their high glycerol production, making them valuable in the production of full-bodied wines.

Recent research has focused on understanding the genetic and metabolic pathways involved in glycerol production during fermentation. This knowledge has led to the development of genetically modified yeast strains with enhanced glycerol production capabilities, offering new possibilities for flavor modulation in fermented foods. However, the use of such strains remains controversial and is subject to regulatory restrictions in many countries.

Market Demand Analysis

The market demand for fermented foods has been steadily increasing in recent years, driven by growing consumer awareness of the health benefits associated with these products. Glycerol, a key component in many fermented foods, plays a crucial role in flavor development, making it a significant factor in market demand analysis.

Consumer preferences for unique and complex flavors have led to a surge in demand for artisanal and craft fermented products. The impact of glycerol on flavor profiles has become a focal point for manufacturers seeking to differentiate their offerings in a competitive market. This trend is particularly evident in the beverage industry, where fermented drinks like kombucha and kefir have gained popularity due to their distinctive taste profiles influenced by glycerol content.

The global fermented food and beverage market is experiencing robust growth, with projections indicating continued expansion in the coming years. This growth is largely attributed to the increasing recognition of the role of fermented foods in gut health and overall well-being. As consumers become more health-conscious, the demand for products with enhanced flavor profiles and potential health benefits continues to rise.

In the dairy sector, glycerol's impact on flavor development in fermented products such as yogurt and cheese has led to increased research and development efforts. Manufacturers are exploring ways to optimize glycerol production during fermentation to achieve desired taste characteristics and meet consumer expectations for premium products.

The meat industry has also seen a growing interest in fermented products, with glycerol playing a crucial role in developing complex flavor profiles in cured and fermented meats. This has opened up new market opportunities for specialty and gourmet meat products, catering to consumers seeking unique culinary experiences.

Asian markets, in particular, have shown significant growth in demand for fermented foods, with traditional products like kimchi and miso gaining popularity globally. The unique flavor profiles of these products, influenced by glycerol content, have contributed to their increasing market share in Western countries.

The rising popularity of plant-based diets has also created new opportunities for fermented products. Manufacturers are exploring the use of glycerol in plant-based fermented foods to enhance flavor profiles and improve texture, meeting the demand for alternatives to traditional dairy and meat products.

As the market for fermented foods continues to expand, there is an increasing need for research and innovation in glycerol management during fermentation processes. This presents opportunities for companies to develop proprietary technologies and formulations that can deliver superior flavor profiles, potentially leading to a competitive advantage in the market.

Consumer preferences for unique and complex flavors have led to a surge in demand for artisanal and craft fermented products. The impact of glycerol on flavor profiles has become a focal point for manufacturers seeking to differentiate their offerings in a competitive market. This trend is particularly evident in the beverage industry, where fermented drinks like kombucha and kefir have gained popularity due to their distinctive taste profiles influenced by glycerol content.

The global fermented food and beverage market is experiencing robust growth, with projections indicating continued expansion in the coming years. This growth is largely attributed to the increasing recognition of the role of fermented foods in gut health and overall well-being. As consumers become more health-conscious, the demand for products with enhanced flavor profiles and potential health benefits continues to rise.

In the dairy sector, glycerol's impact on flavor development in fermented products such as yogurt and cheese has led to increased research and development efforts. Manufacturers are exploring ways to optimize glycerol production during fermentation to achieve desired taste characteristics and meet consumer expectations for premium products.

The meat industry has also seen a growing interest in fermented products, with glycerol playing a crucial role in developing complex flavor profiles in cured and fermented meats. This has opened up new market opportunities for specialty and gourmet meat products, catering to consumers seeking unique culinary experiences.

Asian markets, in particular, have shown significant growth in demand for fermented foods, with traditional products like kimchi and miso gaining popularity globally. The unique flavor profiles of these products, influenced by glycerol content, have contributed to their increasing market share in Western countries.

The rising popularity of plant-based diets has also created new opportunities for fermented products. Manufacturers are exploring the use of glycerol in plant-based fermented foods to enhance flavor profiles and improve texture, meeting the demand for alternatives to traditional dairy and meat products.

As the market for fermented foods continues to expand, there is an increasing need for research and innovation in glycerol management during fermentation processes. This presents opportunities for companies to develop proprietary technologies and formulations that can deliver superior flavor profiles, potentially leading to a competitive advantage in the market.

Current Challenges

The current challenges in understanding glycerol's impact on flavor development in fermented foods are multifaceted and complex. One of the primary obstacles is the intricate interplay between glycerol and other compounds during fermentation processes. Researchers face difficulties in isolating the specific effects of glycerol from those of other metabolites produced by microorganisms.

Another significant challenge lies in the variability of fermentation conditions across different food products. The diverse range of substrates, microbial strains, and environmental factors makes it challenging to establish standardized protocols for studying glycerol's role in flavor formation. This variability often leads to inconsistent results and complicates the development of predictive models.

The lack of advanced analytical techniques specifically tailored for glycerol and its derivatives in complex food matrices poses another hurdle. Current methods may not be sensitive or selective enough to accurately quantify glycerol and its metabolites in the presence of numerous other flavor compounds. This limitation hampers the precise measurement of glycerol's contributions to overall flavor profiles.

Furthermore, the time-dependent nature of flavor development during fermentation presents a challenge in capturing the dynamic role of glycerol. Real-time monitoring of glycerol metabolism and its impact on flavor compounds throughout the fermentation process remains technically challenging and resource-intensive.

The genetic diversity of fermentative microorganisms adds another layer of complexity. Different strains of bacteria and yeast may metabolize glycerol differently, leading to varied flavor outcomes. Unraveling the genetic basis for these differences and their implications for flavor development is a formidable task that requires extensive genomic and metabolomic studies.

Additionally, the sensory evaluation of glycerol's impact on flavor poses challenges due to the subjective nature of taste perception. Developing standardized sensory protocols that can reliably correlate glycerol levels with specific flavor attributes across different food products and consumer populations is an ongoing challenge.

Lastly, the regulatory landscape surrounding the use of glycerol as a flavor enhancer or fermentation additive presents obstacles in translating research findings into practical applications. Navigating the complex regulatory requirements for food additives and processing aids across different jurisdictions can impede the implementation of new technologies or formulations involving glycerol in fermented foods.

Another significant challenge lies in the variability of fermentation conditions across different food products. The diverse range of substrates, microbial strains, and environmental factors makes it challenging to establish standardized protocols for studying glycerol's role in flavor formation. This variability often leads to inconsistent results and complicates the development of predictive models.

The lack of advanced analytical techniques specifically tailored for glycerol and its derivatives in complex food matrices poses another hurdle. Current methods may not be sensitive or selective enough to accurately quantify glycerol and its metabolites in the presence of numerous other flavor compounds. This limitation hampers the precise measurement of glycerol's contributions to overall flavor profiles.

Furthermore, the time-dependent nature of flavor development during fermentation presents a challenge in capturing the dynamic role of glycerol. Real-time monitoring of glycerol metabolism and its impact on flavor compounds throughout the fermentation process remains technically challenging and resource-intensive.

The genetic diversity of fermentative microorganisms adds another layer of complexity. Different strains of bacteria and yeast may metabolize glycerol differently, leading to varied flavor outcomes. Unraveling the genetic basis for these differences and their implications for flavor development is a formidable task that requires extensive genomic and metabolomic studies.

Additionally, the sensory evaluation of glycerol's impact on flavor poses challenges due to the subjective nature of taste perception. Developing standardized sensory protocols that can reliably correlate glycerol levels with specific flavor attributes across different food products and consumer populations is an ongoing challenge.

Lastly, the regulatory landscape surrounding the use of glycerol as a flavor enhancer or fermentation additive presents obstacles in translating research findings into practical applications. Navigating the complex regulatory requirements for food additives and processing aids across different jurisdictions can impede the implementation of new technologies or formulations involving glycerol in fermented foods.

Existing Flavor Solutions

01 Glycerol as a flavor enhancer

Glycerol can be used as a flavor enhancer in various food and beverage applications. It helps to improve the overall taste profile and mouthfeel of products by enhancing sweetness and masking off-flavors. This versatile ingredient can be incorporated into a wide range of formulations to enhance flavor perception.- Glycerol as a flavor enhancer: Glycerol can be used as a flavor enhancer in various food and beverage applications. It helps to improve the overall taste profile and mouthfeel of products by enhancing sweetness and masking off-flavors. This versatile ingredient can be incorporated into a wide range of formulations to enhance flavor perception.

- Glycerol in tobacco products: Glycerol is utilized in tobacco products to improve flavor and moisture retention. It can be added to cigarettes, e-cigarettes, and other tobacco-based products to enhance the smoking experience by providing a smoother taste and reducing harshness. The hygroscopic properties of glycerol also help maintain product freshness.

- Glycerol in fermentation processes: Glycerol plays a role in fermentation processes, particularly in the production of alcoholic beverages. It can be used as a substrate for microbial fermentation or as an additive to improve the flavor profile of fermented products. The presence of glycerol can contribute to the smoothness and body of the final product.

- Glycerol as a solvent for flavors: Glycerol serves as an effective solvent for various flavor compounds. Its ability to dissolve both water-soluble and oil-soluble ingredients makes it useful in creating flavor concentrates and extracts. This property allows for the development of stable and concentrated flavor formulations that can be easily incorporated into food and beverage products.

- Glycerol in flavor encapsulation: Glycerol is used in flavor encapsulation technologies to protect and stabilize volatile flavor compounds. It can be incorporated into various encapsulation systems, such as spray-dried powders or microemulsions, to improve the shelf life and release properties of flavors. This application is particularly useful in the production of long-lasting and controlled-release flavor systems.

02 Glycerol in tobacco products

Glycerol is utilized in tobacco products to improve flavor and moisture retention. It can be added to cigarettes, e-cigarettes, and other tobacco-based products to enhance the smoking experience by providing a smoother taste and reducing harshness. The hygroscopic properties of glycerol also help maintain product freshness.Expand Specific Solutions03 Glycerol in fermentation processes

Glycerol plays a role in fermentation processes, particularly in the production of alcoholic beverages. It can be used as a substrate for microbial fermentation or as an additive to improve the flavor profile of fermented products. The presence of glycerol can contribute to the smoothness and body of the final product.Expand Specific Solutions04 Glycerol as a solvent for flavors

Glycerol serves as an effective solvent for various flavor compounds. Its ability to dissolve both water-soluble and oil-soluble flavors makes it a versatile ingredient in flavor formulations. This property allows for the creation of concentrated flavor solutions that can be easily incorporated into food and beverage products.Expand Specific Solutions05 Glycerol in flavor encapsulation

Glycerol is used in flavor encapsulation technologies to protect and stabilize volatile flavor compounds. It can be incorporated into various encapsulation systems, such as emulsions or spray-dried powders, to improve flavor retention and release. This application is particularly useful in extending the shelf life of flavored products and controlling flavor release during consumption.Expand Specific Solutions

Key Industry Players

The glycerol's impact on flavor development in fermented foods market is in a growth phase, driven by increasing consumer demand for enhanced flavors and natural ingredients. The market size is expanding, with major players like Suntory Holdings, Foshan Haitian, and Yakult Honsha investing in research and development. Technologically, the field is advancing rapidly, with companies like Chr. Hansen and DSM IP Assets leading innovations in fermentation processes and flavor enhancement. Academic institutions such as Tsinghua University and Jiangnan University are contributing to the scientific understanding, while established food companies like CJ CheilJedang and Kewpie Corp. are applying these insights to product development, indicating a maturing but still evolving technological landscape.

Chr. Hansen A/S

Technical Solution: Chr. Hansen has developed a novel approach to leverage glycerol's impact on flavor development in fermented foods through their advanced culture technology. Their method involves using specially selected and genetically optimized bacterial strains that can efficiently convert glycerol into flavor-enhancing compounds during fermentation. The company has also created a unique blend of enzymes that work synergistically with the bacterial cultures to break down complex carbohydrates into glycerol, providing a continuous supply of the substrate throughout the fermentation process[2]. Furthermore, Chr. Hansen has implemented a sophisticated monitoring system that uses real-time sensors to track glycerol levels and adjust fermentation parameters accordingly, ensuring optimal flavor development[4].

Strengths: Tailored bacterial strains and enzyme blends allow for precise control over flavor development. Real-time monitoring system ensures consistency and quality. Weaknesses: The technology may be more expensive to implement compared to traditional fermentation methods, potentially limiting its adoption by smaller producers.

Société des Produits Nestlé SA

Technical Solution: Nestlé has developed a comprehensive approach to utilizing glycerol for flavor enhancement in fermented foods. Their method combines traditional fermentation techniques with advanced biotechnology. The company uses a proprietary blend of probiotic bacteria that have been genetically modified to produce specific enzymes that efficiently convert glycerol into flavor precursors[7]. Nestlé has also developed a controlled release system for glycerol, which allows for a steady supply of the substrate throughout the fermentation process, resulting in more complex and balanced flavor profiles[8]. Additionally, the company employs artificial intelligence algorithms to predict and optimize flavor outcomes based on glycerol concentration and fermentation parameters.

Strengths: Integration of traditional techniques with cutting-edge biotechnology and AI for flavor optimization. Controlled release system allows for precise flavor development. Weaknesses: Use of genetically modified organisms may face regulatory challenges or consumer resistance in some markets.

Glycerol Mechanisms

Improved fermented food and method for producing the same-

PatentActiveJP2021145602A

Innovation

- Adding a specific amount of triacylglycerol with medium-chain fatty acids of 6 to 12 carbon atoms to fermented foods suppresses unpleasant odors and sourness while enhancing umami flavor.

Fermented foods and process for producing the same

PatentInactiveAU2001252569B2

Innovation

- Using a glyceride derivative of conjugated fatty acids, such as monoglyceride, diglyceride, or triglyceride, which are added to the fermentation medium before or after bacterial growth, to create a fermented food base that is non-toxic to bacteria and enhances digestibility, absorption, and sensory properties.

Regulatory Considerations

The regulatory landscape surrounding glycerol's use in fermented foods is complex and multifaceted, requiring careful consideration by manufacturers and food producers. In the United States, the Food and Drug Administration (FDA) classifies glycerol as Generally Recognized as Safe (GRAS) for use in food products, including fermented foods. However, its use is subject to specific limitations and guidelines to ensure consumer safety and product quality.

European Union regulations, governed by the European Food Safety Authority (EFSA), also permit the use of glycerol in food products, including fermented foods. The EU has established specific E-numbers for glycerol and its derivatives, with E422 designating glycerol itself. These regulations stipulate maximum permitted levels and specific applications within food production processes.

Labeling requirements for glycerol in fermented foods vary by jurisdiction. In the US, glycerol must be listed as an ingredient when added to fermented foods, typically under its common name or as "glycerin." The EU mandates similar labeling practices, requiring clear indication of glycerol's presence in the ingredient list.

Regulatory bodies worldwide are increasingly focusing on the potential health impacts of glycerol in fermented foods. Recent studies exploring glycerol's role in flavor development have prompted ongoing reviews of existing regulations. Manufacturers must stay abreast of these evolving guidelines to ensure compliance and maintain consumer trust.

The use of glycerol in organic fermented foods faces additional regulatory scrutiny. Many organic certification bodies restrict or prohibit the use of synthetic glycerol, favoring naturally derived alternatives. This presents challenges for manufacturers seeking to leverage glycerol's flavor-enhancing properties in organic product lines.

International trade of fermented foods containing glycerol is subject to varying regulatory standards across different countries. Exporters must navigate these disparate requirements, often necessitating product reformulations or additional certifications to access global markets. Harmonization efforts are underway to streamline these regulations, but significant variations persist.

Food safety regulations also impact glycerol usage in fermented foods. Manufacturers must implement robust quality control measures to prevent contamination and ensure consistent glycerol concentrations. Regular testing and documentation are typically required to demonstrate compliance with food safety standards and maintain regulatory approvals.

European Union regulations, governed by the European Food Safety Authority (EFSA), also permit the use of glycerol in food products, including fermented foods. The EU has established specific E-numbers for glycerol and its derivatives, with E422 designating glycerol itself. These regulations stipulate maximum permitted levels and specific applications within food production processes.

Labeling requirements for glycerol in fermented foods vary by jurisdiction. In the US, glycerol must be listed as an ingredient when added to fermented foods, typically under its common name or as "glycerin." The EU mandates similar labeling practices, requiring clear indication of glycerol's presence in the ingredient list.

Regulatory bodies worldwide are increasingly focusing on the potential health impacts of glycerol in fermented foods. Recent studies exploring glycerol's role in flavor development have prompted ongoing reviews of existing regulations. Manufacturers must stay abreast of these evolving guidelines to ensure compliance and maintain consumer trust.

The use of glycerol in organic fermented foods faces additional regulatory scrutiny. Many organic certification bodies restrict or prohibit the use of synthetic glycerol, favoring naturally derived alternatives. This presents challenges for manufacturers seeking to leverage glycerol's flavor-enhancing properties in organic product lines.

International trade of fermented foods containing glycerol is subject to varying regulatory standards across different countries. Exporters must navigate these disparate requirements, often necessitating product reformulations or additional certifications to access global markets. Harmonization efforts are underway to streamline these regulations, but significant variations persist.

Food safety regulations also impact glycerol usage in fermented foods. Manufacturers must implement robust quality control measures to prevent contamination and ensure consistent glycerol concentrations. Regular testing and documentation are typically required to demonstrate compliance with food safety standards and maintain regulatory approvals.

Sensory Evaluation Methods

Sensory evaluation methods play a crucial role in assessing the impact of glycerol on flavor development in fermented foods. These methods provide valuable insights into the organoleptic properties of the final products, allowing researchers and food manufacturers to understand how glycerol influences taste, aroma, texture, and overall consumer acceptance.

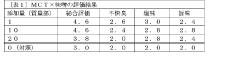

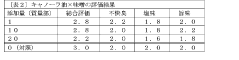

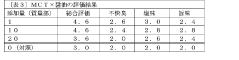

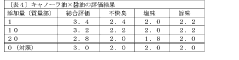

One of the primary sensory evaluation techniques used in this context is descriptive analysis. Trained panelists are employed to identify and quantify specific flavor attributes associated with glycerol-influenced fermentation. These attributes may include sweetness, sourness, bitterness, umami, and various aromatic notes. The intensity of each attribute is typically rated on a standardized scale, providing a comprehensive flavor profile of the fermented food product.

Another commonly used method is the difference test, which aims to determine if consumers can detect differences between samples with varying glycerol concentrations. Triangle tests and duo-trio tests are frequently employed for this purpose. In a triangle test, panelists are presented with three samples, two of which are identical, and asked to identify the odd one out. The duo-trio test involves comparing two samples to a reference sample to determine which one matches the reference.

Preference testing is essential for understanding consumer acceptance of glycerol-influenced fermented foods. Hedonic scales are often used to rate overall liking and specific sensory attributes. This method helps researchers correlate glycerol concentrations with consumer preferences, guiding product development and optimization.

Time-intensity profiling is a dynamic sensory evaluation method that can provide valuable information on how glycerol affects flavor perception over time. Panelists continuously rate the intensity of specific attributes during consumption, allowing researchers to understand the temporal aspects of flavor development and persistence in glycerol-influenced fermented foods.

Sensory evaluation can also be complemented by instrumental analysis techniques to correlate sensory perceptions with measurable chemical compounds. Gas chromatography-mass spectrometry (GC-MS) and high-performance liquid chromatography (HPLC) are commonly used to identify and quantify flavor compounds influenced by glycerol during fermentation.

To ensure the reliability and validity of sensory evaluation results, proper panel selection and training are essential. Panelists should be screened for their sensory acuity and trained to recognize and describe specific flavor attributes associated with glycerol in fermented foods. Regular calibration sessions and the use of reference standards help maintain consistency in panel performance.

Statistical analysis of sensory data is crucial for drawing meaningful conclusions. Analysis of variance (ANOVA), principal component analysis (PCA), and partial least squares regression (PLS) are commonly employed to interpret sensory evaluation results and identify significant relationships between glycerol concentrations and flavor attributes.

One of the primary sensory evaluation techniques used in this context is descriptive analysis. Trained panelists are employed to identify and quantify specific flavor attributes associated with glycerol-influenced fermentation. These attributes may include sweetness, sourness, bitterness, umami, and various aromatic notes. The intensity of each attribute is typically rated on a standardized scale, providing a comprehensive flavor profile of the fermented food product.

Another commonly used method is the difference test, which aims to determine if consumers can detect differences between samples with varying glycerol concentrations. Triangle tests and duo-trio tests are frequently employed for this purpose. In a triangle test, panelists are presented with three samples, two of which are identical, and asked to identify the odd one out. The duo-trio test involves comparing two samples to a reference sample to determine which one matches the reference.

Preference testing is essential for understanding consumer acceptance of glycerol-influenced fermented foods. Hedonic scales are often used to rate overall liking and specific sensory attributes. This method helps researchers correlate glycerol concentrations with consumer preferences, guiding product development and optimization.

Time-intensity profiling is a dynamic sensory evaluation method that can provide valuable information on how glycerol affects flavor perception over time. Panelists continuously rate the intensity of specific attributes during consumption, allowing researchers to understand the temporal aspects of flavor development and persistence in glycerol-influenced fermented foods.

Sensory evaluation can also be complemented by instrumental analysis techniques to correlate sensory perceptions with measurable chemical compounds. Gas chromatography-mass spectrometry (GC-MS) and high-performance liquid chromatography (HPLC) are commonly used to identify and quantify flavor compounds influenced by glycerol during fermentation.

To ensure the reliability and validity of sensory evaluation results, proper panel selection and training are essential. Panelists should be screened for their sensory acuity and trained to recognize and describe specific flavor attributes associated with glycerol in fermented foods. Regular calibration sessions and the use of reference standards help maintain consistency in panel performance.

Statistical analysis of sensory data is crucial for drawing meaningful conclusions. Analysis of variance (ANOVA), principal component analysis (PCA), and partial least squares regression (PLS) are commonly employed to interpret sensory evaluation results and identify significant relationships between glycerol concentrations and flavor attributes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!