Reflective polarizer use cases in AMOLED applications.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Reflective Polarizer Background

AMOLED (Active-Matrix Organic Light-Emitting Diode) technology has revolutionized the display industry with its superior image quality, energy efficiency, and form factor flexibility. As AMOLED displays continue to evolve, manufacturers are constantly seeking ways to enhance their performance and overcome inherent limitations. One such innovation is the integration of reflective polarizers into AMOLED applications.

Reflective polarizers are optical films designed to selectively reflect one polarization of light while transmitting the orthogonal polarization. This unique property makes them particularly valuable in display technologies, where light management is crucial for improving efficiency and visual quality. In the context of AMOLED displays, reflective polarizers offer several potential benefits that address key challenges in display performance.

The primary motivation behind incorporating reflective polarizers in AMOLED applications is to enhance display brightness and energy efficiency. AMOLED displays emit light directly from each pixel, but a significant portion of this light is typically lost due to various optical phenomena, including internal reflections and polarization effects. By strategically placing a reflective polarizer within the display stack, manufacturers can recycle a portion of the light that would otherwise be wasted, effectively boosting the overall brightness without increasing power consumption.

Another critical aspect driving the adoption of reflective polarizers in AMOLED displays is the improvement of outdoor visibility. AMOLED screens often struggle with readability in bright ambient light conditions due to reflections from the display surface. Reflective polarizers can help mitigate this issue by reducing the amount of ambient light that enters the display structure, thereby enhancing contrast and maintaining image quality even in challenging lighting environments.

The integration of reflective polarizers also aligns with the broader trend of display miniaturization and power efficiency in mobile devices. As consumers demand longer battery life and sleeker form factors, display manufacturers are under pressure to optimize every aspect of their designs. Reflective polarizers offer a passive solution to improve display performance without significantly increasing power draw or device thickness.

However, the implementation of reflective polarizers in AMOLED applications is not without challenges. Engineers must carefully consider factors such as color accuracy, viewing angle performance, and manufacturing complexity when incorporating these optical films into display designs. The interplay between the reflective polarizer and other display components, such as the OLED emitters and touch sensors, requires precise optimization to achieve the desired performance gains without compromising other aspects of display quality.

As AMOLED technology continues to mature and find applications beyond smartphones and tablets, the role of reflective polarizers is likely to expand. From automotive displays to wearable devices, the potential use cases for this technology are diverse and promising. The ongoing research and development in this area underscore the importance of reflective polarizers as a key enabler for next-generation AMOLED displays, driving improvements in efficiency, visibility, and overall user experience.

Reflective polarizers are optical films designed to selectively reflect one polarization of light while transmitting the orthogonal polarization. This unique property makes them particularly valuable in display technologies, where light management is crucial for improving efficiency and visual quality. In the context of AMOLED displays, reflective polarizers offer several potential benefits that address key challenges in display performance.

The primary motivation behind incorporating reflective polarizers in AMOLED applications is to enhance display brightness and energy efficiency. AMOLED displays emit light directly from each pixel, but a significant portion of this light is typically lost due to various optical phenomena, including internal reflections and polarization effects. By strategically placing a reflective polarizer within the display stack, manufacturers can recycle a portion of the light that would otherwise be wasted, effectively boosting the overall brightness without increasing power consumption.

Another critical aspect driving the adoption of reflective polarizers in AMOLED displays is the improvement of outdoor visibility. AMOLED screens often struggle with readability in bright ambient light conditions due to reflections from the display surface. Reflective polarizers can help mitigate this issue by reducing the amount of ambient light that enters the display structure, thereby enhancing contrast and maintaining image quality even in challenging lighting environments.

The integration of reflective polarizers also aligns with the broader trend of display miniaturization and power efficiency in mobile devices. As consumers demand longer battery life and sleeker form factors, display manufacturers are under pressure to optimize every aspect of their designs. Reflective polarizers offer a passive solution to improve display performance without significantly increasing power draw or device thickness.

However, the implementation of reflective polarizers in AMOLED applications is not without challenges. Engineers must carefully consider factors such as color accuracy, viewing angle performance, and manufacturing complexity when incorporating these optical films into display designs. The interplay between the reflective polarizer and other display components, such as the OLED emitters and touch sensors, requires precise optimization to achieve the desired performance gains without compromising other aspects of display quality.

As AMOLED technology continues to mature and find applications beyond smartphones and tablets, the role of reflective polarizers is likely to expand. From automotive displays to wearable devices, the potential use cases for this technology are diverse and promising. The ongoing research and development in this area underscore the importance of reflective polarizers as a key enabler for next-generation AMOLED displays, driving improvements in efficiency, visibility, and overall user experience.

Market Analysis for AMOLED Displays

The AMOLED display market has experienced significant growth in recent years, driven by the increasing demand for high-quality displays in smartphones, televisions, and other electronic devices. As of 2023, the global AMOLED display market is valued at over $30 billion, with projections indicating continued growth at a compound annual growth rate (CAGR) of around 20% through 2028.

The smartphone segment dominates the AMOLED display market, accounting for approximately 70% of the total market share. This dominance is attributed to the superior color reproduction, contrast ratios, and energy efficiency offered by AMOLED displays compared to traditional LCD screens. Major smartphone manufacturers, including Samsung, Apple, and Huawei, have increasingly adopted AMOLED technology in their flagship devices, further driving market growth.

The television sector represents another significant market for AMOLED displays, particularly in the high-end and premium segments. AMOLED TVs offer superior picture quality, wider viewing angles, and thinner form factors compared to LED-LCD alternatives. While OLED TVs currently hold a smaller market share compared to LED-LCD TVs, their adoption is growing steadily, with major manufacturers like LG and Sony investing heavily in OLED technology.

Emerging applications for AMOLED displays include wearable devices, automotive displays, and virtual/augmented reality headsets. The wearable device market, including smartwatches and fitness trackers, has seen rapid adoption of AMOLED displays due to their energy efficiency and vibrant color reproduction. In the automotive sector, AMOLED displays are increasingly being used in infotainment systems and digital instrument clusters, offering improved visibility and aesthetics.

Geographically, Asia-Pacific leads the AMOLED display market, with South Korea and China being the primary manufacturing hubs. South Korean companies, particularly Samsung Display and LG Display, dominate the market with their advanced manufacturing capabilities and extensive patent portfolios. Chinese manufacturers, such as BOE and CSOT, are rapidly expanding their production capacities and technological capabilities, aiming to capture a larger market share.

The integration of reflective polarizers in AMOLED applications presents a significant opportunity for market growth. These polarizers can enhance display brightness, improve outdoor visibility, and reduce power consumption – addressing key challenges in AMOLED technology. As manufacturers seek to differentiate their products and improve display performance, the demand for reflective polarizer technology is expected to increase, potentially creating a new sub-segment within the AMOLED market.

The smartphone segment dominates the AMOLED display market, accounting for approximately 70% of the total market share. This dominance is attributed to the superior color reproduction, contrast ratios, and energy efficiency offered by AMOLED displays compared to traditional LCD screens. Major smartphone manufacturers, including Samsung, Apple, and Huawei, have increasingly adopted AMOLED technology in their flagship devices, further driving market growth.

The television sector represents another significant market for AMOLED displays, particularly in the high-end and premium segments. AMOLED TVs offer superior picture quality, wider viewing angles, and thinner form factors compared to LED-LCD alternatives. While OLED TVs currently hold a smaller market share compared to LED-LCD TVs, their adoption is growing steadily, with major manufacturers like LG and Sony investing heavily in OLED technology.

Emerging applications for AMOLED displays include wearable devices, automotive displays, and virtual/augmented reality headsets. The wearable device market, including smartwatches and fitness trackers, has seen rapid adoption of AMOLED displays due to their energy efficiency and vibrant color reproduction. In the automotive sector, AMOLED displays are increasingly being used in infotainment systems and digital instrument clusters, offering improved visibility and aesthetics.

Geographically, Asia-Pacific leads the AMOLED display market, with South Korea and China being the primary manufacturing hubs. South Korean companies, particularly Samsung Display and LG Display, dominate the market with their advanced manufacturing capabilities and extensive patent portfolios. Chinese manufacturers, such as BOE and CSOT, are rapidly expanding their production capacities and technological capabilities, aiming to capture a larger market share.

The integration of reflective polarizers in AMOLED applications presents a significant opportunity for market growth. These polarizers can enhance display brightness, improve outdoor visibility, and reduce power consumption – addressing key challenges in AMOLED technology. As manufacturers seek to differentiate their products and improve display performance, the demand for reflective polarizer technology is expected to increase, potentially creating a new sub-segment within the AMOLED market.

Reflective Polarizer Challenges

The implementation of reflective polarizers in AMOLED applications faces several significant challenges that need to be addressed for widespread adoption. One of the primary obstacles is the complexity of integrating reflective polarizers into existing AMOLED display structures without compromising the overall display performance. The thin-film design of reflective polarizers must be carefully engineered to maintain the high contrast ratios and wide viewing angles that AMOLED displays are known for.

Another challenge lies in the manufacturing process of reflective polarizers for AMOLED applications. The production of these specialized optical films requires precise control over the deposition of multiple layers with varying refractive indices. Achieving consistent quality and uniformity across large-area substrates remains a significant hurdle, particularly as display sizes continue to increase.

The cost-effectiveness of incorporating reflective polarizers into AMOLED displays is also a major concern. While these components can potentially improve energy efficiency, the additional manufacturing steps and materials required may lead to increased production costs. Balancing the benefits of improved display performance and power savings against the higher manufacturing expenses is crucial for market acceptance.

Thermal management presents another challenge in the use of reflective polarizers for AMOLED applications. The heat generated by AMOLED displays can affect the optical properties of the reflective polarizer, potentially leading to performance degradation over time. Developing thermally stable materials and structures that can withstand the operating temperatures of AMOLED devices without compromising polarization efficiency is essential.

Furthermore, the optical performance of reflective polarizers must be optimized for the specific requirements of AMOLED displays. This includes achieving high polarization efficiency across the entire visible spectrum, minimizing color shifts, and maintaining performance under various viewing angles. The challenge lies in designing a reflective polarizer that can effectively manage both the emitted light from the OLED pixels and the ambient light reflections.

Lastly, the long-term reliability and durability of reflective polarizers in AMOLED applications need to be addressed. These components must withstand the rigors of daily use, including exposure to varying environmental conditions and potential mechanical stress. Ensuring that the reflective polarizer maintains its optical properties and adhesion to the display stack over the device's lifetime is critical for consumer acceptance and product longevity.

Another challenge lies in the manufacturing process of reflective polarizers for AMOLED applications. The production of these specialized optical films requires precise control over the deposition of multiple layers with varying refractive indices. Achieving consistent quality and uniformity across large-area substrates remains a significant hurdle, particularly as display sizes continue to increase.

The cost-effectiveness of incorporating reflective polarizers into AMOLED displays is also a major concern. While these components can potentially improve energy efficiency, the additional manufacturing steps and materials required may lead to increased production costs. Balancing the benefits of improved display performance and power savings against the higher manufacturing expenses is crucial for market acceptance.

Thermal management presents another challenge in the use of reflective polarizers for AMOLED applications. The heat generated by AMOLED displays can affect the optical properties of the reflective polarizer, potentially leading to performance degradation over time. Developing thermally stable materials and structures that can withstand the operating temperatures of AMOLED devices without compromising polarization efficiency is essential.

Furthermore, the optical performance of reflective polarizers must be optimized for the specific requirements of AMOLED displays. This includes achieving high polarization efficiency across the entire visible spectrum, minimizing color shifts, and maintaining performance under various viewing angles. The challenge lies in designing a reflective polarizer that can effectively manage both the emitted light from the OLED pixels and the ambient light reflections.

Lastly, the long-term reliability and durability of reflective polarizers in AMOLED applications need to be addressed. These components must withstand the rigors of daily use, including exposure to varying environmental conditions and potential mechanical stress. Ensuring that the reflective polarizer maintains its optical properties and adhesion to the display stack over the device's lifetime is critical for consumer acceptance and product longevity.

Current Reflective Polarizer Solutions

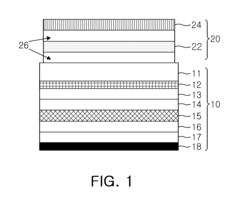

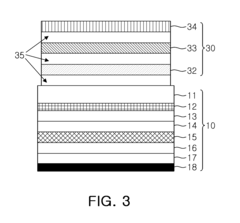

01 Structure and composition of reflective polarizers

Reflective polarizers are optical components that selectively reflect one polarization of light while transmitting the orthogonal polarization. They typically consist of multiple layers of birefringent materials or cholesteric liquid crystals. The structure and composition of these layers determine the polarization and reflection properties of the polarizer.- Structure and composition of reflective polarizers: Reflective polarizers are optical components that selectively reflect one polarization of light while transmitting the orthogonal polarization. They typically consist of multiple layers of birefringent materials or cholesteric liquid crystals. The structure and composition of these layers determine the polarization and reflection properties of the polarizer.

- Applications in display technologies: Reflective polarizers are widely used in various display technologies, including LCD screens, projectors, and head-mounted displays. They enhance brightness, improve contrast, and reduce power consumption by recycling light that would otherwise be absorbed by conventional polarizers. These polarizers can be integrated into backlight units or combined with other optical components to optimize display performance.

- Manufacturing methods for reflective polarizers: Various manufacturing techniques are employed to produce reflective polarizers, including coextrusion, solution casting, and roll-to-roll processes. These methods involve precise control of layer thickness, material properties, and surface characteristics to achieve the desired optical performance. Advanced manufacturing processes may incorporate nanoimprinting or self-assembly techniques to create complex structures at the nanoscale.

- Integration with other optical components: Reflective polarizers can be combined with other optical components to create advanced optical systems. These may include retarders, diffusers, prisms, or waveplates. The integration of reflective polarizers with other components allows for the creation of compact, high-performance optical devices for various applications in imaging, sensing, and communications.

- Emerging applications and future trends: Research is ongoing to develop new types of reflective polarizers and expand their applications. Emerging areas include the use of reflective polarizers in augmented reality devices, automotive displays, and energy-efficient windows. Future trends may involve the development of tunable or switchable reflective polarizers, as well as the incorporation of novel materials such as metamaterials or plasmonic structures to enhance performance and functionality.

02 Applications in display technology

Reflective polarizers are widely used in display technologies, particularly in LCD screens. They enhance brightness and contrast by recycling light that would otherwise be absorbed by conventional polarizers. This application improves energy efficiency and display performance in various devices, including monitors, televisions, and mobile screens.Expand Specific Solutions03 Integration with other optical components

Reflective polarizers can be integrated with other optical components to create advanced optical systems. This includes combination with retarders, diffusers, or prismatic films to achieve specific optical effects or improve overall system performance. Such integrations are particularly useful in projection systems, automotive displays, and augmented reality devices.Expand Specific Solutions04 Manufacturing techniques

Various manufacturing techniques are employed to produce reflective polarizers, including coextrusion, solution casting, and roll-to-roll processing. These methods aim to create precise multilayer structures or aligned liquid crystal domains necessary for the polarizing effect. Advances in manufacturing focus on improving uniformity, reducing defects, and scaling up production for large-area applications.Expand Specific Solutions05 Emerging applications and innovations

Ongoing research explores new applications and innovations for reflective polarizers. This includes their use in smart windows for energy-efficient buildings, advanced optical sensors, and photonic devices. Innovations also focus on developing reflective polarizers with broader spectral ranges, improved angular performance, and enhanced durability for demanding environments.Expand Specific Solutions

Key AMOLED Industry Players

The reflective polarizer market for AMOLED applications is in a growth phase, driven by increasing demand for high-quality displays in smartphones, wearables, and automotive sectors. The market size is expanding rapidly, with major players like 3M Innovative Properties, BOE Technology, and LG Chem leading the way. Technological advancements are ongoing, with companies such as Sharp, Huawei, and Samsung SDI investing heavily in R&D to improve polarizer performance and efficiency. The technology is maturing, but there's still room for innovation, particularly in areas like flexible displays and energy efficiency. Emerging players like Wuhan China Star Optoelectronics and Visionox are also making significant strides, intensifying competition in this dynamic market.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced reflective polarizer technology for AMOLED applications, focusing on enhancing display brightness and energy efficiency. Their DBEF (Dual Brightness Enhancement Film) technology utilizes a multi-layer optical film structure to selectively reflect and transmit light[1]. This technology recycles light that would otherwise be absorbed by the display's polarizer, effectively increasing the overall brightness by up to 100% without consuming additional power[2]. 3M's reflective polarizers are designed to work in conjunction with AMOLED displays, improving contrast ratios and color vibrancy while reducing power consumption[3]. The company has also developed flexible versions of their reflective polarizers, enabling their use in foldable and curved AMOLED displays[4].

Strengths: Industry-leading optical film technology, significant brightness enhancement, and energy efficiency improvements. Weaknesses: Potential cost increase for display manufacturers and complexity in integration with existing AMOLED structures.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has integrated reflective polarizer technology into their AMOLED display production, focusing on improving display performance and energy efficiency. Their approach involves incorporating thin-film reflective polarizers directly into the AMOLED panel structure[5]. This integration allows for enhanced light recycling, resulting in improved brightness and contrast ratios. BOE's technology also includes a specialized optical design that minimizes color shift at wide viewing angles, a common challenge in AMOLED displays[6]. The company has reported achieving up to 30% increase in display brightness without additional power consumption when using their reflective polarizer technology[7]. BOE has also developed flexible reflective polarizers for use in their curved and foldable AMOLED displays, maintaining performance benefits across various form factors[8].

Strengths: Seamless integration with AMOLED panel production, significant brightness and contrast improvements. Weaknesses: Potential increase in production complexity and cost, may require adjustments to existing manufacturing processes.

Innovative Polarizer Technologies

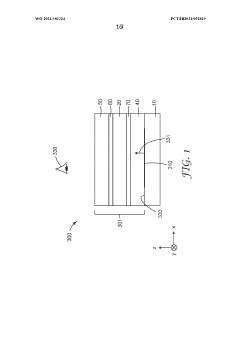

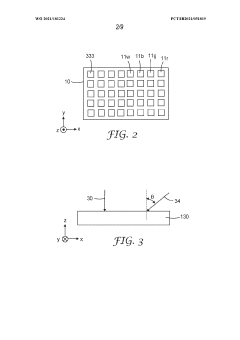

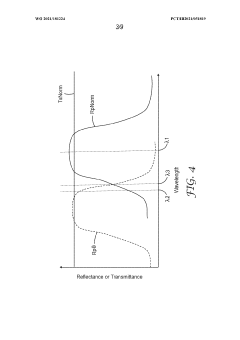

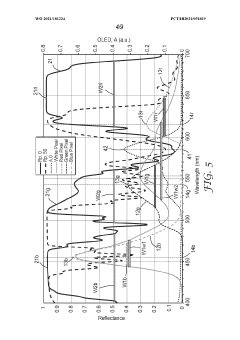

Reflective polarizer and display system

PatentWO2021181224A1

Innovation

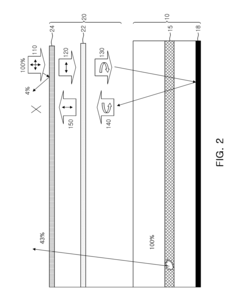

- A reflective polarizer with distinct blue, green, and red-infrared reflection bands and an absorption peak between the green and red emission spectra is used, which decreases reflectance for blue and green wavelengths at higher angles and maintains or slightly increases reflectance for red wavelengths, improving color gamut and reducing ghosting.

Luminance-enhancing polarising plate for an organic light-emitting element

PatentActiveUS8338823B2

Innovation

- A polarizer configuration that includes a linear polarizer, a ¼ retardation plate, and a reflective polarizer film, with optional adhesive layers of color compensation adhesive containing a light absorbing agent, to selectively transmit and reflect polarized light, thereby enhancing contrast and brightness.

Environmental Impact of Polarizers

The environmental impact of polarizers in AMOLED applications is a critical consideration as the demand for these displays continues to grow. Reflective polarizers, in particular, have gained attention due to their potential to enhance display performance while potentially reducing energy consumption.

Polarizers are essential components in AMOLED displays, but their production and disposal can have significant environmental implications. The manufacturing process of polarizers often involves the use of chemicals and materials that may be harmful to the environment if not properly managed. These include solvents, adhesives, and various synthetic polymers.

One of the primary environmental concerns associated with polarizers is their limited recyclability. Many polarizers are composed of multiple layers of different materials, making them challenging to separate and recycle effectively. This often results in polarizers ending up in landfills or being incinerated, contributing to waste accumulation and potentially releasing harmful substances into the environment.

However, reflective polarizers offer some potential environmental benefits in AMOLED applications. By improving the efficiency of light utilization within the display, reflective polarizers can help reduce power consumption. This, in turn, can lead to longer battery life in mobile devices and lower energy requirements for larger displays, potentially reducing overall energy consumption and associated carbon emissions.

The use of reflective polarizers may also contribute to extending the lifespan of AMOLED displays. By enhancing display performance and reducing the need for high brightness settings, these polarizers could potentially slow down the degradation of OLED materials, leading to longer-lasting devices and reduced electronic waste.

Despite these potential benefits, the production of reflective polarizers still raises environmental concerns. The materials used in their manufacture, such as multi-layer polymer films, may have a significant carbon footprint. Additionally, the complexity of these polarizers may make them even more challenging to recycle than traditional polarizers.

To address these environmental challenges, research is ongoing into more sustainable materials and manufacturing processes for polarizers. This includes exploring bio-based polymers, developing more efficient recycling techniques, and investigating ways to reduce the use of harmful chemicals in production. Some companies are also looking into designing polarizers that are easier to separate and recycle at the end of their life cycle.

As the AMOLED industry continues to grow, balancing the performance benefits of reflective polarizers with their environmental impact will be crucial. This may involve adopting lifecycle assessment approaches to fully understand the environmental implications of different polarizer technologies and working towards more sustainable solutions that minimize negative impacts while maximizing display performance and energy efficiency.

Polarizers are essential components in AMOLED displays, but their production and disposal can have significant environmental implications. The manufacturing process of polarizers often involves the use of chemicals and materials that may be harmful to the environment if not properly managed. These include solvents, adhesives, and various synthetic polymers.

One of the primary environmental concerns associated with polarizers is their limited recyclability. Many polarizers are composed of multiple layers of different materials, making them challenging to separate and recycle effectively. This often results in polarizers ending up in landfills or being incinerated, contributing to waste accumulation and potentially releasing harmful substances into the environment.

However, reflective polarizers offer some potential environmental benefits in AMOLED applications. By improving the efficiency of light utilization within the display, reflective polarizers can help reduce power consumption. This, in turn, can lead to longer battery life in mobile devices and lower energy requirements for larger displays, potentially reducing overall energy consumption and associated carbon emissions.

The use of reflective polarizers may also contribute to extending the lifespan of AMOLED displays. By enhancing display performance and reducing the need for high brightness settings, these polarizers could potentially slow down the degradation of OLED materials, leading to longer-lasting devices and reduced electronic waste.

Despite these potential benefits, the production of reflective polarizers still raises environmental concerns. The materials used in their manufacture, such as multi-layer polymer films, may have a significant carbon footprint. Additionally, the complexity of these polarizers may make them even more challenging to recycle than traditional polarizers.

To address these environmental challenges, research is ongoing into more sustainable materials and manufacturing processes for polarizers. This includes exploring bio-based polymers, developing more efficient recycling techniques, and investigating ways to reduce the use of harmful chemicals in production. Some companies are also looking into designing polarizers that are easier to separate and recycle at the end of their life cycle.

As the AMOLED industry continues to grow, balancing the performance benefits of reflective polarizers with their environmental impact will be crucial. This may involve adopting lifecycle assessment approaches to fully understand the environmental implications of different polarizer technologies and working towards more sustainable solutions that minimize negative impacts while maximizing display performance and energy efficiency.

Optical Performance Metrics

Reflective polarizers play a crucial role in enhancing the optical performance of AMOLED displays. These specialized optical components significantly impact several key metrics that determine the overall visual quality and efficiency of the display.

One of the primary benefits of incorporating reflective polarizers in AMOLED applications is the improvement in contrast ratio. By selectively reflecting light of one polarization while transmitting the orthogonal polarization, these polarizers effectively reduce ambient light reflection from the display surface. This results in deeper blacks and more vibrant colors, especially in high-ambient light conditions, leading to a more immersive viewing experience.

Brightness is another critical metric that sees substantial enhancement with the use of reflective polarizers. By recycling light that would otherwise be absorbed by the conventional polarizer, reflective polarizers can increase the overall light output of the display. This boost in brightness allows for better visibility in outdoor environments and can potentially reduce power consumption by achieving the same perceived brightness at lower backlight intensities.

Color gamut and color accuracy are also positively affected by the implementation of reflective polarizers. The selective reflection of specific wavelengths can be tuned to enhance certain color ranges, potentially expanding the display's color gamut. Additionally, by reducing unwanted reflections, these polarizers help maintain color accuracy across various viewing conditions.

Viewing angle performance is another area where reflective polarizers contribute significantly. They can help maintain consistent color and contrast across a wider range of viewing angles, reducing color shift and contrast degradation that are often observed in displays at extreme angles.

Energy efficiency is a critical consideration in AMOLED applications, and reflective polarizers offer notable improvements in this aspect. By recycling light that would otherwise be lost, these components can increase the overall optical efficiency of the display system. This can lead to reduced power consumption, which is particularly valuable in battery-powered devices.

Lastly, the impact on display readability in various lighting conditions is a key performance metric enhanced by reflective polarizers. By managing ambient light reflections more effectively, these polarizers can significantly improve the legibility of displayed content in challenging environments, such as direct sunlight or brightly lit indoor spaces.

One of the primary benefits of incorporating reflective polarizers in AMOLED applications is the improvement in contrast ratio. By selectively reflecting light of one polarization while transmitting the orthogonal polarization, these polarizers effectively reduce ambient light reflection from the display surface. This results in deeper blacks and more vibrant colors, especially in high-ambient light conditions, leading to a more immersive viewing experience.

Brightness is another critical metric that sees substantial enhancement with the use of reflective polarizers. By recycling light that would otherwise be absorbed by the conventional polarizer, reflective polarizers can increase the overall light output of the display. This boost in brightness allows for better visibility in outdoor environments and can potentially reduce power consumption by achieving the same perceived brightness at lower backlight intensities.

Color gamut and color accuracy are also positively affected by the implementation of reflective polarizers. The selective reflection of specific wavelengths can be tuned to enhance certain color ranges, potentially expanding the display's color gamut. Additionally, by reducing unwanted reflections, these polarizers help maintain color accuracy across various viewing conditions.

Viewing angle performance is another area where reflective polarizers contribute significantly. They can help maintain consistent color and contrast across a wider range of viewing angles, reducing color shift and contrast degradation that are often observed in displays at extreme angles.

Energy efficiency is a critical consideration in AMOLED applications, and reflective polarizers offer notable improvements in this aspect. By recycling light that would otherwise be lost, these components can increase the overall optical efficiency of the display system. This can lead to reduced power consumption, which is particularly valuable in battery-powered devices.

Lastly, the impact on display readability in various lighting conditions is a key performance metric enhanced by reflective polarizers. By managing ambient light reflections more effectively, these polarizers can significantly improve the legibility of displayed content in challenging environments, such as direct sunlight or brightly lit indoor spaces.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!