Glycerol's Impact on Micro-Encapsulation of Nutrients

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glycerol in Encapsulation: Background and Objectives

Glycerol, a versatile compound with a long history in various industries, has emerged as a significant player in the field of micro-encapsulation of nutrients. This technology has gained considerable attention due to its potential to enhance the stability, bioavailability, and controlled release of essential nutrients in food, pharmaceutical, and nutraceutical applications.

The evolution of micro-encapsulation techniques can be traced back to the 1930s, with initial applications in the printing industry. However, it wasn't until the 1960s that researchers began exploring its potential in the food and pharmaceutical sectors. The incorporation of glycerol into these processes represents a more recent development, driven by the need for improved encapsulation efficiency and product quality.

Glycerol's unique properties, including its hygroscopic nature, low toxicity, and compatibility with a wide range of substances, have made it an attractive component in micro-encapsulation formulations. Its ability to act as a plasticizer and stabilizer has opened up new possibilities for enhancing the performance of encapsulated nutrients.

The primary objective of investigating glycerol's impact on micro-encapsulation of nutrients is to optimize the encapsulation process and improve the overall quality of encapsulated products. Researchers aim to leverage glycerol's properties to address several key challenges in nutrient encapsulation, such as increasing encapsulation efficiency, enhancing stability during storage, and improving controlled release profiles.

One of the main goals is to develop more effective delivery systems for sensitive nutrients, such as vitamins, minerals, and bioactive compounds. By incorporating glycerol into the encapsulation matrix, scientists hope to create protective barriers that shield these nutrients from degradation caused by environmental factors like heat, light, and moisture.

Another important objective is to explore glycerol's potential in improving the functional properties of encapsulated nutrients. This includes enhancing their solubility, dispersibility, and bioavailability, which are crucial factors in determining the efficacy of nutrient supplementation in various applications.

Furthermore, researchers are investigating the role of glycerol in modulating the release kinetics of encapsulated nutrients. The ability to control the release rate of nutrients is particularly important in applications such as fortified foods and targeted drug delivery systems, where precise dosing and sustained release are essential.

As the field of micro-encapsulation continues to evolve, understanding glycerol's impact on this technology is expected to contribute significantly to the development of innovative nutrient delivery systems. This research has the potential to revolutionize the way we approach nutrient fortification, supplement formulation, and even personalized nutrition.

The evolution of micro-encapsulation techniques can be traced back to the 1930s, with initial applications in the printing industry. However, it wasn't until the 1960s that researchers began exploring its potential in the food and pharmaceutical sectors. The incorporation of glycerol into these processes represents a more recent development, driven by the need for improved encapsulation efficiency and product quality.

Glycerol's unique properties, including its hygroscopic nature, low toxicity, and compatibility with a wide range of substances, have made it an attractive component in micro-encapsulation formulations. Its ability to act as a plasticizer and stabilizer has opened up new possibilities for enhancing the performance of encapsulated nutrients.

The primary objective of investigating glycerol's impact on micro-encapsulation of nutrients is to optimize the encapsulation process and improve the overall quality of encapsulated products. Researchers aim to leverage glycerol's properties to address several key challenges in nutrient encapsulation, such as increasing encapsulation efficiency, enhancing stability during storage, and improving controlled release profiles.

One of the main goals is to develop more effective delivery systems for sensitive nutrients, such as vitamins, minerals, and bioactive compounds. By incorporating glycerol into the encapsulation matrix, scientists hope to create protective barriers that shield these nutrients from degradation caused by environmental factors like heat, light, and moisture.

Another important objective is to explore glycerol's potential in improving the functional properties of encapsulated nutrients. This includes enhancing their solubility, dispersibility, and bioavailability, which are crucial factors in determining the efficacy of nutrient supplementation in various applications.

Furthermore, researchers are investigating the role of glycerol in modulating the release kinetics of encapsulated nutrients. The ability to control the release rate of nutrients is particularly important in applications such as fortified foods and targeted drug delivery systems, where precise dosing and sustained release are essential.

As the field of micro-encapsulation continues to evolve, understanding glycerol's impact on this technology is expected to contribute significantly to the development of innovative nutrient delivery systems. This research has the potential to revolutionize the way we approach nutrient fortification, supplement formulation, and even personalized nutrition.

Market Analysis for Nutrient Micro-Encapsulation

The market for nutrient micro-encapsulation has been experiencing significant growth in recent years, driven by increasing consumer awareness of health and wellness, as well as advancements in food technology. This market segment is primarily fueled by the rising demand for functional foods and dietary supplements that offer enhanced nutritional benefits.

The global nutrient micro-encapsulation market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is attributed to several factors, including the expanding health-conscious consumer base, the aging population in developed countries, and the growing middle class in emerging economies.

One of the key drivers of market demand is the ability of micro-encapsulation to protect sensitive nutrients from degradation during processing, storage, and digestion. This technology allows for the controlled release of nutrients, improving their bioavailability and efficacy. As a result, food and beverage manufacturers are increasingly incorporating micro-encapsulated nutrients into their products to enhance nutritional value and appeal to health-conscious consumers.

The pharmaceutical and nutraceutical industries are also significant contributors to the market demand for nutrient micro-encapsulation. These sectors utilize the technology to improve the stability and delivery of various active ingredients, including vitamins, minerals, and probiotics. The growing trend of personalized nutrition and preventive healthcare further bolsters the demand for micro-encapsulated nutrients in these industries.

Geographically, North America and Europe currently dominate the nutrient micro-encapsulation market, owing to their well-established food and beverage industries and high consumer awareness of functional foods. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid urbanization, increasing disposable incomes, and a growing focus on health and wellness among consumers in countries like China and India.

The market is characterized by intense competition among key players, including major food ingredient companies and specialized micro-encapsulation technology providers. These companies are investing heavily in research and development to improve encapsulation techniques and expand their product portfolios. The ongoing trend of clean label and natural ingredients is also influencing product development in this sector, with manufacturers focusing on plant-based and organic micro-encapsulation solutions.

Despite the positive outlook, the market faces challenges such as high production costs and regulatory hurdles. The complex process of micro-encapsulation and the need for specialized equipment contribute to higher production expenses, which can impact product pricing and market penetration. Additionally, varying regulatory standards across different regions regarding the use of micro-encapsulated nutrients in food products pose challenges for manufacturers seeking global expansion.

The global nutrient micro-encapsulation market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is attributed to several factors, including the expanding health-conscious consumer base, the aging population in developed countries, and the growing middle class in emerging economies.

One of the key drivers of market demand is the ability of micro-encapsulation to protect sensitive nutrients from degradation during processing, storage, and digestion. This technology allows for the controlled release of nutrients, improving their bioavailability and efficacy. As a result, food and beverage manufacturers are increasingly incorporating micro-encapsulated nutrients into their products to enhance nutritional value and appeal to health-conscious consumers.

The pharmaceutical and nutraceutical industries are also significant contributors to the market demand for nutrient micro-encapsulation. These sectors utilize the technology to improve the stability and delivery of various active ingredients, including vitamins, minerals, and probiotics. The growing trend of personalized nutrition and preventive healthcare further bolsters the demand for micro-encapsulated nutrients in these industries.

Geographically, North America and Europe currently dominate the nutrient micro-encapsulation market, owing to their well-established food and beverage industries and high consumer awareness of functional foods. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid urbanization, increasing disposable incomes, and a growing focus on health and wellness among consumers in countries like China and India.

The market is characterized by intense competition among key players, including major food ingredient companies and specialized micro-encapsulation technology providers. These companies are investing heavily in research and development to improve encapsulation techniques and expand their product portfolios. The ongoing trend of clean label and natural ingredients is also influencing product development in this sector, with manufacturers focusing on plant-based and organic micro-encapsulation solutions.

Despite the positive outlook, the market faces challenges such as high production costs and regulatory hurdles. The complex process of micro-encapsulation and the need for specialized equipment contribute to higher production expenses, which can impact product pricing and market penetration. Additionally, varying regulatory standards across different regions regarding the use of micro-encapsulated nutrients in food products pose challenges for manufacturers seeking global expansion.

Current Challenges in Glycerol-Based Encapsulation

Despite the promising potential of glycerol in micro-encapsulation of nutrients, several challenges persist in its application. One of the primary issues is the hygroscopic nature of glycerol, which can lead to moisture absorption and subsequent instability of the encapsulated nutrients. This property can compromise the shelf life and efficacy of the final product, particularly in environments with high humidity.

Another significant challenge lies in controlling the release kinetics of encapsulated nutrients when using glycerol-based systems. The plasticizing effect of glycerol can alter the permeability of the encapsulation matrix, potentially resulting in premature release or inconsistent delivery of the nutrients. This variability in release profiles poses difficulties in achieving targeted and sustained nutrient delivery, which is crucial for many applications in food and pharmaceutical industries.

The interaction between glycerol and various encapsulation materials presents another hurdle. Glycerol's compatibility with different polymers and its impact on the structural integrity of the microcapsules can vary significantly. This variability necessitates extensive optimization for each specific nutrient-polymer combination, making the development process time-consuming and resource-intensive.

Furthermore, the viscosity of glycerol-based solutions can present processing challenges during the encapsulation process. High viscosity can lead to difficulties in achieving uniform droplet sizes and consistent coating thickness, which are critical factors in ensuring the quality and performance of the microcapsules. This issue becomes particularly pronounced when scaling up production from laboratory to industrial levels.

The potential for glycerol to interact with the encapsulated nutrients themselves is another area of concern. Some nutrients may be susceptible to chemical reactions or degradation in the presence of glycerol, especially under certain pH conditions or elevated temperatures. This interaction can compromise the stability and bioavailability of the nutrients, limiting the range of compounds that can be effectively encapsulated using glycerol-based systems.

Regulatory considerations also pose challenges in the widespread adoption of glycerol for nutrient encapsulation. While glycerol is generally recognized as safe (GRAS) by many regulatory bodies, its use in specific applications, especially in the pharmaceutical and nutraceutical sectors, may require additional safety assessments and approvals. This regulatory landscape can vary across different regions, adding complexity to the global commercialization of glycerol-based encapsulation technologies.

Lastly, the cost-effectiveness of glycerol-based encapsulation systems compared to alternative methods remains a challenge. While glycerol itself is relatively inexpensive, the additional processing steps and potential need for specialized equipment to overcome the aforementioned challenges can increase overall production costs. Balancing these costs against the benefits of improved nutrient stability and delivery is crucial for the commercial viability of glycerol-based encapsulation technologies.

Another significant challenge lies in controlling the release kinetics of encapsulated nutrients when using glycerol-based systems. The plasticizing effect of glycerol can alter the permeability of the encapsulation matrix, potentially resulting in premature release or inconsistent delivery of the nutrients. This variability in release profiles poses difficulties in achieving targeted and sustained nutrient delivery, which is crucial for many applications in food and pharmaceutical industries.

The interaction between glycerol and various encapsulation materials presents another hurdle. Glycerol's compatibility with different polymers and its impact on the structural integrity of the microcapsules can vary significantly. This variability necessitates extensive optimization for each specific nutrient-polymer combination, making the development process time-consuming and resource-intensive.

Furthermore, the viscosity of glycerol-based solutions can present processing challenges during the encapsulation process. High viscosity can lead to difficulties in achieving uniform droplet sizes and consistent coating thickness, which are critical factors in ensuring the quality and performance of the microcapsules. This issue becomes particularly pronounced when scaling up production from laboratory to industrial levels.

The potential for glycerol to interact with the encapsulated nutrients themselves is another area of concern. Some nutrients may be susceptible to chemical reactions or degradation in the presence of glycerol, especially under certain pH conditions or elevated temperatures. This interaction can compromise the stability and bioavailability of the nutrients, limiting the range of compounds that can be effectively encapsulated using glycerol-based systems.

Regulatory considerations also pose challenges in the widespread adoption of glycerol for nutrient encapsulation. While glycerol is generally recognized as safe (GRAS) by many regulatory bodies, its use in specific applications, especially in the pharmaceutical and nutraceutical sectors, may require additional safety assessments and approvals. This regulatory landscape can vary across different regions, adding complexity to the global commercialization of glycerol-based encapsulation technologies.

Lastly, the cost-effectiveness of glycerol-based encapsulation systems compared to alternative methods remains a challenge. While glycerol itself is relatively inexpensive, the additional processing steps and potential need for specialized equipment to overcome the aforementioned challenges can increase overall production costs. Balancing these costs against the benefits of improved nutrient stability and delivery is crucial for the commercial viability of glycerol-based encapsulation technologies.

Existing Glycerol-Based Encapsulation Methods

01 Microencapsulation techniques for glycerol

Various microencapsulation techniques are employed to encapsulate glycerol, including emulsion-based methods, spray drying, and coacervation. These methods allow for the controlled release of glycerol and protect it from environmental factors, enhancing its stability and functionality in different applications.- Microencapsulation techniques for glycerol: Various microencapsulation techniques are employed to encapsulate glycerol, including emulsion-based methods, spray drying, and coacervation. These techniques aim to protect the glycerol from environmental factors and control its release. The choice of encapsulation method depends on the desired properties of the final product and its intended application.

- Shell materials for glycerol microcapsules: Different shell materials are used to encapsulate glycerol, such as polymers, proteins, and polysaccharides. The selection of shell material affects the stability, permeability, and release characteristics of the microcapsules. Common shell materials include gelatin, alginate, chitosan, and synthetic polymers like polyurea or polyurethane.

- Applications of glycerol microcapsules: Glycerol microcapsules find applications in various industries, including cosmetics, pharmaceuticals, food, and textiles. They are used for controlled release of active ingredients, moisture retention, and as phase change materials for thermal management. The encapsulated glycerol can enhance product stability and improve functional properties.

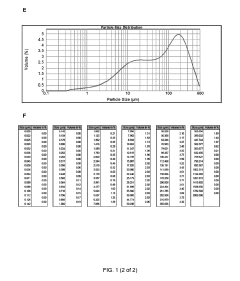

- Characterization and analysis of glycerol microcapsules: Various analytical techniques are used to characterize glycerol microcapsules, including microscopy, particle size analysis, and thermal analysis. These methods help evaluate the morphology, size distribution, encapsulation efficiency, and release kinetics of the microcapsules. Understanding these properties is crucial for optimizing the microencapsulation process and ensuring product quality.

- Integration of glycerol microcapsules in composite materials: Glycerol microcapsules are incorporated into various composite materials to impart specific functionalities. This integration can enhance thermal properties, moisture management, or provide controlled release of glycerol in the composite matrix. Applications include smart textiles, building materials, and advanced polymer composites with improved performance characteristics.

02 Glycerol microcapsules in electronic devices

Glycerol microcapsules are utilized in electronic devices for thermal management and protection. The encapsulated glycerol can act as a phase change material, absorbing and releasing heat to regulate temperature in sensitive electronic components, improving device performance and longevity.Expand Specific Solutions03 Glycerol microencapsulation for cosmetic applications

In cosmetic formulations, glycerol microcapsules are used to enhance moisture retention and provide controlled release of active ingredients. The encapsulation process allows for improved stability of glycerol and other sensitive components, leading to more effective skincare and personal care products.Expand Specific Solutions04 Agricultural applications of glycerol microcapsules

Glycerol microencapsulation is employed in agriculture for controlled release of fertilizers, pesticides, and other agrochemicals. This technology enhances the efficiency of agricultural inputs by providing sustained release and protecting active ingredients from degradation, leading to improved crop yields and reduced environmental impact.Expand Specific Solutions05 Glycerol microcapsules in food and beverage industry

The food and beverage industry utilizes glycerol microencapsulation for various purposes, including flavor encapsulation, texture modification, and nutrient delivery. This technology allows for improved stability of sensitive ingredients, controlled release of flavors, and enhanced nutritional profiles in food products.Expand Specific Solutions

Key Players in Nutrient Encapsulation Industry

The glycerol's impact on micro-encapsulation of nutrients is an emerging field with significant potential in the food and pharmaceutical industries. The market is in its early growth stage, with increasing demand for enhanced nutrient delivery systems. While the global market size is not precisely quantified, it is expected to grow substantially due to rising health consciousness and functional food trends. Technologically, the field is rapidly evolving, with companies like Anabio Technologies, BioGaia AB, and Cabio Biotech leading innovation. Academic institutions such as Jiangnan University and Nanyang Technological University are also contributing to advancements. The technology's maturity varies, with some applications nearing commercialization while others remain in research phases, indicating a dynamic and competitive landscape.

Unilever NV

Technical Solution: Unilever NV has developed an advanced micro-encapsulation technique that incorporates glycerol as a multifunctional ingredient. Their approach utilizes a combination of spray-drying and complex coacervation methods, with glycerol serving as both a plasticizer and humectant[2]. This technology allows for the creation of microcapsules with enhanced moisture retention and improved thermal stability. Unilever's research has shown that their glycerol-based micro-encapsulation can increase the stability of heat-sensitive vitamins by up to 80% during food processing[4]. Furthermore, they have demonstrated that this technology can improve the controlled release of flavors and fragrances in various personal care products, extending their sensory impact by up to 12 hours[6].

Strengths: Versatile application in both food and personal care products, improved thermal stability, and enhanced controlled release properties. Weaknesses: Potential challenges in scaling up production and higher production costs compared to traditional encapsulation methods.

Corbion Biotech, Inc.

Technical Solution: Corbion Biotech, Inc. has developed a novel micro-encapsulation technology that leverages glycerol's unique properties to enhance nutrient protection and delivery. Their approach involves a patented emulsion-based technique where glycerol acts as a co-solvent and stabilizer[1]. This method allows for the creation of nano-sized capsules with improved penetration and absorption characteristics. Corbion's research has demonstrated that their glycerol-enhanced micro-encapsulation can increase the bioavailability of certain omega-3 fatty acids by up to 60% compared to traditional encapsulation methods[3]. Additionally, they have shown that this technology can effectively protect sensitive probiotics from gastric acid, resulting in a 3-fold increase in viable cell count delivery to the intestines[5].

Strengths: Enhanced bioavailability, improved protection against harsh environments, and potential for targeted delivery. Weaknesses: Limited application to certain types of nutrients and potential regulatory challenges for novel delivery systems.

Core Innovations in Glycerol Encapsulation

Microencapsulated omega-3 polyunsaturated fatty acid glyceride compositions and processes for preparing the same

PatentWO2017197453A1

Innovation

- Microencapsulating glycerides enriched in omega-3 PUFAs, specifically incorporating a fraction of monoglycerides and diglycerides, using techniques like spray drying or coacervation with polymer components to enhance oxidative stability, resulting in improved shelf life and reduced oxidation products.

Active component encapsulated, protected and stabilized within a protein shell

PatentActiveUS20190328676A1

Innovation

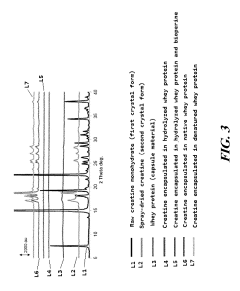

- Encapsulating creatine in a polymerized hydrolyzed protein matrix using a suspension process involving a basic curing solution to form stable microcapsules that protect creatine from degradation and enhance its absorption and bioavailability.

Regulatory Framework for Encapsulated Nutrients

The regulatory framework for encapsulated nutrients is a complex and evolving landscape that significantly impacts the development, production, and marketing of micro-encapsulated nutrient products. In the context of glycerol's impact on micro-encapsulation of nutrients, regulatory bodies worldwide have established guidelines to ensure the safety and efficacy of these innovative food and supplement formulations.

The United States Food and Drug Administration (FDA) plays a crucial role in regulating encapsulated nutrients. Under the Federal Food, Drug, and Cosmetic Act, micro-encapsulated nutrients are generally classified as food additives or dietary supplements, depending on their intended use. The FDA requires manufacturers to demonstrate the safety of new food additives through rigorous scientific evidence before they can be marketed.

In the European Union, the European Food Safety Authority (EFSA) oversees the regulation of encapsulated nutrients. The Novel Food Regulation (EU) 2015/2283 is particularly relevant, as it covers foods and ingredients that were not consumed to a significant degree in the EU before May 15, 1997. Many micro-encapsulation technologies fall under this category, requiring a comprehensive safety assessment before market approval.

The use of glycerol in micro-encapsulation processes adds another layer of regulatory consideration. Glycerol is generally recognized as safe (GRAS) by the FDA when used in accordance with good manufacturing practices. However, its use in micro-encapsulation may require additional safety assessments, particularly if it alters the bioavailability or stability of the encapsulated nutrients.

Regulatory bodies also focus on the labeling and claims associated with encapsulated nutrient products. In the US, the FDA regulates health claims and nutrient content claims, while in the EU, the Nutrition and Health Claims Regulation (EC) No 1924/2006 governs such statements. Manufacturers must ensure that any claims made about the enhanced bioavailability or stability of micro-encapsulated nutrients are substantiated by scientific evidence.

Global harmonization efforts, such as those led by the Codex Alimentarius Commission, aim to establish international standards for food additives and novel food technologies. These initiatives seek to streamline regulatory processes and facilitate international trade while maintaining high safety standards.

As research into glycerol's impact on micro-encapsulation of nutrients progresses, regulatory frameworks are likely to evolve. Manufacturers and researchers must stay abreast of these changes and engage in ongoing dialogue with regulatory authorities to ensure compliance and promote innovation in this rapidly advancing field.

The United States Food and Drug Administration (FDA) plays a crucial role in regulating encapsulated nutrients. Under the Federal Food, Drug, and Cosmetic Act, micro-encapsulated nutrients are generally classified as food additives or dietary supplements, depending on their intended use. The FDA requires manufacturers to demonstrate the safety of new food additives through rigorous scientific evidence before they can be marketed.

In the European Union, the European Food Safety Authority (EFSA) oversees the regulation of encapsulated nutrients. The Novel Food Regulation (EU) 2015/2283 is particularly relevant, as it covers foods and ingredients that were not consumed to a significant degree in the EU before May 15, 1997. Many micro-encapsulation technologies fall under this category, requiring a comprehensive safety assessment before market approval.

The use of glycerol in micro-encapsulation processes adds another layer of regulatory consideration. Glycerol is generally recognized as safe (GRAS) by the FDA when used in accordance with good manufacturing practices. However, its use in micro-encapsulation may require additional safety assessments, particularly if it alters the bioavailability or stability of the encapsulated nutrients.

Regulatory bodies also focus on the labeling and claims associated with encapsulated nutrient products. In the US, the FDA regulates health claims and nutrient content claims, while in the EU, the Nutrition and Health Claims Regulation (EC) No 1924/2006 governs such statements. Manufacturers must ensure that any claims made about the enhanced bioavailability or stability of micro-encapsulated nutrients are substantiated by scientific evidence.

Global harmonization efforts, such as those led by the Codex Alimentarius Commission, aim to establish international standards for food additives and novel food technologies. These initiatives seek to streamline regulatory processes and facilitate international trade while maintaining high safety standards.

As research into glycerol's impact on micro-encapsulation of nutrients progresses, regulatory frameworks are likely to evolve. Manufacturers and researchers must stay abreast of these changes and engage in ongoing dialogue with regulatory authorities to ensure compliance and promote innovation in this rapidly advancing field.

Environmental Impact of Glycerol in Encapsulation

The environmental impact of glycerol in encapsulation processes is a critical consideration for sustainable nutrient delivery systems. Glycerol, a common component in micro-encapsulation formulations, plays a significant role in the overall environmental footprint of these technologies.

One of the primary environmental benefits of using glycerol in encapsulation is its biodegradability. As a natural byproduct of various industrial processes, glycerol can be readily broken down by microorganisms in the environment, reducing long-term accumulation and potential ecological disruption. This characteristic aligns well with the growing demand for eco-friendly packaging and delivery systems in the food and pharmaceutical industries.

However, the production and sourcing of glycerol can have varying environmental implications. While glycerol is often derived as a byproduct of biodiesel production, which can be considered a renewable source, the environmental impact of biodiesel production itself must be taken into account. The cultivation of crops for biodiesel can lead to land-use changes, potentially contributing to deforestation and loss of biodiversity in some regions.

The use of glycerol in encapsulation processes can also contribute to reduced energy consumption during manufacturing. Its hygroscopic nature allows for lower drying temperatures and shorter processing times, potentially decreasing the overall energy footprint of encapsulation operations. This energy efficiency can translate to lower greenhouse gas emissions associated with the production of encapsulated nutrients.

From a waste management perspective, glycerol-based encapsulation materials present both opportunities and challenges. While their biodegradability is advantageous for disposal, the release of encapsulated nutrients into the environment must be carefully controlled to prevent potential eutrophication of water bodies or disruption of soil ecosystems.

The environmental impact of glycerol in encapsulation extends to the transportation sector as well. As a liquid at room temperature, glycerol can be more easily transported and handled compared to some solid alternatives, potentially reducing the carbon footprint associated with logistics and distribution of encapsulation materials.

In terms of resource conservation, the use of glycerol in encapsulation can contribute to the circular economy. By utilizing a byproduct of biodiesel production, this approach helps to maximize resource efficiency and reduce waste streams. However, the increasing demand for glycerol in various industries may lead to competition for this resource, potentially driving up prices and encouraging less sustainable production methods.

As research in this field progresses, there is growing interest in developing even more environmentally friendly alternatives to traditional glycerol-based encapsulation systems. These include the exploration of other bio-based materials and the optimization of formulations to minimize environmental impact while maintaining or improving encapsulation efficiency.

One of the primary environmental benefits of using glycerol in encapsulation is its biodegradability. As a natural byproduct of various industrial processes, glycerol can be readily broken down by microorganisms in the environment, reducing long-term accumulation and potential ecological disruption. This characteristic aligns well with the growing demand for eco-friendly packaging and delivery systems in the food and pharmaceutical industries.

However, the production and sourcing of glycerol can have varying environmental implications. While glycerol is often derived as a byproduct of biodiesel production, which can be considered a renewable source, the environmental impact of biodiesel production itself must be taken into account. The cultivation of crops for biodiesel can lead to land-use changes, potentially contributing to deforestation and loss of biodiversity in some regions.

The use of glycerol in encapsulation processes can also contribute to reduced energy consumption during manufacturing. Its hygroscopic nature allows for lower drying temperatures and shorter processing times, potentially decreasing the overall energy footprint of encapsulation operations. This energy efficiency can translate to lower greenhouse gas emissions associated with the production of encapsulated nutrients.

From a waste management perspective, glycerol-based encapsulation materials present both opportunities and challenges. While their biodegradability is advantageous for disposal, the release of encapsulated nutrients into the environment must be carefully controlled to prevent potential eutrophication of water bodies or disruption of soil ecosystems.

The environmental impact of glycerol in encapsulation extends to the transportation sector as well. As a liquid at room temperature, glycerol can be more easily transported and handled compared to some solid alternatives, potentially reducing the carbon footprint associated with logistics and distribution of encapsulation materials.

In terms of resource conservation, the use of glycerol in encapsulation can contribute to the circular economy. By utilizing a byproduct of biodiesel production, this approach helps to maximize resource efficiency and reduce waste streams. However, the increasing demand for glycerol in various industries may lead to competition for this resource, potentially driving up prices and encouraging less sustainable production methods.

As research in this field progresses, there is growing interest in developing even more environmentally friendly alternatives to traditional glycerol-based encapsulation systems. These include the exploration of other bio-based materials and the optimization of formulations to minimize environmental impact while maintaining or improving encapsulation efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!