Glycerol as a Precursor for Synthesizing Biodegradable Polymers

JUL 23, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glycerol-Based Biopolymer Synthesis: Background and Objectives

Glycerol-based biopolymer synthesis has emerged as a promising field in the quest for sustainable and environmentally friendly materials. The background of this research stems from the increasing global concern over plastic pollution and the urgent need for biodegradable alternatives. Glycerol, a byproduct of biodiesel production, has gained attention as a versatile and abundant precursor for synthesizing biodegradable polymers.

The evolution of this technology can be traced back to the early 2000s when researchers began exploring glycerol's potential in polymer synthesis. Initially, the focus was on utilizing glycerol as a plasticizer or additive in existing polymer formulations. However, as the demand for fully biodegradable materials grew, scientists shifted their attention to developing novel polymers with glycerol as the primary building block.

Over the past two decades, significant advancements have been made in understanding the chemical properties and reactivity of glycerol in polymer synthesis. Researchers have explored various polymerization techniques, including polycondensation, ring-opening polymerization, and enzymatic polymerization, to create a diverse range of glycerol-based polymers with tailored properties.

The primary objective of research in glycerol-based biopolymer synthesis is to develop high-performance, cost-effective, and environmentally friendly materials that can replace conventional petroleum-based plastics. This goal encompasses several key aspects, including optimizing the synthesis processes, enhancing the mechanical and thermal properties of the resulting polymers, and ensuring their complete biodegradability under various environmental conditions.

Another crucial objective is to expand the application scope of glycerol-based biopolymers. While initial research focused on packaging materials and disposable items, recent efforts have been directed towards more specialized applications such as biomedical devices, drug delivery systems, and smart materials with stimuli-responsive properties.

The technology trend in this field is moving towards the development of multi-functional glycerol-based polymers that can address complex challenges in various industries. This includes the creation of composite materials that combine the biodegradability of glycerol-based polymers with enhanced mechanical strength or specific functional properties.

As the research in this area progresses, there is a growing emphasis on scalability and industrial feasibility. The ultimate aim is to transition glycerol-based biopolymer synthesis from laboratory-scale experiments to large-scale production, making these materials economically competitive with traditional plastics while offering superior environmental benefits.

The evolution of this technology can be traced back to the early 2000s when researchers began exploring glycerol's potential in polymer synthesis. Initially, the focus was on utilizing glycerol as a plasticizer or additive in existing polymer formulations. However, as the demand for fully biodegradable materials grew, scientists shifted their attention to developing novel polymers with glycerol as the primary building block.

Over the past two decades, significant advancements have been made in understanding the chemical properties and reactivity of glycerol in polymer synthesis. Researchers have explored various polymerization techniques, including polycondensation, ring-opening polymerization, and enzymatic polymerization, to create a diverse range of glycerol-based polymers with tailored properties.

The primary objective of research in glycerol-based biopolymer synthesis is to develop high-performance, cost-effective, and environmentally friendly materials that can replace conventional petroleum-based plastics. This goal encompasses several key aspects, including optimizing the synthesis processes, enhancing the mechanical and thermal properties of the resulting polymers, and ensuring their complete biodegradability under various environmental conditions.

Another crucial objective is to expand the application scope of glycerol-based biopolymers. While initial research focused on packaging materials and disposable items, recent efforts have been directed towards more specialized applications such as biomedical devices, drug delivery systems, and smart materials with stimuli-responsive properties.

The technology trend in this field is moving towards the development of multi-functional glycerol-based polymers that can address complex challenges in various industries. This includes the creation of composite materials that combine the biodegradability of glycerol-based polymers with enhanced mechanical strength or specific functional properties.

As the research in this area progresses, there is a growing emphasis on scalability and industrial feasibility. The ultimate aim is to transition glycerol-based biopolymer synthesis from laboratory-scale experiments to large-scale production, making these materials economically competitive with traditional plastics while offering superior environmental benefits.

Market Analysis for Biodegradable Polymers

The market for biodegradable polymers derived from glycerol as a precursor is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. This market segment is part of the broader biodegradable plastics industry, which is projected to reach a global value of $7.1 billion by 2025, growing at a CAGR of 9.5% from 2020 to 2025.

The demand for glycerol-based biodegradable polymers is particularly strong in packaging, agriculture, and consumer goods sectors. In the packaging industry, these materials are increasingly used for food packaging, disposable cutlery, and shopping bags, as companies seek to meet consumer preferences for eco-friendly products. The agricultural sector is adopting biodegradable mulch films and plant pots made from these polymers to reduce soil contamination and improve crop yields.

Geographically, Europe leads the market for glycerol-based biodegradable polymers, followed by North America and Asia-Pacific. European countries, with their stringent regulations on single-use plastics and strong environmental policies, are driving the adoption of these materials. The Asia-Pacific region is expected to show the highest growth rate in the coming years, fueled by rapid industrialization, increasing environmental awareness, and government initiatives to promote sustainable materials.

Key market drivers include the abundance of glycerol as a byproduct of biodiesel production, making it a cost-effective and sustainable raw material for polymer synthesis. Additionally, the versatility of glycerol-based polymers in terms of their mechanical properties and biodegradability timeframes makes them suitable for a wide range of applications.

However, the market faces challenges such as higher production costs compared to conventional plastics and the need for improved waste management infrastructure to properly handle biodegradable materials. The performance limitations of some glycerol-based polymers in certain applications also present obstacles to wider adoption.

Despite these challenges, the market outlook remains positive. Ongoing research and development efforts are focused on enhancing the properties of glycerol-based biodegradable polymers and reducing production costs. As sustainability becomes increasingly important to consumers and businesses alike, the demand for these materials is expected to continue its upward trajectory, creating opportunities for innovation and market expansion in the coming years.

The demand for glycerol-based biodegradable polymers is particularly strong in packaging, agriculture, and consumer goods sectors. In the packaging industry, these materials are increasingly used for food packaging, disposable cutlery, and shopping bags, as companies seek to meet consumer preferences for eco-friendly products. The agricultural sector is adopting biodegradable mulch films and plant pots made from these polymers to reduce soil contamination and improve crop yields.

Geographically, Europe leads the market for glycerol-based biodegradable polymers, followed by North America and Asia-Pacific. European countries, with their stringent regulations on single-use plastics and strong environmental policies, are driving the adoption of these materials. The Asia-Pacific region is expected to show the highest growth rate in the coming years, fueled by rapid industrialization, increasing environmental awareness, and government initiatives to promote sustainable materials.

Key market drivers include the abundance of glycerol as a byproduct of biodiesel production, making it a cost-effective and sustainable raw material for polymer synthesis. Additionally, the versatility of glycerol-based polymers in terms of their mechanical properties and biodegradability timeframes makes them suitable for a wide range of applications.

However, the market faces challenges such as higher production costs compared to conventional plastics and the need for improved waste management infrastructure to properly handle biodegradable materials. The performance limitations of some glycerol-based polymers in certain applications also present obstacles to wider adoption.

Despite these challenges, the market outlook remains positive. Ongoing research and development efforts are focused on enhancing the properties of glycerol-based biodegradable polymers and reducing production costs. As sustainability becomes increasingly important to consumers and businesses alike, the demand for these materials is expected to continue its upward trajectory, creating opportunities for innovation and market expansion in the coming years.

Current State and Challenges in Glycerol-Based Polymer Synthesis

The current state of glycerol-based polymer synthesis is characterized by significant advancements and persistent challenges. Glycerol, a byproduct of biodiesel production, has emerged as a promising precursor for biodegradable polymers due to its abundance, low cost, and renewable nature. Researchers have successfully developed various polymerization techniques to utilize glycerol in the synthesis of biodegradable materials.

One of the primary approaches involves the direct polymerization of glycerol through polycondensation reactions. This method has yielded hyperbranched polymers with unique properties, such as high functionality and low viscosity. However, controlling the molecular weight and achieving uniform structures remain challenging due to the multifunctional nature of glycerol.

Another significant development is the use of glycerol-derived monomers in polymer synthesis. For instance, acrylic acid and methacrylic acid derived from glycerol have been employed in the production of biodegradable hydrogels and superabsorbent materials. These polymers show promise in applications ranging from agriculture to personal care products.

The synthesis of polyesters using glycerol as a co-monomer has also gained traction. By combining glycerol with dicarboxylic acids or their derivatives, researchers have created biodegradable polyesters with tunable properties. However, achieving high molecular weights and controlling the degree of branching continue to be significant hurdles in this approach.

One of the major challenges in glycerol-based polymer synthesis is the presence of impurities in crude glycerol obtained from biodiesel production. These impurities can interfere with polymerization reactions, leading to inconsistent product quality. Developing efficient purification methods or polymerization techniques that are tolerant to impurities is an ongoing area of research.

Another critical challenge is the limited reactivity of glycerol's hydroxyl groups under mild conditions. This often necessitates the use of harsh reaction conditions or catalysts, which can compromise the sustainability of the process. Researchers are exploring novel catalytic systems and activation methods to overcome this limitation and enable more environmentally friendly synthesis routes.

The scalability of glycerol-based polymer production also presents a significant challenge. While many promising materials have been developed at the laboratory scale, translating these processes to industrial production remains difficult. Issues such as heat management, reaction kinetics, and product separation need to be addressed to make large-scale production economically viable.

One of the primary approaches involves the direct polymerization of glycerol through polycondensation reactions. This method has yielded hyperbranched polymers with unique properties, such as high functionality and low viscosity. However, controlling the molecular weight and achieving uniform structures remain challenging due to the multifunctional nature of glycerol.

Another significant development is the use of glycerol-derived monomers in polymer synthesis. For instance, acrylic acid and methacrylic acid derived from glycerol have been employed in the production of biodegradable hydrogels and superabsorbent materials. These polymers show promise in applications ranging from agriculture to personal care products.

The synthesis of polyesters using glycerol as a co-monomer has also gained traction. By combining glycerol with dicarboxylic acids or their derivatives, researchers have created biodegradable polyesters with tunable properties. However, achieving high molecular weights and controlling the degree of branching continue to be significant hurdles in this approach.

One of the major challenges in glycerol-based polymer synthesis is the presence of impurities in crude glycerol obtained from biodiesel production. These impurities can interfere with polymerization reactions, leading to inconsistent product quality. Developing efficient purification methods or polymerization techniques that are tolerant to impurities is an ongoing area of research.

Another critical challenge is the limited reactivity of glycerol's hydroxyl groups under mild conditions. This often necessitates the use of harsh reaction conditions or catalysts, which can compromise the sustainability of the process. Researchers are exploring novel catalytic systems and activation methods to overcome this limitation and enable more environmentally friendly synthesis routes.

The scalability of glycerol-based polymer production also presents a significant challenge. While many promising materials have been developed at the laboratory scale, translating these processes to industrial production remains difficult. Issues such as heat management, reaction kinetics, and product separation need to be addressed to make large-scale production economically viable.

Existing Glycerol-to-Polymer Conversion Methods

01 Biodegradability of glycerol in various environments

Glycerol exhibits high biodegradability in different environmental conditions, including soil, water, and activated sludge systems. Its natural occurrence and simple molecular structure contribute to its rapid breakdown by microorganisms, making it an environmentally friendly compound for various applications.- Biodegradability of glycerol in various environments: Glycerol exhibits high biodegradability in different environmental conditions, including soil, water, and industrial waste treatment systems. Its natural occurrence and simple molecular structure contribute to its rapid breakdown by microorganisms, making it an environmentally friendly compound for various applications.

- Use of glycerol in biodegradable polymers and materials: Glycerol is utilized as a key component in the production of biodegradable polymers and materials. Its incorporation enhances the overall biodegradability of the final products, making them more environmentally sustainable. These materials find applications in packaging, disposable items, and other eco-friendly products.

- Glycerol as a substrate for microbial fermentation: Glycerol serves as an excellent substrate for microbial fermentation processes. Its biodegradability allows various microorganisms to utilize it as a carbon source, leading to the production of valuable compounds such as biofuels, organic acids, and other industrial chemicals through biotechnological processes.

- Biodegradation of glycerol-containing waste streams: Industrial and municipal waste streams containing glycerol can be effectively treated through biodegradation processes. Specialized microbial consortia or engineered systems are employed to break down glycerol-rich waste, reducing environmental impact and potentially recovering valuable byproducts.

- Enhancing glycerol biodegradability for specific applications: Research focuses on improving the biodegradability of glycerol for targeted applications. This includes developing novel formulations, modifying glycerol-based compounds, or creating synergistic blends to enhance its breakdown in specific environments or for particular uses, such as in cosmetics, pharmaceuticals, or agricultural products.

02 Use of glycerol in biodegradable polymers and materials

Glycerol is utilized as a key component in the production of biodegradable polymers and materials. Its incorporation enhances the overall biodegradability of the final products, making them more eco-friendly and suitable for applications where environmental impact is a concern.Expand Specific Solutions03 Glycerol as a substrate for microbial growth and fermentation

Microorganisms can effectively utilize glycerol as a carbon source for growth and fermentation processes. This property makes glycerol a valuable substrate in biotechnology applications, including the production of various chemicals and biofuels through microbial conversion.Expand Specific Solutions04 Biodegradation of glycerol-containing waste streams

Industrial and municipal waste streams containing glycerol can be effectively treated through biodegradation processes. Specialized microbial consortia or engineered systems are employed to break down glycerol-rich waste, reducing environmental impact and potentially recovering valuable byproducts.Expand Specific Solutions05 Analytical methods for assessing glycerol biodegradability

Various analytical techniques and standardized methods have been developed to assess the biodegradability of glycerol and glycerol-containing compounds. These methods help in determining the environmental fate of glycerol and its derivatives, ensuring compliance with regulatory requirements and environmental standards.Expand Specific Solutions

Key Players in Biopolymer Research and Production

The research on using glycerol as a precursor for synthesizing biodegradable polymers is in an emerging stage, with growing market potential due to increasing environmental concerns. The global biodegradable polymers market is expanding, driven by sustainability initiatives and regulations. While the technology is still developing, several key players are advancing research in this field. Academic institutions like MIT and Boston University are conducting fundamental research, while companies such as DuPont and Archer-Daniels-Midland are exploring commercial applications. The involvement of both academic and industrial entities indicates a growing interest in this technology, but further development is needed to achieve widespread commercial viability.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have pioneered an innovative approach to synthesizing biodegradable polymers from glycerol. Their method involves a controlled ring-opening polymerization of glycerol-derived cyclic carbonates, resulting in polycarbonates with tailored molecular weights and architectures [2]. The process utilizes metal-free organocatalysts, reducing environmental impact and enhancing biocompatibility [4]. MIT's technology also incorporates the use of supercritical CO2 as a green solvent, further improving the sustainability of the synthesis [6]. The resulting polymers demonstrate excellent biodegradability and can be engineered to have specific mechanical and thermal properties, making them suitable for applications ranging from medical implants to environmentally friendly packaging materials [8].

Strengths: Cutting-edge research, highly customizable polymer properties, and environmentally friendly synthesis. Weaknesses: Potential scalability issues and higher production costs compared to conventional methods.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a large-scale process for synthesizing biodegradable polymers using glycerol as a key precursor. Their approach involves the catalytic conversion of glycerol to acrylic acid, which is then polymerized to form biodegradable polyacrylates [7]. The process utilizes proprietary heterogeneous catalysts that enable high conversion rates and selectivity [9]. Sinopec's technology also incorporates an innovative purification system that allows for the efficient removal of byproducts, resulting in high-quality polymers suitable for various applications, including superabsorbent materials and biodegradable plastics [11]. The company has successfully scaled up this technology to industrial production levels, demonstrating its commercial viability [13].

Strengths: Large-scale production capability, cost-effective process, and integration with existing petrochemical infrastructure. Weaknesses: Potential limitations in polymer diversity and properties compared to more specialized approaches.

Innovative Approaches in Glycerol-Based Polymer Synthesis

Poly(acetal) elastomers

PatentActiveUS20200199283A1

Innovation

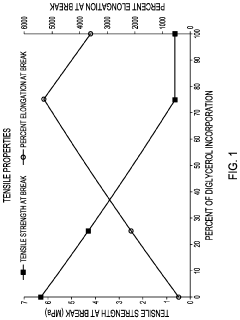

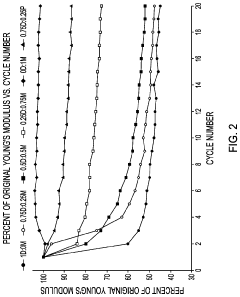

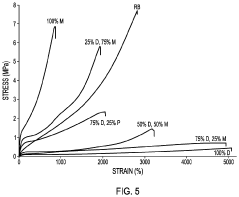

- The development of processable, elastomeric polymers containing poly(cycloacetal) monomer units derived from diglycerol or erythritol, which can be reversibly crosslinked and synthesized using a method involving mixing diglycerol with a compound and treating it with heat or acid to initiate polymerization, allowing for the formation of robust, flexible, and biodegradable materials with higher molecular weights.

Environmental Impact Assessment

The environmental impact assessment of using glycerol as a precursor for synthesizing biodegradable polymers reveals both positive and negative aspects. On the positive side, this approach contributes to the circular economy by utilizing glycerol, a byproduct of biodiesel production, which would otherwise be considered waste. This repurposing of glycerol reduces the overall environmental burden associated with its disposal and helps to maximize resource efficiency.

Furthermore, the resulting biodegradable polymers offer significant environmental benefits compared to traditional petroleum-based plastics. These polymers can decompose naturally in the environment, potentially reducing plastic pollution in ecosystems and landfills. The biodegradation process typically produces non-toxic byproducts, minimizing long-term environmental harm.

However, the production process of these biodegradable polymers still requires energy and resources, which must be considered in the overall environmental impact. The synthesis often involves chemical reactions and processing steps that may generate emissions or require the use of solvents. It is crucial to optimize these processes to minimize energy consumption and reduce the use of potentially harmful chemicals.

Water usage is another factor to consider, as the production of biodegradable polymers from glycerol may require significant amounts of water for reactions and purification steps. Proper water management and recycling systems should be implemented to mitigate this impact.

The sourcing of glycerol is also an important consideration. While using glycerol from biodiesel production is generally positive, increased demand could potentially lead to expanded biodiesel production, which may have its own environmental implications, such as land use changes or competition with food crops.

Life cycle assessments (LCAs) of these biodegradable polymers show that their overall environmental impact is generally lower than that of conventional plastics. However, the specific impact can vary depending on factors such as production methods, transportation, and end-of-life scenarios. It is essential to conduct comprehensive LCAs for each specific polymer and application to ensure a net positive environmental outcome.

In conclusion, while the use of glycerol as a precursor for biodegradable polymers offers promising environmental benefits, careful consideration must be given to the entire production and lifecycle process to maximize positive impacts and minimize potential negative consequences.

Furthermore, the resulting biodegradable polymers offer significant environmental benefits compared to traditional petroleum-based plastics. These polymers can decompose naturally in the environment, potentially reducing plastic pollution in ecosystems and landfills. The biodegradation process typically produces non-toxic byproducts, minimizing long-term environmental harm.

However, the production process of these biodegradable polymers still requires energy and resources, which must be considered in the overall environmental impact. The synthesis often involves chemical reactions and processing steps that may generate emissions or require the use of solvents. It is crucial to optimize these processes to minimize energy consumption and reduce the use of potentially harmful chemicals.

Water usage is another factor to consider, as the production of biodegradable polymers from glycerol may require significant amounts of water for reactions and purification steps. Proper water management and recycling systems should be implemented to mitigate this impact.

The sourcing of glycerol is also an important consideration. While using glycerol from biodiesel production is generally positive, increased demand could potentially lead to expanded biodiesel production, which may have its own environmental implications, such as land use changes or competition with food crops.

Life cycle assessments (LCAs) of these biodegradable polymers show that their overall environmental impact is generally lower than that of conventional plastics. However, the specific impact can vary depending on factors such as production methods, transportation, and end-of-life scenarios. It is essential to conduct comprehensive LCAs for each specific polymer and application to ensure a net positive environmental outcome.

In conclusion, while the use of glycerol as a precursor for biodegradable polymers offers promising environmental benefits, careful consideration must be given to the entire production and lifecycle process to maximize positive impacts and minimize potential negative consequences.

Scalability and Industrial Application Potential

The scalability and industrial application potential of using glycerol as a precursor for synthesizing biodegradable polymers are significant factors in determining the viability of this technology for large-scale production. Glycerol, a byproduct of biodiesel production, is abundant and relatively inexpensive, making it an attractive starting material for polymer synthesis.

From a scalability perspective, the use of glycerol offers several advantages. The availability of glycerol as a renewable resource ensures a consistent supply chain for polymer production. Additionally, the chemical structure of glycerol allows for various polymerization routes, providing flexibility in manufacturing processes. However, challenges in scaling up production include optimizing reaction conditions, maintaining product quality, and managing heat transfer in larger reactors.

Industrial application potential for glycerol-based biodegradable polymers spans multiple sectors. In packaging, these polymers can replace conventional plastics, addressing environmental concerns and meeting growing consumer demand for sustainable products. The medical field presents opportunities for biodegradable implants and drug delivery systems, leveraging the biocompatibility of these materials.

The automotive and construction industries are exploring glycerol-based polymers for lightweight, durable components. These materials offer potential weight reduction in vehicles, contributing to improved fuel efficiency. In construction, they can be used for insulation and temporary structures with reduced environmental impact.

Textile manufacturing is another promising area, where glycerol-based fibers could provide biodegradable alternatives to synthetic fabrics. This aligns with the growing trend of sustainable fashion and circular economy principles in the textile industry.

To realize the full industrial potential, further research is needed to enhance the mechanical properties and processability of glycerol-based polymers. Developing cost-effective production methods and optimizing polymer formulations for specific applications will be crucial for widespread adoption. Collaboration between academic institutions and industry partners can accelerate this process, bridging the gap between laboratory-scale synthesis and commercial production.

Regulatory considerations and standardization of biodegradable polymer specifications will play a vital role in facilitating market acceptance and integration into existing manufacturing processes. As the technology matures, economies of scale are expected to improve, potentially making glycerol-based biodegradable polymers competitive with traditional petroleum-based plastics in terms of cost and performance.

From a scalability perspective, the use of glycerol offers several advantages. The availability of glycerol as a renewable resource ensures a consistent supply chain for polymer production. Additionally, the chemical structure of glycerol allows for various polymerization routes, providing flexibility in manufacturing processes. However, challenges in scaling up production include optimizing reaction conditions, maintaining product quality, and managing heat transfer in larger reactors.

Industrial application potential for glycerol-based biodegradable polymers spans multiple sectors. In packaging, these polymers can replace conventional plastics, addressing environmental concerns and meeting growing consumer demand for sustainable products. The medical field presents opportunities for biodegradable implants and drug delivery systems, leveraging the biocompatibility of these materials.

The automotive and construction industries are exploring glycerol-based polymers for lightweight, durable components. These materials offer potential weight reduction in vehicles, contributing to improved fuel efficiency. In construction, they can be used for insulation and temporary structures with reduced environmental impact.

Textile manufacturing is another promising area, where glycerol-based fibers could provide biodegradable alternatives to synthetic fabrics. This aligns with the growing trend of sustainable fashion and circular economy principles in the textile industry.

To realize the full industrial potential, further research is needed to enhance the mechanical properties and processability of glycerol-based polymers. Developing cost-effective production methods and optimizing polymer formulations for specific applications will be crucial for widespread adoption. Collaboration between academic institutions and industry partners can accelerate this process, bridging the gap between laboratory-scale synthesis and commercial production.

Regulatory considerations and standardization of biodegradable polymer specifications will play a vital role in facilitating market acceptance and integration into existing manufacturing processes. As the technology matures, economies of scale are expected to improve, potentially making glycerol-based biodegradable polymers competitive with traditional petroleum-based plastics in terms of cost and performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!