How renewable energy aligns with AMOLED production synergies?

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED and Renewables: Background and Objectives

The convergence of AMOLED (Active-Matrix Organic Light-Emitting Diode) technology and renewable energy represents a significant milestone in the evolution of display manufacturing and sustainable industrial practices. AMOLED technology has revolutionized the display industry with its superior image quality, energy efficiency, and flexibility. Concurrently, renewable energy sources have gained prominence as a solution to mitigate environmental impacts and ensure long-term energy sustainability.

The primary objective of this technical research is to explore the synergies between AMOLED production and renewable energy integration. This alignment aims to address the increasing demand for eco-friendly manufacturing processes in the electronics industry while maintaining the high-quality standards associated with AMOLED displays.

AMOLED technology has progressed rapidly since its inception, moving from small-scale applications in mobile devices to larger implementations in televisions and automotive displays. The technology's evolution has been marked by improvements in color accuracy, contrast ratios, and power efficiency. However, the production of AMOLED displays remains energy-intensive, presenting an opportunity for the integration of renewable energy sources.

Renewable energy, including solar, wind, and hydroelectric power, has seen significant advancements in efficiency and cost-effectiveness over the past decade. The decreasing costs of renewable technologies, coupled with global initiatives to reduce carbon emissions, have created a favorable environment for their adoption in industrial processes.

The intersection of these two technological trajectories presents a unique opportunity to enhance the sustainability of AMOLED production. By leveraging renewable energy sources, manufacturers can potentially reduce the carbon footprint of display production, align with global sustainability goals, and potentially realize long-term cost savings.

This research aims to investigate the technical feasibility, economic viability, and potential challenges of integrating renewable energy systems into AMOLED production facilities. It will explore how such integration might impact production processes, energy consumption patterns, and overall manufacturing efficiency.

Furthermore, this study will examine the potential for renewable energy to address specific energy-intensive stages of AMOLED production, such as the deposition of organic materials and the operation of clean room facilities. The research will also consider how the intermittent nature of some renewable energy sources can be managed to ensure consistent power supply for precision manufacturing processes.

By exploring these synergies, this technical research seeks to contribute to the development of more sustainable manufacturing practices in the display industry, potentially setting new standards for eco-friendly production of high-performance electronic components.

The primary objective of this technical research is to explore the synergies between AMOLED production and renewable energy integration. This alignment aims to address the increasing demand for eco-friendly manufacturing processes in the electronics industry while maintaining the high-quality standards associated with AMOLED displays.

AMOLED technology has progressed rapidly since its inception, moving from small-scale applications in mobile devices to larger implementations in televisions and automotive displays. The technology's evolution has been marked by improvements in color accuracy, contrast ratios, and power efficiency. However, the production of AMOLED displays remains energy-intensive, presenting an opportunity for the integration of renewable energy sources.

Renewable energy, including solar, wind, and hydroelectric power, has seen significant advancements in efficiency and cost-effectiveness over the past decade. The decreasing costs of renewable technologies, coupled with global initiatives to reduce carbon emissions, have created a favorable environment for their adoption in industrial processes.

The intersection of these two technological trajectories presents a unique opportunity to enhance the sustainability of AMOLED production. By leveraging renewable energy sources, manufacturers can potentially reduce the carbon footprint of display production, align with global sustainability goals, and potentially realize long-term cost savings.

This research aims to investigate the technical feasibility, economic viability, and potential challenges of integrating renewable energy systems into AMOLED production facilities. It will explore how such integration might impact production processes, energy consumption patterns, and overall manufacturing efficiency.

Furthermore, this study will examine the potential for renewable energy to address specific energy-intensive stages of AMOLED production, such as the deposition of organic materials and the operation of clean room facilities. The research will also consider how the intermittent nature of some renewable energy sources can be managed to ensure consistent power supply for precision manufacturing processes.

By exploring these synergies, this technical research seeks to contribute to the development of more sustainable manufacturing practices in the display industry, potentially setting new standards for eco-friendly production of high-performance electronic components.

Market Demand Analysis for Green AMOLED Production

The market demand for green AMOLED production is experiencing significant growth, driven by increasing consumer awareness of environmental issues and the push for sustainable technologies. As consumers become more environmentally conscious, there is a growing preference for eco-friendly electronic devices, including smartphones, tablets, and televisions that utilize AMOLED displays. This shift in consumer behavior is creating a substantial market opportunity for manufacturers who can align their production processes with renewable energy sources.

The AMOLED display market itself is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) expected to be in the double digits. This growth is fueled by the superior performance characteristics of AMOLED technology, such as better color reproduction, higher contrast ratios, and improved energy efficiency compared to traditional LCD displays. The integration of renewable energy into AMOLED production processes adds another layer of appeal to these already desirable products.

Major smartphone manufacturers, who are among the largest consumers of AMOLED displays, are increasingly committing to reducing their carbon footprint. This commitment extends to their supply chains, creating pressure on display manufacturers to adopt greener production methods. As a result, AMOLED producers who can demonstrate the use of renewable energy in their manufacturing processes are likely to gain a competitive edge and secure contracts with these high-volume customers.

The automotive industry represents another significant growth area for green AMOLED production. As electric vehicles gain market share, there is an increasing demand for advanced, energy-efficient displays for infotainment systems and digital dashboards. Automakers are particularly sensitive to the environmental credentials of their components, making renewable energy-powered AMOLED production an attractive proposition for suppliers targeting this sector.

Consumer electronics retailers and e-commerce platforms are also recognizing the marketing potential of eco-friendly products. Many are creating dedicated sections for sustainable electronics, providing additional visibility and sales channels for devices featuring green AMOLED displays. This trend is expected to further stimulate demand and potentially command premium pricing for products that can boast environmentally responsible manufacturing processes.

However, the market demand for green AMOLED production is not without challenges. The initial costs associated with transitioning to renewable energy sources can be substantial, potentially leading to higher product prices in the short term. Manufacturers will need to balance these costs against the long-term benefits and market demand to remain competitive. Additionally, there is a need for standardization and certification processes to verify claims of renewable energy usage in production, ensuring transparency and building consumer trust in the green credentials of AMOLED products.

The AMOLED display market itself is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) expected to be in the double digits. This growth is fueled by the superior performance characteristics of AMOLED technology, such as better color reproduction, higher contrast ratios, and improved energy efficiency compared to traditional LCD displays. The integration of renewable energy into AMOLED production processes adds another layer of appeal to these already desirable products.

Major smartphone manufacturers, who are among the largest consumers of AMOLED displays, are increasingly committing to reducing their carbon footprint. This commitment extends to their supply chains, creating pressure on display manufacturers to adopt greener production methods. As a result, AMOLED producers who can demonstrate the use of renewable energy in their manufacturing processes are likely to gain a competitive edge and secure contracts with these high-volume customers.

The automotive industry represents another significant growth area for green AMOLED production. As electric vehicles gain market share, there is an increasing demand for advanced, energy-efficient displays for infotainment systems and digital dashboards. Automakers are particularly sensitive to the environmental credentials of their components, making renewable energy-powered AMOLED production an attractive proposition for suppliers targeting this sector.

Consumer electronics retailers and e-commerce platforms are also recognizing the marketing potential of eco-friendly products. Many are creating dedicated sections for sustainable electronics, providing additional visibility and sales channels for devices featuring green AMOLED displays. This trend is expected to further stimulate demand and potentially command premium pricing for products that can boast environmentally responsible manufacturing processes.

However, the market demand for green AMOLED production is not without challenges. The initial costs associated with transitioning to renewable energy sources can be substantial, potentially leading to higher product prices in the short term. Manufacturers will need to balance these costs against the long-term benefits and market demand to remain competitive. Additionally, there is a need for standardization and certification processes to verify claims of renewable energy usage in production, ensuring transparency and building consumer trust in the green credentials of AMOLED products.

Current Challenges in Renewable Energy Integration

The integration of renewable energy into AMOLED production processes presents several significant challenges that need to be addressed. One of the primary obstacles is the intermittent nature of renewable energy sources, particularly solar and wind power. AMOLED manufacturing requires a consistent and stable power supply to maintain precise control over the production environment. Fluctuations in energy supply can lead to quality issues, reduced yield rates, and increased production costs.

Another challenge lies in the high energy demands of AMOLED production. The manufacturing process involves energy-intensive steps such as vapor deposition and thermal evaporation, which require substantial amounts of power. While renewable energy technologies have made significant strides in recent years, they may still struggle to meet the peak energy demands of large-scale AMOLED production facilities without substantial energy storage systems in place.

The geographical limitations of renewable energy sources also pose a challenge for AMOLED manufacturers. Many production facilities are located in areas that may not have optimal conditions for solar or wind energy generation. This mismatch between energy production and consumption locations necessitates the development of robust energy transmission and storage infrastructure, which can be both costly and technologically complex.

Furthermore, the initial capital investment required for implementing renewable energy systems in AMOLED production facilities can be substantial. While the long-term benefits of reduced energy costs and improved sustainability are clear, the upfront costs may be prohibitive for some manufacturers, particularly in a highly competitive market where profit margins are often tight.

The integration of renewable energy systems also introduces new complexities in facility management and operations. AMOLED production requires precise environmental control, and the introduction of on-site renewable energy generation may necessitate additional monitoring and control systems to ensure seamless integration with existing production processes.

Lastly, there is the challenge of aligning renewable energy generation with the 24/7 operational requirements of many AMOLED production facilities. While energy storage technologies are advancing, ensuring a constant power supply during periods of low renewable energy generation remains a significant hurdle. This necessitates either substantial energy storage capacity or the maintenance of conventional power sources as backup, which can complicate the transition to a fully renewable energy-powered production process.

Another challenge lies in the high energy demands of AMOLED production. The manufacturing process involves energy-intensive steps such as vapor deposition and thermal evaporation, which require substantial amounts of power. While renewable energy technologies have made significant strides in recent years, they may still struggle to meet the peak energy demands of large-scale AMOLED production facilities without substantial energy storage systems in place.

The geographical limitations of renewable energy sources also pose a challenge for AMOLED manufacturers. Many production facilities are located in areas that may not have optimal conditions for solar or wind energy generation. This mismatch between energy production and consumption locations necessitates the development of robust energy transmission and storage infrastructure, which can be both costly and technologically complex.

Furthermore, the initial capital investment required for implementing renewable energy systems in AMOLED production facilities can be substantial. While the long-term benefits of reduced energy costs and improved sustainability are clear, the upfront costs may be prohibitive for some manufacturers, particularly in a highly competitive market where profit margins are often tight.

The integration of renewable energy systems also introduces new complexities in facility management and operations. AMOLED production requires precise environmental control, and the introduction of on-site renewable energy generation may necessitate additional monitoring and control systems to ensure seamless integration with existing production processes.

Lastly, there is the challenge of aligning renewable energy generation with the 24/7 operational requirements of many AMOLED production facilities. While energy storage technologies are advancing, ensuring a constant power supply during periods of low renewable energy generation remains a significant hurdle. This necessitates either substantial energy storage capacity or the maintenance of conventional power sources as backup, which can complicate the transition to a fully renewable energy-powered production process.

Existing Renewable Energy Solutions for AMOLED Production

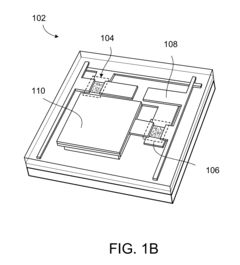

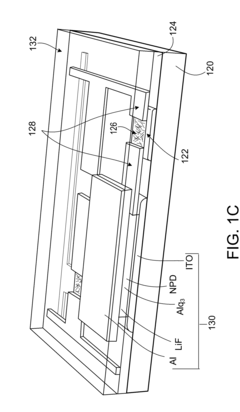

01 AMOLED display panel structure

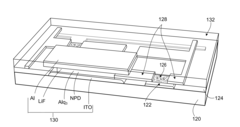

AMOLED production involves the development of advanced display panel structures. This includes the design and fabrication of thin-film transistors (TFTs), pixel circuits, and light-emitting layers. The structure aims to improve display performance, such as brightness, contrast, and color accuracy, while optimizing power efficiency.- AMOLED display panel structure: AMOLED production involves the development of advanced display panel structures. This includes the design and fabrication of thin-film transistors (TFTs), pixel circuits, and light-emitting layers. The structure aims to improve display performance, such as brightness, contrast, and power efficiency.

- Driving methods for AMOLED displays: Various driving methods are employed in AMOLED production to enhance display quality and reduce power consumption. These methods include advanced pixel compensation techniques, voltage programming, and current driving schemes to address issues like non-uniformity and degradation of organic light-emitting diodes.

- AMOLED manufacturing processes: AMOLED production involves specialized manufacturing processes, including deposition of organic materials, encapsulation techniques, and integration of thin-film transistors. These processes are crucial for achieving high-quality displays with improved lifetime and performance characteristics.

- Touch integration in AMOLED displays: Integration of touch functionality into AMOLED displays is an important aspect of production. This involves developing in-cell or on-cell touch solutions, optimizing touch sensitivity, and reducing interference between touch and display functions to create more compact and responsive devices.

- Color management and image quality enhancement: AMOLED production focuses on improving color accuracy, gamut, and overall image quality. This includes developing advanced color management systems, implementing high dynamic range (HDR) capabilities, and optimizing subpixel arrangements to enhance display performance and visual experience.

02 Pixel driving techniques

Various pixel driving techniques are employed in AMOLED production to enhance display quality and reduce power consumption. These methods include advanced compensation algorithms, voltage programming, and current driving schemes. The goal is to achieve uniform brightness across the display and mitigate issues like image retention and burn-in.Expand Specific Solutions03 OLED material deposition

The production of AMOLED displays involves precise deposition of organic light-emitting materials. Techniques such as vacuum thermal evaporation, inkjet printing, and laser-induced thermal imaging are used to deposit these materials accurately. The process aims to achieve uniform layer thickness and prevent contamination, ensuring high-quality light emission.Expand Specific Solutions04 Encapsulation and protection

AMOLED production includes advanced encapsulation techniques to protect the organic materials from moisture and oxygen. This may involve the use of thin-film encapsulation layers, getter materials, and hermetic sealing methods. The goal is to extend the lifespan of the display and maintain its performance over time.Expand Specific Solutions05 Display driver integration

The integration of display drivers is a crucial aspect of AMOLED production. This involves the design and fabrication of integrated circuits that control the display panel. Advanced driver ICs may incorporate features such as image processing, power management, and touch integration to enhance overall display performance and functionality.Expand Specific Solutions

Key Players in AMOLED and Renewable Energy Sectors

The renewable energy integration with AMOLED production is in its early stages, with a growing market driven by sustainability demands. The technology's maturity varies among key players. BOE Technology Group and Samsung Display are leading innovators, leveraging their extensive OLED expertise to pioneer eco-friendly manufacturing processes. LG Display and Tianma Microelectronics are also making significant strides in this area. Emerging companies like Visionox and TCL CSOT are rapidly advancing their capabilities, while established firms such as Applied Materials are developing specialized equipment to support this transition. The synergy between renewable energy and AMOLED production represents a promising frontier in display technology, with potential for substantial market growth and environmental impact.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology Group has been actively incorporating renewable energy into its AMOLED production processes. The company has implemented a "Green Light" strategy, focusing on energy conservation and emission reduction in display manufacturing. BOE has invested in solar power installations at its production facilities, aiming to increase the proportion of renewable energy in its overall energy mix[7]. In AMOLED production, BOE has developed energy-efficient manufacturing techniques, including the use of low-temperature processes and advanced materials that require less energy to produce. The company has also introduced AI-powered energy management systems in its factories to optimize power consumption and align with renewable energy availability[8]. BOE's flexible AMOLED displays are designed to be more energy-efficient, indirectly supporting the use of renewable energy in end-user devices[9].

Strengths: Large-scale production capacity, ongoing investments in renewable energy infrastructure, energy-efficient AMOLED technologies. Weaknesses: Still in transition to full renewable energy adoption, potential regional variations in renewable energy access across global facilities.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has been at the forefront of integrating renewable energy into AMOLED production. They have implemented a comprehensive green manufacturing strategy, which includes the use of solar panels and wind turbines to power their production facilities. The company has achieved a 100% renewable energy use in all of its operations in China, Europe and the U.S. as of 2020[1]. Their AMOLED production lines utilize energy-efficient processes, such as low-temperature polycrystalline silicon (LTPS) technology, which reduces energy consumption during the manufacturing process[2]. Additionally, Samsung has developed eco-friendly OLED materials that require less energy to produce and operate, aligning with their commitment to sustainability in AMOLED technology[3].

Strengths: Industry leader in AMOLED technology, strong commitment to renewable energy, advanced eco-friendly materials. Weaknesses: High initial investment costs for renewable energy infrastructure, potential supply chain disruptions for specialized eco-materials.

Core Innovations in Green AMOLED Manufacturing

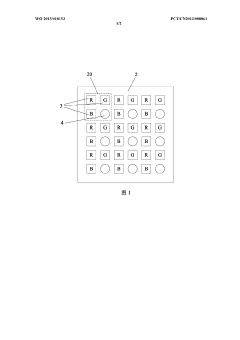

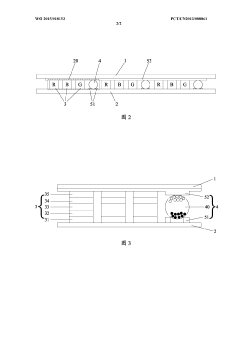

Display panel and drive method therefor, and display device

PatentWO2015018153A1

Innovation

- A display panel is used, including pixel units arranged in an array. Each pixel unit includes three OLED sub-pixels and one EPD sub-pixel. The EPD sub-pixel is used to display by reflecting ambient light without requiring continuous power-up. Black and white images, reducing power consumption, and color images displayed by OLED sub-pixels when needed.

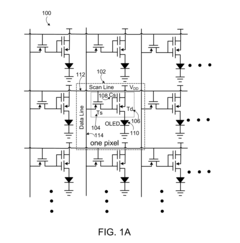

Separated Carbon Nanotube-Based Active Matrix Organic Light-Emitting Diode Displays

PatentInactiveUS20140070169A1

Innovation

- The use of separated semiconducting nanotubes as the active channel material in transistors, with a network of nanotubes disposed over a functionalized gate dielectric layer, and integrated into a display control circuit to drive OLED pixels, enabling high on/off ratios and current density.

Environmental Impact Assessment

The integration of renewable energy sources with AMOLED production processes presents a significant opportunity for reducing the environmental impact of display manufacturing. AMOLED technology, known for its energy efficiency and superior image quality, has become increasingly prevalent in consumer electronics. However, the production of these displays traditionally involves energy-intensive processes and the use of potentially harmful materials.

By aligning renewable energy strategies with AMOLED production, manufacturers can substantially decrease their carbon footprint and mitigate other environmental concerns. Solar and wind power installations can be integrated into production facilities, providing clean energy for the high-power consumption stages of AMOLED manufacturing, such as vapor deposition and encapsulation processes.

The use of renewable energy in AMOLED production can lead to a reduction in greenhouse gas emissions, contributing to global efforts to combat climate change. This shift also aligns with increasingly stringent environmental regulations and consumer demand for more sustainable products. Additionally, the implementation of renewable energy systems can help mitigate the environmental risks associated with traditional power sources, such as air and water pollution from fossil fuel combustion.

Water conservation is another critical aspect of environmental impact that can be addressed through the synergy of renewable energy and AMOLED production. By utilizing solar thermal systems, manufacturers can reduce the energy required for heating water used in cleaning processes, potentially leading to more efficient water usage and reduced wastewater generation.

The adoption of renewable energy in AMOLED production also presents opportunities for improving waste management practices. Energy recovery systems can be implemented to capture and repurpose heat generated during manufacturing processes, further enhancing overall energy efficiency. Moreover, the use of clean energy can facilitate the development of more environmentally friendly disposal and recycling methods for AMOLED components at the end of their lifecycle.

Lifecycle assessment studies have shown that the environmental benefits of integrating renewable energy into AMOLED production extend beyond the manufacturing phase. The reduced environmental impact during production can significantly lower the overall carbon footprint of devices utilizing AMOLED displays throughout their entire lifecycle, from raw material extraction to end-of-life disposal.

As the AMOLED industry continues to grow, the potential for positive environmental impact through renewable energy integration becomes increasingly significant. This alignment not only addresses immediate environmental concerns but also positions AMOLED technology as a leader in sustainable electronics manufacturing, potentially influencing broader industry practices and standards.

By aligning renewable energy strategies with AMOLED production, manufacturers can substantially decrease their carbon footprint and mitigate other environmental concerns. Solar and wind power installations can be integrated into production facilities, providing clean energy for the high-power consumption stages of AMOLED manufacturing, such as vapor deposition and encapsulation processes.

The use of renewable energy in AMOLED production can lead to a reduction in greenhouse gas emissions, contributing to global efforts to combat climate change. This shift also aligns with increasingly stringent environmental regulations and consumer demand for more sustainable products. Additionally, the implementation of renewable energy systems can help mitigate the environmental risks associated with traditional power sources, such as air and water pollution from fossil fuel combustion.

Water conservation is another critical aspect of environmental impact that can be addressed through the synergy of renewable energy and AMOLED production. By utilizing solar thermal systems, manufacturers can reduce the energy required for heating water used in cleaning processes, potentially leading to more efficient water usage and reduced wastewater generation.

The adoption of renewable energy in AMOLED production also presents opportunities for improving waste management practices. Energy recovery systems can be implemented to capture and repurpose heat generated during manufacturing processes, further enhancing overall energy efficiency. Moreover, the use of clean energy can facilitate the development of more environmentally friendly disposal and recycling methods for AMOLED components at the end of their lifecycle.

Lifecycle assessment studies have shown that the environmental benefits of integrating renewable energy into AMOLED production extend beyond the manufacturing phase. The reduced environmental impact during production can significantly lower the overall carbon footprint of devices utilizing AMOLED displays throughout their entire lifecycle, from raw material extraction to end-of-life disposal.

As the AMOLED industry continues to grow, the potential for positive environmental impact through renewable energy integration becomes increasingly significant. This alignment not only addresses immediate environmental concerns but also positions AMOLED technology as a leader in sustainable electronics manufacturing, potentially influencing broader industry practices and standards.

Policy and Incentives for Green AMOLED Manufacturing

The alignment of renewable energy with AMOLED production synergies has become a focal point for policymakers and industry leaders alike. Governments worldwide are implementing a range of policies and incentives to promote green AMOLED manufacturing practices, recognizing the potential for significant environmental and economic benefits.

At the forefront of these initiatives are tax incentives designed to encourage AMOLED manufacturers to adopt renewable energy sources. Many countries offer substantial tax credits or deductions for companies that invest in solar, wind, or other clean energy technologies to power their production facilities. These incentives often extend to the entire supply chain, promoting a holistic approach to sustainability in the AMOLED industry.

Grants and subsidies play a crucial role in accelerating the transition to green AMOLED manufacturing. Government agencies and environmental organizations provide financial support for research and development of energy-efficient AMOLED technologies and production processes. These funds help offset the initial costs associated with implementing renewable energy systems and upgrading manufacturing equipment to reduce energy consumption.

Regulatory frameworks are being established to set standards for energy efficiency and emissions in AMOLED production. Many jurisdictions have introduced mandatory targets for renewable energy usage in manufacturing, coupled with penalties for non-compliance. These regulations create a level playing field and drive industry-wide adoption of sustainable practices.

Green certification programs have emerged as powerful tools for incentivizing environmentally responsible AMOLED manufacturing. These programs offer recognition and market advantages to companies that meet stringent criteria for energy efficiency, waste reduction, and renewable energy utilization. Certified manufacturers often enjoy preferential treatment in government procurement processes and increased consumer appeal.

Public-private partnerships are fostering innovation in green AMOLED production technologies. Governments are collaborating with industry leaders to establish research centers and pilot projects focused on integrating renewable energy into AMOLED manufacturing processes. These initiatives not only drive technological advancements but also create valuable knowledge-sharing platforms for the entire industry.

Energy performance contracting is gaining traction as a policy tool to promote renewable energy adoption in AMOLED facilities. Under these arrangements, energy service companies implement renewable energy solutions and efficiency improvements, with costs recouped through the resulting energy savings. This model reduces financial barriers for manufacturers and accelerates the transition to sustainable production methods.

As the AMOLED industry continues to grow, policymakers are increasingly recognizing the importance of aligning renewable energy goals with manufacturing synergies. By implementing a comprehensive suite of policies and incentives, governments are laying the groundwork for a more sustainable and competitive AMOLED sector, driving innovation and environmental stewardship in equal measure.

At the forefront of these initiatives are tax incentives designed to encourage AMOLED manufacturers to adopt renewable energy sources. Many countries offer substantial tax credits or deductions for companies that invest in solar, wind, or other clean energy technologies to power their production facilities. These incentives often extend to the entire supply chain, promoting a holistic approach to sustainability in the AMOLED industry.

Grants and subsidies play a crucial role in accelerating the transition to green AMOLED manufacturing. Government agencies and environmental organizations provide financial support for research and development of energy-efficient AMOLED technologies and production processes. These funds help offset the initial costs associated with implementing renewable energy systems and upgrading manufacturing equipment to reduce energy consumption.

Regulatory frameworks are being established to set standards for energy efficiency and emissions in AMOLED production. Many jurisdictions have introduced mandatory targets for renewable energy usage in manufacturing, coupled with penalties for non-compliance. These regulations create a level playing field and drive industry-wide adoption of sustainable practices.

Green certification programs have emerged as powerful tools for incentivizing environmentally responsible AMOLED manufacturing. These programs offer recognition and market advantages to companies that meet stringent criteria for energy efficiency, waste reduction, and renewable energy utilization. Certified manufacturers often enjoy preferential treatment in government procurement processes and increased consumer appeal.

Public-private partnerships are fostering innovation in green AMOLED production technologies. Governments are collaborating with industry leaders to establish research centers and pilot projects focused on integrating renewable energy into AMOLED manufacturing processes. These initiatives not only drive technological advancements but also create valuable knowledge-sharing platforms for the entire industry.

Energy performance contracting is gaining traction as a policy tool to promote renewable energy adoption in AMOLED facilities. Under these arrangements, energy service companies implement renewable energy solutions and efficiency improvements, with costs recouped through the resulting energy savings. This model reduces financial barriers for manufacturers and accelerates the transition to sustainable production methods.

As the AMOLED industry continues to grow, policymakers are increasingly recognizing the importance of aligning renewable energy goals with manufacturing synergies. By implementing a comprehensive suite of policies and incentives, governments are laying the groundwork for a more sustainable and competitive AMOLED sector, driving innovation and environmental stewardship in equal measure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!