Investigating Glycerol's Role in Lab-on-a-Chip Devices

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glycerol in LOC: Background and Objectives

Lab-on-a-Chip (LOC) devices have emerged as a revolutionary technology in the field of microfluidics, offering miniaturized platforms for various analytical and diagnostic applications. These devices integrate multiple laboratory functions onto a single chip, enabling rapid, efficient, and cost-effective analysis of small sample volumes. The development of LOC technology has been driven by the need for portable, user-friendly, and high-throughput analytical tools in various sectors, including healthcare, environmental monitoring, and biomedical research.

Glycerol, a simple polyol compound, has played a significant role in the evolution of LOC devices. Its unique physicochemical properties, including high viscosity, low volatility, and excellent biocompatibility, have made it an attractive component in microfluidic systems. The incorporation of glycerol in LOC devices has been explored for various purposes, such as improving fluid control, enhancing sample preservation, and optimizing reaction conditions.

The primary objective of investigating glycerol's role in LOC devices is to harness its potential for enhancing the performance and functionality of these miniaturized systems. Researchers aim to exploit glycerol's properties to overcome existing limitations in microfluidic technologies and expand the range of applications for LOC devices. By understanding the interactions between glycerol and other components within the microfluidic environment, scientists seek to develop more robust and versatile LOC platforms.

One of the key areas of interest is the use of glycerol as a viscosity modifier in microfluidic channels. By adjusting the concentration of glycerol in the fluid medium, researchers can fine-tune the flow characteristics within the device, enabling precise control over sample movement and reaction kinetics. This capability is particularly valuable in applications requiring controlled mixing, separation, or particle manipulation.

Another important aspect of glycerol's role in LOC devices is its potential as a stabilizing agent for biological samples. The hygroscopic nature of glycerol helps maintain sample hydration, preserving the integrity of sensitive biomolecules during storage and analysis. This property is especially beneficial in point-of-care diagnostic devices, where sample stability is crucial for accurate results.

Furthermore, the investigation of glycerol in LOC devices aims to explore its impact on surface tension and wetting behavior within microfluidic channels. Understanding these interactions can lead to improved design strategies for channel geometries and surface modifications, ultimately enhancing the overall performance of LOC systems.

As the field of microfluidics continues to advance, the exploration of glycerol's role in LOC devices is expected to contribute to the development of next-generation analytical platforms. By leveraging the unique properties of glycerol, researchers aspire to create more efficient, reliable, and versatile LOC devices capable of addressing complex analytical challenges across various scientific disciplines.

Glycerol, a simple polyol compound, has played a significant role in the evolution of LOC devices. Its unique physicochemical properties, including high viscosity, low volatility, and excellent biocompatibility, have made it an attractive component in microfluidic systems. The incorporation of glycerol in LOC devices has been explored for various purposes, such as improving fluid control, enhancing sample preservation, and optimizing reaction conditions.

The primary objective of investigating glycerol's role in LOC devices is to harness its potential for enhancing the performance and functionality of these miniaturized systems. Researchers aim to exploit glycerol's properties to overcome existing limitations in microfluidic technologies and expand the range of applications for LOC devices. By understanding the interactions between glycerol and other components within the microfluidic environment, scientists seek to develop more robust and versatile LOC platforms.

One of the key areas of interest is the use of glycerol as a viscosity modifier in microfluidic channels. By adjusting the concentration of glycerol in the fluid medium, researchers can fine-tune the flow characteristics within the device, enabling precise control over sample movement and reaction kinetics. This capability is particularly valuable in applications requiring controlled mixing, separation, or particle manipulation.

Another important aspect of glycerol's role in LOC devices is its potential as a stabilizing agent for biological samples. The hygroscopic nature of glycerol helps maintain sample hydration, preserving the integrity of sensitive biomolecules during storage and analysis. This property is especially beneficial in point-of-care diagnostic devices, where sample stability is crucial for accurate results.

Furthermore, the investigation of glycerol in LOC devices aims to explore its impact on surface tension and wetting behavior within microfluidic channels. Understanding these interactions can lead to improved design strategies for channel geometries and surface modifications, ultimately enhancing the overall performance of LOC systems.

As the field of microfluidics continues to advance, the exploration of glycerol's role in LOC devices is expected to contribute to the development of next-generation analytical platforms. By leveraging the unique properties of glycerol, researchers aspire to create more efficient, reliable, and versatile LOC devices capable of addressing complex analytical challenges across various scientific disciplines.

Market Analysis for Glycerol-Enhanced LOC Devices

The market for glycerol-enhanced Lab-on-a-Chip (LOC) devices is experiencing significant growth, driven by the increasing demand for point-of-care diagnostics and miniaturized analytical systems. Glycerol's unique properties, including its viscosity and biocompatibility, make it an attractive component for LOC devices, particularly in microfluidic applications.

The global LOC market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 10% over the next five years. This growth is fueled by advancements in microfluidics, nanotechnology, and biosensors, as well as the rising need for rapid, portable, and cost-effective diagnostic solutions. Glycerol-enhanced LOC devices are poised to capture a substantial share of this market due to their improved performance and versatility.

Key market segments for glycerol-enhanced LOC devices include healthcare, environmental monitoring, and food safety. In the healthcare sector, these devices are particularly valuable for point-of-care diagnostics, drug discovery, and personalized medicine applications. The ability of glycerol to stabilize biomolecules and enhance fluid control in microchannels makes it especially suitable for these applications.

Geographically, North America and Europe currently dominate the LOC market, with Asia-Pacific emerging as the fastest-growing region. This growth is attributed to increasing healthcare expenditure, rising awareness of personalized medicine, and government initiatives to promote advanced diagnostic technologies.

Market trends indicate a shift towards integrated, multifunctional LOC devices that can perform complex analytical tasks. Glycerol's role in these devices is expected to expand, as it enables better control over fluid dynamics and improves the overall efficiency of microfluidic systems. Additionally, there is a growing interest in sustainable and eco-friendly LOC devices, where glycerol, being a biodegradable compound, offers a significant advantage.

Challenges in the market include the need for standardization of LOC devices and the complexity of integrating multiple functions into a single chip. However, ongoing research and development efforts are addressing these issues, with glycerol playing a crucial role in overcoming some of the technical barriers.

The competitive landscape is characterized by a mix of established players and innovative startups. Major companies are investing heavily in R&D to develop advanced LOC technologies, with glycerol-based solutions gaining traction. Collaborations between academic institutions and industry partners are also driving innovation in this field.

In conclusion, the market for glycerol-enhanced LOC devices shows strong growth potential, driven by technological advancements and increasing demand across various sectors. As research continues to uncover new applications for glycerol in microfluidic systems, its role in shaping the future of LOC devices is expected to become even more significant.

The global LOC market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 10% over the next five years. This growth is fueled by advancements in microfluidics, nanotechnology, and biosensors, as well as the rising need for rapid, portable, and cost-effective diagnostic solutions. Glycerol-enhanced LOC devices are poised to capture a substantial share of this market due to their improved performance and versatility.

Key market segments for glycerol-enhanced LOC devices include healthcare, environmental monitoring, and food safety. In the healthcare sector, these devices are particularly valuable for point-of-care diagnostics, drug discovery, and personalized medicine applications. The ability of glycerol to stabilize biomolecules and enhance fluid control in microchannels makes it especially suitable for these applications.

Geographically, North America and Europe currently dominate the LOC market, with Asia-Pacific emerging as the fastest-growing region. This growth is attributed to increasing healthcare expenditure, rising awareness of personalized medicine, and government initiatives to promote advanced diagnostic technologies.

Market trends indicate a shift towards integrated, multifunctional LOC devices that can perform complex analytical tasks. Glycerol's role in these devices is expected to expand, as it enables better control over fluid dynamics and improves the overall efficiency of microfluidic systems. Additionally, there is a growing interest in sustainable and eco-friendly LOC devices, where glycerol, being a biodegradable compound, offers a significant advantage.

Challenges in the market include the need for standardization of LOC devices and the complexity of integrating multiple functions into a single chip. However, ongoing research and development efforts are addressing these issues, with glycerol playing a crucial role in overcoming some of the technical barriers.

The competitive landscape is characterized by a mix of established players and innovative startups. Major companies are investing heavily in R&D to develop advanced LOC technologies, with glycerol-based solutions gaining traction. Collaborations between academic institutions and industry partners are also driving innovation in this field.

In conclusion, the market for glycerol-enhanced LOC devices shows strong growth potential, driven by technological advancements and increasing demand across various sectors. As research continues to uncover new applications for glycerol in microfluidic systems, its role in shaping the future of LOC devices is expected to become even more significant.

Current Challenges in Glycerol Integration

The integration of glycerol in lab-on-a-chip devices presents several significant challenges that researchers and engineers must address. One of the primary obstacles is the precise control of glycerol's viscosity within microfluidic channels. Glycerol's viscosity is highly sensitive to temperature fluctuations, making it difficult to maintain consistent flow rates and mixing ratios in miniaturized systems. This variability can lead to inconsistent results and reduced reproducibility in experiments.

Another challenge lies in the compatibility of glycerol with various materials used in lab-on-a-chip fabrication. While glycerol is generally inert, its interactions with certain polymers and surface coatings can lead to unwanted chemical reactions or alterations in the device's physical properties. This necessitates careful selection of materials and thorough testing to ensure long-term stability and functionality of the devices.

The hygroscopic nature of glycerol poses additional complications. Its tendency to absorb moisture from the environment can alter its concentration and, consequently, its physical properties. This characteristic makes it challenging to maintain precise glycerol concentrations over extended periods, potentially affecting the reliability of long-term experiments or stored devices.

Bubble formation is another critical issue when integrating glycerol into microfluidic systems. The high viscosity of glycerol can trap air bubbles during fluid handling and device assembly. These bubbles can disrupt fluid flow, interfere with optical measurements, and compromise the overall performance of the lab-on-a-chip device. Developing effective degassing techniques and optimizing channel geometries to minimize bubble entrapment are ongoing areas of research.

Furthermore, the integration of glycerol often requires specialized pumping and fluid handling systems. Traditional syringe pumps may struggle to deliver consistent flow rates due to the high viscosity of glycerol solutions. This necessitates the development of more robust pumping mechanisms or the use of pressure-driven flow systems, which can add complexity and cost to the overall device design.

Lastly, the optical properties of glycerol present both opportunities and challenges. While its refractive index can be advantageous for certain applications, such as index matching in optical detection systems, it can also introduce distortions or aberrations in imaging-based assays. Researchers must carefully consider these optical effects when designing experiments and interpreting results in glycerol-containing microfluidic devices.

Addressing these challenges requires interdisciplinary approaches, combining expertise in fluid dynamics, materials science, and microfluidic engineering. Ongoing research efforts focus on developing novel materials, optimizing device geometries, and creating advanced control systems to harness the full potential of glycerol in lab-on-a-chip applications while mitigating its inherent limitations.

Another challenge lies in the compatibility of glycerol with various materials used in lab-on-a-chip fabrication. While glycerol is generally inert, its interactions with certain polymers and surface coatings can lead to unwanted chemical reactions or alterations in the device's physical properties. This necessitates careful selection of materials and thorough testing to ensure long-term stability and functionality of the devices.

The hygroscopic nature of glycerol poses additional complications. Its tendency to absorb moisture from the environment can alter its concentration and, consequently, its physical properties. This characteristic makes it challenging to maintain precise glycerol concentrations over extended periods, potentially affecting the reliability of long-term experiments or stored devices.

Bubble formation is another critical issue when integrating glycerol into microfluidic systems. The high viscosity of glycerol can trap air bubbles during fluid handling and device assembly. These bubbles can disrupt fluid flow, interfere with optical measurements, and compromise the overall performance of the lab-on-a-chip device. Developing effective degassing techniques and optimizing channel geometries to minimize bubble entrapment are ongoing areas of research.

Furthermore, the integration of glycerol often requires specialized pumping and fluid handling systems. Traditional syringe pumps may struggle to deliver consistent flow rates due to the high viscosity of glycerol solutions. This necessitates the development of more robust pumping mechanisms or the use of pressure-driven flow systems, which can add complexity and cost to the overall device design.

Lastly, the optical properties of glycerol present both opportunities and challenges. While its refractive index can be advantageous for certain applications, such as index matching in optical detection systems, it can also introduce distortions or aberrations in imaging-based assays. Researchers must carefully consider these optical effects when designing experiments and interpreting results in glycerol-containing microfluidic devices.

Addressing these challenges requires interdisciplinary approaches, combining expertise in fluid dynamics, materials science, and microfluidic engineering. Ongoing research efforts focus on developing novel materials, optimizing device geometries, and creating advanced control systems to harness the full potential of glycerol in lab-on-a-chip applications while mitigating its inherent limitations.

Existing Glycerol Incorporation Techniques

01 Production of glycerol from renewable resources

Methods for producing glycerol from renewable resources, such as biomass or plant-based materials. These processes often involve fermentation or chemical conversion of organic matter to yield glycerol as a valuable byproduct or main product.- Production of glycerol from renewable resources: Methods for producing glycerol from renewable resources, such as biomass or plant-based materials, have been developed. These processes often involve fermentation or chemical conversion of organic matter to yield glycerol as a valuable byproduct or main product.

- Purification and refining of glycerol: Various techniques have been invented for purifying and refining crude glycerol obtained from industrial processes. These methods aim to remove impurities and increase the purity of glycerol for use in different applications, including pharmaceuticals and personal care products.

- Use of glycerol in cosmetic and personal care formulations: Glycerol is widely used in cosmetic and personal care products due to its moisturizing and emollient properties. It is incorporated into various formulations such as lotions, creams, and other skincare products to improve skin hydration and texture.

- Glycerol as a platform chemical for industrial applications: Glycerol serves as a versatile platform chemical for the production of various industrial compounds. It can be converted into value-added products through chemical or biological processes, finding applications in sectors such as polymers, fuels, and fine chemicals.

- Glycerol in pharmaceutical and medical applications: Glycerol has important uses in pharmaceutical and medical fields. It is employed in drug formulations, as a solvent or excipient, and in medical devices. Its properties make it suitable for various therapeutic applications and as a component in medical preparations.

02 Purification and refining of glycerol

Techniques for purifying and refining crude glycerol to obtain high-quality glycerol suitable for various industrial applications. These methods may include distillation, filtration, or other separation processes to remove impurities and increase glycerol concentration.Expand Specific Solutions03 Glycerol as a platform chemical

Utilization of glycerol as a versatile platform chemical for the synthesis of various value-added products. This includes the conversion of glycerol into other chemicals through catalytic processes, oxidation, or other chemical reactions.Expand Specific Solutions04 Glycerol in biodiesel production

The role of glycerol in biodiesel production processes, including its generation as a byproduct and potential uses or treatments. This may involve methods for handling excess glycerol or integrating it back into the production cycle.Expand Specific Solutions05 Industrial applications of glycerol

Various industrial applications of glycerol, including its use in pharmaceuticals, cosmetics, food products, and as a chemical intermediate. This covers formulations, processes, and products that incorporate glycerol for its unique properties.Expand Specific Solutions

Key Players in Glycerol-Based LOC Development

The investigation of glycerol's role in Lab-on-a-Chip devices is in a developing stage, with the market showing promising growth potential. The technology is advancing rapidly, driven by collaborations between academic institutions and industry players. Key companies like HP Development Co. LP, DuPont de Nemours, Inc., and Agilent Technologies, Inc. are investing in research and development, indicating a moderate level of technological maturity. Universities such as South China University of Technology, University of Washington, and California Institute of Technology are contributing significantly to the field's advancement. The competitive landscape is diverse, with both established corporations and emerging startups vying for market share in this innovative sector.

HP Development Co. LP

Technical Solution: HP has developed innovative lab-on-a-chip devices incorporating glycerol as a key component. Their technology utilizes glycerol's unique properties to enhance microfluidic operations. HP's approach involves using glycerol as a viscosity modifier in microchannels, allowing for precise control of fluid flow and mixing[1]. They have also explored glycerol's role in preventing evaporation and maintaining sample integrity in miniaturized assays. HP's lab-on-a-chip devices featuring glycerol-based solutions have shown improved performance in applications such as DNA amplification and protein analysis[2].

Strengths: Improved fluid control, enhanced sample stability, and versatility in various bioassays. Weaknesses: Potential compatibility issues with certain biomolecules and increased complexity in device fabrication.

BIONEER Corp.

Technical Solution: BIONEER has developed a novel lab-on-a-chip platform that incorporates glycerol in its microfluidic formulations. Their approach focuses on using glycerol as a stabilizing agent for enzymes and other biomolecules in miniaturized assays. BIONEER's technology employs glycerol-based buffers to maintain the activity of sensitive reagents during storage and operation of the chip[3]. They have also explored the use of glycerol in creating density gradients for particle separation within microchannels. BIONEER's lab-on-a-chip devices have demonstrated enhanced performance in nucleic acid amplification and immunoassays, with glycerol playing a crucial role in maintaining reagent stability and improving assay sensitivity[4].

Strengths: Improved reagent stability, enhanced assay sensitivity, and applicability in various diagnostic tests. Weaknesses: Potential interference with certain detection methods and increased production costs due to specialized formulations.

Innovative Glycerol Utilization Patents

Lab-on-a-chip comprising a mixing chamber

PatentWO2008143415A1

Innovation

- A lab-on-a-chip design featuring a mixing chamber with wider channels and specific angles between channels, allowing for efficient mixing without the need for capillary tubes, where the reagent and sample channels intersect at an angle less than 180° and the mixing channel is formed at a width greater than the individual channels, facilitating uniform and prompt mixing.

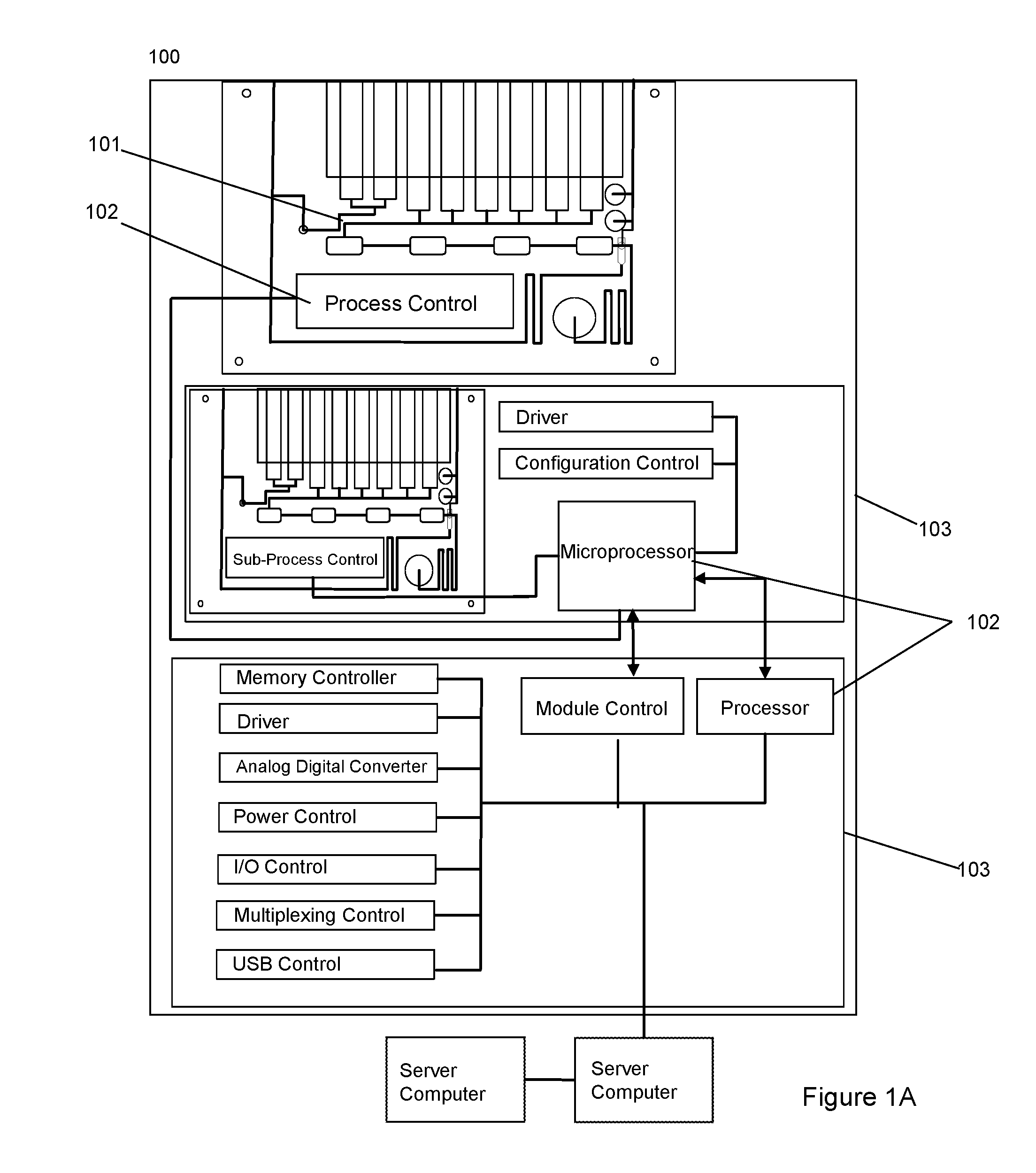

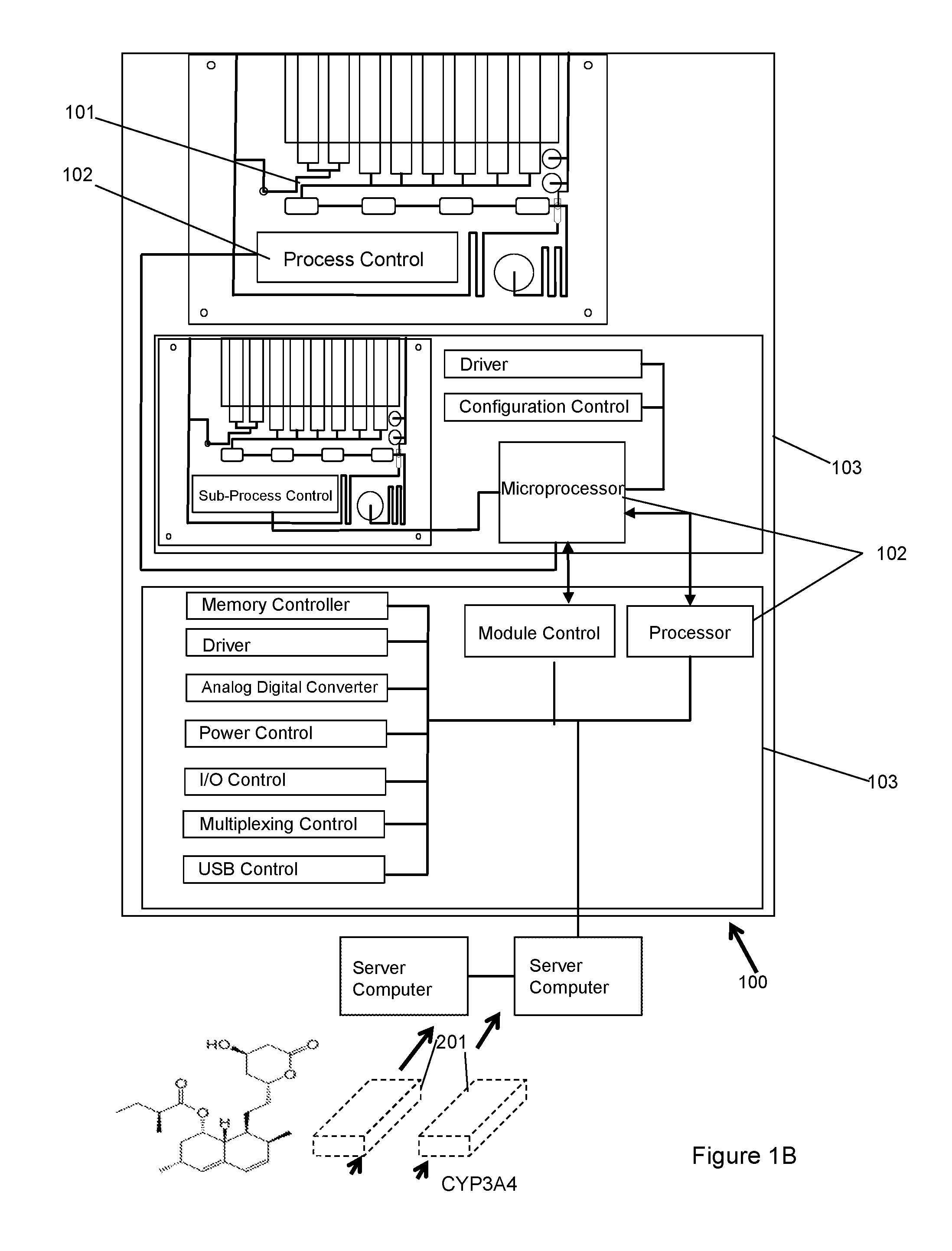

Dynamic Lab on a Chip Based Point-Of-Care Device For Analysis of Pluripotent Stem Cells, Tumor Cells, Drug Metabolites, Immunological Response, Glucose Monitoring, Hospital Based Infectious Diseases, and Drone Delivery Point-of-Care Systems

PatentInactiveUS20160144358A1

Innovation

- A dynamic lab-on-a-chip device with embedded structural reconfiguration capabilities and an integrated computer interface, equipped with a biochemical processing module, microfluidic elements, sensors, and software algorithms that allow for real-time data processing and device reconfiguration based on patient samples, enabling various analytical functions such as glucose level determination, stem cell analysis, and antimicrobial resistance testing.

Regulatory Considerations for Glycerol in LOC

The regulatory landscape for glycerol in Lab-on-a-Chip (LOC) devices is complex and multifaceted, requiring careful consideration of various aspects to ensure compliance and safety. As glycerol is increasingly utilized in LOC applications, it is essential to address the regulatory requirements that govern its use in these miniaturized analytical systems.

One of the primary regulatory considerations is the classification of LOC devices incorporating glycerol. Depending on the intended use and functionality, these devices may fall under different regulatory categories, such as in vitro diagnostic devices (IVDs) or medical devices. In the United States, the Food and Drug Administration (FDA) oversees the regulation of such devices, while in Europe, the European Medicines Agency (EMA) and national regulatory bodies play crucial roles.

The purity and quality of glycerol used in LOC devices are subject to stringent regulatory standards. Manufacturers must ensure that the glycerol meets pharmacopeia-grade specifications, such as those outlined in the United States Pharmacopeia (USP) or European Pharmacopoeia (Ph. Eur.). These standards typically include limits on impurities, microbial contamination, and other quality parameters.

Risk assessment is a critical component of regulatory compliance for glycerol-containing LOC devices. Manufacturers must conduct thorough evaluations to identify potential risks associated with glycerol use, including its impact on sample integrity, device performance, and user safety. This assessment should be documented and incorporated into the overall risk management plan for the device.

Biocompatibility testing is another crucial regulatory consideration. As glycerol comes into contact with biological samples in LOC devices, it is essential to demonstrate that it does not adversely affect the samples or produce toxic effects. Manufacturers may need to conduct biocompatibility studies in accordance with ISO 10993 standards or other relevant guidelines.

Labeling and documentation requirements for LOC devices using glycerol must also be addressed. Clear instructions for use, including any precautions related to glycerol handling or disposal, should be provided. Additionally, manufacturers must maintain detailed records of glycerol sourcing, quality control measures, and any stability studies conducted to support the device's shelf life.

Environmental considerations are becoming increasingly important in regulatory frameworks. Manufacturers should be prepared to address questions regarding the environmental impact of glycerol use in LOC devices, including disposal methods and potential for recycling or reuse.

As the field of LOC technology continues to evolve, regulatory bodies are likely to update their guidelines and requirements. Manufacturers and researchers working with glycerol in LOC devices must stay informed about these changes and be prepared to adapt their processes and documentation accordingly. Engaging with regulatory agencies early in the development process can help ensure compliance and smooth the path to market approval.

One of the primary regulatory considerations is the classification of LOC devices incorporating glycerol. Depending on the intended use and functionality, these devices may fall under different regulatory categories, such as in vitro diagnostic devices (IVDs) or medical devices. In the United States, the Food and Drug Administration (FDA) oversees the regulation of such devices, while in Europe, the European Medicines Agency (EMA) and national regulatory bodies play crucial roles.

The purity and quality of glycerol used in LOC devices are subject to stringent regulatory standards. Manufacturers must ensure that the glycerol meets pharmacopeia-grade specifications, such as those outlined in the United States Pharmacopeia (USP) or European Pharmacopoeia (Ph. Eur.). These standards typically include limits on impurities, microbial contamination, and other quality parameters.

Risk assessment is a critical component of regulatory compliance for glycerol-containing LOC devices. Manufacturers must conduct thorough evaluations to identify potential risks associated with glycerol use, including its impact on sample integrity, device performance, and user safety. This assessment should be documented and incorporated into the overall risk management plan for the device.

Biocompatibility testing is another crucial regulatory consideration. As glycerol comes into contact with biological samples in LOC devices, it is essential to demonstrate that it does not adversely affect the samples or produce toxic effects. Manufacturers may need to conduct biocompatibility studies in accordance with ISO 10993 standards or other relevant guidelines.

Labeling and documentation requirements for LOC devices using glycerol must also be addressed. Clear instructions for use, including any precautions related to glycerol handling or disposal, should be provided. Additionally, manufacturers must maintain detailed records of glycerol sourcing, quality control measures, and any stability studies conducted to support the device's shelf life.

Environmental considerations are becoming increasingly important in regulatory frameworks. Manufacturers should be prepared to address questions regarding the environmental impact of glycerol use in LOC devices, including disposal methods and potential for recycling or reuse.

As the field of LOC technology continues to evolve, regulatory bodies are likely to update their guidelines and requirements. Manufacturers and researchers working with glycerol in LOC devices must stay informed about these changes and be prepared to adapt their processes and documentation accordingly. Engaging with regulatory agencies early in the development process can help ensure compliance and smooth the path to market approval.

Environmental Impact of Glycerol in Microfluidics

The environmental impact of glycerol in microfluidics is a crucial consideration as lab-on-a-chip devices become increasingly prevalent in research and diagnostic applications. Glycerol, a common component in microfluidic systems, offers several advantages but also raises environmental concerns that warrant careful examination.

Glycerol's biodegradability is a significant factor in its environmental profile. As a naturally occurring compound, glycerol can be broken down by microorganisms in the environment, reducing its long-term impact. However, the rate of biodegradation can vary depending on environmental conditions and the concentration of glycerol released.

The production of glycerol for microfluidic applications also has environmental implications. While glycerol can be derived from renewable sources such as vegetable oils, its industrial production may involve energy-intensive processes and the use of chemicals that can contribute to environmental pollution if not properly managed.

In microfluidic devices, glycerol is often used in small quantities, which might suggest a minimal environmental footprint. However, the cumulative effect of widespread adoption of these devices could lead to significant glycerol consumption and subsequent release into the environment. This necessitates a thorough assessment of potential ecological impacts, particularly in aquatic ecosystems where discharged glycerol may accumulate.

The disposal of microfluidic devices containing glycerol presents another environmental challenge. Proper waste management protocols are essential to prevent the uncontrolled release of glycerol and other potentially harmful substances into the environment. Recycling and recovery of glycerol from used devices could mitigate some of these concerns, but such processes are not yet widely implemented.

Furthermore, the interaction between glycerol and other materials used in microfluidic devices, such as polymers and metals, may lead to the formation of secondary compounds with unknown environmental effects. This underscores the need for comprehensive lifecycle assessments of lab-on-a-chip devices that incorporate glycerol.

Efforts to reduce the environmental impact of glycerol in microfluidics include the development of alternative, more environmentally friendly fluids and the optimization of device designs to minimize glycerol usage. Additionally, research into closed-loop systems that recycle glycerol within the device could significantly reduce environmental release.

As the field of microfluidics continues to expand, it is imperative to balance the benefits of glycerol use with its potential environmental consequences. Ongoing research and regulatory oversight will be crucial in ensuring that the environmental impact of glycerol in lab-on-a-chip devices is minimized, promoting sustainable development in this rapidly advancing technological domain.

Glycerol's biodegradability is a significant factor in its environmental profile. As a naturally occurring compound, glycerol can be broken down by microorganisms in the environment, reducing its long-term impact. However, the rate of biodegradation can vary depending on environmental conditions and the concentration of glycerol released.

The production of glycerol for microfluidic applications also has environmental implications. While glycerol can be derived from renewable sources such as vegetable oils, its industrial production may involve energy-intensive processes and the use of chemicals that can contribute to environmental pollution if not properly managed.

In microfluidic devices, glycerol is often used in small quantities, which might suggest a minimal environmental footprint. However, the cumulative effect of widespread adoption of these devices could lead to significant glycerol consumption and subsequent release into the environment. This necessitates a thorough assessment of potential ecological impacts, particularly in aquatic ecosystems where discharged glycerol may accumulate.

The disposal of microfluidic devices containing glycerol presents another environmental challenge. Proper waste management protocols are essential to prevent the uncontrolled release of glycerol and other potentially harmful substances into the environment. Recycling and recovery of glycerol from used devices could mitigate some of these concerns, but such processes are not yet widely implemented.

Furthermore, the interaction between glycerol and other materials used in microfluidic devices, such as polymers and metals, may lead to the formation of secondary compounds with unknown environmental effects. This underscores the need for comprehensive lifecycle assessments of lab-on-a-chip devices that incorporate glycerol.

Efforts to reduce the environmental impact of glycerol in microfluidics include the development of alternative, more environmentally friendly fluids and the optimization of device designs to minimize glycerol usage. Additionally, research into closed-loop systems that recycle glycerol within the device could significantly reduce environmental release.

As the field of microfluidics continues to expand, it is imperative to balance the benefits of glycerol use with its potential environmental consequences. Ongoing research and regulatory oversight will be crucial in ensuring that the environmental impact of glycerol in lab-on-a-chip devices is minimized, promoting sustainable development in this rapidly advancing technological domain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!