Role of Glycerol in Improving Low-Temperature Polymer Flexibility

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glycerol and Polymer Flexibility: Background and Objectives

Glycerol, a simple polyol compound, has emerged as a crucial component in enhancing the flexibility of polymers at low temperatures. This technological advancement addresses a longstanding challenge in polymer science and engineering: maintaining material pliability and functionality in cold environments. The evolution of this field traces back to the early days of polymer chemistry, where researchers sought ways to overcome the inherent brittleness of many polymeric materials when exposed to low temperatures.

The primary objective of incorporating glycerol into polymer systems is to improve their low-temperature performance, particularly in terms of flexibility and impact resistance. This goal is driven by the increasing demand for materials that can withstand extreme environmental conditions while maintaining their structural integrity and functional properties. Industries such as automotive, aerospace, and outdoor equipment manufacturing have been at the forefront of pushing for these advancements.

Historically, the use of plasticizers to enhance polymer flexibility has been a common practice. However, traditional plasticizers often suffer from migration issues and can negatively impact other material properties. Glycerol, with its unique molecular structure and compatibility with various polymer types, offers a promising alternative. Its ability to interact with polymer chains through hydrogen bonding and other intermolecular forces provides a mechanism for improving flexibility without compromising other essential material characteristics.

The technological trajectory in this field has been marked by significant milestones. Early research focused on understanding the fundamental interactions between glycerol and polymer matrices. This was followed by experimental studies to optimize glycerol concentrations and develop processing techniques for effective incorporation. Recent years have seen a shift towards more sophisticated approaches, including the development of glycerol-based copolymers and the exploration of synergistic effects with other additives.

Current research aims to expand the application scope of glycerol in polymer flexibility enhancement. This includes investigating its effectiveness in a broader range of polymer types, from commodity plastics to high-performance engineering polymers. Additionally, there is growing interest in understanding the long-term stability and aging characteristics of glycerol-modified polymers, ensuring their reliability in real-world applications over extended periods.

The technological goals in this field extend beyond mere flexibility improvement. Researchers are also exploring how glycerol can contribute to other desirable properties, such as improved barrier characteristics, enhanced biodegradability, and reduced environmental impact. These multifaceted objectives reflect the evolving demands of modern materials science, where performance, sustainability, and cost-effectiveness must be balanced.

The primary objective of incorporating glycerol into polymer systems is to improve their low-temperature performance, particularly in terms of flexibility and impact resistance. This goal is driven by the increasing demand for materials that can withstand extreme environmental conditions while maintaining their structural integrity and functional properties. Industries such as automotive, aerospace, and outdoor equipment manufacturing have been at the forefront of pushing for these advancements.

Historically, the use of plasticizers to enhance polymer flexibility has been a common practice. However, traditional plasticizers often suffer from migration issues and can negatively impact other material properties. Glycerol, with its unique molecular structure and compatibility with various polymer types, offers a promising alternative. Its ability to interact with polymer chains through hydrogen bonding and other intermolecular forces provides a mechanism for improving flexibility without compromising other essential material characteristics.

The technological trajectory in this field has been marked by significant milestones. Early research focused on understanding the fundamental interactions between glycerol and polymer matrices. This was followed by experimental studies to optimize glycerol concentrations and develop processing techniques for effective incorporation. Recent years have seen a shift towards more sophisticated approaches, including the development of glycerol-based copolymers and the exploration of synergistic effects with other additives.

Current research aims to expand the application scope of glycerol in polymer flexibility enhancement. This includes investigating its effectiveness in a broader range of polymer types, from commodity plastics to high-performance engineering polymers. Additionally, there is growing interest in understanding the long-term stability and aging characteristics of glycerol-modified polymers, ensuring their reliability in real-world applications over extended periods.

The technological goals in this field extend beyond mere flexibility improvement. Researchers are also exploring how glycerol can contribute to other desirable properties, such as improved barrier characteristics, enhanced biodegradability, and reduced environmental impact. These multifaceted objectives reflect the evolving demands of modern materials science, where performance, sustainability, and cost-effectiveness must be balanced.

Market Demand for Low-Temperature Flexible Polymers

The market demand for low-temperature flexible polymers has been steadily increasing across various industries due to their unique properties and versatile applications. These materials offer exceptional performance in extreme cold conditions, maintaining flexibility and structural integrity where traditional polymers become brittle and fail. This characteristic makes them invaluable in sectors such as aerospace, automotive, construction, and consumer electronics.

In the aerospace industry, low-temperature flexible polymers are crucial for developing reliable components that can withstand the harsh conditions of high-altitude flight and space exploration. The automotive sector utilizes these materials in seals, gaskets, and hoses that must remain pliable in cold climates to ensure vehicle safety and performance. The construction industry benefits from low-temperature flexible polymers in roofing membranes, insulation, and sealants that can endure freeze-thaw cycles without degradation.

Consumer electronics manufacturers are increasingly incorporating these polymers into wearable devices, outdoor equipment, and portable electronics to enhance durability and functionality in cold environments. The medical field also shows growing interest in low-temperature flexible polymers for developing cold-resistant medical devices and packaging solutions for temperature-sensitive pharmaceuticals.

The global market for low-temperature flexible polymers is driven by the rising demand for high-performance materials in extreme environments. Factors such as technological advancements, increasing industrial applications, and the growing emphasis on energy efficiency contribute to market expansion. Additionally, the push for sustainable and eco-friendly materials has led to research into bio-based low-temperature flexible polymers, opening new market opportunities.

Geographically, North America and Europe lead the market due to their advanced manufacturing capabilities and stringent regulations in industries like automotive and aerospace. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization, increasing automotive production, and expanding electronics manufacturing.

The role of glycerol in improving low-temperature polymer flexibility aligns with the market's demand for enhanced material performance. As a natural, non-toxic plasticizer, glycerol offers a sustainable solution to improve polymer flexibility at low temperatures, addressing both performance requirements and environmental concerns. This innovation could potentially expand the application range of low-temperature flexible polymers, further driving market growth and opening new avenues for product development across various industries.

In the aerospace industry, low-temperature flexible polymers are crucial for developing reliable components that can withstand the harsh conditions of high-altitude flight and space exploration. The automotive sector utilizes these materials in seals, gaskets, and hoses that must remain pliable in cold climates to ensure vehicle safety and performance. The construction industry benefits from low-temperature flexible polymers in roofing membranes, insulation, and sealants that can endure freeze-thaw cycles without degradation.

Consumer electronics manufacturers are increasingly incorporating these polymers into wearable devices, outdoor equipment, and portable electronics to enhance durability and functionality in cold environments. The medical field also shows growing interest in low-temperature flexible polymers for developing cold-resistant medical devices and packaging solutions for temperature-sensitive pharmaceuticals.

The global market for low-temperature flexible polymers is driven by the rising demand for high-performance materials in extreme environments. Factors such as technological advancements, increasing industrial applications, and the growing emphasis on energy efficiency contribute to market expansion. Additionally, the push for sustainable and eco-friendly materials has led to research into bio-based low-temperature flexible polymers, opening new market opportunities.

Geographically, North America and Europe lead the market due to their advanced manufacturing capabilities and stringent regulations in industries like automotive and aerospace. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization, increasing automotive production, and expanding electronics manufacturing.

The role of glycerol in improving low-temperature polymer flexibility aligns with the market's demand for enhanced material performance. As a natural, non-toxic plasticizer, glycerol offers a sustainable solution to improve polymer flexibility at low temperatures, addressing both performance requirements and environmental concerns. This innovation could potentially expand the application range of low-temperature flexible polymers, further driving market growth and opening new avenues for product development across various industries.

Current Challenges in Polymer Flexibility at Low Temperatures

Polymer flexibility at low temperatures remains a significant challenge in materials science and engineering. As temperatures decrease, many polymers experience a transition from a flexible, rubbery state to a rigid, glassy state. This phenomenon, known as the glass transition, severely limits the application of polymers in cold environments, affecting industries ranging from aerospace to consumer electronics.

One of the primary challenges is maintaining the desired mechanical properties of polymers at low temperatures. As the temperature drops, the mobility of polymer chains decreases, leading to increased brittleness and reduced impact resistance. This can result in material failure under stress, compromising the integrity and functionality of polymer-based products.

Another critical issue is the development of micro-cracks and internal stresses within the polymer matrix at low temperatures. These defects can propagate rapidly under load, leading to catastrophic failure. The prevention and mitigation of such defects require innovative approaches in polymer design and processing.

The incorporation of plasticizers, such as glycerol, into polymer systems has shown promise in improving low-temperature flexibility. However, optimizing the concentration and distribution of plasticizers without compromising other material properties remains a complex task. Balancing the trade-offs between flexibility, strength, and thermal stability is a persistent challenge for researchers and engineers.

Furthermore, the heterogeneous nature of many polymer systems complicates the prediction and control of low-temperature behavior. Different components within a polymer blend or composite may respond differently to temperature changes, leading to internal stresses and potential phase separation. Developing models and simulation techniques to accurately predict these complex interactions is an ongoing challenge in the field.

The environmental impact of additives used to improve low-temperature flexibility is also a growing concern. As sustainability becomes increasingly important, there is a need to develop eco-friendly solutions that can enhance polymer performance without negatively impacting the environment or human health.

Lastly, the scalability and cost-effectiveness of solutions for improving low-temperature polymer flexibility present significant hurdles. While laboratory-scale experiments may yield promising results, translating these findings into commercially viable products that can be manufactured at scale remains a challenge. Balancing performance improvements with economic feasibility is crucial for the widespread adoption of new technologies in this field.

One of the primary challenges is maintaining the desired mechanical properties of polymers at low temperatures. As the temperature drops, the mobility of polymer chains decreases, leading to increased brittleness and reduced impact resistance. This can result in material failure under stress, compromising the integrity and functionality of polymer-based products.

Another critical issue is the development of micro-cracks and internal stresses within the polymer matrix at low temperatures. These defects can propagate rapidly under load, leading to catastrophic failure. The prevention and mitigation of such defects require innovative approaches in polymer design and processing.

The incorporation of plasticizers, such as glycerol, into polymer systems has shown promise in improving low-temperature flexibility. However, optimizing the concentration and distribution of plasticizers without compromising other material properties remains a complex task. Balancing the trade-offs between flexibility, strength, and thermal stability is a persistent challenge for researchers and engineers.

Furthermore, the heterogeneous nature of many polymer systems complicates the prediction and control of low-temperature behavior. Different components within a polymer blend or composite may respond differently to temperature changes, leading to internal stresses and potential phase separation. Developing models and simulation techniques to accurately predict these complex interactions is an ongoing challenge in the field.

The environmental impact of additives used to improve low-temperature flexibility is also a growing concern. As sustainability becomes increasingly important, there is a need to develop eco-friendly solutions that can enhance polymer performance without negatively impacting the environment or human health.

Lastly, the scalability and cost-effectiveness of solutions for improving low-temperature polymer flexibility present significant hurdles. While laboratory-scale experiments may yield promising results, translating these findings into commercially viable products that can be manufactured at scale remains a challenge. Balancing performance improvements with economic feasibility is crucial for the widespread adoption of new technologies in this field.

Existing Glycerol Incorporation Methods for Polymers

01 Glycerol as a plasticizer in polymers

Glycerol is used as a plasticizer in various polymer compositions to enhance flexibility and improve mechanical properties. It can be incorporated into biopolymers, synthetic polymers, and composite materials to increase their elasticity and reduce brittleness. The addition of glycerol can also improve the processability of these materials.- Glycerol as a plasticizer in polymers: Glycerol is used as a plasticizer in various polymer compositions to enhance flexibility and improve mechanical properties. It can be incorporated into biopolymers, synthetic polymers, and composite materials to increase their elasticity and reduce brittleness. The addition of glycerol can also improve the processability of these materials.

- Glycerol in pharmaceutical formulations: Glycerol is utilized in pharmaceutical formulations to enhance the flexibility and stability of drug delivery systems. It can be used in the preparation of soft gelatin capsules, suppositories, and topical formulations. The addition of glycerol can improve the plasticity of these formulations, making them easier to manufacture and administer.

- Glycerol in personal care products: Glycerol is widely used in personal care products to improve the flexibility and moisturizing properties of formulations. It can be incorporated into skincare products, hair care products, and cosmetics to enhance their texture and performance. The hygroscopic nature of glycerol helps to maintain product flexibility and prevent drying out.

- Glycerol in food applications: Glycerol is employed in food applications to improve the flexibility and texture of various products. It can be used as a humectant in baked goods, confectionery, and processed foods to maintain moisture content and prevent hardening. Glycerol also contributes to the flexibility of edible films and coatings used in food packaging.

- Glycerol in industrial applications: Glycerol finds applications in various industrial processes where flexibility is required. It can be used as a plasticizer in the production of flexible plastics, rubber compounds, and adhesives. Glycerol is also utilized in the manufacturing of flexible polyurethane foams and as a component in lubricants and coolants to improve their performance characteristics.

02 Glycerol in pharmaceutical formulations

Glycerol is utilized in pharmaceutical formulations to enhance the flexibility and stability of drug delivery systems. It can be used in the preparation of soft gelatin capsules, suppositories, and topical formulations. The addition of glycerol can improve the plasticity of these formulations, making them easier to manufacture and administer.Expand Specific Solutions03 Glycerol in personal care products

Glycerol is widely used in personal care products to improve the flexibility and moisturizing properties of formulations. It can be incorporated into skincare products, hair care products, and cosmetics to enhance their texture, spreadability, and skin feel. The hygroscopic nature of glycerol helps to maintain product flexibility and prevent drying out.Expand Specific Solutions04 Glycerol in food applications

Glycerol is employed in food applications to improve the flexibility and texture of various products. It can be used as a humectant in baked goods, confectionery, and processed foods to maintain moisture content and prevent hardening. Glycerol also contributes to the flexibility of edible films and coatings used in food packaging.Expand Specific Solutions05 Glycerol in industrial applications

Glycerol finds use in various industrial applications where flexibility is required. It can be used as a plasticizer in the production of flexible plastics, rubber compounds, and adhesives. Glycerol is also employed in the manufacturing of flexible films, coatings, and lubricants, where it imparts softness and pliability to the final products.Expand Specific Solutions

Key Players in Glycerol-Based Polymer Additives

The role of glycerol in improving low-temperature polymer flexibility is an emerging field with significant potential. The market is in its early growth stage, driven by increasing demand for cold-resistant materials in various industries. While the market size is still relatively small, it is expected to expand rapidly as research progresses. Technologically, the field is advancing, with companies like Mitsui Chemicals, BASF, and Covestro leading innovation. These firms are developing novel formulations and processes to enhance polymer flexibility at low temperatures using glycerol. However, the technology is not yet fully mature, and ongoing research is focused on optimizing glycerol incorporation methods and understanding long-term material performance.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has developed an advanced glycerol-based technology for enhancing low-temperature polymer flexibility, particularly focusing on polyolefins and engineering plastics. Their approach involves the creation of glycerol-derived copolymers that can be blended with various polymer systems. These copolymers act as internal plasticizers and nucleating agents, simultaneously improving flexibility and controlling crystallization behavior at low temperatures[1]. Mitsui's research has shown that their glycerol-based additives can improve the low-temperature impact strength of polymers by up to 150% while maintaining excellent dimensional stability[3]. The company has also developed a proprietary process for grafting glycerol-based molecules onto polymer backbones, creating hybrid materials with enhanced low-temperature properties[5]. Mitsui's technology has been successfully applied in various applications, including automotive parts, outdoor equipment, and flexible packaging, demonstrating its versatility across different industries[7].

Strengths: Dual functionality as plasticizer and nucleating agent, significant improvement in low-temperature impact strength, and wide range of applications. Weaknesses: Potential for increased material complexity and the need for specialized processing techniques.

The Lubrizol Corp.

Technical Solution: Lubrizol has made significant strides in improving low-temperature polymer flexibility through their glycerol-based technology. Their approach involves the development of complex glycerol derivatives that function as both plasticizers and polymer modifiers. These derivatives are designed to interact with the polymer matrix at multiple points, effectively disrupting crystallization and improving chain mobility at low temperatures[2]. Lubrizol's research has demonstrated that their glycerol-based additives can reduce the brittle-to-ductile transition temperature of polymers by up to 30°C[4]. The company has also developed a range of glycerol-based viscosity modifiers that not only improve low-temperature flexibility but also enhance the overall performance of polymer systems across a wide temperature range[6]. Lubrizol's technology has found particular success in the automotive and industrial sectors, where low-temperature performance is critical[8].

Strengths: Multifunctional additives improving both flexibility and overall performance, significant reduction in brittle-to-ductile transition temperature. Weaknesses: Complexity of formulation may require specialized knowledge, potential for increased production costs.

Glycerol's Mechanism in Enhancing Polymer Flexibility

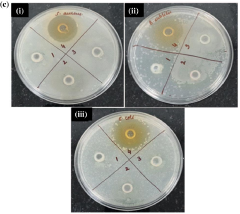

Process for the production of guar gum based novel nanocomposites impregnated with nanocellulose

PatentUndeterminedIN202211000126A

Innovation

- A crosslinked guar gum/nanocellulose composite film is developed using polyethylene glycol and glutaraldehyde, optimizing process parameters to enhance tensile strength and water vapor permeability, and incorporating nanocellulose to improve mechanical and antibacterial properties.

Improved polymer dispersions

PatentInactiveEP2476727A1

Innovation

- The development of polymer dispersions comprising polyolefins, dispersing components, mineral oil, and glycerol esters derived from unsaturated carboxylic acids, which allow for high polyolefin content, low viscosity, and improved low-temperature stability, enabling easier production and adjustment of viscosity.

Environmental Impact of Glycerol in Polymer Production

The incorporation of glycerol in polymer production has significant environmental implications that warrant careful consideration. Glycerol, a byproduct of biodiesel production, offers a sustainable alternative to petroleum-based plasticizers traditionally used in polymer manufacturing. Its utilization contributes to the circular economy by repurposing a waste product, thereby reducing the overall environmental footprint of polymer production.

One of the primary environmental benefits of using glycerol in polymer production is the reduction of greenhouse gas emissions. Unlike conventional petroleum-derived plasticizers, glycerol is derived from renewable resources, primarily vegetable oils and animal fats. This shift towards bio-based materials aligns with global efforts to mitigate climate change and reduce dependency on fossil fuels. Studies have shown that the carbon footprint of glycerol-based polymers can be significantly lower than their petroleum-based counterparts, with some estimates suggesting up to a 40% reduction in CO2 emissions.

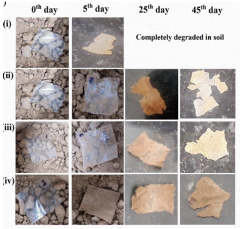

Furthermore, the biodegradability of glycerol-enhanced polymers presents a potential solution to the persistent problem of plastic waste accumulation in the environment. While the rate of biodegradation varies depending on the specific polymer formulation and environmental conditions, glycerol-containing polymers generally exhibit improved degradability compared to conventional plastics. This characteristic can help reduce the long-term environmental impact of plastic products, particularly in marine ecosystems where plastic pollution poses a severe threat to wildlife.

However, the environmental impact of glycerol in polymer production is not without challenges. The increased demand for glycerol as a polymer additive could potentially lead to expanded biodiesel production, which may have indirect land-use change effects. This could result in deforestation or the conversion of food crops to biofuel crops, potentially offsetting some of the environmental benefits. Additionally, the purification process of crude glycerol from biodiesel production can be energy-intensive and may involve the use of chemicals that require proper handling and disposal.

Water consumption and wastewater management are also important considerations in the environmental assessment of glycerol-based polymer production. While glycerol itself is non-toxic and water-soluble, the manufacturing processes may require significant water usage for purification and polymer synthesis. Proper wastewater treatment systems must be implemented to prevent the release of organic compounds and other pollutants into aquatic ecosystems.

In terms of end-of-life management, glycerol-enhanced polymers offer improved recyclability options. The presence of glycerol can enhance the thermal and mechanical properties of recycled polymers, potentially increasing the number of recycling cycles a material can undergo before quality degradation becomes significant. This extended lifecycle contributes to resource conservation and waste reduction, aligning with principles of sustainable materials management.

One of the primary environmental benefits of using glycerol in polymer production is the reduction of greenhouse gas emissions. Unlike conventional petroleum-derived plasticizers, glycerol is derived from renewable resources, primarily vegetable oils and animal fats. This shift towards bio-based materials aligns with global efforts to mitigate climate change and reduce dependency on fossil fuels. Studies have shown that the carbon footprint of glycerol-based polymers can be significantly lower than their petroleum-based counterparts, with some estimates suggesting up to a 40% reduction in CO2 emissions.

Furthermore, the biodegradability of glycerol-enhanced polymers presents a potential solution to the persistent problem of plastic waste accumulation in the environment. While the rate of biodegradation varies depending on the specific polymer formulation and environmental conditions, glycerol-containing polymers generally exhibit improved degradability compared to conventional plastics. This characteristic can help reduce the long-term environmental impact of plastic products, particularly in marine ecosystems where plastic pollution poses a severe threat to wildlife.

However, the environmental impact of glycerol in polymer production is not without challenges. The increased demand for glycerol as a polymer additive could potentially lead to expanded biodiesel production, which may have indirect land-use change effects. This could result in deforestation or the conversion of food crops to biofuel crops, potentially offsetting some of the environmental benefits. Additionally, the purification process of crude glycerol from biodiesel production can be energy-intensive and may involve the use of chemicals that require proper handling and disposal.

Water consumption and wastewater management are also important considerations in the environmental assessment of glycerol-based polymer production. While glycerol itself is non-toxic and water-soluble, the manufacturing processes may require significant water usage for purification and polymer synthesis. Proper wastewater treatment systems must be implemented to prevent the release of organic compounds and other pollutants into aquatic ecosystems.

In terms of end-of-life management, glycerol-enhanced polymers offer improved recyclability options. The presence of glycerol can enhance the thermal and mechanical properties of recycled polymers, potentially increasing the number of recycling cycles a material can undergo before quality degradation becomes significant. This extended lifecycle contributes to resource conservation and waste reduction, aligning with principles of sustainable materials management.

Regulatory Framework for Glycerol Use in Polymers

The regulatory framework for glycerol use in polymers is a complex and evolving landscape that significantly impacts the development and application of glycerol-enhanced polymer products. At the global level, organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) have established guidelines for the use of glycerol in various polymer applications. These standards often focus on safety, performance, and environmental considerations.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating glycerol use in polymers, particularly for food contact materials and medical devices. The FDA's regulations, outlined in the Code of Federal Regulations (CFR), specify the permissible levels and conditions for glycerol use in different polymer applications. Similarly, the European Union has established comprehensive regulations through the European Chemicals Agency (ECHA) and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework.

Environmental regulations also significantly influence the use of glycerol in polymers. Many countries have implemented policies to promote the use of bio-based materials, including glycerol derived from renewable sources. For instance, the EU's Circular Economy Action Plan encourages the development of sustainable plastics, which may include glycerol-enhanced polymers with improved low-temperature flexibility.

The regulatory landscape also addresses the end-of-life considerations for glycerol-containing polymers. Waste management regulations, such as the EU's Waste Framework Directive, impact the disposal and recycling of these materials. Manufacturers must consider these regulations when developing and marketing glycerol-enhanced polymer products to ensure compliance with waste management and recycling requirements.

Safety regulations are another critical aspect of the regulatory framework. Occupational safety and health administrations in various countries have established guidelines for handling glycerol and its polymer composites in industrial settings. These regulations often cover aspects such as exposure limits, personal protective equipment requirements, and storage conditions.

As the use of glycerol in improving low-temperature polymer flexibility continues to advance, regulatory bodies are likely to update their frameworks to address new applications and potential risks. This dynamic regulatory environment requires manufacturers and researchers to stay informed about evolving standards and adapt their development processes accordingly. Compliance with these regulations is essential not only for legal reasons but also for ensuring product safety, environmental sustainability, and market acceptance of glycerol-enhanced polymer products.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating glycerol use in polymers, particularly for food contact materials and medical devices. The FDA's regulations, outlined in the Code of Federal Regulations (CFR), specify the permissible levels and conditions for glycerol use in different polymer applications. Similarly, the European Union has established comprehensive regulations through the European Chemicals Agency (ECHA) and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) framework.

Environmental regulations also significantly influence the use of glycerol in polymers. Many countries have implemented policies to promote the use of bio-based materials, including glycerol derived from renewable sources. For instance, the EU's Circular Economy Action Plan encourages the development of sustainable plastics, which may include glycerol-enhanced polymers with improved low-temperature flexibility.

The regulatory landscape also addresses the end-of-life considerations for glycerol-containing polymers. Waste management regulations, such as the EU's Waste Framework Directive, impact the disposal and recycling of these materials. Manufacturers must consider these regulations when developing and marketing glycerol-enhanced polymer products to ensure compliance with waste management and recycling requirements.

Safety regulations are another critical aspect of the regulatory framework. Occupational safety and health administrations in various countries have established guidelines for handling glycerol and its polymer composites in industrial settings. These regulations often cover aspects such as exposure limits, personal protective equipment requirements, and storage conditions.

As the use of glycerol in improving low-temperature polymer flexibility continues to advance, regulatory bodies are likely to update their frameworks to address new applications and potential risks. This dynamic regulatory environment requires manufacturers and researchers to stay informed about evolving standards and adapt their development processes accordingly. Compliance with these regulations is essential not only for legal reasons but also for ensuring product safety, environmental sustainability, and market acceptance of glycerol-enhanced polymer products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!