How AMOLED assists adaptive automation in industrial designs?

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED in Automation

AMOLED (Active-Matrix Organic Light-Emitting Diode) technology has emerged as a game-changer in the realm of industrial automation, offering unprecedented opportunities for adaptive and intelligent systems. The integration of AMOLED displays in industrial designs has revolutionized the way operators interact with complex machinery and control systems.

One of the key advantages of AMOLED in automation is its ability to provide high-contrast, vibrant displays that remain clearly visible even in challenging industrial environments. This enhanced visibility ensures that critical information is readily accessible to operators, reducing the likelihood of errors and improving overall efficiency. The superior color reproduction of AMOLED displays also allows for more intuitive representation of complex data, facilitating quicker decision-making processes.

AMOLED's flexibility in form factor has enabled the development of curved and even foldable displays, which can be seamlessly integrated into various industrial equipment designs. This adaptability allows for more ergonomic and space-efficient control panels, enhancing operator comfort and productivity. The ability to create custom-shaped displays also opens up new possibilities for innovative machine interfaces that can be tailored to specific industrial applications.

The low power consumption of AMOLED technology contributes to the overall energy efficiency of automated systems. This is particularly beneficial in industrial settings where power management is crucial. The reduced energy requirements not only lead to cost savings but also align with the growing emphasis on sustainable manufacturing practices.

AMOLED displays' fast response times and high refresh rates are instrumental in real-time monitoring and control applications. This capability is essential for adaptive automation systems that require rapid adjustments based on changing conditions. The quick response of AMOLED screens ensures that operators can react swiftly to any anomalies or critical situations, enhancing overall system safety and reliability.

Furthermore, the long lifespan and durability of AMOLED displays make them ideal for industrial environments where equipment is expected to operate continuously for extended periods. The resistance to image burn-in and the ability to maintain consistent performance over time contribute to reduced maintenance needs and improved long-term reliability of automated systems.

The integration of touch functionality with AMOLED displays has led to the development of more intuitive and interactive control interfaces. This allows for the creation of adaptive user interfaces that can change based on the context or the specific needs of different operators, enhancing the flexibility and user-friendliness of industrial automation systems.

One of the key advantages of AMOLED in automation is its ability to provide high-contrast, vibrant displays that remain clearly visible even in challenging industrial environments. This enhanced visibility ensures that critical information is readily accessible to operators, reducing the likelihood of errors and improving overall efficiency. The superior color reproduction of AMOLED displays also allows for more intuitive representation of complex data, facilitating quicker decision-making processes.

AMOLED's flexibility in form factor has enabled the development of curved and even foldable displays, which can be seamlessly integrated into various industrial equipment designs. This adaptability allows for more ergonomic and space-efficient control panels, enhancing operator comfort and productivity. The ability to create custom-shaped displays also opens up new possibilities for innovative machine interfaces that can be tailored to specific industrial applications.

The low power consumption of AMOLED technology contributes to the overall energy efficiency of automated systems. This is particularly beneficial in industrial settings where power management is crucial. The reduced energy requirements not only lead to cost savings but also align with the growing emphasis on sustainable manufacturing practices.

AMOLED displays' fast response times and high refresh rates are instrumental in real-time monitoring and control applications. This capability is essential for adaptive automation systems that require rapid adjustments based on changing conditions. The quick response of AMOLED screens ensures that operators can react swiftly to any anomalies or critical situations, enhancing overall system safety and reliability.

Furthermore, the long lifespan and durability of AMOLED displays make them ideal for industrial environments where equipment is expected to operate continuously for extended periods. The resistance to image burn-in and the ability to maintain consistent performance over time contribute to reduced maintenance needs and improved long-term reliability of automated systems.

The integration of touch functionality with AMOLED displays has led to the development of more intuitive and interactive control interfaces. This allows for the creation of adaptive user interfaces that can change based on the context or the specific needs of different operators, enhancing the flexibility and user-friendliness of industrial automation systems.

Market Demand Analysis

The market demand for AMOLED technology in adaptive automation for industrial designs has been steadily increasing in recent years. This growth is driven by the need for more efficient, flexible, and user-friendly interfaces in industrial settings. AMOLED displays offer several advantages that make them particularly suitable for adaptive automation applications, including high contrast ratios, wide color gamuts, and fast response times.

In the industrial sector, there is a growing trend towards smart factories and Industry 4.0 concepts, which rely heavily on advanced human-machine interfaces. AMOLED displays are well-positioned to meet these demands, as they provide superior visibility in various lighting conditions and can be easily integrated into complex control systems. The ability of AMOLED screens to display deep blacks and vibrant colors enhances the readability of critical information, reducing operator fatigue and improving overall productivity.

The automotive industry has been a significant driver of AMOLED adoption in industrial designs. As vehicles become more automated and connected, there is an increasing need for high-quality displays that can adapt to changing environmental conditions. AMOLED technology's ability to provide clear, bright images even in direct sunlight makes it ideal for use in automotive dashboards and control panels.

Another key market segment driving demand for AMOLED in adaptive automation is the aerospace and defense sector. These industries require robust, reliable displays that can perform in extreme conditions while providing critical information to operators. AMOLED's durability and flexibility make it an attractive option for cockpit displays, mission control interfaces, and other high-stakes applications.

The healthcare industry is also showing increased interest in AMOLED technology for adaptive automation. Medical devices and diagnostic equipment benefit from the high contrast and color accuracy of AMOLED displays, enabling more precise readings and improved visualization of patient data. As telemedicine and remote patient monitoring become more prevalent, the demand for high-quality displays in medical settings is expected to grow further.

In the energy sector, AMOLED displays are gaining traction for use in control rooms and monitoring stations. The ability to clearly display complex data and adjust brightness levels automatically helps operators manage power grids and industrial processes more effectively. This is particularly important in scenarios where rapid decision-making is crucial, such as during power outages or system anomalies.

As the Internet of Things (IoT) continues to expand in industrial settings, the demand for adaptive displays that can seamlessly integrate with various sensors and automation systems is increasing. AMOLED technology's compatibility with flexible form factors and its energy efficiency make it well-suited for IoT devices and smart sensors used in industrial environments.

In the industrial sector, there is a growing trend towards smart factories and Industry 4.0 concepts, which rely heavily on advanced human-machine interfaces. AMOLED displays are well-positioned to meet these demands, as they provide superior visibility in various lighting conditions and can be easily integrated into complex control systems. The ability of AMOLED screens to display deep blacks and vibrant colors enhances the readability of critical information, reducing operator fatigue and improving overall productivity.

The automotive industry has been a significant driver of AMOLED adoption in industrial designs. As vehicles become more automated and connected, there is an increasing need for high-quality displays that can adapt to changing environmental conditions. AMOLED technology's ability to provide clear, bright images even in direct sunlight makes it ideal for use in automotive dashboards and control panels.

Another key market segment driving demand for AMOLED in adaptive automation is the aerospace and defense sector. These industries require robust, reliable displays that can perform in extreme conditions while providing critical information to operators. AMOLED's durability and flexibility make it an attractive option for cockpit displays, mission control interfaces, and other high-stakes applications.

The healthcare industry is also showing increased interest in AMOLED technology for adaptive automation. Medical devices and diagnostic equipment benefit from the high contrast and color accuracy of AMOLED displays, enabling more precise readings and improved visualization of patient data. As telemedicine and remote patient monitoring become more prevalent, the demand for high-quality displays in medical settings is expected to grow further.

In the energy sector, AMOLED displays are gaining traction for use in control rooms and monitoring stations. The ability to clearly display complex data and adjust brightness levels automatically helps operators manage power grids and industrial processes more effectively. This is particularly important in scenarios where rapid decision-making is crucial, such as during power outages or system anomalies.

As the Internet of Things (IoT) continues to expand in industrial settings, the demand for adaptive displays that can seamlessly integrate with various sensors and automation systems is increasing. AMOLED technology's compatibility with flexible form factors and its energy efficiency make it well-suited for IoT devices and smart sensors used in industrial environments.

Technical Challenges

The integration of AMOLED technology in adaptive automation for industrial designs faces several significant technical challenges. One of the primary obstacles is the durability and longevity of AMOLED displays in harsh industrial environments. These settings often involve exposure to extreme temperatures, vibrations, and potentially corrosive substances, which can compromise the integrity and performance of AMOLED screens over time.

Another critical challenge lies in the power consumption of AMOLED displays, particularly in always-on scenarios common in industrial applications. While AMOLED technology offers advantages in terms of power efficiency for displaying dark content, the need for continuous operation in industrial settings can still lead to substantial energy demands, potentially impacting the overall efficiency of automated systems.

The color accuracy and consistency of AMOLED displays across different lighting conditions pose another technical hurdle. Industrial environments often have varying and sometimes challenging lighting situations, which can affect the visibility and interpretation of information displayed on AMOLED screens. Ensuring consistent color reproduction and readability across these diverse conditions is crucial for maintaining the reliability of automated systems.

Additionally, the integration of touch functionality with AMOLED displays in industrial contexts presents unique challenges. Industrial operators often wear protective gear such as gloves, which can interfere with the capacitive touch technology typically used in AMOLED displays. Developing robust touch interfaces that can function reliably under these conditions is essential for effective human-machine interaction in adaptive automation systems.

The cost factor also remains a significant challenge in widespread adoption. While AMOLED technology has become more affordable in consumer electronics, the specialized requirements of industrial applications often necessitate custom designs and enhanced durability, leading to higher production costs. This can limit the feasibility of implementing AMOLED-based solutions in cost-sensitive industrial sectors.

Furthermore, the complexity of interfacing AMOLED displays with existing industrial control systems and software presents a technical challenge. Ensuring seamless integration and compatibility with a wide range of legacy systems and protocols used in industrial automation requires significant development efforts and standardization.

Lastly, the challenge of scalability and flexibility in AMOLED display sizes and form factors for diverse industrial applications cannot be overlooked. Different industrial processes may require displays of varying sizes and shapes, necessitating adaptable AMOLED manufacturing processes and custom design solutions to meet these diverse needs effectively.

Another critical challenge lies in the power consumption of AMOLED displays, particularly in always-on scenarios common in industrial applications. While AMOLED technology offers advantages in terms of power efficiency for displaying dark content, the need for continuous operation in industrial settings can still lead to substantial energy demands, potentially impacting the overall efficiency of automated systems.

The color accuracy and consistency of AMOLED displays across different lighting conditions pose another technical hurdle. Industrial environments often have varying and sometimes challenging lighting situations, which can affect the visibility and interpretation of information displayed on AMOLED screens. Ensuring consistent color reproduction and readability across these diverse conditions is crucial for maintaining the reliability of automated systems.

Additionally, the integration of touch functionality with AMOLED displays in industrial contexts presents unique challenges. Industrial operators often wear protective gear such as gloves, which can interfere with the capacitive touch technology typically used in AMOLED displays. Developing robust touch interfaces that can function reliably under these conditions is essential for effective human-machine interaction in adaptive automation systems.

The cost factor also remains a significant challenge in widespread adoption. While AMOLED technology has become more affordable in consumer electronics, the specialized requirements of industrial applications often necessitate custom designs and enhanced durability, leading to higher production costs. This can limit the feasibility of implementing AMOLED-based solutions in cost-sensitive industrial sectors.

Furthermore, the complexity of interfacing AMOLED displays with existing industrial control systems and software presents a technical challenge. Ensuring seamless integration and compatibility with a wide range of legacy systems and protocols used in industrial automation requires significant development efforts and standardization.

Lastly, the challenge of scalability and flexibility in AMOLED display sizes and form factors for diverse industrial applications cannot be overlooked. Different industrial processes may require displays of varying sizes and shapes, necessitating adaptable AMOLED manufacturing processes and custom design solutions to meet these diverse needs effectively.

Current AMOLED Solutions

01 Adaptive brightness control for AMOLED displays

This technology involves automatically adjusting the brightness of AMOLED displays based on ambient light conditions and user preferences. The system uses sensors to detect environmental lighting and adjusts screen brightness accordingly, optimizing visibility and power consumption.- Adaptive brightness control for AMOLED displays: This technology involves automatically adjusting the brightness of AMOLED displays based on ambient light conditions and user preferences. It aims to optimize power consumption and improve visual comfort by dynamically adapting the display's luminance to different environments.

- Pixel compensation techniques for AMOLED displays: These methods focus on compensating for pixel degradation and non-uniformity in AMOLED displays. By implementing various compensation algorithms and circuits, the technology aims to maintain consistent image quality and extend the lifespan of AMOLED panels.

- Power-efficient driving schemes for AMOLED displays: This category includes innovative driving techniques designed to reduce power consumption in AMOLED displays. These methods may involve optimizing voltage levels, current control, and timing sequences to achieve energy savings without compromising display quality.

- AMOLED display structure and manufacturing improvements: These innovations focus on enhancing the physical structure and manufacturing processes of AMOLED displays. They may include advancements in pixel layouts, electrode designs, and fabrication techniques to improve display performance and production efficiency.

- Adaptive content rendering for AMOLED displays: This technology involves dynamically adjusting the content displayed on AMOLED screens based on various factors such as ambient conditions, viewing angle, and content type. It aims to optimize image quality, reduce power consumption, and enhance the overall user experience.

02 Power-efficient AMOLED pixel circuits

Advanced pixel circuit designs for AMOLED displays that improve power efficiency and image quality. These circuits incorporate adaptive driving schemes and compensation techniques to reduce power consumption while maintaining display performance.Expand Specific Solutions03 Adaptive refresh rate for AMOLED displays

This technology dynamically adjusts the refresh rate of AMOLED displays based on content and user interaction. By lowering the refresh rate during static content display and increasing it for dynamic content, power consumption is optimized without compromising visual quality.Expand Specific Solutions04 AMOLED display color management

Adaptive color management systems for AMOLED displays that adjust color parameters based on ambient light conditions and content type. These systems enhance color accuracy, contrast, and visibility across various viewing environments.Expand Specific Solutions05 AMOLED panel structure optimization

Innovations in AMOLED panel structure design to improve display performance and efficiency. These include advancements in electrode materials, pixel layouts, and encapsulation techniques that enhance overall display quality and lifespan.Expand Specific Solutions

Key Industry Players

The AMOLED technology in industrial automation is in a growth phase, with increasing market size and evolving technical maturity. Key players like Samsung Display, LG Display, and BOE Technology are driving innovation in this space. The market is expanding as AMOLED displays offer advantages in adaptive automation interfaces, such as high contrast ratios, wide color gamut, and flexibility. While the technology is advancing rapidly, there is still room for improvement in areas like durability and cost-effectiveness for industrial applications. As more companies invest in research and development, we can expect to see further advancements in AMOLED's role in adaptive industrial automation systems.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology Group has made significant strides in AMOLED technology for industrial automation. They have developed flexible AMOLED displays that can be integrated into curved control panels and wearable devices for industrial workers[17]. BOE's AMOLED panels feature high refresh rates and low latency, crucial for responsive industrial human-machine interfaces[19]. The company has also implemented advanced color management systems in their AMOLED displays, ensuring accurate representation of industrial data and alerts[18]. BOE has focused on improving the lifespan of their AMOLED panels to meet the demanding requirements of 24/7 industrial operations[20].

Strengths: Large-scale production capabilities for various display sizes. Strong R&D in flexible and foldable AMOLED technologies. Weaknesses: Relatively new entrant to the high-end AMOLED market. Quality perception not yet on par with top-tier competitors in some markets.

LG Display Co., Ltd.

Technical Solution: LG Display has pioneered AMOLED technology for industrial automation with their P-OLED (Plastic OLED) displays. These flexible panels can be curved or folded, allowing for innovative industrial control interfaces[4]. LG's AMOLED displays incorporate in-cell touch technology, reducing the overall thickness of the display assembly and improving touch sensitivity for industrial applications[6]. They have also developed transparent AMOLED displays, enabling augmented reality overlays for industrial processes and maintenance procedures[8]. LG's AMOLED panels feature low latency and high refresh rates, essential for real-time industrial control systems[7].

Strengths: Flexible and transparent display options for diverse industrial applications. Excellent viewing angles and color accuracy. Weaknesses: Higher initial costs for implementation in industrial settings. Limited lifespan compared to some industrial-grade LCD panels.

Core AMOLED Innovations

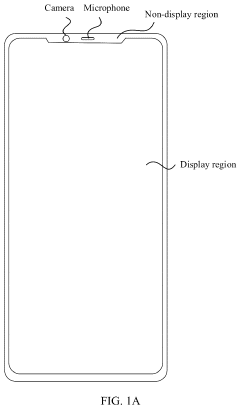

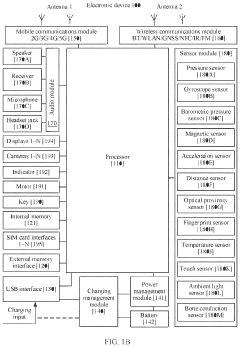

Display, electronic device, and display fabrication method

PatentActiveUS12021070B2

Innovation

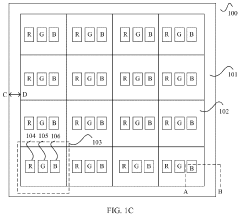

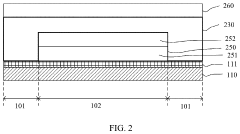

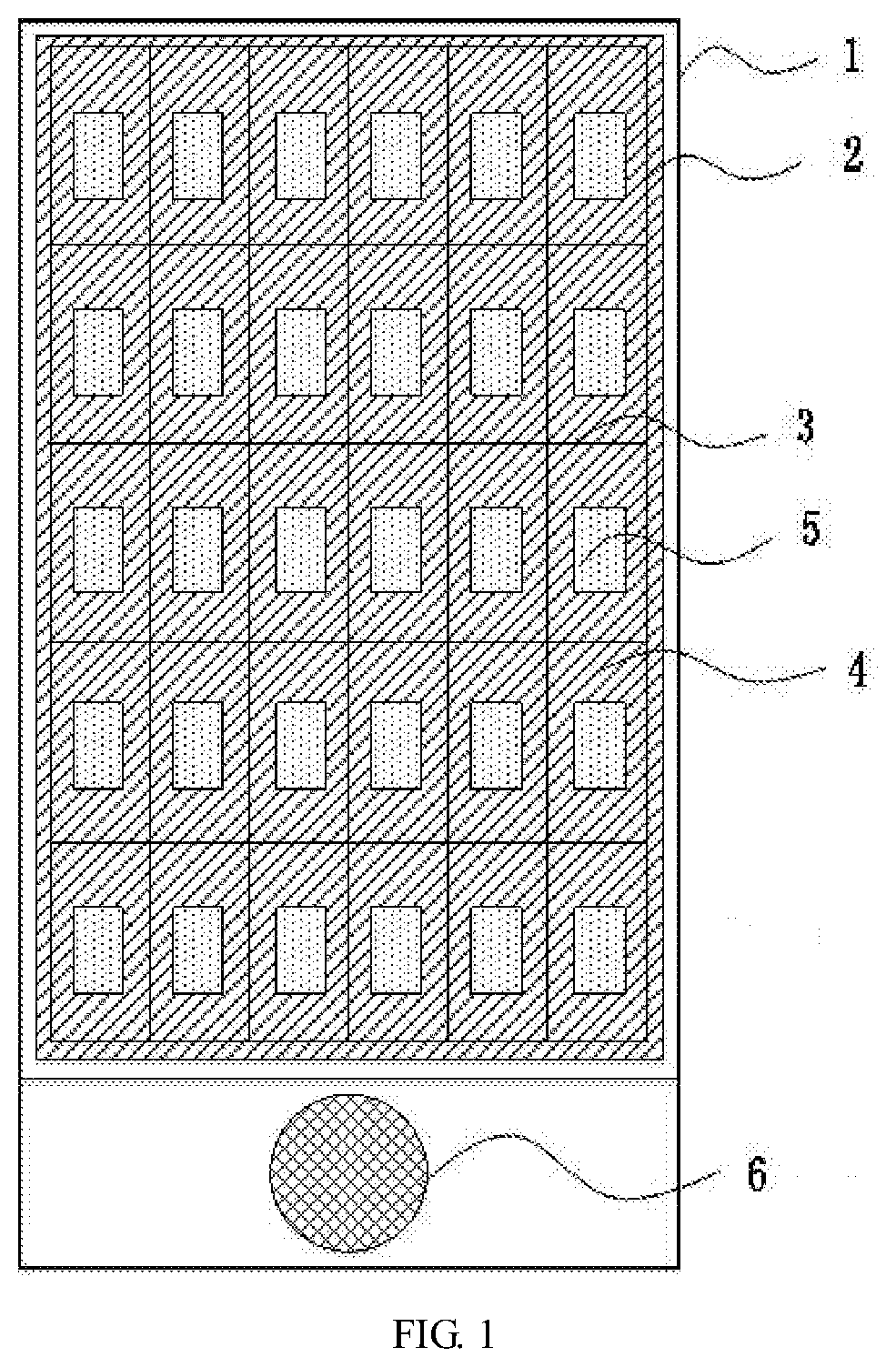

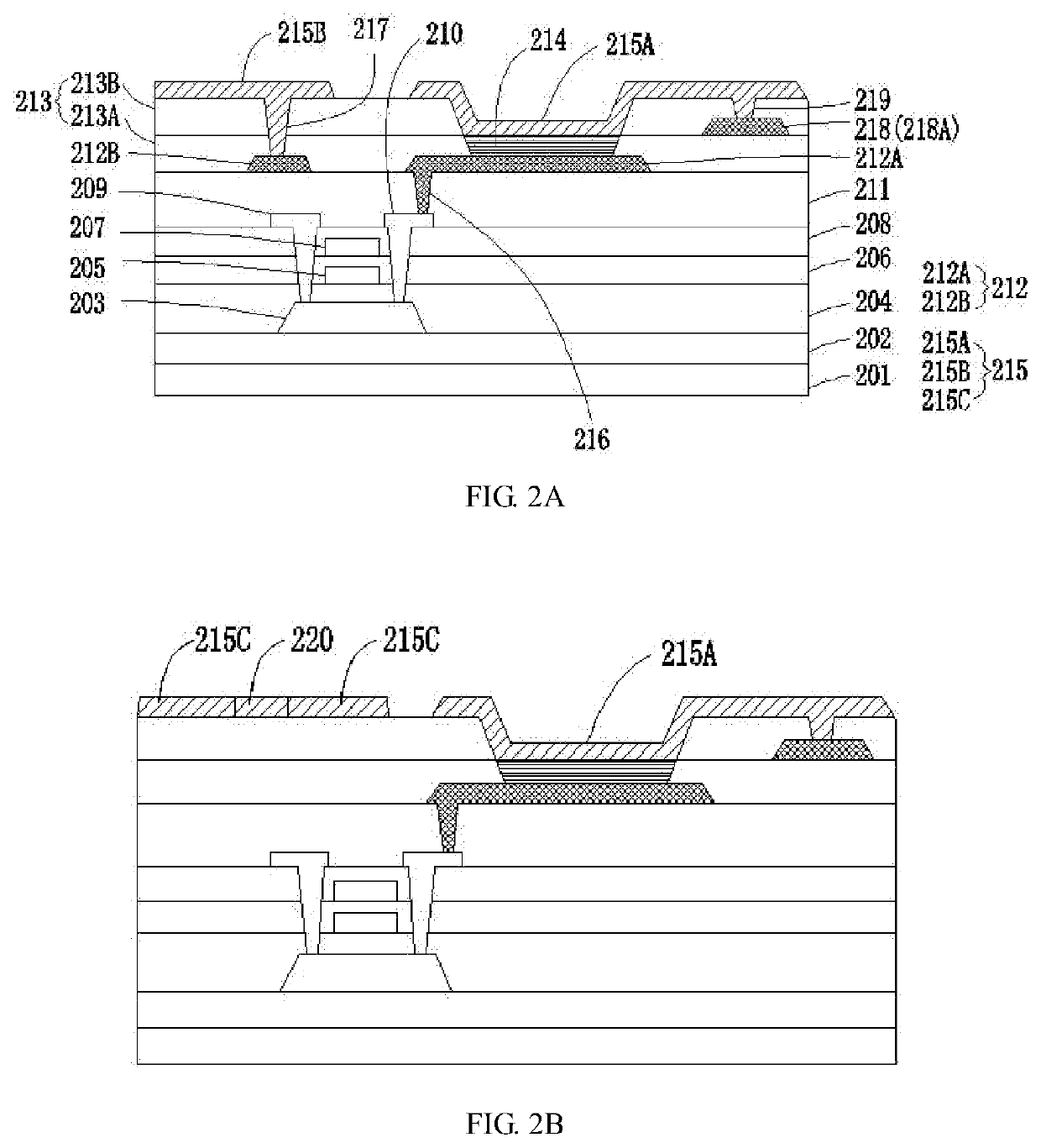

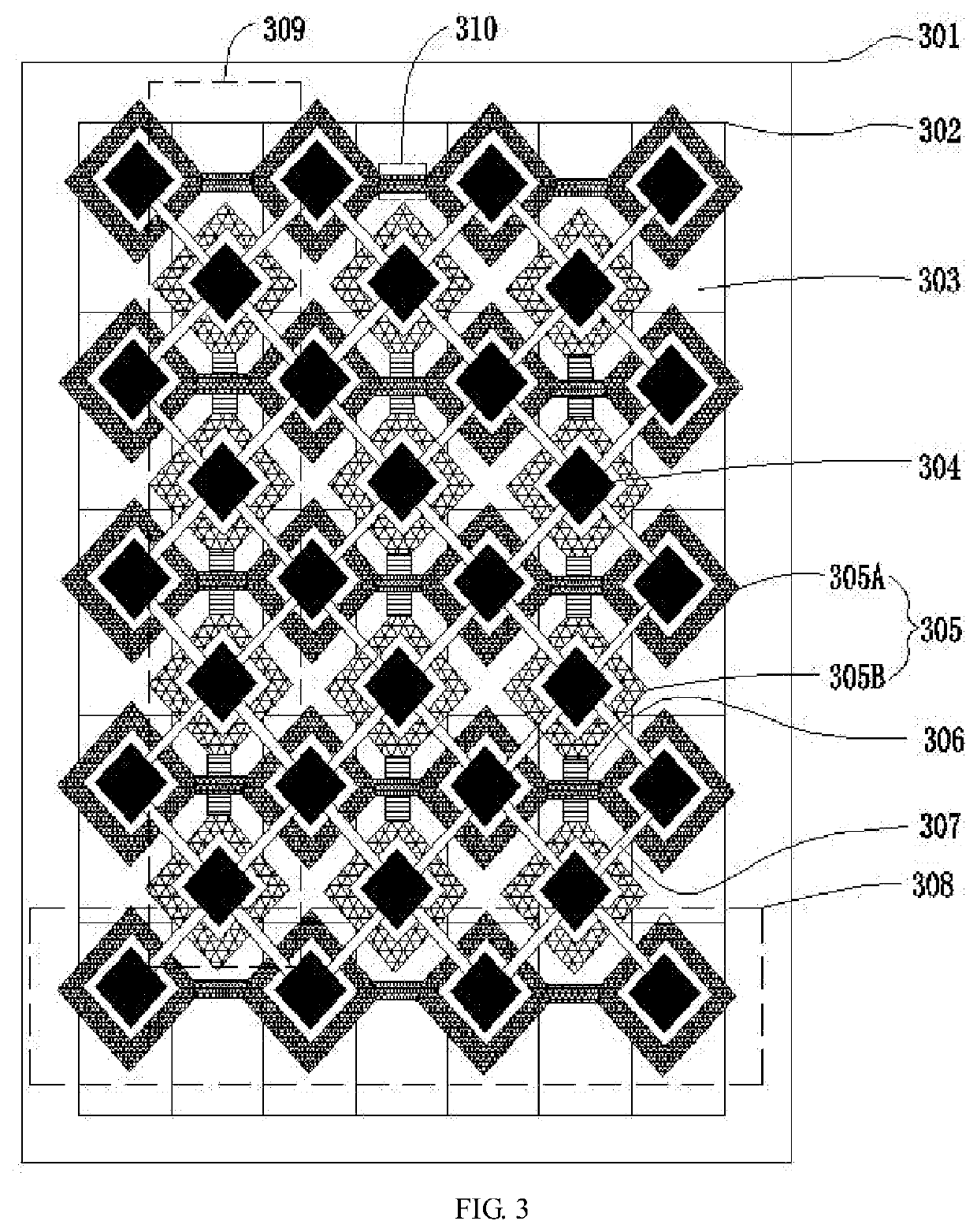

- The implementation of a display structure that includes a substrate, a driver circuit backplane, a first pixel layer with organic light-emitting diodes, and a second pixel layer with micro light-emitting diodes surrounding the first layer, where the micro LED layer is used to reduce the non-display region by replacing the traditional bezel function and isolating the OLED components from water and oxygen.

Active matrix organic light emitting diode (amoled) display panel

PatentInactiveUS20210343972A1

Innovation

- The integration of sensing electrodes into the AMOLED display panel allows for underscreen fingerprint identification, utilizing a patterned cathode layer with insulated first and second electrode rows and conductive bridges to form capacitors for fingerprint recognition, thereby embedding fingerprint identification within the screen and increasing the display area ratio.

Industrial Design Impact

The integration of AMOLED technology in industrial designs has significantly transformed the landscape of adaptive automation. This advanced display technology offers unique advantages that enhance the functionality and efficiency of automated systems in industrial settings.

AMOLED displays provide superior visual quality with high contrast ratios and vibrant colors, enabling clearer and more detailed information presentation. This improved visibility is crucial in industrial environments where accurate data interpretation is essential for decision-making and process control. The enhanced visual feedback allows operators to quickly identify and respond to changes in production parameters, leading to more efficient and precise automation processes.

The flexibility of AMOLED displays allows for the creation of curved or even foldable interfaces, revolutionizing the design of control panels and human-machine interfaces (HMIs) in industrial settings. This adaptability enables the integration of displays into complex machinery and equipment, optimizing space utilization and improving ergonomics for operators. The ability to conform to various surfaces and shapes opens up new possibilities for innovative industrial design solutions that were previously impractical with traditional display technologies.

AMOLED's energy efficiency contributes to the overall sustainability of industrial automation systems. The lower power consumption of these displays reduces the energy footprint of control systems, aligning with the growing emphasis on eco-friendly industrial practices. This efficiency is particularly beneficial in portable or battery-operated industrial devices, extending operational times and reducing maintenance requirements.

The high refresh rates and fast response times of AMOLED displays enhance the real-time capabilities of industrial automation systems. This improved responsiveness is critical in applications requiring rapid visual feedback, such as quality control inspections or high-speed production lines. The seamless updating of information on AMOLED screens ensures that operators and automated systems can react swiftly to changing conditions, minimizing delays and improving overall productivity.

AMOLED technology also facilitates the implementation of adaptive user interfaces in industrial designs. The ability to selectively activate individual pixels allows for dynamic screen layouts that can adjust based on the specific task or user preferences. This adaptability enhances the user experience, reducing cognitive load on operators and improving the efficiency of human-machine interactions in complex industrial environments.

AMOLED displays provide superior visual quality with high contrast ratios and vibrant colors, enabling clearer and more detailed information presentation. This improved visibility is crucial in industrial environments where accurate data interpretation is essential for decision-making and process control. The enhanced visual feedback allows operators to quickly identify and respond to changes in production parameters, leading to more efficient and precise automation processes.

The flexibility of AMOLED displays allows for the creation of curved or even foldable interfaces, revolutionizing the design of control panels and human-machine interfaces (HMIs) in industrial settings. This adaptability enables the integration of displays into complex machinery and equipment, optimizing space utilization and improving ergonomics for operators. The ability to conform to various surfaces and shapes opens up new possibilities for innovative industrial design solutions that were previously impractical with traditional display technologies.

AMOLED's energy efficiency contributes to the overall sustainability of industrial automation systems. The lower power consumption of these displays reduces the energy footprint of control systems, aligning with the growing emphasis on eco-friendly industrial practices. This efficiency is particularly beneficial in portable or battery-operated industrial devices, extending operational times and reducing maintenance requirements.

The high refresh rates and fast response times of AMOLED displays enhance the real-time capabilities of industrial automation systems. This improved responsiveness is critical in applications requiring rapid visual feedback, such as quality control inspections or high-speed production lines. The seamless updating of information on AMOLED screens ensures that operators and automated systems can react swiftly to changing conditions, minimizing delays and improving overall productivity.

AMOLED technology also facilitates the implementation of adaptive user interfaces in industrial designs. The ability to selectively activate individual pixels allows for dynamic screen layouts that can adjust based on the specific task or user preferences. This adaptability enhances the user experience, reducing cognitive load on operators and improving the efficiency of human-machine interactions in complex industrial environments.

Energy Efficiency Gains

AMOLED technology has significantly contributed to energy efficiency gains in adaptive automation systems for industrial designs. The inherent characteristics of AMOLED displays, such as their ability to selectively illuminate individual pixels, have paved the way for substantial power savings in industrial applications.

One of the primary advantages of AMOLED in industrial designs is its capacity for local dimming. This feature allows specific areas of the display to be dimmed or turned off entirely when not in use, resulting in considerable energy savings. In adaptive automation systems, where information display requirements can vary greatly depending on the task at hand, this capability proves invaluable.

Furthermore, AMOLED displays offer superior contrast ratios compared to traditional LCD screens. This enhanced contrast allows for better visibility in various lighting conditions, reducing the need for high brightness settings and consequently lowering power consumption. In industrial environments where lighting conditions can be challenging, this feature ensures optimal visibility while maintaining energy efficiency.

The fast response times of AMOLED displays also contribute to energy efficiency in adaptive automation systems. Quick pixel state changes enable rapid updates to displayed information, reducing the overall time the display needs to be active. This is particularly beneficial in scenarios where real-time data visualization is crucial, as it allows for more frequent updates without compromising energy efficiency.

AMOLED technology's ability to produce true blacks by completely turning off pixels not only enhances visual quality but also significantly reduces power consumption in applications where dark interfaces are prevalent. This is especially relevant in industrial control panels and monitoring systems that often utilize dark-themed interfaces to reduce eye strain during extended use.

Moreover, the thin and flexible nature of AMOLED displays allows for more compact and energy-efficient designs in industrial equipment. This reduction in size and weight can lead to overall system energy savings, as smaller devices generally require less power to operate and cool.

As adaptive automation systems continue to evolve, the integration of AMOLED technology is expected to play an increasingly important role in achieving energy efficiency goals. The ongoing development of more efficient AMOLED panels, coupled with advancements in power management techniques, promises even greater energy savings in future industrial applications.

One of the primary advantages of AMOLED in industrial designs is its capacity for local dimming. This feature allows specific areas of the display to be dimmed or turned off entirely when not in use, resulting in considerable energy savings. In adaptive automation systems, where information display requirements can vary greatly depending on the task at hand, this capability proves invaluable.

Furthermore, AMOLED displays offer superior contrast ratios compared to traditional LCD screens. This enhanced contrast allows for better visibility in various lighting conditions, reducing the need for high brightness settings and consequently lowering power consumption. In industrial environments where lighting conditions can be challenging, this feature ensures optimal visibility while maintaining energy efficiency.

The fast response times of AMOLED displays also contribute to energy efficiency in adaptive automation systems. Quick pixel state changes enable rapid updates to displayed information, reducing the overall time the display needs to be active. This is particularly beneficial in scenarios where real-time data visualization is crucial, as it allows for more frequent updates without compromising energy efficiency.

AMOLED technology's ability to produce true blacks by completely turning off pixels not only enhances visual quality but also significantly reduces power consumption in applications where dark interfaces are prevalent. This is especially relevant in industrial control panels and monitoring systems that often utilize dark-themed interfaces to reduce eye strain during extended use.

Moreover, the thin and flexible nature of AMOLED displays allows for more compact and energy-efficient designs in industrial equipment. This reduction in size and weight can lead to overall system energy savings, as smaller devices generally require less power to operate and cool.

As adaptive automation systems continue to evolve, the integration of AMOLED technology is expected to play an increasingly important role in achieving energy efficiency goals. The ongoing development of more efficient AMOLED panels, coupled with advancements in power management techniques, promises even greater energy savings in future industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!