Glycerol's Role in Modulating Hygroscopicity of Materials

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glycerol Hygroscopicity Background and Objectives

Glycerol, a simple polyol compound, has played a significant role in various industries due to its unique hygroscopic properties. The study of glycerol's impact on material hygroscopicity has gained increasing attention in recent years, driven by the growing demand for moisture-sensitive applications across multiple sectors.

The historical context of glycerol's use in modulating hygroscopicity dates back to the early 20th century when its humectant properties were first recognized. Initially employed in food preservation and cosmetics, glycerol's ability to attract and retain moisture has since found applications in pharmaceuticals, textiles, and advanced materials science.

As technology progressed, researchers began to explore the molecular mechanisms behind glycerol's hygroscopic behavior. The presence of three hydroxyl groups in its structure allows glycerol to form hydrogen bonds with water molecules, effectively capturing and retaining moisture from the surrounding environment. This fundamental understanding has paved the way for more sophisticated applications and targeted material modifications.

The evolution of glycerol-based hygroscopicity research has been marked by several key milestones. These include the development of glycerol-infused polymers for controlled drug release, the creation of moisture-regulating textiles, and the formulation of glycerol-containing coatings for corrosion protection. Each advancement has contributed to a deeper understanding of how glycerol interacts with different materials and environments.

In recent years, the focus has shifted towards leveraging glycerol's hygroscopic properties in emerging fields such as flexible electronics, energy storage, and biomaterials. This expansion into new domains has necessitated a more comprehensive investigation of glycerol's behavior under various conditions and its compatibility with diverse material systems.

The primary objectives of current research in this field are multifaceted. Scientists aim to elucidate the precise mechanisms by which glycerol modulates the hygroscopicity of different materials at the molecular level. This includes studying the kinetics of moisture absorption and desorption, as well as the impact of glycerol concentration on overall material properties.

Another key goal is to develop predictive models that can accurately forecast the hygroscopic behavior of glycerol-containing materials under diverse environmental conditions. Such models would greatly enhance the design and optimization of moisture-sensitive products across industries.

Furthermore, researchers are exploring novel methods to fine-tune glycerol's hygroscopic effects, such as chemical modifications or the incorporation of complementary additives. These efforts aim to create tailored solutions for specific applications, balancing moisture retention with other desired material properties.

As we look to the future, the study of glycerol's role in modulating hygroscopicity continues to evolve, driven by the need for more sustainable, efficient, and adaptable materials in an increasingly moisture-sensitive world.

The historical context of glycerol's use in modulating hygroscopicity dates back to the early 20th century when its humectant properties were first recognized. Initially employed in food preservation and cosmetics, glycerol's ability to attract and retain moisture has since found applications in pharmaceuticals, textiles, and advanced materials science.

As technology progressed, researchers began to explore the molecular mechanisms behind glycerol's hygroscopic behavior. The presence of three hydroxyl groups in its structure allows glycerol to form hydrogen bonds with water molecules, effectively capturing and retaining moisture from the surrounding environment. This fundamental understanding has paved the way for more sophisticated applications and targeted material modifications.

The evolution of glycerol-based hygroscopicity research has been marked by several key milestones. These include the development of glycerol-infused polymers for controlled drug release, the creation of moisture-regulating textiles, and the formulation of glycerol-containing coatings for corrosion protection. Each advancement has contributed to a deeper understanding of how glycerol interacts with different materials and environments.

In recent years, the focus has shifted towards leveraging glycerol's hygroscopic properties in emerging fields such as flexible electronics, energy storage, and biomaterials. This expansion into new domains has necessitated a more comprehensive investigation of glycerol's behavior under various conditions and its compatibility with diverse material systems.

The primary objectives of current research in this field are multifaceted. Scientists aim to elucidate the precise mechanisms by which glycerol modulates the hygroscopicity of different materials at the molecular level. This includes studying the kinetics of moisture absorption and desorption, as well as the impact of glycerol concentration on overall material properties.

Another key goal is to develop predictive models that can accurately forecast the hygroscopic behavior of glycerol-containing materials under diverse environmental conditions. Such models would greatly enhance the design and optimization of moisture-sensitive products across industries.

Furthermore, researchers are exploring novel methods to fine-tune glycerol's hygroscopic effects, such as chemical modifications or the incorporation of complementary additives. These efforts aim to create tailored solutions for specific applications, balancing moisture retention with other desired material properties.

As we look to the future, the study of glycerol's role in modulating hygroscopicity continues to evolve, driven by the need for more sustainable, efficient, and adaptable materials in an increasingly moisture-sensitive world.

Market Analysis for Hygroscopic Materials

The market for hygroscopic materials has been experiencing significant growth in recent years, driven by increasing demand across various industries. These materials, which have the ability to absorb moisture from the surrounding environment, find applications in diverse sectors such as pharmaceuticals, food packaging, electronics, and construction.

In the pharmaceutical industry, hygroscopic materials play a crucial role in maintaining the stability and efficacy of drugs. They are used in packaging to control moisture levels and protect sensitive medications from degradation. The growing pharmaceutical market, particularly in emerging economies, is expected to fuel the demand for hygroscopic materials in this sector.

The food and beverage industry represents another major market for hygroscopic materials. These materials are extensively used in food packaging to extend shelf life and maintain product quality. With the rising consumer demand for convenience foods and the expansion of the packaged food industry, the market for hygroscopic materials in this sector is projected to grow substantially.

In the electronics industry, hygroscopic materials are essential for protecting sensitive components from moisture-related damage. As the electronics market continues to expand, particularly with the advent of IoT devices and wearable technology, the demand for hygroscopic materials is expected to increase correspondingly.

The construction industry also utilizes hygroscopic materials for moisture control in buildings. These materials help regulate indoor humidity levels, improve energy efficiency, and prevent mold growth. With the growing emphasis on sustainable and energy-efficient construction, the market for hygroscopic materials in this sector is anticipated to witness steady growth.

The global market for hygroscopic materials is influenced by several factors, including technological advancements, environmental regulations, and changing consumer preferences. Innovations in material science are leading to the development of more efficient and sustainable hygroscopic materials, opening up new market opportunities.

Geographically, Asia-Pacific is expected to be the fastest-growing market for hygroscopic materials, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India. North America and Europe are also significant markets, with a strong presence of key industries that utilize hygroscopic materials.

In the pharmaceutical industry, hygroscopic materials play a crucial role in maintaining the stability and efficacy of drugs. They are used in packaging to control moisture levels and protect sensitive medications from degradation. The growing pharmaceutical market, particularly in emerging economies, is expected to fuel the demand for hygroscopic materials in this sector.

The food and beverage industry represents another major market for hygroscopic materials. These materials are extensively used in food packaging to extend shelf life and maintain product quality. With the rising consumer demand for convenience foods and the expansion of the packaged food industry, the market for hygroscopic materials in this sector is projected to grow substantially.

In the electronics industry, hygroscopic materials are essential for protecting sensitive components from moisture-related damage. As the electronics market continues to expand, particularly with the advent of IoT devices and wearable technology, the demand for hygroscopic materials is expected to increase correspondingly.

The construction industry also utilizes hygroscopic materials for moisture control in buildings. These materials help regulate indoor humidity levels, improve energy efficiency, and prevent mold growth. With the growing emphasis on sustainable and energy-efficient construction, the market for hygroscopic materials in this sector is anticipated to witness steady growth.

The global market for hygroscopic materials is influenced by several factors, including technological advancements, environmental regulations, and changing consumer preferences. Innovations in material science are leading to the development of more efficient and sustainable hygroscopic materials, opening up new market opportunities.

Geographically, Asia-Pacific is expected to be the fastest-growing market for hygroscopic materials, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India. North America and Europe are also significant markets, with a strong presence of key industries that utilize hygroscopic materials.

Current Challenges in Glycerol-Based Hygroscopicity Control

Despite the widespread use of glycerol in hygroscopicity control, several challenges persist in fully harnessing its potential. One of the primary obstacles is achieving precise and consistent control over the hygroscopic properties of materials. The hygroscopicity of glycerol-based systems can be highly sensitive to environmental conditions, making it difficult to maintain stable performance across varying humidity levels and temperatures.

Another significant challenge lies in the long-term stability of glycerol-based hygroscopic materials. Over time, these materials may experience changes in their physical and chemical properties, potentially leading to reduced effectiveness or even degradation. This issue is particularly pronounced in applications requiring extended periods of use or exposure to harsh environmental conditions.

The integration of glycerol into complex material systems presents additional hurdles. Compatibility issues may arise when incorporating glycerol into certain matrices, affecting the overall performance and durability of the final product. Researchers and engineers must carefully consider the interactions between glycerol and other components to optimize the desired hygroscopic properties while maintaining the integrity of the material system.

Furthermore, the concentration-dependent behavior of glycerol in modulating hygroscopicity poses challenges in formulation and application. Determining the optimal glycerol concentration for specific applications requires extensive experimentation and fine-tuning, as the relationship between glycerol content and hygroscopic performance is often non-linear and can vary significantly depending on the base material and intended use.

The potential for glycerol migration within materials over time is another concern that researchers must address. This phenomenon can lead to uneven distribution of glycerol throughout the material, resulting in inconsistent hygroscopic properties and potentially compromising the overall performance of the product.

Scaling up glycerol-based hygroscopicity control solutions from laboratory settings to industrial applications presents its own set of challenges. Maintaining uniform glycerol distribution and ensuring consistent performance across large-scale production processes can be technically demanding and may require significant process optimization.

Lastly, the environmental impact and sustainability of glycerol-based hygroscopic materials are becoming increasingly important considerations. While glycerol itself is generally considered environmentally friendly, its production methods and the overall life cycle of glycerol-containing products must be carefully evaluated to ensure alignment with sustainability goals and regulations.

Another significant challenge lies in the long-term stability of glycerol-based hygroscopic materials. Over time, these materials may experience changes in their physical and chemical properties, potentially leading to reduced effectiveness or even degradation. This issue is particularly pronounced in applications requiring extended periods of use or exposure to harsh environmental conditions.

The integration of glycerol into complex material systems presents additional hurdles. Compatibility issues may arise when incorporating glycerol into certain matrices, affecting the overall performance and durability of the final product. Researchers and engineers must carefully consider the interactions between glycerol and other components to optimize the desired hygroscopic properties while maintaining the integrity of the material system.

Furthermore, the concentration-dependent behavior of glycerol in modulating hygroscopicity poses challenges in formulation and application. Determining the optimal glycerol concentration for specific applications requires extensive experimentation and fine-tuning, as the relationship between glycerol content and hygroscopic performance is often non-linear and can vary significantly depending on the base material and intended use.

The potential for glycerol migration within materials over time is another concern that researchers must address. This phenomenon can lead to uneven distribution of glycerol throughout the material, resulting in inconsistent hygroscopic properties and potentially compromising the overall performance of the product.

Scaling up glycerol-based hygroscopicity control solutions from laboratory settings to industrial applications presents its own set of challenges. Maintaining uniform glycerol distribution and ensuring consistent performance across large-scale production processes can be technically demanding and may require significant process optimization.

Lastly, the environmental impact and sustainability of glycerol-based hygroscopic materials are becoming increasingly important considerations. While glycerol itself is generally considered environmentally friendly, its production methods and the overall life cycle of glycerol-containing products must be carefully evaluated to ensure alignment with sustainability goals and regulations.

Existing Glycerol-Based Hygroscopicity Solutions

01 Hygroscopic properties of glycerol in various applications

Glycerol's hygroscopic nature is utilized in various applications, including moisture retention in food products, pharmaceuticals, and personal care items. Its ability to absorb and retain water helps maintain product stability and prevent drying out. This property is particularly useful in formulations where moisture control is crucial for product efficacy and shelf life.- Hygroscopic properties of glycerol in various applications: Glycerol's hygroscopic nature is utilized in diverse applications, including moisture retention in food products, pharmaceuticals, and personal care items. Its ability to absorb and retain water from the surrounding environment makes it valuable for maintaining product stability and preventing dryness.

- Glycerol as a humectant in cosmetic and personal care products: The hygroscopic properties of glycerol make it an excellent humectant in cosmetic and personal care formulations. It helps to attract and retain moisture, keeping skin and hair hydrated. This property is particularly useful in lotions, creams, and hair care products to improve texture and moisturizing effects.

- Use of glycerol in pharmaceutical formulations: Glycerol's hygroscopicity is beneficial in pharmaceutical formulations, where it can help maintain the moisture content of drugs and prevent them from drying out. It is used in various dosage forms, including oral liquids, topical preparations, and suppositories, to improve stability and enhance drug delivery.

- Glycerol in industrial and technical applications: The hygroscopic nature of glycerol is exploited in various industrial and technical applications. It is used as a plasticizer in polymers, a lubricant in machinery, and a component in antifreeze formulations. Its ability to absorb moisture helps prevent corrosion and improves the performance of certain materials and products.

- Glycerol's role in food preservation and quality enhancement: In the food industry, glycerol's hygroscopicity is utilized for moisture retention and preservation. It helps maintain the texture and freshness of baked goods, confectionery, and processed foods. Additionally, it can act as a sweetener and flavor enhancer while contributing to the overall stability and shelf life of food products.

02 Glycerol as a humectant in cosmetic and personal care products

The hygroscopic nature of glycerol makes it an excellent humectant in cosmetic and personal care formulations. It helps to attract and retain moisture, keeping skin and hair hydrated. This property is beneficial in lotions, creams, and hair care products, where it can improve product texture and enhance the moisturizing effects.Expand Specific Solutions03 Use of glycerol in pharmaceutical and medical applications

Glycerol's hygroscopicity is advantageous in pharmaceutical and medical applications. It can be used as a solvent, preservative, and moisture-retaining agent in various drug formulations. Its ability to maintain moisture levels is particularly useful in topical medications and wound dressings, where it can help create a moist environment conducive to healing.Expand Specific Solutions04 Glycerol in food preservation and quality enhancement

The hygroscopic properties of glycerol are utilized in food preservation and quality enhancement. It acts as a humectant in food products, helping to maintain moisture content and prevent drying out. This property is particularly useful in baked goods, confectionery, and processed meats, where it can improve texture, extend shelf life, and prevent crystallization.Expand Specific Solutions05 Industrial applications of glycerol's hygroscopicity

Glycerol's hygroscopic nature finds applications in various industrial processes. It is used in the production of plastics, resins, and lubricants, where its moisture-retaining properties can enhance product performance. In the textile industry, it can be used as a softening agent and to improve fabric moisture management. Its hygroscopicity is also utilized in certain types of coatings and adhesives to control drying rates and improve product stability.Expand Specific Solutions

Key Players in Glycerol and Hygroscopic Materials Industry

The glycerol modulation of material hygroscopicity market is in a growth phase, driven by increasing demand for moisture control in various industries. The global market size is estimated to be in the hundreds of millions of dollars, with steady expansion projected. Technologically, the field is moderately mature, with ongoing research to enhance efficacy and sustainability. Key players like Omya International AG, China Petroleum & Chemical Corp., and LG Chem Ltd. are investing in R&D to develop advanced glycerol-based solutions. Emerging companies such as Sakamoto Yakuhin Kogyo Co., Ltd. and EnviroScent, Inc. are also contributing to innovation in this space, focusing on specialized applications and eco-friendly formulations.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced glycerol-based technologies for modulating hygroscopicity in battery materials and polymer composites. Their research focuses on using glycerol as a hygroscopic agent in lithium-ion battery electrolytes to improve performance and safety. The company has patented a method that incorporates glycerol-derived compounds into electrolyte formulations, enhancing moisture absorption and reducing the risk of battery degradation due to water contamination[3]. Additionally, LG Chem has explored the use of glycerol in polymer blends to create hygroscopic films with controlled moisture permeability for packaging applications. Their approach involves optimizing the glycerol content and distribution within the polymer matrix to achieve desired hygroscopic properties[4].

Strengths: Strong presence in the battery and materials industries, extensive R&D resources, and potential for cross-sector applications. Weaknesses: Intense competition in the battery market and the need to balance hygroscopicity with other material properties.

Evonik Operations GmbH

Technical Solution: Evonik has developed innovative glycerol-based solutions for modulating hygroscopicity in various materials. Their approach involves incorporating glycerol into polymer matrices to create hygroscopic composites with controlled moisture absorption properties. The company has patented a method using glycerol-modified silica particles to enhance the moisture retention capabilities of materials while maintaining their structural integrity[1]. This technology allows for precise control over the hygroscopic behavior of materials, making them suitable for applications in pharmaceuticals, food packaging, and personal care products. Evonik's research has also explored the use of glycerol as a plasticizer in biodegradable polymers, improving their flexibility and moisture barrier properties[2].

Strengths: Extensive expertise in specialty chemicals, strong R&D capabilities, and a wide range of potential applications across industries. Weaknesses: Potential competition from other major chemical companies and the need for continuous innovation to maintain market leadership.

Core Innovations in Glycerol Hygroscopicity Modulation

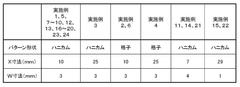

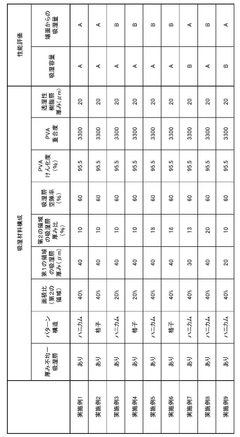

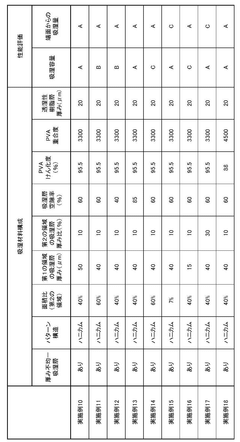

Hygroscopic material, method for producing the same, and packaging material

PatentInactiveUS20180043301A1

Innovation

- A hygroscopic material comprising a transparent base material, a hygroscopic layer with an inorganic salt moisture-absorbing agent, and an upper layer of vinyl acetate resin, where the vinyl acetate resin is applied as particles with a specific particle diameter and copolymer composition to prevent aggregate formation and maintain transparency.

Hygroscopic material, method for producing same, packaging material, and package item

PatentWO2017057607A1

Innovation

- A moisture-absorbing material with a layered structure comprising a moisture-permeable resin layer, a moisture-absorption layer with uneven thickness, and a moisture-proof layer, where the moisture-absorption layer has a pattern with a thicker first region and a thinner second region, inhibiting moisture infiltration from the edges, and a porosity of 45-85% for enhanced absorption capacity.

Environmental Impact of Glycerol in Hygroscopic Applications

The environmental impact of glycerol in hygroscopic applications is a critical consideration as the use of this compound becomes more widespread. Glycerol, a byproduct of biodiesel production, has gained attention for its ability to modulate the hygroscopicity of materials. However, its increased utilization raises questions about potential environmental consequences.

Glycerol's biodegradability is a significant advantage from an environmental perspective. When released into the environment, it can be readily broken down by microorganisms, reducing long-term accumulation in ecosystems. This characteristic makes glycerol a more environmentally friendly option compared to some synthetic hygroscopic agents.

However, the production and disposal of glycerol-containing products can still have environmental implications. The manufacturing process of glycerol, particularly when derived from non-renewable sources, may contribute to carbon emissions and energy consumption. Additionally, while biodegradable, improper disposal of glycerol-rich materials can lead to localized environmental issues, such as increased biochemical oxygen demand in water bodies.

In hygroscopic applications, glycerol's ability to retain moisture can have both positive and negative environmental effects. On one hand, it can enhance the durability and longevity of certain materials, potentially reducing waste and the need for frequent replacements. This can lead to a decrease in overall resource consumption and waste generation. On the other hand, the increased moisture retention in some applications might promote microbial growth, potentially leading to faster degradation of organic materials or the need for additional preservatives.

The use of glycerol in hygroscopic materials can also impact energy consumption. In some cases, it may improve the thermal insulation properties of materials, potentially reducing energy needs for heating or cooling. However, in other applications, the increased moisture content might necessitate additional energy for drying or processing.

From a lifecycle perspective, the environmental impact of glycerol in hygroscopic applications depends heavily on the specific use case and end-of-life management. Proper recycling and waste management strategies are crucial to mitigate potential negative impacts. Furthermore, the source of glycerol (renewable vs. non-renewable) plays a significant role in its overall environmental footprint.

As research continues, there is growing interest in developing more sustainable production methods for glycerol and optimizing its use in hygroscopic applications to maximize environmental benefits while minimizing potential drawbacks. This includes exploring bio-based sources of glycerol and improving the efficiency of its production and application processes.

Glycerol's biodegradability is a significant advantage from an environmental perspective. When released into the environment, it can be readily broken down by microorganisms, reducing long-term accumulation in ecosystems. This characteristic makes glycerol a more environmentally friendly option compared to some synthetic hygroscopic agents.

However, the production and disposal of glycerol-containing products can still have environmental implications. The manufacturing process of glycerol, particularly when derived from non-renewable sources, may contribute to carbon emissions and energy consumption. Additionally, while biodegradable, improper disposal of glycerol-rich materials can lead to localized environmental issues, such as increased biochemical oxygen demand in water bodies.

In hygroscopic applications, glycerol's ability to retain moisture can have both positive and negative environmental effects. On one hand, it can enhance the durability and longevity of certain materials, potentially reducing waste and the need for frequent replacements. This can lead to a decrease in overall resource consumption and waste generation. On the other hand, the increased moisture retention in some applications might promote microbial growth, potentially leading to faster degradation of organic materials or the need for additional preservatives.

The use of glycerol in hygroscopic materials can also impact energy consumption. In some cases, it may improve the thermal insulation properties of materials, potentially reducing energy needs for heating or cooling. However, in other applications, the increased moisture content might necessitate additional energy for drying or processing.

From a lifecycle perspective, the environmental impact of glycerol in hygroscopic applications depends heavily on the specific use case and end-of-life management. Proper recycling and waste management strategies are crucial to mitigate potential negative impacts. Furthermore, the source of glycerol (renewable vs. non-renewable) plays a significant role in its overall environmental footprint.

As research continues, there is growing interest in developing more sustainable production methods for glycerol and optimizing its use in hygroscopic applications to maximize environmental benefits while minimizing potential drawbacks. This includes exploring bio-based sources of glycerol and improving the efficiency of its production and application processes.

Regulatory Framework for Glycerol Use in Materials

The regulatory framework for glycerol use in materials is a complex and evolving landscape that varies across different regions and industries. In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating glycerol's use in food, pharmaceuticals, and cosmetics. The FDA classifies glycerol as Generally Recognized as Safe (GRAS) for use in food products, with specific guidelines for its application in various food categories. For pharmaceutical applications, glycerol is listed in the United States Pharmacopeia (USP) and must comply with strict quality and purity standards.

In the European Union, the European Chemicals Agency (ECHA) oversees the regulation of glycerol under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework. Manufacturers and importers of glycerol must register the substance and provide safety data to ensure its safe use in various applications. The European Food Safety Authority (EFSA) also evaluates glycerol's safety for use in food products and food contact materials.

Globally, the International Organization for Standardization (ISO) has developed standards for glycerol quality and testing methods, which are widely adopted by industries worldwide. These standards help ensure consistency and safety in glycerol production and use across different applications and markets.

In the context of materials science, regulatory bodies often focus on the safety and environmental impact of glycerol-containing materials. For instance, the Environmental Protection Agency (EPA) in the United States may regulate glycerol-based materials used in construction or industrial applications to ensure they meet environmental standards. Similarly, the European Union's Construction Products Regulation (CPR) sets requirements for construction materials, which may include those incorporating glycerol for hygroscopic properties.

As the use of glycerol in materials science continues to expand, particularly in areas such as biodegradable plastics and smart materials, regulatory frameworks are likely to evolve. Emerging regulations may focus on the lifecycle assessment of glycerol-based materials, including their production, use, and disposal. This could lead to new standards for biodegradability, recyclability, and overall environmental impact.

Manufacturers and researchers working with glycerol in materials applications must navigate this complex regulatory landscape, ensuring compliance with relevant standards and regulations. This often requires ongoing monitoring of regulatory changes, participation in industry associations, and engagement with regulatory bodies to stay informed of emerging requirements and best practices.

In the European Union, the European Chemicals Agency (ECHA) oversees the regulation of glycerol under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework. Manufacturers and importers of glycerol must register the substance and provide safety data to ensure its safe use in various applications. The European Food Safety Authority (EFSA) also evaluates glycerol's safety for use in food products and food contact materials.

Globally, the International Organization for Standardization (ISO) has developed standards for glycerol quality and testing methods, which are widely adopted by industries worldwide. These standards help ensure consistency and safety in glycerol production and use across different applications and markets.

In the context of materials science, regulatory bodies often focus on the safety and environmental impact of glycerol-containing materials. For instance, the Environmental Protection Agency (EPA) in the United States may regulate glycerol-based materials used in construction or industrial applications to ensure they meet environmental standards. Similarly, the European Union's Construction Products Regulation (CPR) sets requirements for construction materials, which may include those incorporating glycerol for hygroscopic properties.

As the use of glycerol in materials science continues to expand, particularly in areas such as biodegradable plastics and smart materials, regulatory frameworks are likely to evolve. Emerging regulations may focus on the lifecycle assessment of glycerol-based materials, including their production, use, and disposal. This could lead to new standards for biodegradability, recyclability, and overall environmental impact.

Manufacturers and researchers working with glycerol in materials applications must navigate this complex regulatory landscape, ensuring compliance with relevant standards and regulations. This often requires ongoing monitoring of regulatory changes, participation in industry associations, and engagement with regulatory bodies to stay informed of emerging requirements and best practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!