How AMOLED-integrated textiles influence interactive fashion?

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Textile Tech Evolution

The evolution of AMOLED-integrated textiles represents a significant leap in the convergence of fashion and technology. This innovative approach has its roots in the development of flexible displays and wearable electronics, which began to gain traction in the early 2010s. As AMOLED (Active-Matrix Organic Light-Emitting Diode) technology matured, researchers and designers started exploring ways to incorporate these displays into fabric structures.

The initial attempts focused on attaching small AMOLED panels to clothing, but this approach was limited in flexibility and integration. The breakthrough came with the development of fiber-based OLED technology around 2015, which allowed for the creation of light-emitting fibers that could be woven into textiles. This marked the beginning of truly integrated AMOLED textiles.

From 2015 to 2018, the focus was on improving the durability and washability of these electronic textiles. Researchers developed encapsulation techniques to protect the OLED components from moisture and mechanical stress, a crucial step in making the technology practical for everyday wear.

The period from 2018 to 2020 saw advancements in the resolution and color capabilities of AMOLED textiles. Manufacturers began producing fabrics with higher pixel densities, enabling more detailed and vibrant displays. This phase also witnessed the integration of touch-sensitive elements, transforming AMOLED textiles from passive displays to interactive surfaces.

2020 marked a turning point with the introduction of stretchable AMOLED textiles. This innovation allowed the electronic components to maintain functionality even when the fabric was stretched or deformed, greatly enhancing comfort and wearability. It opened up new possibilities for form-fitting garments and accessories with seamlessly integrated displays.

In recent years, the focus has shifted towards energy efficiency and power management. Researchers have been developing ways to harvest energy from body heat and movement to power these displays, reducing the need for bulky batteries. Additionally, advancements in low-power AMOLED technology have extended the operational life of these interactive garments.

The latest developments in AMOLED textile technology are exploring the integration of other smart functionalities. This includes incorporating sensors for health monitoring, NFC for contactless payments, and even thermoregulation capabilities. These advancements are pushing AMOLED-integrated textiles beyond mere visual displays, transforming them into comprehensive, multifunctional smart garments.

The initial attempts focused on attaching small AMOLED panels to clothing, but this approach was limited in flexibility and integration. The breakthrough came with the development of fiber-based OLED technology around 2015, which allowed for the creation of light-emitting fibers that could be woven into textiles. This marked the beginning of truly integrated AMOLED textiles.

From 2015 to 2018, the focus was on improving the durability and washability of these electronic textiles. Researchers developed encapsulation techniques to protect the OLED components from moisture and mechanical stress, a crucial step in making the technology practical for everyday wear.

The period from 2018 to 2020 saw advancements in the resolution and color capabilities of AMOLED textiles. Manufacturers began producing fabrics with higher pixel densities, enabling more detailed and vibrant displays. This phase also witnessed the integration of touch-sensitive elements, transforming AMOLED textiles from passive displays to interactive surfaces.

2020 marked a turning point with the introduction of stretchable AMOLED textiles. This innovation allowed the electronic components to maintain functionality even when the fabric was stretched or deformed, greatly enhancing comfort and wearability. It opened up new possibilities for form-fitting garments and accessories with seamlessly integrated displays.

In recent years, the focus has shifted towards energy efficiency and power management. Researchers have been developing ways to harvest energy from body heat and movement to power these displays, reducing the need for bulky batteries. Additionally, advancements in low-power AMOLED technology have extended the operational life of these interactive garments.

The latest developments in AMOLED textile technology are exploring the integration of other smart functionalities. This includes incorporating sensors for health monitoring, NFC for contactless payments, and even thermoregulation capabilities. These advancements are pushing AMOLED-integrated textiles beyond mere visual displays, transforming them into comprehensive, multifunctional smart garments.

Interactive Fashion Market Analysis

The interactive fashion market has experienced significant growth in recent years, driven by advancements in wearable technology and increasing consumer demand for innovative, multifunctional clothing. The integration of AMOLED (Active-Matrix Organic Light-Emitting Diode) technology into textiles has emerged as a game-changing development, revolutionizing the concept of interactive fashion.

Market research indicates that the global smart textile market, which includes AMOLED-integrated textiles, is projected to expand rapidly. This growth is fueled by the convergence of fashion and technology, as well as the rising popularity of IoT-enabled devices. The interactive fashion segment, in particular, has shown promising potential, with consumers expressing interest in garments that offer both aesthetic appeal and functional capabilities.

AMOLED-integrated textiles have opened up new possibilities for interactive fashion, allowing for the creation of clothing that can display dynamic patterns, colors, and even information. This technology has found applications in various sectors, including high-end fashion, sportswear, and performance apparel. The ability to customize and change the appearance of clothing on-demand has resonated with consumers seeking personalization and uniqueness in their wardrobe.

The market demand for AMOLED-integrated textiles in interactive fashion is driven by several factors. Firstly, there is a growing interest in sustainable and versatile clothing options. AMOLED technology allows for the creation of garments that can adapt to different occasions, potentially reducing the need for multiple clothing items. Secondly, the increasing focus on health and wellness has led to demand for smart clothing that can monitor vital signs and provide real-time feedback, a feature that AMOLED displays can facilitate.

Industry trends suggest that the interactive fashion market is moving towards more seamless integration of technology and textiles. Consumers are looking for wearable tech that doesn't compromise on comfort or style. AMOLED-integrated textiles address this need by offering flexible, lightweight displays that can be incorporated into various fabric types without significantly altering their properties.

The potential applications of AMOLED-integrated textiles in interactive fashion extend beyond mere aesthetics. There is growing interest in using this technology for functional purposes, such as displaying navigation information, environmental data, or social media updates. This multifunctionality is expected to drive further market growth and innovation in the interactive fashion sector.

Market research indicates that the global smart textile market, which includes AMOLED-integrated textiles, is projected to expand rapidly. This growth is fueled by the convergence of fashion and technology, as well as the rising popularity of IoT-enabled devices. The interactive fashion segment, in particular, has shown promising potential, with consumers expressing interest in garments that offer both aesthetic appeal and functional capabilities.

AMOLED-integrated textiles have opened up new possibilities for interactive fashion, allowing for the creation of clothing that can display dynamic patterns, colors, and even information. This technology has found applications in various sectors, including high-end fashion, sportswear, and performance apparel. The ability to customize and change the appearance of clothing on-demand has resonated with consumers seeking personalization and uniqueness in their wardrobe.

The market demand for AMOLED-integrated textiles in interactive fashion is driven by several factors. Firstly, there is a growing interest in sustainable and versatile clothing options. AMOLED technology allows for the creation of garments that can adapt to different occasions, potentially reducing the need for multiple clothing items. Secondly, the increasing focus on health and wellness has led to demand for smart clothing that can monitor vital signs and provide real-time feedback, a feature that AMOLED displays can facilitate.

Industry trends suggest that the interactive fashion market is moving towards more seamless integration of technology and textiles. Consumers are looking for wearable tech that doesn't compromise on comfort or style. AMOLED-integrated textiles address this need by offering flexible, lightweight displays that can be incorporated into various fabric types without significantly altering their properties.

The potential applications of AMOLED-integrated textiles in interactive fashion extend beyond mere aesthetics. There is growing interest in using this technology for functional purposes, such as displaying navigation information, environmental data, or social media updates. This multifunctionality is expected to drive further market growth and innovation in the interactive fashion sector.

AMOLED Textile Integration Challenges

The integration of AMOLED technology into textiles presents several significant challenges that researchers and engineers must overcome to realize the full potential of interactive fashion. One of the primary obstacles is the inherent flexibility required for wearable textiles, which conflicts with the traditionally rigid nature of AMOLED displays. Developing flexible AMOLED panels that can withstand repeated bending, stretching, and folding without compromising display quality or longevity is a complex task.

Another major challenge lies in the power requirements of AMOLED displays. While these displays are known for their energy efficiency compared to other technologies, they still consume considerable power when integrated into textiles. This necessitates the development of innovative power solutions, such as flexible batteries or energy harvesting technologies, that can seamlessly integrate with the fabric without adding bulk or discomfort to the wearer.

Durability and environmental resistance pose additional hurdles. AMOLED-integrated textiles must withstand various environmental factors, including moisture, temperature fluctuations, and physical stress from regular wear and washing. Creating effective encapsulation methods to protect the sensitive electronic components from these elements while maintaining the fabric's natural properties is crucial for the long-term viability of interactive fashion garments.

The manufacturing process itself presents significant challenges. Integrating AMOLED displays into textiles requires the development of new production techniques that can seamlessly combine electronic components with fabric materials. This includes addressing issues such as precise alignment, uniform adhesion, and maintaining the structural integrity of both the display and the textile during the integration process.

Scalability and cost-effectiveness are also major concerns. Current methods for integrating AMOLED displays into textiles are often labor-intensive and expensive, limiting their potential for mass production. Developing automated manufacturing processes and reducing material costs are essential for making AMOLED-integrated textiles commercially viable and accessible to a broader market.

Lastly, the challenge of achieving uniform light distribution and color accuracy across the textile surface is significant. Unlike traditional rigid displays, AMOLED-integrated textiles must maintain consistent visual performance even when the fabric is in motion or subjected to various forms of deformation. This requires advanced optical engineering and material science solutions to ensure that the display remains clear, vibrant, and readable under diverse conditions.

Another major challenge lies in the power requirements of AMOLED displays. While these displays are known for their energy efficiency compared to other technologies, they still consume considerable power when integrated into textiles. This necessitates the development of innovative power solutions, such as flexible batteries or energy harvesting technologies, that can seamlessly integrate with the fabric without adding bulk or discomfort to the wearer.

Durability and environmental resistance pose additional hurdles. AMOLED-integrated textiles must withstand various environmental factors, including moisture, temperature fluctuations, and physical stress from regular wear and washing. Creating effective encapsulation methods to protect the sensitive electronic components from these elements while maintaining the fabric's natural properties is crucial for the long-term viability of interactive fashion garments.

The manufacturing process itself presents significant challenges. Integrating AMOLED displays into textiles requires the development of new production techniques that can seamlessly combine electronic components with fabric materials. This includes addressing issues such as precise alignment, uniform adhesion, and maintaining the structural integrity of both the display and the textile during the integration process.

Scalability and cost-effectiveness are also major concerns. Current methods for integrating AMOLED displays into textiles are often labor-intensive and expensive, limiting their potential for mass production. Developing automated manufacturing processes and reducing material costs are essential for making AMOLED-integrated textiles commercially viable and accessible to a broader market.

Lastly, the challenge of achieving uniform light distribution and color accuracy across the textile surface is significant. Unlike traditional rigid displays, AMOLED-integrated textiles must maintain consistent visual performance even when the fabric is in motion or subjected to various forms of deformation. This requires advanced optical engineering and material science solutions to ensure that the display remains clear, vibrant, and readable under diverse conditions.

Current AMOLED Textile Solutions

01 AMOLED display integration in textiles

Integration of AMOLED displays into textiles to create interactive fabrics. This technology allows for the incorporation of flexible, high-quality displays directly into clothing or other textile products, enabling various interactive applications and wearable displays.- AMOLED display integration in textiles: Integration of AMOLED displays into textiles to create interactive fabrics. This technology allows for the incorporation of flexible, high-quality displays directly into clothing or other textile products, enabling various interactive applications and wearable displays.

- Touch-sensitive fabric interfaces: Development of touch-sensitive interfaces within textiles, allowing users to interact with the integrated AMOLED displays through touch gestures on the fabric surface. This technology enables intuitive control and input methods for wearable devices and smart textiles.

- Power management for AMOLED textiles: Implementation of efficient power management systems for AMOLED-integrated textiles, including energy harvesting techniques and low-power display technologies. These innovations help extend battery life and improve the practicality of interactive textile displays.

- Data processing and communication for interactive textiles: Integration of data processing and communication capabilities within AMOLED-integrated textiles, enabling connectivity with other devices and networks. This technology allows for real-time updates, data exchange, and enhanced functionality of interactive textile displays.

- Durability and flexibility of AMOLED textile displays: Development of techniques to enhance the durability and flexibility of AMOLED displays integrated into textiles. This includes methods for protecting the displays from wear and tear, as well as improving their ability to conform to the shape and movement of the fabric.

02 Touch-sensitive fabric interfaces

Development of touch-sensitive fabrics that can detect user input through touch or gestures. These interactive textiles combine conductive materials with AMOLED displays to create responsive surfaces capable of registering user interactions and providing visual feedback.Expand Specific Solutions03 Flexible OLED technology for wearables

Advancements in flexible OLED technology specifically designed for wearable applications. This includes the development of bendable, stretchable, and durable AMOLED displays that can withstand the rigors of daily wear while maintaining high performance and visual quality.Expand Specific Solutions04 Power management for AMOLED-integrated textiles

Innovative power management solutions for AMOLED-integrated textiles, addressing the challenges of powering electronic displays in wearable form factors. This includes energy-efficient display technologies, battery integration, and power distribution systems within the fabric structure.Expand Specific Solutions05 Data processing and communication for interactive textiles

Systems and methods for processing data and facilitating communication in AMOLED-integrated textiles. This encompasses wireless connectivity, data storage, and processing capabilities integrated into the fabric to enable advanced interactive features and connectivity with other devices or networks.Expand Specific Solutions

Key Players in E-Textile Industry

The integration of AMOLED technology into textiles for interactive fashion is an emerging field at the intersection of electronics and textiles. This market is in its early stages of development, with significant potential for growth as wearable technology becomes more mainstream. The global smart textile market, which includes interactive fashion, is projected to reach $5.55 billion by 2025, growing at a CAGR of 30.4%. Technologically, AMOLED-integrated textiles are still in the research and development phase, with companies like Samsung Electronics, BOE Technology, and Tianma Microelectronics leading the way in flexible AMOLED display development. Academic institutions such as Drexel University and Donghua University are also contributing to advancements in this field, focusing on the integration of electronic components into fabrics.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has made significant strides in AMOLED-integrated textiles for interactive fashion. The company has developed a flexible AMOLED display technology that can be seamlessly incorporated into various fabric types. BOE's approach focuses on creating ultra-thin, lightweight AMOLED panels that maintain high flexibility and can withstand repeated bending and folding[4]. Their technology utilizes a specialized encapsulation method to protect the OLED elements from moisture and oxygen, ensuring longevity in wearable applications. BOE has also developed a unique pixel structure that allows for improved brightness and color accuracy in textile-integrated displays[5]. The company's AMOLED textiles feature touch sensitivity and can be connected to various smart devices, enabling interactive fashion items such as programmable t-shirts and smart accessories[6].

Strengths: Strong expertise in display manufacturing, advanced flexible OLED technology, and established supply chain. Weaknesses: Limited experience in textile integration and potential challenges in mass production scalability.

NIKE, Inc.

Technical Solution: Nike has been exploring AMOLED-integrated textiles as part of its innovation in interactive sportswear. The company's approach focuses on combining AMOLED display technology with performance fabrics to create dynamic, customizable athletic wear. Nike's research has led to the development of flexible, sweat-resistant AMOLED panels that can be integrated into various sportswear items[7]. These displays are designed to provide real-time performance data, such as heart rate, pace, and distance, directly on the garment. Nike has also experimented with using AMOLED textiles for adaptive camouflage in sports uniforms, allowing teams to change colors or patterns instantly[8]. The company's technology incorporates touch-sensitive areas within the fabric, enabling users to interact with the display and control connected devices without the need for separate wearables[9].

Strengths: Strong brand presence in sportswear, extensive experience in wearable technology, and established partnerships with technology companies. Weaknesses: Less expertise in display manufacturing compared to dedicated electronics companies.

AMOLED Textile Core Innovations

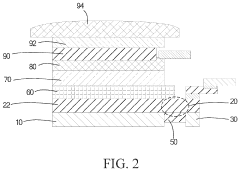

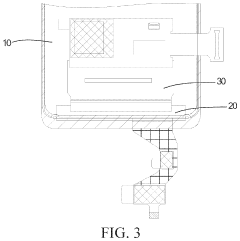

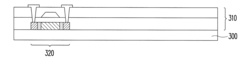

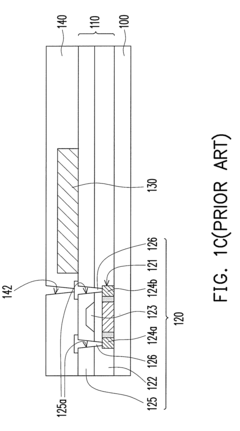

Active matrix organic light emitting diode panel

PatentInactiveUS20200185645A1

Innovation

- An AMOLED panel design featuring a hydrogel layer coated between two backing plates at the bent portion, which is then solidified with ultraviolet light, providing structural strength and toughness to the fillet formed when the panel is folded, thereby preventing deformation and breakage.

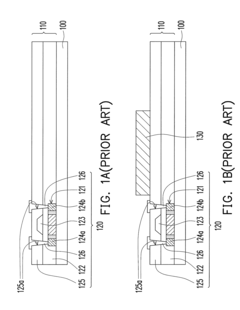

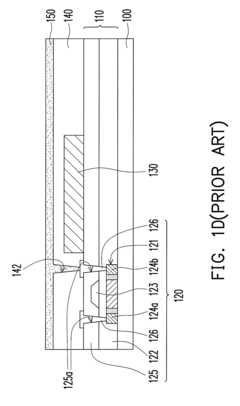

Active matrix organic light emitting diode display device and structure of such device

PatentInactiveUS20090033217A1

Innovation

- A method using a half-tone mask to pattern color photoresistant layers, which simplifies the process by eliminating the need for pixel defining layers and etching masks, allowing the color filter layers to function as both filters and masks for creating contact window openings, thereby reducing production costs and complexity.

Sustainability in E-Textiles

The integration of AMOLED technology into textiles presents both opportunities and challenges for sustainability in the realm of interactive fashion. As e-textiles continue to evolve, addressing environmental concerns becomes increasingly crucial. The production of AMOLED-integrated textiles involves complex manufacturing processes that require careful consideration of resource consumption and waste management.

One of the primary sustainability challenges lies in the sourcing of materials for AMOLED displays. The rare earth elements and precious metals used in these displays are often mined through environmentally destructive practices. However, advancements in recycling technologies and the development of alternative materials show promise in reducing the environmental impact of AMOLED production.

Energy efficiency is a key factor in the sustainability of AMOLED-integrated textiles. While AMOLED displays are known for their low power consumption compared to traditional LED displays, the integration of these displays into fabrics introduces new energy considerations. Researchers are exploring innovative power management systems and energy harvesting techniques to minimize the environmental footprint of interactive fashion pieces.

The durability and longevity of AMOLED-integrated textiles also play a crucial role in their sustainability profile. Designing these garments for extended use and easy repair can significantly reduce waste and the need for frequent replacements. This approach aligns with the growing trend of circular fashion, where products are created with their entire lifecycle in mind.

End-of-life considerations for AMOLED-integrated textiles present unique challenges. The complex nature of these hybrid products makes recycling and proper disposal more difficult than traditional textiles. Developing effective separation and recycling processes for the electronic components and fabric materials is essential for minimizing environmental impact.

Water usage and chemical pollution are additional concerns in the production of AMOLED-integrated textiles. The textile industry is already known for its high water consumption and use of harmful chemicals. Integrating electronic components into fabrics may exacerbate these issues if not carefully managed. Innovations in water-efficient manufacturing processes and eco-friendly dyeing techniques are being explored to address these challenges.

As the field of interactive fashion evolves, there is a growing emphasis on sustainable design practices. This includes the use of bio-based materials, modular design for easy upgrades, and the implementation of take-back programs for responsible disposal and recycling. These initiatives aim to create a more sustainable ecosystem for AMOLED-integrated textiles and interactive fashion as a whole.

One of the primary sustainability challenges lies in the sourcing of materials for AMOLED displays. The rare earth elements and precious metals used in these displays are often mined through environmentally destructive practices. However, advancements in recycling technologies and the development of alternative materials show promise in reducing the environmental impact of AMOLED production.

Energy efficiency is a key factor in the sustainability of AMOLED-integrated textiles. While AMOLED displays are known for their low power consumption compared to traditional LED displays, the integration of these displays into fabrics introduces new energy considerations. Researchers are exploring innovative power management systems and energy harvesting techniques to minimize the environmental footprint of interactive fashion pieces.

The durability and longevity of AMOLED-integrated textiles also play a crucial role in their sustainability profile. Designing these garments for extended use and easy repair can significantly reduce waste and the need for frequent replacements. This approach aligns with the growing trend of circular fashion, where products are created with their entire lifecycle in mind.

End-of-life considerations for AMOLED-integrated textiles present unique challenges. The complex nature of these hybrid products makes recycling and proper disposal more difficult than traditional textiles. Developing effective separation and recycling processes for the electronic components and fabric materials is essential for minimizing environmental impact.

Water usage and chemical pollution are additional concerns in the production of AMOLED-integrated textiles. The textile industry is already known for its high water consumption and use of harmful chemicals. Integrating electronic components into fabrics may exacerbate these issues if not carefully managed. Innovations in water-efficient manufacturing processes and eco-friendly dyeing techniques are being explored to address these challenges.

As the field of interactive fashion evolves, there is a growing emphasis on sustainable design practices. This includes the use of bio-based materials, modular design for easy upgrades, and the implementation of take-back programs for responsible disposal and recycling. These initiatives aim to create a more sustainable ecosystem for AMOLED-integrated textiles and interactive fashion as a whole.

Wearable Tech Safety Standards

The integration of AMOLED technology into textiles for interactive fashion brings forth new safety considerations that necessitate the development and implementation of comprehensive wearable tech safety standards. These standards must address the unique challenges posed by the combination of electronic components and fabric materials, ensuring user safety without compromising the functionality and aesthetics of interactive fashion items.

Electrical safety is a primary concern for AMOLED-integrated textiles. Standards must be established to regulate the voltage and current levels used in these garments, minimizing the risk of electric shock or burns. Additionally, guidelines for proper insulation and grounding techniques specific to textile-based electronics are essential to prevent electrical hazards in various environmental conditions, including exposure to moisture or extreme temperatures.

Electromagnetic radiation emitted by AMOLED displays and associated circuitry is another critical area that requires standardization. Safety limits for electromagnetic field (EMF) exposure must be defined, taking into account the proximity of these devices to the human body during prolonged wear. Testing protocols should be developed to measure and certify EMF emissions from AMOLED-integrated textiles, ensuring compliance with international health and safety regulations.

The potential for overheating in AMOLED-integrated textiles presents a unique safety challenge. Standards must address thermal management techniques and establish maximum temperature thresholds for different parts of the garment. This includes guidelines for heat dissipation methods and the use of temperature-sensitive materials that can provide early warning signs of overheating.

Chemical safety is another crucial aspect that wearable tech safety standards must cover. The interaction between electronic components and textile materials may lead to the release of harmful substances over time. Standards should define acceptable levels of chemical emissions and establish testing procedures to evaluate the long-term safety of these integrated products. This includes guidelines for the use of flame retardants and other protective chemicals that do not compromise the wearer's health.

Durability and reliability standards specific to AMOLED-integrated textiles are essential to ensure the longevity and consistent performance of these interactive fashion items. These standards should address the resilience of electronic components to washing, wear and tear, and environmental factors such as UV exposure and humidity. Testing protocols for assessing the lifespan of AMOLED displays in textile applications and the integrity of electrical connections under various stress conditions must be established.

Finally, wearable tech safety standards for AMOLED-integrated textiles should include guidelines for proper disposal and recycling. As these products combine electronic waste with textile waste, specific procedures for separating and processing these components at the end of their lifecycle are necessary to minimize environmental impact and potential health hazards associated with improper disposal.

Electrical safety is a primary concern for AMOLED-integrated textiles. Standards must be established to regulate the voltage and current levels used in these garments, minimizing the risk of electric shock or burns. Additionally, guidelines for proper insulation and grounding techniques specific to textile-based electronics are essential to prevent electrical hazards in various environmental conditions, including exposure to moisture or extreme temperatures.

Electromagnetic radiation emitted by AMOLED displays and associated circuitry is another critical area that requires standardization. Safety limits for electromagnetic field (EMF) exposure must be defined, taking into account the proximity of these devices to the human body during prolonged wear. Testing protocols should be developed to measure and certify EMF emissions from AMOLED-integrated textiles, ensuring compliance with international health and safety regulations.

The potential for overheating in AMOLED-integrated textiles presents a unique safety challenge. Standards must address thermal management techniques and establish maximum temperature thresholds for different parts of the garment. This includes guidelines for heat dissipation methods and the use of temperature-sensitive materials that can provide early warning signs of overheating.

Chemical safety is another crucial aspect that wearable tech safety standards must cover. The interaction between electronic components and textile materials may lead to the release of harmful substances over time. Standards should define acceptable levels of chemical emissions and establish testing procedures to evaluate the long-term safety of these integrated products. This includes guidelines for the use of flame retardants and other protective chemicals that do not compromise the wearer's health.

Durability and reliability standards specific to AMOLED-integrated textiles are essential to ensure the longevity and consistent performance of these interactive fashion items. These standards should address the resilience of electronic components to washing, wear and tear, and environmental factors such as UV exposure and humidity. Testing protocols for assessing the lifespan of AMOLED displays in textile applications and the integrity of electrical connections under various stress conditions must be established.

Finally, wearable tech safety standards for AMOLED-integrated textiles should include guidelines for proper disposal and recycling. As these products combine electronic waste with textile waste, specific procedures for separating and processing these components at the end of their lifecycle are necessary to minimize environmental impact and potential health hazards associated with improper disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!