Glycerol in the Modulation of Biodegradable Foam Expansion

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glycerol in Foam Expansion: Background and Objectives

Glycerol, a byproduct of biodiesel production, has emerged as a promising agent in the modulation of biodegradable foam expansion. This research area has gained significant attention due to the increasing demand for sustainable and environmentally friendly materials in various industries. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternative uses for glycerol to address the surplus generated by the biodiesel industry.

The primary objective of this research is to develop innovative methods for utilizing glycerol in the production of biodegradable foams with enhanced expansion properties. This goal aligns with the broader trend towards circular economy principles and the reduction of environmental impact in manufacturing processes. By incorporating glycerol into foam formulations, researchers aim to improve the physical and chemical properties of biodegradable foams while simultaneously addressing the challenge of glycerol oversupply.

Recent technological advancements have focused on understanding the mechanisms by which glycerol influences foam expansion. Studies have shown that glycerol can act as a plasticizer, modifying the rheological properties of foam precursors and affecting the nucleation and growth of gas bubbles during the foaming process. This has led to the development of new foam formulations with improved expansion ratios and cellular structures.

The potential applications for glycerol-modulated biodegradable foams span across multiple sectors, including packaging, construction, automotive, and biomedical industries. In the packaging sector, these foams offer a sustainable alternative to traditional petroleum-based materials, addressing growing consumer demand for eco-friendly products. The construction industry sees potential in using these foams for insulation purposes, leveraging their biodegradability and enhanced thermal properties.

As research in this field progresses, several key technological trends have emerged. These include the optimization of glycerol concentration in foam formulations, the development of novel processing techniques to enhance foam expansion, and the exploration of synergistic effects between glycerol and other bio-based additives. Additionally, efforts are being made to scale up laboratory findings to industrial production levels, addressing challenges related to consistency, cost-effectiveness, and quality control.

The future trajectory of this technology is expected to focus on further improving the mechanical properties of glycerol-modulated foams, extending their shelf life, and expanding their range of applications. Researchers are also exploring the potential of using waste glycerol from various industrial processes, further enhancing the sustainability profile of these materials. As environmental regulations become more stringent and consumer awareness of sustainable products grows, the development of glycerol-based biodegradable foams is poised to play a crucial role in the transition towards a more sustainable materials economy.

The primary objective of this research is to develop innovative methods for utilizing glycerol in the production of biodegradable foams with enhanced expansion properties. This goal aligns with the broader trend towards circular economy principles and the reduction of environmental impact in manufacturing processes. By incorporating glycerol into foam formulations, researchers aim to improve the physical and chemical properties of biodegradable foams while simultaneously addressing the challenge of glycerol oversupply.

Recent technological advancements have focused on understanding the mechanisms by which glycerol influences foam expansion. Studies have shown that glycerol can act as a plasticizer, modifying the rheological properties of foam precursors and affecting the nucleation and growth of gas bubbles during the foaming process. This has led to the development of new foam formulations with improved expansion ratios and cellular structures.

The potential applications for glycerol-modulated biodegradable foams span across multiple sectors, including packaging, construction, automotive, and biomedical industries. In the packaging sector, these foams offer a sustainable alternative to traditional petroleum-based materials, addressing growing consumer demand for eco-friendly products. The construction industry sees potential in using these foams for insulation purposes, leveraging their biodegradability and enhanced thermal properties.

As research in this field progresses, several key technological trends have emerged. These include the optimization of glycerol concentration in foam formulations, the development of novel processing techniques to enhance foam expansion, and the exploration of synergistic effects between glycerol and other bio-based additives. Additionally, efforts are being made to scale up laboratory findings to industrial production levels, addressing challenges related to consistency, cost-effectiveness, and quality control.

The future trajectory of this technology is expected to focus on further improving the mechanical properties of glycerol-modulated foams, extending their shelf life, and expanding their range of applications. Researchers are also exploring the potential of using waste glycerol from various industrial processes, further enhancing the sustainability profile of these materials. As environmental regulations become more stringent and consumer awareness of sustainable products grows, the development of glycerol-based biodegradable foams is poised to play a crucial role in the transition towards a more sustainable materials economy.

Market Analysis for Biodegradable Foam Products

The biodegradable foam products market has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations on plastic waste. This market segment is expected to continue its upward trajectory as consumers and businesses alike seek more sustainable packaging and insulation solutions.

The global biodegradable foam market is primarily segmented into starch-based, cellulose-based, and protein-based foams. Among these, starch-based foams have gained considerable traction due to their versatility and cost-effectiveness. The use of glycerol in modulating biodegradable foam expansion presents an opportunity to enhance the performance and properties of these materials, potentially expanding their application range.

Key industries driving the demand for biodegradable foam products include packaging, construction, automotive, and consumer goods. The packaging sector, in particular, has shown robust growth as companies seek alternatives to traditional plastic foam packaging. Food and beverage packaging represents a significant portion of this demand, with biodegradable foam products offering excellent insulation properties and reduced environmental impact.

The construction industry is another major consumer of biodegradable foam products, particularly for insulation applications. As green building practices gain momentum worldwide, the demand for sustainable insulation materials is expected to rise. Biodegradable foams offer an attractive alternative to petroleum-based insulation materials, providing comparable performance with a lower carbon footprint.

Geographically, North America and Europe lead the biodegradable foam products market, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, urbanization, and government initiatives promoting sustainable materials.

Market challenges include the higher cost of biodegradable foam products compared to traditional petroleum-based foams and the need for improved performance characteristics. Research on glycerol's use in foam expansion could potentially address some of these challenges by enhancing material properties and reducing production costs.

The market is characterized by intense competition and ongoing research and development efforts. Key players are focusing on product innovation, sustainable sourcing of raw materials, and strategic partnerships to gain a competitive edge. The integration of glycerol in biodegradable foam production could provide companies with a unique selling proposition, potentially reshaping the competitive landscape.

The global biodegradable foam market is primarily segmented into starch-based, cellulose-based, and protein-based foams. Among these, starch-based foams have gained considerable traction due to their versatility and cost-effectiveness. The use of glycerol in modulating biodegradable foam expansion presents an opportunity to enhance the performance and properties of these materials, potentially expanding their application range.

Key industries driving the demand for biodegradable foam products include packaging, construction, automotive, and consumer goods. The packaging sector, in particular, has shown robust growth as companies seek alternatives to traditional plastic foam packaging. Food and beverage packaging represents a significant portion of this demand, with biodegradable foam products offering excellent insulation properties and reduced environmental impact.

The construction industry is another major consumer of biodegradable foam products, particularly for insulation applications. As green building practices gain momentum worldwide, the demand for sustainable insulation materials is expected to rise. Biodegradable foams offer an attractive alternative to petroleum-based insulation materials, providing comparable performance with a lower carbon footprint.

Geographically, North America and Europe lead the biodegradable foam products market, owing to stringent environmental regulations and high consumer awareness. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, urbanization, and government initiatives promoting sustainable materials.

Market challenges include the higher cost of biodegradable foam products compared to traditional petroleum-based foams and the need for improved performance characteristics. Research on glycerol's use in foam expansion could potentially address some of these challenges by enhancing material properties and reducing production costs.

The market is characterized by intense competition and ongoing research and development efforts. Key players are focusing on product innovation, sustainable sourcing of raw materials, and strategic partnerships to gain a competitive edge. The integration of glycerol in biodegradable foam production could provide companies with a unique selling proposition, potentially reshaping the competitive landscape.

Current Challenges in Biodegradable Foam Expansion

The expansion of biodegradable foams presents several significant challenges that researchers and manufacturers are currently grappling with. One of the primary issues is achieving consistent and controlled expansion while maintaining the foam's biodegradable properties. The use of glycerol as a modulating agent in this process introduces both opportunities and complexities.

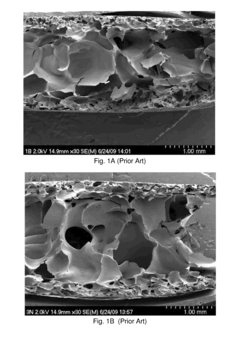

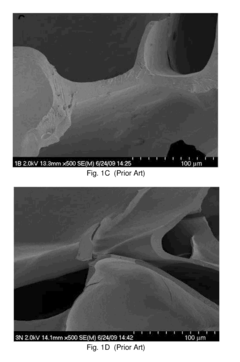

A major challenge lies in balancing the expansion rate with the foam's structural integrity. Biodegradable materials often have inherent limitations in terms of strength and durability compared to their non-biodegradable counterparts. When expanding these foams, there's a risk of compromising the cellular structure, leading to inconsistent density and potential collapse of the foam matrix.

The incorporation of glycerol into the foam formulation adds another layer of complexity. While glycerol can act as a plasticizer and potentially enhance the expansion process, it also affects the foam's moisture sensitivity and degradation rate. Controlling these parameters to achieve the desired foam properties while ensuring biodegradability remains a significant challenge.

Temperature control during the expansion process is crucial and becomes more critical with the addition of glycerol. The viscosity and thermal properties of glycerol-containing mixtures can vary significantly, making it difficult to maintain optimal expansion conditions across different batches or scales of production.

Another challenge is the potential for phase separation or incompatibility between glycerol and other components of the biodegradable foam formulation. This can lead to inconsistent distribution of glycerol within the foam structure, resulting in non-uniform expansion and properties.

The environmental impact of using glycerol in biodegradable foams is also a concern. While glycerol itself is biodegradable, its sourcing and production methods need to be considered to ensure the overall sustainability of the foam product. There's an ongoing challenge to optimize the use of glycerol to maximize its benefits while minimizing any potential negative environmental effects.

Scalability remains a significant hurdle in the production of glycerol-modulated biodegradable foams. Techniques that work well in laboratory settings may face difficulties when scaled up to industrial production levels. Maintaining consistent foam quality, expansion rates, and biodegradability across large-scale manufacturing processes is an area that requires further research and development.

Lastly, the regulatory landscape for biodegradable materials is evolving, and ensuring compliance with various standards and regulations while incorporating glycerol into foam formulations adds another layer of complexity to the development process. Manufacturers must navigate these regulatory challenges while striving to innovate and improve their biodegradable foam products.

A major challenge lies in balancing the expansion rate with the foam's structural integrity. Biodegradable materials often have inherent limitations in terms of strength and durability compared to their non-biodegradable counterparts. When expanding these foams, there's a risk of compromising the cellular structure, leading to inconsistent density and potential collapse of the foam matrix.

The incorporation of glycerol into the foam formulation adds another layer of complexity. While glycerol can act as a plasticizer and potentially enhance the expansion process, it also affects the foam's moisture sensitivity and degradation rate. Controlling these parameters to achieve the desired foam properties while ensuring biodegradability remains a significant challenge.

Temperature control during the expansion process is crucial and becomes more critical with the addition of glycerol. The viscosity and thermal properties of glycerol-containing mixtures can vary significantly, making it difficult to maintain optimal expansion conditions across different batches or scales of production.

Another challenge is the potential for phase separation or incompatibility between glycerol and other components of the biodegradable foam formulation. This can lead to inconsistent distribution of glycerol within the foam structure, resulting in non-uniform expansion and properties.

The environmental impact of using glycerol in biodegradable foams is also a concern. While glycerol itself is biodegradable, its sourcing and production methods need to be considered to ensure the overall sustainability of the foam product. There's an ongoing challenge to optimize the use of glycerol to maximize its benefits while minimizing any potential negative environmental effects.

Scalability remains a significant hurdle in the production of glycerol-modulated biodegradable foams. Techniques that work well in laboratory settings may face difficulties when scaled up to industrial production levels. Maintaining consistent foam quality, expansion rates, and biodegradability across large-scale manufacturing processes is an area that requires further research and development.

Lastly, the regulatory landscape for biodegradable materials is evolving, and ensuring compliance with various standards and regulations while incorporating glycerol into foam formulations adds another layer of complexity to the development process. Manufacturers must navigate these regulatory challenges while striving to innovate and improve their biodegradable foam products.

Existing Glycerol-based Foam Modulation Methods

01 Biodegradable foam composition

Development of biodegradable foam compositions using environmentally friendly materials. These foams are designed to expand and provide insulation or cushioning properties while being able to decompose naturally over time, reducing environmental impact.- Biodegradable foam composition: Development of biodegradable foam compositions using environmentally friendly materials. These foams are designed to expand and provide insulation or cushioning properties while being able to decompose naturally over time, reducing environmental impact.

- Expansion techniques for biodegradable foams: Various methods and techniques for expanding biodegradable foams, including chemical blowing agents, physical blowing processes, and microwave-assisted expansion. These techniques aim to achieve desired foam properties while maintaining biodegradability.

- Biodegradable foam applications: Exploration of diverse applications for biodegradable foams, such as packaging materials, insulation in construction, agricultural uses, and personal care products. The focus is on replacing traditional non-biodegradable foams with eco-friendly alternatives.

- Enhancing biodegradability and performance: Research into improving both the biodegradability and performance characteristics of expandable foams. This includes incorporating additives, modifying polymer structures, and optimizing processing conditions to achieve desired properties.

- Sustainable production processes: Development of sustainable manufacturing processes for biodegradable expandable foams. This involves using renewable resources, reducing energy consumption, and minimizing waste generation during foam production and expansion.

02 Expansion techniques for biodegradable foams

Various methods and techniques for expanding biodegradable foams, including chemical blowing agents, physical blowing processes, and temperature-controlled expansion. These techniques aim to achieve desired foam properties while maintaining biodegradability.Expand Specific Solutions03 Biodegradable foam applications

Exploration of diverse applications for biodegradable expanded foams, such as packaging materials, insulation in construction, agricultural uses, and disposable consumer products. These applications leverage the foam's biodegradability and expansion properties.Expand Specific Solutions04 Enhancing biodegradation rate of expanded foams

Research into methods to accelerate the biodegradation process of expanded foams. This includes incorporating specific additives, optimizing foam structure, and developing new formulations to ensure faster decomposition after use.Expand Specific Solutions05 Sustainable production of biodegradable expanded foams

Focus on sustainable manufacturing processes for biodegradable expanded foams. This involves using renewable resources, optimizing energy consumption during production, and minimizing waste generation to create environmentally friendly foam products.Expand Specific Solutions

Key Players in Biodegradable Materials Industry

The research on glycerol use in biodegradable foam expansion is in an early development stage, with a growing market potential due to increasing environmental concerns. The technology's maturity is still evolving, with academic institutions like Carnegie Mellon University, MIT, and Vanderbilt University leading fundamental research. Companies such as DuPont, Dow Global Technologies, and Lifemade Products are exploring commercial applications, while research organizations like CSIR and Fraunhofer-Gesellschaft are bridging the gap between academia and industry. The involvement of diverse players indicates a competitive landscape with opportunities for innovation and market growth in sustainable packaging and materials sectors.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach to utilizing glycerol in biodegradable foam production, focusing on polyester-based systems. Their method involves incorporating glycerol as a chain extender and plasticizer in the foam formulation, which allows for improved control over foam expansion and cell structure. The process includes a reactive extrusion step where glycerol is partially reacted with polyester oligomers, followed by the addition of a chemical blowing agent and foam expansion. This technique results in foams with enhanced flexibility, improved thermal stability, and controlled biodegradation rates[13][15]. Sinopec has also explored the use of glycerol-derived compounds to further optimize foam properties and expand the range of applications[17].

Strengths: Improved foam flexibility, enhanced thermal stability, and controlled biodegradation rates. Weaknesses: May require specialized equipment and process optimization for different polyester systems.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies LLC has developed a novel approach for modulating biodegradable foam expansion using glycerol. Their method involves incorporating glycerol into a starch-based foam formulation, where it acts as a plasticizer and expansion control agent. The process utilizes a twin-screw extruder to blend the starch, glycerol, and other additives, followed by injection of a physical blowing agent. This results in a foam with improved flexibility, reduced density, and enhanced biodegradability[1][3]. The company has also explored the use of glycerol in combination with other bio-based plasticizers to further optimize foam properties and expansion characteristics[5].

Strengths: Improved foam flexibility and biodegradability, reduced density, and enhanced control over expansion process. Weaknesses: May require specialized equipment and process optimization for different starch sources.

Innovative Glycerol Applications in Foam Expansion

Extruded starch-lignin foams

PatentInactiveUS20160368186A1

Innovation

- A biodegradable and water-resistant packaging foam is produced by co-extruding unmodified starch with lignin, a hydrophobic natural polymer, which retains integrity after immersion in water and does not require chemical modification, utilizing an extrusion process that compatibilizes the polymeric components.

Stable expandable foam & concentrate & method

PatentInactiveUS4836939A

Innovation

- A stable expandable aqueous foam system is developed using a reactive polymer that cross-links with micellar structures in the foam concentrate, enhancing solubility and stability, allowing for easier manufacturing and use, with a micelle formation process that ensures the polymer bonds with surfactant molecules to create a stable foam structure.

Environmental Impact Assessment

The use of glycerol in modulating biodegradable foam expansion presents both environmental benefits and potential concerns that require careful assessment. This innovative approach to foam production aligns with the growing demand for sustainable materials in various industries, including packaging, construction, and automotive sectors.

One of the primary environmental advantages of using glycerol in biodegradable foam production is its potential to reduce reliance on petroleum-based raw materials. Glycerol, a byproduct of biodiesel production, can be sourced from renewable resources, contributing to a more circular economy. This shift towards bio-based materials can significantly lower the carbon footprint associated with foam manufacturing processes.

Furthermore, the biodegradability of the resulting foam products offers a promising solution to the persistent problem of plastic waste accumulation in landfills and oceans. As these foams break down naturally over time, they have the potential to minimize long-term environmental pollution and reduce the impact on wildlife and ecosystems.

However, the environmental impact assessment must also consider potential drawbacks and challenges. The production process itself may require energy-intensive steps or additional chemical treatments, which could offset some of the environmental gains. It is crucial to conduct a comprehensive life cycle analysis to accurately quantify the net environmental impact of glycerol-modulated biodegradable foams compared to traditional foam products.

Water consumption and potential water pollution during the manufacturing process are additional factors that warrant careful examination. The use of glycerol may introduce new water treatment requirements or alter existing wastewater management practices in foam production facilities.

Land use implications must also be evaluated, particularly if there is an increased demand for crops used in glycerol production. This could potentially lead to competition with food crops or contribute to deforestation if not managed sustainably.

The end-of-life management of these biodegradable foams presents both opportunities and challenges. While they offer the advantage of natural decomposition, proper disposal infrastructure and consumer education are essential to ensure these materials are handled correctly and do not contribute to unintended environmental issues.

In conclusion, the environmental impact assessment of using glycerol in biodegradable foam expansion must weigh the potential benefits of reduced fossil fuel dependence and improved end-of-life outcomes against possible drawbacks in production processes and resource management. Ongoing research and development efforts should focus on optimizing the environmental performance of these materials throughout their entire lifecycle.

One of the primary environmental advantages of using glycerol in biodegradable foam production is its potential to reduce reliance on petroleum-based raw materials. Glycerol, a byproduct of biodiesel production, can be sourced from renewable resources, contributing to a more circular economy. This shift towards bio-based materials can significantly lower the carbon footprint associated with foam manufacturing processes.

Furthermore, the biodegradability of the resulting foam products offers a promising solution to the persistent problem of plastic waste accumulation in landfills and oceans. As these foams break down naturally over time, they have the potential to minimize long-term environmental pollution and reduce the impact on wildlife and ecosystems.

However, the environmental impact assessment must also consider potential drawbacks and challenges. The production process itself may require energy-intensive steps or additional chemical treatments, which could offset some of the environmental gains. It is crucial to conduct a comprehensive life cycle analysis to accurately quantify the net environmental impact of glycerol-modulated biodegradable foams compared to traditional foam products.

Water consumption and potential water pollution during the manufacturing process are additional factors that warrant careful examination. The use of glycerol may introduce new water treatment requirements or alter existing wastewater management practices in foam production facilities.

Land use implications must also be evaluated, particularly if there is an increased demand for crops used in glycerol production. This could potentially lead to competition with food crops or contribute to deforestation if not managed sustainably.

The end-of-life management of these biodegradable foams presents both opportunities and challenges. While they offer the advantage of natural decomposition, proper disposal infrastructure and consumer education are essential to ensure these materials are handled correctly and do not contribute to unintended environmental issues.

In conclusion, the environmental impact assessment of using glycerol in biodegradable foam expansion must weigh the potential benefits of reduced fossil fuel dependence and improved end-of-life outcomes against possible drawbacks in production processes and resource management. Ongoing research and development efforts should focus on optimizing the environmental performance of these materials throughout their entire lifecycle.

Scalability and Industrial Implementation

The scalability and industrial implementation of glycerol-based biodegradable foam expansion technology present both opportunities and challenges for large-scale production. As the demand for sustainable packaging solutions continues to grow, the potential for this technology to be adopted in various industries is significant. However, several factors must be considered to ensure successful scaling and implementation.

One of the primary advantages of using glycerol in biodegradable foam expansion is its availability as a byproduct of biodiesel production. This abundant and relatively low-cost raw material can potentially reduce production costs and improve the economic viability of large-scale manufacturing. Additionally, glycerol's biodegradable nature aligns well with increasing environmental regulations and consumer preferences for eco-friendly packaging materials.

To scale up production, manufacturers will need to invest in specialized equipment capable of handling glycerol-based foam formulations. This may include modified extrusion systems, precise temperature control mechanisms, and advanced mixing technologies to ensure consistent foam quality across large production volumes. The development of automated processes for glycerol incorporation and foam expansion will be crucial for maintaining efficiency and product uniformity in industrial settings.

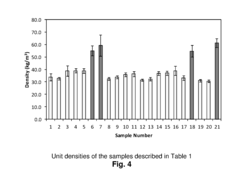

One of the key challenges in scaling this technology is maintaining the desired foam properties across different production batches. Factors such as glycerol concentration, temperature, pressure, and mixing ratios must be carefully controlled to achieve consistent foam density, cell structure, and biodegradability. Implementing robust quality control measures and real-time monitoring systems will be essential for ensuring product consistency and meeting industry standards.

Another important consideration for industrial implementation is the integration of this technology into existing manufacturing processes. Companies may need to modify their current production lines or establish new dedicated facilities for glycerol-based foam production. This transition may require significant capital investment and employee training to operate and maintain the new equipment effectively.

The storage and transportation of glycerol-based biodegradable foams also present unique challenges. These materials may be more sensitive to environmental conditions compared to traditional petroleum-based foams. Developing appropriate packaging and storage solutions to maintain product integrity throughout the supply chain will be crucial for successful commercialization.

As the technology scales up, optimizing the formulation for different applications and industries will be necessary. This may involve adjusting glycerol concentrations, incorporating additional additives, or modifying processing parameters to meet specific performance requirements for various end-use applications, such as food packaging, protective packaging, or construction materials.

One of the primary advantages of using glycerol in biodegradable foam expansion is its availability as a byproduct of biodiesel production. This abundant and relatively low-cost raw material can potentially reduce production costs and improve the economic viability of large-scale manufacturing. Additionally, glycerol's biodegradable nature aligns well with increasing environmental regulations and consumer preferences for eco-friendly packaging materials.

To scale up production, manufacturers will need to invest in specialized equipment capable of handling glycerol-based foam formulations. This may include modified extrusion systems, precise temperature control mechanisms, and advanced mixing technologies to ensure consistent foam quality across large production volumes. The development of automated processes for glycerol incorporation and foam expansion will be crucial for maintaining efficiency and product uniformity in industrial settings.

One of the key challenges in scaling this technology is maintaining the desired foam properties across different production batches. Factors such as glycerol concentration, temperature, pressure, and mixing ratios must be carefully controlled to achieve consistent foam density, cell structure, and biodegradability. Implementing robust quality control measures and real-time monitoring systems will be essential for ensuring product consistency and meeting industry standards.

Another important consideration for industrial implementation is the integration of this technology into existing manufacturing processes. Companies may need to modify their current production lines or establish new dedicated facilities for glycerol-based foam production. This transition may require significant capital investment and employee training to operate and maintain the new equipment effectively.

The storage and transportation of glycerol-based biodegradable foams also present unique challenges. These materials may be more sensitive to environmental conditions compared to traditional petroleum-based foams. Developing appropriate packaging and storage solutions to maintain product integrity throughout the supply chain will be crucial for successful commercialization.

As the technology scales up, optimizing the formulation for different applications and industries will be necessary. This may involve adjusting glycerol concentrations, incorporating additional additives, or modifying processing parameters to meet specific performance requirements for various end-use applications, such as food packaging, protective packaging, or construction materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!