How Glycerol Modulates Viscosity of Baking Ingredients

JUL 23, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glycerol in Baking: Background and Objectives

Glycerol, also known as glycerin or glycerine, has been a staple ingredient in the baking industry for decades. Its unique properties have made it an invaluable component in various baking applications, particularly in modulating the viscosity of ingredients. The journey of glycerol in baking can be traced back to the early 20th century when food scientists began exploring its potential as a humectant and texture modifier.

The primary objective of utilizing glycerol in baking is to enhance the quality, texture, and shelf life of baked goods. As a polyol compound, glycerol possesses hygroscopic properties that allow it to retain moisture, thereby preventing baked products from drying out quickly. This characteristic has been crucial in the development of shelf-stable baked goods, meeting the growing consumer demand for convenience foods.

Over the years, the baking industry has witnessed a significant evolution in the understanding and application of glycerol. Initially used primarily as a sweetener and preservative, its role has expanded to include viscosity modulation, which is critical in achieving desired textures in various baked products. This shift in focus has been driven by advancements in food science and changing consumer preferences for improved mouthfeel and texture in baked goods.

The technological progression in glycerol application has been marked by several key milestones. These include the development of glycerol-based emulsifiers, the optimization of glycerol concentrations for specific baking applications, and the exploration of synergistic effects between glycerol and other ingredients. Each of these advancements has contributed to a more nuanced understanding of how glycerol interacts with other baking components to influence viscosity.

Current research in this field aims to further elucidate the molecular mechanisms by which glycerol modulates the viscosity of baking ingredients. This includes investigating its interactions with proteins, starches, and fats under various baking conditions. The goal is to develop more precise and efficient ways of utilizing glycerol to achieve desired viscosities in different types of baked goods, from bread and pastries to cakes and cookies.

As the baking industry continues to evolve, driven by consumer demands for healthier options and clean label products, the role of glycerol is also being reevaluated. There is growing interest in understanding how glycerol can be used to reduce sugar and fat content in baked goods while maintaining desirable textures and mouthfeel. This aligns with the broader trend towards healthier baking alternatives without compromising on taste or texture.

The primary objective of utilizing glycerol in baking is to enhance the quality, texture, and shelf life of baked goods. As a polyol compound, glycerol possesses hygroscopic properties that allow it to retain moisture, thereby preventing baked products from drying out quickly. This characteristic has been crucial in the development of shelf-stable baked goods, meeting the growing consumer demand for convenience foods.

Over the years, the baking industry has witnessed a significant evolution in the understanding and application of glycerol. Initially used primarily as a sweetener and preservative, its role has expanded to include viscosity modulation, which is critical in achieving desired textures in various baked products. This shift in focus has been driven by advancements in food science and changing consumer preferences for improved mouthfeel and texture in baked goods.

The technological progression in glycerol application has been marked by several key milestones. These include the development of glycerol-based emulsifiers, the optimization of glycerol concentrations for specific baking applications, and the exploration of synergistic effects between glycerol and other ingredients. Each of these advancements has contributed to a more nuanced understanding of how glycerol interacts with other baking components to influence viscosity.

Current research in this field aims to further elucidate the molecular mechanisms by which glycerol modulates the viscosity of baking ingredients. This includes investigating its interactions with proteins, starches, and fats under various baking conditions. The goal is to develop more precise and efficient ways of utilizing glycerol to achieve desired viscosities in different types of baked goods, from bread and pastries to cakes and cookies.

As the baking industry continues to evolve, driven by consumer demands for healthier options and clean label products, the role of glycerol is also being reevaluated. There is growing interest in understanding how glycerol can be used to reduce sugar and fat content in baked goods while maintaining desirable textures and mouthfeel. This aligns with the broader trend towards healthier baking alternatives without compromising on taste or texture.

Market Analysis of Glycerol-Enhanced Baking Products

The market for glycerol-enhanced baking products has shown significant growth in recent years, driven by increasing consumer demand for improved texture and shelf life in baked goods. Glycerol, also known as glycerin, has emerged as a versatile ingredient in the baking industry due to its ability to modulate viscosity and retain moisture in various baking ingredients.

The global market for glycerol in food applications, including baking, was valued at approximately $1.2 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026. This growth is primarily attributed to the rising awareness of glycerol's functional properties in baking and its potential to enhance product quality.

In the baking sector, glycerol-enhanced products have gained traction across various categories, including bread, cakes, pastries, and cookies. The bread segment holds the largest market share, accounting for over 40% of glycerol usage in baking applications. This is due to glycerol's ability to improve dough handling, extend shelf life, and maintain softness in bread products.

Consumer preferences for clean label and natural ingredients have also contributed to the market growth of glycerol-enhanced baking products. Glycerol, being a natural humectant, aligns well with these trends and is increasingly being used as a replacement for artificial additives in baked goods.

The market for glycerol-enhanced baking products is geographically diverse, with North America and Europe leading in terms of adoption and market value. These regions collectively account for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth, with a CAGR of 7.2% during the forecast period, driven by changing dietary habits and increasing disposable incomes.

Key market players in the glycerol-enhanced baking products sector include major food manufacturers and ingredient suppliers. Companies such as Cargill, Archer Daniels Midland, and Ingredion have been at the forefront of developing and marketing glycerol-based solutions for the baking industry. These companies are investing heavily in research and development to create innovative formulations that optimize the use of glycerol in various baking applications.

The market is also witnessing a trend towards the development of organic and non-GMO glycerol options to cater to the growing demand for clean label products. This has led to the emergence of specialized suppliers focusing on natural and sustainable glycerol production methods.

The global market for glycerol in food applications, including baking, was valued at approximately $1.2 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026. This growth is primarily attributed to the rising awareness of glycerol's functional properties in baking and its potential to enhance product quality.

In the baking sector, glycerol-enhanced products have gained traction across various categories, including bread, cakes, pastries, and cookies. The bread segment holds the largest market share, accounting for over 40% of glycerol usage in baking applications. This is due to glycerol's ability to improve dough handling, extend shelf life, and maintain softness in bread products.

Consumer preferences for clean label and natural ingredients have also contributed to the market growth of glycerol-enhanced baking products. Glycerol, being a natural humectant, aligns well with these trends and is increasingly being used as a replacement for artificial additives in baked goods.

The market for glycerol-enhanced baking products is geographically diverse, with North America and Europe leading in terms of adoption and market value. These regions collectively account for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth, with a CAGR of 7.2% during the forecast period, driven by changing dietary habits and increasing disposable incomes.

Key market players in the glycerol-enhanced baking products sector include major food manufacturers and ingredient suppliers. Companies such as Cargill, Archer Daniels Midland, and Ingredion have been at the forefront of developing and marketing glycerol-based solutions for the baking industry. These companies are investing heavily in research and development to create innovative formulations that optimize the use of glycerol in various baking applications.

The market is also witnessing a trend towards the development of organic and non-GMO glycerol options to cater to the growing demand for clean label products. This has led to the emergence of specialized suppliers focusing on natural and sustainable glycerol production methods.

Current Challenges in Glycerol-Based Viscosity Modulation

The modulation of viscosity in baking ingredients using glycerol presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary issues is achieving consistent and predictable viscosity control across a wide range of baking ingredients. Different ingredients, such as flour, eggs, and oils, interact with glycerol in varied ways, making it difficult to establish a standardized approach for viscosity modulation.

Temperature sensitivity poses another major challenge in glycerol-based viscosity control. Baking processes often involve temperature fluctuations, which can significantly affect the viscosity-modulating properties of glycerol. This temperature dependence complicates the formulation of stable recipes and can lead to inconsistencies in the final baked products.

The hygroscopic nature of glycerol introduces additional complexities. Its ability to absorb moisture from the environment can alter the water content of baking mixtures over time, potentially leading to changes in viscosity and texture. This property makes it challenging to maintain the desired viscosity throughout the shelf life of baking ingredients or premixed formulations.

Interactions between glycerol and other ingredients in baking formulations present yet another hurdle. Proteins, starches, and fats can all influence how glycerol affects viscosity, sometimes leading to unexpected results. Understanding and predicting these complex interactions remains a significant challenge for food scientists and bakers alike.

Dosage control is a critical aspect that requires careful consideration. Determining the optimal concentration of glycerol for different baking applications while balancing viscosity modulation with other factors such as taste, texture, and nutritional value is an ongoing challenge. Too little glycerol may not achieve the desired viscosity, while too much can negatively impact flavor or cause excessive moisture retention.

Regulatory compliance and consumer perception also pose challenges in the use of glycerol for viscosity modulation. While glycerol is generally recognized as safe, there are limitations on its use in certain food categories. Additionally, the growing consumer demand for "clean label" products has led to scrutiny of ingredients like glycerol, necessitating careful consideration of its use in baking applications.

Lastly, the cost-effectiveness of glycerol-based viscosity modulation remains a concern for many manufacturers. Balancing the benefits of improved viscosity control with the additional costs associated with glycerol usage and potential reformulation of existing products is an ongoing challenge in the baking industry.

Temperature sensitivity poses another major challenge in glycerol-based viscosity control. Baking processes often involve temperature fluctuations, which can significantly affect the viscosity-modulating properties of glycerol. This temperature dependence complicates the formulation of stable recipes and can lead to inconsistencies in the final baked products.

The hygroscopic nature of glycerol introduces additional complexities. Its ability to absorb moisture from the environment can alter the water content of baking mixtures over time, potentially leading to changes in viscosity and texture. This property makes it challenging to maintain the desired viscosity throughout the shelf life of baking ingredients or premixed formulations.

Interactions between glycerol and other ingredients in baking formulations present yet another hurdle. Proteins, starches, and fats can all influence how glycerol affects viscosity, sometimes leading to unexpected results. Understanding and predicting these complex interactions remains a significant challenge for food scientists and bakers alike.

Dosage control is a critical aspect that requires careful consideration. Determining the optimal concentration of glycerol for different baking applications while balancing viscosity modulation with other factors such as taste, texture, and nutritional value is an ongoing challenge. Too little glycerol may not achieve the desired viscosity, while too much can negatively impact flavor or cause excessive moisture retention.

Regulatory compliance and consumer perception also pose challenges in the use of glycerol for viscosity modulation. While glycerol is generally recognized as safe, there are limitations on its use in certain food categories. Additionally, the growing consumer demand for "clean label" products has led to scrutiny of ingredients like glycerol, necessitating careful consideration of its use in baking applications.

Lastly, the cost-effectiveness of glycerol-based viscosity modulation remains a concern for many manufacturers. Balancing the benefits of improved viscosity control with the additional costs associated with glycerol usage and potential reformulation of existing products is an ongoing challenge in the baking industry.

Existing Methods for Glycerol-Induced Viscosity Control

01 Glycerol as a viscosity modifier in various compositions

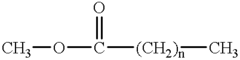

Glycerol is widely used as a viscosity modifier in various compositions, including cosmetics, pharmaceuticals, and industrial products. Its ability to adjust viscosity makes it a versatile ingredient in formulations where specific flow properties are required. The concentration of glycerol can be adjusted to achieve desired viscosity levels in different applications.- Glycerol as a viscosity modifier: Glycerol is widely used as a viscosity modifier in various applications. It can increase or decrease the viscosity of solutions depending on its concentration and the other components present. This property makes it valuable in industries such as pharmaceuticals, cosmetics, and food processing.

- Temperature effects on glycerol viscosity: The viscosity of glycerol is highly temperature-dependent. As temperature increases, the viscosity of glycerol decreases significantly. This relationship is important in applications where temperature fluctuations occur, and precise viscosity control is required.

- Glycerol in polymer and composite materials: Glycerol is used in the production of polymer and composite materials to modify their viscosity and other properties. It can act as a plasticizer, improving flexibility and processability of materials such as biopolymers and resins.

- Measurement and control of glycerol viscosity: Various methods and devices are employed to measure and control the viscosity of glycerol and glycerol-containing solutions. These include rheometers, viscometers, and inline process control systems. Accurate measurement and control are crucial in many industrial processes.

- Glycerol in fuel and lubricant formulations: Glycerol and its derivatives are used in fuel and lubricant formulations to modify viscosity and other properties. This application is particularly relevant in the development of biofuels and environmentally friendly lubricants, where glycerol can enhance performance and reduce environmental impact.

02 Relationship between glycerol concentration and viscosity

The viscosity of glycerol-containing solutions is directly related to the concentration of glycerol. As the glycerol concentration increases, the viscosity of the solution typically increases. This relationship is important in formulating products with specific flow characteristics and can be used to control the texture and consistency of various preparations.Expand Specific Solutions03 Temperature effects on glycerol viscosity

The viscosity of glycerol is significantly affected by temperature changes. As temperature increases, the viscosity of glycerol decreases. This temperature-dependent behavior is crucial in applications where the product may be exposed to different temperatures during manufacturing, storage, or use.Expand Specific Solutions04 Glycerol in polymer and biopolymer solutions

Glycerol is often used in polymer and biopolymer solutions to modify their viscosity and other physical properties. It can act as a plasticizer in some polymer systems, affecting not only viscosity but also flexibility and durability. The interaction between glycerol and polymers can lead to unique rheological properties in the resulting solutions or materials.Expand Specific Solutions05 Measurement and control of glycerol viscosity

Accurate measurement and control of glycerol viscosity are essential in many industrial and research applications. Various methods and instruments are used to measure glycerol viscosity, including rotational viscometers and capillary viscometers. Controlling glycerol viscosity often involves precise temperature regulation and careful formulation to achieve desired flow properties in final products.Expand Specific Solutions

Key Players in Glycerol and Baking Ingredients Market

The glycerol modulation of baking ingredients' viscosity is an emerging field in food technology, currently in its early development stage. The market size is relatively small but growing, driven by increasing demand for improved texture and shelf-life in baked goods. Technologically, it's still evolving, with companies like Suntory Holdings, Kao Corp., and Beiersdorf AG leading research efforts. These firms are exploring glycerol's potential in various food applications, leveraging their expertise in chemical formulations. While not yet fully mature, this technology shows promise for enhancing baking processes and product quality, attracting interest from both established food companies and innovative startups.

The Nisshin OilliO Group, Ltd.

Technical Solution: The Nisshin OilliO Group has developed an innovative approach to glycerol-based viscosity modulation that focuses on the interaction between glycerol and various plant-based oils and fats. Their technology involves creating specialized lipid-glycerol complexes that can be precisely tailored to achieve specific viscosity profiles in baking applications[8]. By carefully controlling the ratio of glycerol to different types of fatty acids, Nisshin OilliO can create ingredients that provide optimal viscosity for various baking processes while also contributing to improved nutritional profiles. Their research has also explored the use of enzymatically modified glycerides in combination with glycerol to further enhance viscosity control and stability in challenging baking environments[9].

Strengths: Expertise in lipid chemistry allows for precise control of viscosity in fat-based systems, potential for improved nutritional profiles. Weaknesses: May be more effective in high-fat baking applications, potentially less versatile in low-fat formulations.

Chr. Hansen A/S

Technical Solution: Chr. Hansen has focused on leveraging their expertise in microbial fermentation to develop a novel approach to glycerol-based viscosity modulation in baking ingredients. Their technology involves the use of specially selected probiotic strains that can metabolize glycerol during the fermentation process, producing exopolysaccharides that act as natural thickeners and viscosity modifiers[6]. This bio-based approach allows for dynamic viscosity control throughout the baking process, as the microbial activity continues to influence the rheological properties of the dough or batter. Chr. Hansen's research has shown that this method can significantly improve the texture and shelf-life of baked goods while providing additional health benefits from the probiotic cultures[7].

Strengths: Natural, bio-based approach to viscosity modulation, potential added health benefits from probiotic cultures. Weaknesses: May require careful control of fermentation conditions, potential variability in results due to biological processes.

Innovative Approaches in Glycerol-Baking Interactions

A method for making a soft cake batter

PatentActiveEP2996479A1

Innovation

- A method involving the creation of a sourdough by mixing and proofing a portion of flour with water and culture, then combining it with the remaining flour and other ingredients to form a batter, ensuring at least 40 wt.% cereal material in the final soft cake, without forming a gluten network.

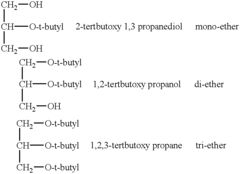

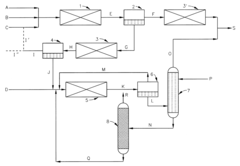

System and process for producing biodiesel fuel with reduced viscosity and a cloud point below thirty-two (32) degrees fahrenheit

PatentInactiveUS6174501B1

Innovation

- A process that separates crude glycerol from transesterified triglycerides and subjects it to etherification to produce etherified glycerol, which is then recombined with the transesterified triglycerides to create an oxygenated biodiesel fuel with a cloud point below 32 degrees Fahrenheit, improving flow characteristics and reducing waste.

Food Safety Regulations for Glycerol in Baking

The use of glycerol in baking ingredients is subject to stringent food safety regulations to ensure consumer protection. In the United States, the Food and Drug Administration (FDA) classifies glycerol as Generally Recognized as Safe (GRAS) when used in accordance with good manufacturing practices. The FDA has established specific guidelines for the use of glycerol in food products, including baked goods.

The European Food Safety Authority (EFSA) has also evaluated the safety of glycerol as a food additive. In the European Union, glycerol is approved for use in various food categories, including bakery products, under the E number E422. The EFSA has set an Acceptable Daily Intake (ADI) of "not specified" for glycerol, indicating that it does not pose a significant health risk when used as intended.

Regulatory bodies worldwide require manufacturers to adhere to specific labeling requirements when using glycerol in baking ingredients. In most jurisdictions, glycerol must be declared on the ingredient list of packaged foods. This transparency allows consumers to make informed choices about the products they purchase and consume.

Food safety regulations also address the purity and quality of glycerol used in baking applications. Manufacturers must ensure that the glycerol they use meets specified purity criteria to prevent contamination with potentially harmful substances. This includes limits on impurities such as diethylene glycol and ethylene glycol, which can be toxic if present in significant quantities.

The use of glycerol in organic baking products is subject to additional regulations. In the United States, the National Organic Program (NOP) allows the use of glycerol in organic products only if it is derived from agricultural sources and processed using approved methods. Similar restrictions apply in other countries with organic certification programs.

Regulatory bodies also monitor the potential for glycerol to interact with other ingredients in baking applications. While glycerol is generally considered safe, its hygroscopic properties can affect the moisture content and shelf life of baked goods. Manufacturers must ensure that the use of glycerol does not compromise the overall safety and stability of their products.

As research on the effects of glycerol in food continues, regulatory bodies periodically review and update their guidelines. Food manufacturers and bakers must stay informed about these changes to maintain compliance with evolving food safety regulations. This ongoing process helps to ensure that the use of glycerol in baking ingredients remains safe and beneficial for consumers.

The European Food Safety Authority (EFSA) has also evaluated the safety of glycerol as a food additive. In the European Union, glycerol is approved for use in various food categories, including bakery products, under the E number E422. The EFSA has set an Acceptable Daily Intake (ADI) of "not specified" for glycerol, indicating that it does not pose a significant health risk when used as intended.

Regulatory bodies worldwide require manufacturers to adhere to specific labeling requirements when using glycerol in baking ingredients. In most jurisdictions, glycerol must be declared on the ingredient list of packaged foods. This transparency allows consumers to make informed choices about the products they purchase and consume.

Food safety regulations also address the purity and quality of glycerol used in baking applications. Manufacturers must ensure that the glycerol they use meets specified purity criteria to prevent contamination with potentially harmful substances. This includes limits on impurities such as diethylene glycol and ethylene glycol, which can be toxic if present in significant quantities.

The use of glycerol in organic baking products is subject to additional regulations. In the United States, the National Organic Program (NOP) allows the use of glycerol in organic products only if it is derived from agricultural sources and processed using approved methods. Similar restrictions apply in other countries with organic certification programs.

Regulatory bodies also monitor the potential for glycerol to interact with other ingredients in baking applications. While glycerol is generally considered safe, its hygroscopic properties can affect the moisture content and shelf life of baked goods. Manufacturers must ensure that the use of glycerol does not compromise the overall safety and stability of their products.

As research on the effects of glycerol in food continues, regulatory bodies periodically review and update their guidelines. Food manufacturers and bakers must stay informed about these changes to maintain compliance with evolving food safety regulations. This ongoing process helps to ensure that the use of glycerol in baking ingredients remains safe and beneficial for consumers.

Sensory Impact of Glycerol on Baked Goods

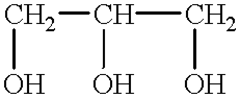

The sensory impact of glycerol on baked goods is a critical aspect of understanding how this ingredient modulates the viscosity of baking ingredients. Glycerol, also known as glycerin, is a polyol compound that plays a significant role in influencing the texture, mouthfeel, and overall sensory experience of baked products.

When incorporated into baked goods, glycerol primarily affects moisture retention and texture. Its hygroscopic nature allows it to attract and hold water molecules, which contributes to maintaining the softness and freshness of baked products over time. This moisture-retaining property is particularly beneficial in extending the shelf life of baked goods, as it helps prevent them from becoming dry and stale.

The impact of glycerol on the texture of baked goods is multifaceted. It can impart a softer, more tender crumb structure to cakes, breads, and pastries. This is due to its ability to interfere with gluten formation, resulting in a less rigid and more pliable texture. Additionally, glycerol can contribute to a smoother mouthfeel, enhancing the overall eating experience of the baked product.

In terms of taste, glycerol has a slightly sweet flavor profile, though it is less intense than sucrose. This subtle sweetness can complement the overall flavor of baked goods without overpowering other taste elements. It can also help to mask bitter notes in certain formulations, leading to a more balanced flavor profile.

The concentration of glycerol used in baking formulations is crucial in determining its sensory impact. At lower concentrations, its effects on texture and moisture retention are more pronounced, while higher concentrations may lead to a noticeable sweetness and potentially affect the product's structure.

Glycerol's influence on the browning of baked goods is another important sensory aspect. It can participate in Maillard reactions, contributing to the development of desirable brown colors and flavors associated with baked products. This can enhance the visual appeal and aroma of the final product.

The sensory impact of glycerol also extends to the perception of freshness in baked goods. Its moisture-retaining properties can create an impression of freshness even in products that have been stored for some time. This can significantly influence consumer perception and satisfaction with the product.

In conclusion, the sensory impact of glycerol on baked goods is complex and multifaceted, affecting texture, moisture content, taste, appearance, and overall eating quality. Understanding these effects is crucial for bakers and food scientists in optimizing formulations and creating products that meet consumer expectations for taste, texture, and freshness.

When incorporated into baked goods, glycerol primarily affects moisture retention and texture. Its hygroscopic nature allows it to attract and hold water molecules, which contributes to maintaining the softness and freshness of baked products over time. This moisture-retaining property is particularly beneficial in extending the shelf life of baked goods, as it helps prevent them from becoming dry and stale.

The impact of glycerol on the texture of baked goods is multifaceted. It can impart a softer, more tender crumb structure to cakes, breads, and pastries. This is due to its ability to interfere with gluten formation, resulting in a less rigid and more pliable texture. Additionally, glycerol can contribute to a smoother mouthfeel, enhancing the overall eating experience of the baked product.

In terms of taste, glycerol has a slightly sweet flavor profile, though it is less intense than sucrose. This subtle sweetness can complement the overall flavor of baked goods without overpowering other taste elements. It can also help to mask bitter notes in certain formulations, leading to a more balanced flavor profile.

The concentration of glycerol used in baking formulations is crucial in determining its sensory impact. At lower concentrations, its effects on texture and moisture retention are more pronounced, while higher concentrations may lead to a noticeable sweetness and potentially affect the product's structure.

Glycerol's influence on the browning of baked goods is another important sensory aspect. It can participate in Maillard reactions, contributing to the development of desirable brown colors and flavors associated with baked products. This can enhance the visual appeal and aroma of the final product.

The sensory impact of glycerol also extends to the perception of freshness in baked goods. Its moisture-retaining properties can create an impression of freshness even in products that have been stored for some time. This can significantly influence consumer perception and satisfaction with the product.

In conclusion, the sensory impact of glycerol on baked goods is complex and multifaceted, affecting texture, moisture content, taste, appearance, and overall eating quality. Understanding these effects is crucial for bakers and food scientists in optimizing formulations and creating products that meet consumer expectations for taste, texture, and freshness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!