Half Wave Rectifier Fundamentals: Key Concepts and Applications

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HWR Background and Objectives

Half-wave rectification has been a fundamental concept in electrical engineering since the early days of electronics. This technology emerged as a crucial component in power supply systems, playing a pivotal role in converting alternating current (AC) to pulsating direct current (DC). The evolution of half-wave rectifiers can be traced back to the invention of vacuum tube diodes in the early 20th century, which paved the way for more efficient and compact rectification solutions.

As electronic devices became increasingly prevalent, the demand for reliable power conversion methods grew exponentially. Half-wave rectifiers, with their simplicity and effectiveness, quickly became a cornerstone in various applications, ranging from small-scale consumer electronics to large industrial power systems. The technology's development has been closely intertwined with advancements in semiconductor materials and manufacturing processes, leading to significant improvements in efficiency, size, and cost-effectiveness over the years.

The primary objective of half-wave rectification is to convert AC input into a unidirectional current flow, effectively utilizing only one half of the AC waveform. This process, while not as efficient as full-wave rectification, offers advantages in terms of simplicity and lower component count, making it suitable for specific applications where these factors are prioritized over power efficiency.

In recent years, the focus on half-wave rectifier technology has shifted towards enhancing its performance in high-frequency applications, improving power quality, and reducing harmonic distortion. Researchers and engineers are exploring innovative materials and circuit designs to overcome the inherent limitations of traditional half-wave rectifiers, such as low power factor and high ripple content in the output voltage.

The ongoing technological trend is geared towards developing more sophisticated half-wave rectifier circuits that can address the growing demands of modern electronic systems. This includes the integration of advanced control mechanisms, the use of wide-bandgap semiconductors, and the implementation of smart power management techniques to optimize energy conversion and utilization.

As we look towards the future, the objectives for half-wave rectifier technology are multifaceted. These include improving energy efficiency to meet stringent power consumption standards, miniaturization to support the development of compact and portable devices, and enhancing reliability to ensure stable operation in diverse environmental conditions. Additionally, there is a growing emphasis on developing eco-friendly rectification solutions that align with global sustainability goals, driving research into materials and designs that minimize environmental impact throughout the product lifecycle.

As electronic devices became increasingly prevalent, the demand for reliable power conversion methods grew exponentially. Half-wave rectifiers, with their simplicity and effectiveness, quickly became a cornerstone in various applications, ranging from small-scale consumer electronics to large industrial power systems. The technology's development has been closely intertwined with advancements in semiconductor materials and manufacturing processes, leading to significant improvements in efficiency, size, and cost-effectiveness over the years.

The primary objective of half-wave rectification is to convert AC input into a unidirectional current flow, effectively utilizing only one half of the AC waveform. This process, while not as efficient as full-wave rectification, offers advantages in terms of simplicity and lower component count, making it suitable for specific applications where these factors are prioritized over power efficiency.

In recent years, the focus on half-wave rectifier technology has shifted towards enhancing its performance in high-frequency applications, improving power quality, and reducing harmonic distortion. Researchers and engineers are exploring innovative materials and circuit designs to overcome the inherent limitations of traditional half-wave rectifiers, such as low power factor and high ripple content in the output voltage.

The ongoing technological trend is geared towards developing more sophisticated half-wave rectifier circuits that can address the growing demands of modern electronic systems. This includes the integration of advanced control mechanisms, the use of wide-bandgap semiconductors, and the implementation of smart power management techniques to optimize energy conversion and utilization.

As we look towards the future, the objectives for half-wave rectifier technology are multifaceted. These include improving energy efficiency to meet stringent power consumption standards, miniaturization to support the development of compact and portable devices, and enhancing reliability to ensure stable operation in diverse environmental conditions. Additionally, there is a growing emphasis on developing eco-friendly rectification solutions that align with global sustainability goals, driving research into materials and designs that minimize environmental impact throughout the product lifecycle.

Market Demand Analysis

The market demand for half wave rectifiers continues to grow steadily, driven by the increasing need for power conversion and signal processing across various industries. These fundamental components play a crucial role in transforming alternating current (AC) to pulsating direct current (DC), making them essential in numerous electronic applications.

In the consumer electronics sector, half wave rectifiers are widely used in power supplies for household appliances, mobile devices, and personal computers. The rapid proliferation of smart home devices and Internet of Things (IoT) technologies has further boosted the demand for efficient power conversion solutions, including half wave rectifiers.

The automotive industry represents another significant market for half wave rectifiers. With the rising adoption of electric and hybrid vehicles, there is a growing need for power management systems that can efficiently convert and regulate electrical energy. Half wave rectifiers are integral components in these systems, contributing to the overall performance and energy efficiency of modern vehicles.

In the renewable energy sector, half wave rectifiers play a vital role in solar power systems and wind turbines. As the global push for clean energy intensifies, the demand for these components in power conversion applications is expected to surge. The ability of half wave rectifiers to convert the variable AC output from renewable sources into usable DC power makes them indispensable in this rapidly expanding market.

The telecommunications industry also relies heavily on half wave rectifiers for signal processing and power management in various communication devices and infrastructure equipment. With the ongoing rollout of 5G networks and the continuous expansion of global connectivity, the demand for these components is projected to remain strong in the coming years.

Industrial automation and control systems represent another key market segment for half wave rectifiers. These components are essential in power supplies for programmable logic controllers (PLCs), sensors, and actuators used in manufacturing and process control applications. As industries worldwide continue to embrace automation and smart manufacturing concepts, the demand for reliable power conversion solutions, including half wave rectifiers, is expected to grow.

The medical equipment sector is emerging as a promising market for half wave rectifiers. Advanced diagnostic and therapeutic devices often require precise power management and signal processing capabilities, creating opportunities for the application of these components in medical electronics.

Overall, the market for half wave rectifiers is characterized by steady growth and diversification across multiple industries. As technology continues to evolve and new applications emerge, the demand for these fundamental components is expected to remain robust, driving innovation and improvements in their design and performance.

In the consumer electronics sector, half wave rectifiers are widely used in power supplies for household appliances, mobile devices, and personal computers. The rapid proliferation of smart home devices and Internet of Things (IoT) technologies has further boosted the demand for efficient power conversion solutions, including half wave rectifiers.

The automotive industry represents another significant market for half wave rectifiers. With the rising adoption of electric and hybrid vehicles, there is a growing need for power management systems that can efficiently convert and regulate electrical energy. Half wave rectifiers are integral components in these systems, contributing to the overall performance and energy efficiency of modern vehicles.

In the renewable energy sector, half wave rectifiers play a vital role in solar power systems and wind turbines. As the global push for clean energy intensifies, the demand for these components in power conversion applications is expected to surge. The ability of half wave rectifiers to convert the variable AC output from renewable sources into usable DC power makes them indispensable in this rapidly expanding market.

The telecommunications industry also relies heavily on half wave rectifiers for signal processing and power management in various communication devices and infrastructure equipment. With the ongoing rollout of 5G networks and the continuous expansion of global connectivity, the demand for these components is projected to remain strong in the coming years.

Industrial automation and control systems represent another key market segment for half wave rectifiers. These components are essential in power supplies for programmable logic controllers (PLCs), sensors, and actuators used in manufacturing and process control applications. As industries worldwide continue to embrace automation and smart manufacturing concepts, the demand for reliable power conversion solutions, including half wave rectifiers, is expected to grow.

The medical equipment sector is emerging as a promising market for half wave rectifiers. Advanced diagnostic and therapeutic devices often require precise power management and signal processing capabilities, creating opportunities for the application of these components in medical electronics.

Overall, the market for half wave rectifiers is characterized by steady growth and diversification across multiple industries. As technology continues to evolve and new applications emerge, the demand for these fundamental components is expected to remain robust, driving innovation and improvements in their design and performance.

Technical Challenges

Half wave rectifiers, while fundamental in power electronics, face several technical challenges that limit their efficiency and applicability. One of the primary issues is the low power output and poor efficiency compared to full wave rectifiers. This is due to the rectifier only utilizing half of the AC input cycle, resulting in significant power loss and a lower average DC output voltage.

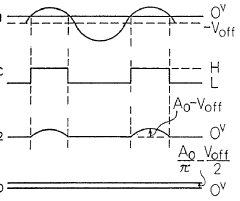

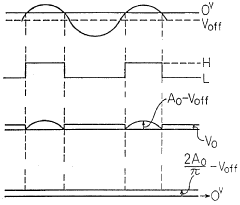

Another challenge is the high ripple content in the output voltage. The pulsating nature of the half wave rectified output requires substantial filtering to achieve a smooth DC voltage, which can be complex and costly to implement effectively. This ripple can lead to noise and interference in sensitive electronic circuits, limiting the rectifier's use in precision applications.

The presence of a DC component in the transformer secondary winding is another significant concern. This DC bias can lead to core saturation, reducing the transformer's efficiency and potentially causing overheating. It may also necessitate the use of larger, more expensive transformers to handle the additional stress.

Harmonic distortion is a further technical challenge associated with half wave rectifiers. The non-linear nature of the rectification process introduces harmonics into the power system, which can cause electromagnetic interference and reduce power quality. This is particularly problematic in grid-connected applications where power quality standards must be met.

Voltage regulation is also a significant issue with half wave rectifiers. The output voltage can vary considerably with changes in load or input voltage, making it difficult to maintain a stable DC output without additional regulation circuitry. This poor voltage regulation can be detrimental in applications requiring consistent power supply.

The reverse recovery time of the diode used in the rectifier circuit presents another challenge. During the negative half-cycle, the diode must quickly switch from conducting to blocking state. Slow reverse recovery can lead to increased power loss and reduced efficiency, especially at higher frequencies.

Lastly, the peak inverse voltage (PIV) rating of the diode is a critical consideration. In a half wave rectifier, the diode must withstand twice the peak voltage of the AC input during the non-conducting half-cycle. This requirement can necessitate the use of higher-rated, more expensive diodes, particularly in high-voltage applications.

These technical challenges collectively limit the widespread adoption of half wave rectifiers in many modern applications, despite their simplicity and low component count. Addressing these issues often requires additional circuitry or component specifications, which can negate the initial advantages of the half wave rectifier's simple design.

Another challenge is the high ripple content in the output voltage. The pulsating nature of the half wave rectified output requires substantial filtering to achieve a smooth DC voltage, which can be complex and costly to implement effectively. This ripple can lead to noise and interference in sensitive electronic circuits, limiting the rectifier's use in precision applications.

The presence of a DC component in the transformer secondary winding is another significant concern. This DC bias can lead to core saturation, reducing the transformer's efficiency and potentially causing overheating. It may also necessitate the use of larger, more expensive transformers to handle the additional stress.

Harmonic distortion is a further technical challenge associated with half wave rectifiers. The non-linear nature of the rectification process introduces harmonics into the power system, which can cause electromagnetic interference and reduce power quality. This is particularly problematic in grid-connected applications where power quality standards must be met.

Voltage regulation is also a significant issue with half wave rectifiers. The output voltage can vary considerably with changes in load or input voltage, making it difficult to maintain a stable DC output without additional regulation circuitry. This poor voltage regulation can be detrimental in applications requiring consistent power supply.

The reverse recovery time of the diode used in the rectifier circuit presents another challenge. During the negative half-cycle, the diode must quickly switch from conducting to blocking state. Slow reverse recovery can lead to increased power loss and reduced efficiency, especially at higher frequencies.

Lastly, the peak inverse voltage (PIV) rating of the diode is a critical consideration. In a half wave rectifier, the diode must withstand twice the peak voltage of the AC input during the non-conducting half-cycle. This requirement can necessitate the use of higher-rated, more expensive diodes, particularly in high-voltage applications.

These technical challenges collectively limit the widespread adoption of half wave rectifiers in many modern applications, despite their simplicity and low component count. Addressing these issues often requires additional circuitry or component specifications, which can negate the initial advantages of the half wave rectifier's simple design.

Current HWR Solutions

01 Circuit design and components

Half wave rectifiers typically consist of a diode and a transformer. The diode allows current to flow in only one direction, effectively converting AC to pulsating DC. The transformer is used to step up or step down the voltage as needed. Some designs may include additional components like capacitors for smoothing the output voltage.- Circuit design and components: Half-wave rectifiers typically consist of a diode and a transformer. The diode allows current to flow in only one direction, effectively converting AC to pulsating DC. The transformer is used to step up or step down the input voltage as needed. Various circuit configurations and component selections can be employed to optimize performance and efficiency.

- Voltage regulation and smoothing: To improve the output quality of half-wave rectifiers, voltage regulation and smoothing techniques are often employed. This can include the use of capacitors for filtering, voltage regulators for maintaining a steady output, and additional circuitry to reduce ripple and noise in the rectified signal.

- Applications in power supplies: Half-wave rectifiers are commonly used in various power supply applications. They can be found in low-power devices, battery chargers, and some specialized power supply units. The simplicity of the half-wave rectifier design makes it suitable for certain applications where cost and complexity are primary concerns.

- Efficiency improvements: Researchers and engineers have developed various methods to improve the efficiency of half-wave rectifiers. These improvements may include the use of advanced semiconductor materials, optimized circuit layouts, and innovative control strategies to minimize power losses and enhance overall performance.

- Integration with other circuits: Half-wave rectifiers can be integrated with other circuit elements to create more complex power management systems. This integration may involve combining the rectifier with voltage multipliers, power factor correction circuits, or other power conditioning components to meet specific application requirements.

02 Efficiency improvements

Various techniques are employed to improve the efficiency of half wave rectifiers. These may include using high-speed switching diodes, optimizing the transformer design, and implementing advanced control algorithms. Some designs incorporate power factor correction circuits to reduce harmonic distortion and improve overall system performance.Expand Specific Solutions03 Applications in power supplies

Half wave rectifiers are commonly used in power supply circuits for various electronic devices. They are particularly useful in low-power applications where simplicity and cost-effectiveness are priorities. Some designs integrate half wave rectifiers with voltage regulators to provide stable DC output for sensitive electronic components.Expand Specific Solutions04 Protection and safety features

Modern half wave rectifier designs often incorporate protection and safety features. These may include overvoltage protection circuits, thermal shutdown mechanisms, and short-circuit protection. Some designs also implement soft-start functionality to reduce inrush current and protect both the rectifier and connected devices.Expand Specific Solutions05 Miniaturization and integration

There is a trend towards miniaturization and integration of half wave rectifier circuits. This includes the development of compact, high-efficiency designs suitable for portable electronics and IoT devices. Some approaches involve integrating the rectifier with other power management functions on a single chip, reducing overall system size and complexity.Expand Specific Solutions

Key Industry Players

The half wave rectifier technology market is in a mature stage, with a stable global market size estimated in the billions of dollars. The technology's fundamental concepts are well-established, but ongoing research focuses on improving efficiency and reducing power losses. Key players like Huawei, Sony, and Mitsubishi Electric are investing in advanced semiconductor technologies to enhance rectifier performance. Smaller specialized firms such as Mixed-Signal Devices and MaxPower Semiconductor are developing innovative solutions for niche applications. Academic institutions like Technical University of Denmark and Zhejiang University contribute to fundamental research, while major electronics manufacturers like LG and Panasonic incorporate rectifier technology into various consumer and industrial products.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed advanced half-wave rectifier circuits for power management in their telecommunications equipment. Their approach utilizes high-efficiency silicon carbide (SiC) diodes, which offer lower forward voltage drop and faster reverse recovery compared to traditional silicon diodes[1]. This results in reduced power losses and improved overall system efficiency. Huawei's implementation also incorporates advanced thermal management techniques to ensure reliable operation in high-power applications, such as 5G base stations[2]. The company has further enhanced their half-wave rectifier designs with intelligent control systems that optimize performance based on load conditions and temperature[3].

Strengths: High efficiency, reduced power losses, and intelligent control. Weaknesses: Higher component costs and complexity compared to traditional rectifier designs.

Sony Group Corp.

Technical Solution: Sony has innovated in half-wave rectifier technology for their consumer electronics and professional audio equipment. Their approach focuses on minimizing signal distortion in audio applications by implementing precision half-wave rectifiers with ultra-fast switching diodes and op-amp based circuits[4]. Sony's design incorporates feedback loops to compensate for diode non-linearities, resulting in highly accurate rectification even at high frequencies[5]. For power supply applications, Sony has developed hybrid half-wave rectifiers that combine traditional diodes with active switching elements to improve efficiency and reduce electromagnetic interference (EMI)[6].

Strengths: High precision for audio applications, reduced EMI, and versatility across different product lines. Weaknesses: Increased circuit complexity and potentially higher production costs.

Core HWR Technologies

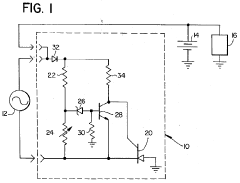

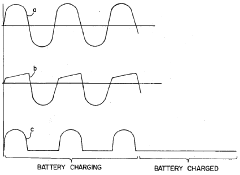

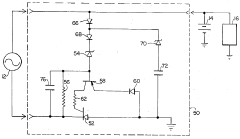

Half-wave regulator rectifier for an alternator

PatentInactiveUS4220909A

Innovation

- A half-wave regulator rectifier using a silicon controlled rectifier (SCR) with a control circuit that includes a voltage tracking circuit and controlled switching means, which inhibits conduction when the battery voltage is above the regulated level and ensures safe charging by monitoring alternator voltage and current flow, protecting components from damage during abnormal conditions.

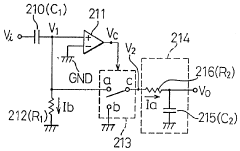

Half-wave rectifier circuit

PatentInactiveUS5579214A

Innovation

- The proposed half-wave rectifier circuit design includes a capacitor to remove DC components, a comparator with an operational amplifier and capacitor to accumulate offset voltage, and a switch circuit with high input impedance during the OFF state to eliminate the influence of offset voltage, ensuring accurate output voltage generation.

Efficiency Optimization

Efficiency optimization is a critical aspect of half-wave rectifier design and implementation. The primary goal is to maximize the conversion of AC input to usable DC output while minimizing power losses. One key approach to improving efficiency is through the careful selection of diode components. High-speed switching diodes with low forward voltage drop and minimal reverse recovery time can significantly reduce conduction losses and switching losses.

Another important consideration is the optimization of the rectifier's load resistance. By matching the load impedance to the source impedance, maximum power transfer can be achieved, thereby enhancing overall system efficiency. Additionally, implementing a smoothing capacitor in parallel with the load can help reduce ripple voltage and improve the quality of the DC output, which indirectly contributes to efficiency by reducing the need for additional filtering stages.

The use of snubber circuits can further enhance efficiency by suppressing voltage spikes and reducing electromagnetic interference (EMI). These circuits typically consist of a resistor-capacitor (RC) network connected across the diode, which helps to dampen oscillations and protect the diode from overvoltage conditions.

In applications where higher efficiency is paramount, synchronous rectification techniques can be employed. This involves replacing the diode with a MOSFET switch, which can be controlled to conduct only during the positive half-cycle of the input waveform. The lower on-resistance of MOSFETs compared to diodes results in reduced conduction losses, especially at higher current levels.

For high-frequency applications, the choice of core material for any transformers or inductors in the rectifier circuit becomes crucial. Materials with low core losses, such as ferrite or powdered iron cores, can significantly improve efficiency at higher operating frequencies.

Thermal management is another key factor in efficiency optimization. Proper heat dissipation through the use of heat sinks or forced-air cooling can help maintain components at optimal operating temperatures, reducing temperature-dependent losses and improving overall reliability and efficiency.

Finally, advanced control strategies, such as adaptive gate drive techniques for synchronous rectifiers or digital control algorithms for power factor correction, can be implemented to dynamically optimize the rectifier's performance across varying load conditions and input voltages. These techniques can lead to substantial improvements in efficiency, particularly in applications with wide-ranging operational parameters.

Another important consideration is the optimization of the rectifier's load resistance. By matching the load impedance to the source impedance, maximum power transfer can be achieved, thereby enhancing overall system efficiency. Additionally, implementing a smoothing capacitor in parallel with the load can help reduce ripple voltage and improve the quality of the DC output, which indirectly contributes to efficiency by reducing the need for additional filtering stages.

The use of snubber circuits can further enhance efficiency by suppressing voltage spikes and reducing electromagnetic interference (EMI). These circuits typically consist of a resistor-capacitor (RC) network connected across the diode, which helps to dampen oscillations and protect the diode from overvoltage conditions.

In applications where higher efficiency is paramount, synchronous rectification techniques can be employed. This involves replacing the diode with a MOSFET switch, which can be controlled to conduct only during the positive half-cycle of the input waveform. The lower on-resistance of MOSFETs compared to diodes results in reduced conduction losses, especially at higher current levels.

For high-frequency applications, the choice of core material for any transformers or inductors in the rectifier circuit becomes crucial. Materials with low core losses, such as ferrite or powdered iron cores, can significantly improve efficiency at higher operating frequencies.

Thermal management is another key factor in efficiency optimization. Proper heat dissipation through the use of heat sinks or forced-air cooling can help maintain components at optimal operating temperatures, reducing temperature-dependent losses and improving overall reliability and efficiency.

Finally, advanced control strategies, such as adaptive gate drive techniques for synchronous rectifiers or digital control algorithms for power factor correction, can be implemented to dynamically optimize the rectifier's performance across varying load conditions and input voltages. These techniques can lead to substantial improvements in efficiency, particularly in applications with wide-ranging operational parameters.

Regulatory Compliance

Regulatory compliance is a critical aspect of half wave rectifier design and implementation, particularly in industries where electrical safety and electromagnetic compatibility are paramount. The use of half wave rectifiers in various applications necessitates adherence to a range of standards and regulations set forth by national and international bodies.

One of the primary regulatory concerns for half wave rectifiers is electromagnetic interference (EMI). These devices can generate significant harmonic content in their output, which may interfere with other electronic equipment. To address this, manufacturers must comply with EMC (Electromagnetic Compatibility) standards such as those outlined in IEC 61000 series. These standards specify limits for conducted and radiated emissions, as well as immunity requirements for various types of equipment.

Safety regulations also play a crucial role in half wave rectifier design. Standards like IEC 60950 for information technology equipment and IEC 61010 for measurement, control, and laboratory equipment outline safety requirements that must be met. These include specifications for insulation, creepage and clearance distances, and protection against electric shock.

In the context of power supplies utilizing half wave rectifiers, energy efficiency regulations have become increasingly important. Many countries have implemented minimum energy performance standards (MEPS) for external power supplies. For instance, the U.S. Department of Energy's Level VI efficiency standards and the European Union's ErP (Energy-related Products) Directive set stringent requirements for power supply efficiency, which indirectly affect the design and implementation of rectifier circuits.

For medical applications, half wave rectifiers used in medical devices must comply with additional standards such as IEC 60601, which specifies safety and essential performance requirements for medical electrical equipment. This standard addresses issues like leakage currents and electrical isolation, which are particularly relevant to rectifier circuits in medical power supplies.

In the automotive sector, half wave rectifiers used in vehicle electrical systems must meet standards like ISO 16750, which defines environmental conditions and electrical tests for automotive electronic equipment. This includes requirements for voltage transients, reverse polarity protection, and electromagnetic compatibility specific to the automotive environment.

Compliance with these regulations often requires careful circuit design, component selection, and extensive testing. Manufacturers must consider factors such as voltage ratings, current handling capabilities, and thermal management to ensure their half wave rectifier designs meet all applicable standards. Additionally, documentation and certification processes are typically required to demonstrate compliance, which may involve third-party testing and verification.

As regulatory requirements continue to evolve, designers and manufacturers must stay informed about changes in standards and adapt their half wave rectifier designs accordingly. This ongoing process ensures that products remain compliant, safe, and efficient across various applications and markets.

One of the primary regulatory concerns for half wave rectifiers is electromagnetic interference (EMI). These devices can generate significant harmonic content in their output, which may interfere with other electronic equipment. To address this, manufacturers must comply with EMC (Electromagnetic Compatibility) standards such as those outlined in IEC 61000 series. These standards specify limits for conducted and radiated emissions, as well as immunity requirements for various types of equipment.

Safety regulations also play a crucial role in half wave rectifier design. Standards like IEC 60950 for information technology equipment and IEC 61010 for measurement, control, and laboratory equipment outline safety requirements that must be met. These include specifications for insulation, creepage and clearance distances, and protection against electric shock.

In the context of power supplies utilizing half wave rectifiers, energy efficiency regulations have become increasingly important. Many countries have implemented minimum energy performance standards (MEPS) for external power supplies. For instance, the U.S. Department of Energy's Level VI efficiency standards and the European Union's ErP (Energy-related Products) Directive set stringent requirements for power supply efficiency, which indirectly affect the design and implementation of rectifier circuits.

For medical applications, half wave rectifiers used in medical devices must comply with additional standards such as IEC 60601, which specifies safety and essential performance requirements for medical electrical equipment. This standard addresses issues like leakage currents and electrical isolation, which are particularly relevant to rectifier circuits in medical power supplies.

In the automotive sector, half wave rectifiers used in vehicle electrical systems must meet standards like ISO 16750, which defines environmental conditions and electrical tests for automotive electronic equipment. This includes requirements for voltage transients, reverse polarity protection, and electromagnetic compatibility specific to the automotive environment.

Compliance with these regulations often requires careful circuit design, component selection, and extensive testing. Manufacturers must consider factors such as voltage ratings, current handling capabilities, and thermal management to ensure their half wave rectifier designs meet all applicable standards. Additionally, documentation and certification processes are typically required to demonstrate compliance, which may involve third-party testing and verification.

As regulatory requirements continue to evolve, designers and manufacturers must stay informed about changes in standards and adapt their half wave rectifier designs accordingly. This ongoing process ensures that products remain compliant, safe, and efficient across various applications and markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!