Development of tactile AMOLED surfaces for virtual interactions.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tactile AMOLED Evolution

The evolution of tactile AMOLED surfaces for virtual interactions has been a journey of continuous innovation and technological advancement. This progression can be traced through several key stages, each marked by significant breakthroughs and improvements in tactile feedback technology.

In the early 2010s, the focus was primarily on developing basic haptic feedback for touchscreens. These initial efforts relied on simple vibration motors to provide rudimentary tactile sensations. While limited in their capabilities, these early systems laid the groundwork for more sophisticated tactile interfaces.

The mid-2010s saw the emergence of more advanced haptic technologies, such as electrostatic vibration and ultrasonic surface waves. These innovations allowed for more nuanced and localized tactile feedback, enhancing the user experience in virtual interactions. Companies like Apple and Samsung began incorporating these technologies into their flagship devices, demonstrating the growing importance of tactile feedback in consumer electronics.

By the late 2010s, researchers and developers turned their attention to integrating tactile feedback directly into AMOLED displays. This marked a significant shift from external haptic systems to embedded solutions. The goal was to create surfaces that could dynamically change their texture and provide more realistic tactile sensations.

The early 2020s witnessed the development of microLED-based tactile displays. These displays offered higher resolution tactile feedback and improved energy efficiency compared to previous technologies. Concurrently, advancements in flexible AMOLED technology opened up new possibilities for creating curved and foldable tactile surfaces.

Recent years have seen a focus on combining multiple tactile technologies to create more immersive experiences. This includes the integration of temperature feedback, variable friction surfaces, and even shape-changing materials. These multi-modal tactile systems aim to provide a more comprehensive and realistic sense of touch in virtual environments.

Looking ahead, the next frontier in tactile AMOLED evolution appears to be the development of high-resolution, pixel-level tactile feedback. This technology promises to offer unprecedented precision in tactile sensations, potentially revolutionizing fields such as virtual reality, telemedicine, and remote robotics.

Throughout this evolution, we've seen a clear trend towards more sophisticated, integrated, and realistic tactile feedback systems. The progression from simple vibration motors to complex, multi-modal tactile surfaces reflects the growing importance of haptic technology in enhancing virtual interactions and bridging the gap between digital and physical experiences.

In the early 2010s, the focus was primarily on developing basic haptic feedback for touchscreens. These initial efforts relied on simple vibration motors to provide rudimentary tactile sensations. While limited in their capabilities, these early systems laid the groundwork for more sophisticated tactile interfaces.

The mid-2010s saw the emergence of more advanced haptic technologies, such as electrostatic vibration and ultrasonic surface waves. These innovations allowed for more nuanced and localized tactile feedback, enhancing the user experience in virtual interactions. Companies like Apple and Samsung began incorporating these technologies into their flagship devices, demonstrating the growing importance of tactile feedback in consumer electronics.

By the late 2010s, researchers and developers turned their attention to integrating tactile feedback directly into AMOLED displays. This marked a significant shift from external haptic systems to embedded solutions. The goal was to create surfaces that could dynamically change their texture and provide more realistic tactile sensations.

The early 2020s witnessed the development of microLED-based tactile displays. These displays offered higher resolution tactile feedback and improved energy efficiency compared to previous technologies. Concurrently, advancements in flexible AMOLED technology opened up new possibilities for creating curved and foldable tactile surfaces.

Recent years have seen a focus on combining multiple tactile technologies to create more immersive experiences. This includes the integration of temperature feedback, variable friction surfaces, and even shape-changing materials. These multi-modal tactile systems aim to provide a more comprehensive and realistic sense of touch in virtual environments.

Looking ahead, the next frontier in tactile AMOLED evolution appears to be the development of high-resolution, pixel-level tactile feedback. This technology promises to offer unprecedented precision in tactile sensations, potentially revolutionizing fields such as virtual reality, telemedicine, and remote robotics.

Throughout this evolution, we've seen a clear trend towards more sophisticated, integrated, and realistic tactile feedback systems. The progression from simple vibration motors to complex, multi-modal tactile surfaces reflects the growing importance of haptic technology in enhancing virtual interactions and bridging the gap between digital and physical experiences.

Virtual Interaction Demand

The demand for virtual interaction technologies has been growing exponentially in recent years, driven by advancements in augmented reality (AR), virtual reality (VR), and mixed reality (MR) applications. This surge in demand is particularly evident in sectors such as gaming, education, healthcare, and industrial training. The global AR and VR market size was valued at $26.7 billion in 2021 and is projected to reach $252.2 billion by 2028, with a compound annual growth rate (CAGR) of 37.9% during this period.

The development of tactile AMOLED surfaces for virtual interactions addresses a critical need in enhancing the immersiveness and realism of virtual experiences. Users increasingly seek more natural and intuitive ways to interact with digital content, moving beyond traditional input methods like keyboards and touchscreens. Tactile feedback, when combined with high-quality visual displays, can significantly improve user engagement and the overall effectiveness of virtual interactions.

In the gaming industry, which is a major driver of this technology, there is a strong demand for haptic feedback systems that can simulate textures, resistance, and other physical sensations. This demand extends to professional training simulations, where tactile feedback can enhance the realism of medical procedures, industrial operations, and military exercises. The healthcare sector also shows significant interest in tactile interfaces for rehabilitation therapies and remote patient care.

The education sector is another area with growing demand for tactile virtual interaction technologies. As remote and hybrid learning models become more prevalent, there is an increasing need for tools that can provide hands-on learning experiences in virtual environments. This is particularly crucial for subjects that traditionally rely on physical interaction, such as chemistry, biology, and engineering.

Consumer electronics manufacturers are also recognizing the potential of tactile AMOLED surfaces. There is a rising demand for smartphones, tablets, and wearable devices that can offer more immersive and interactive experiences. This trend is likely to accelerate with the development of foldable and flexible display technologies, which open up new possibilities for integrating tactile feedback into various form factors.

The automotive industry is another sector showing significant interest in this technology. As vehicles become more autonomous and infotainment systems more sophisticated, there is a growing need for intuitive, tactile interfaces that can enhance driver and passenger experiences while minimizing distractions. This includes applications in dashboard controls, navigation systems, and entertainment interfaces.

As the Internet of Things (IoT) continues to expand, there is an emerging demand for tactile interfaces in smart home devices and industrial control systems. These interfaces could provide more intuitive ways to interact with connected devices, potentially improving accessibility for users with visual impairments or in situations where visual attention is limited.

The development of tactile AMOLED surfaces for virtual interactions addresses a critical need in enhancing the immersiveness and realism of virtual experiences. Users increasingly seek more natural and intuitive ways to interact with digital content, moving beyond traditional input methods like keyboards and touchscreens. Tactile feedback, when combined with high-quality visual displays, can significantly improve user engagement and the overall effectiveness of virtual interactions.

In the gaming industry, which is a major driver of this technology, there is a strong demand for haptic feedback systems that can simulate textures, resistance, and other physical sensations. This demand extends to professional training simulations, where tactile feedback can enhance the realism of medical procedures, industrial operations, and military exercises. The healthcare sector also shows significant interest in tactile interfaces for rehabilitation therapies and remote patient care.

The education sector is another area with growing demand for tactile virtual interaction technologies. As remote and hybrid learning models become more prevalent, there is an increasing need for tools that can provide hands-on learning experiences in virtual environments. This is particularly crucial for subjects that traditionally rely on physical interaction, such as chemistry, biology, and engineering.

Consumer electronics manufacturers are also recognizing the potential of tactile AMOLED surfaces. There is a rising demand for smartphones, tablets, and wearable devices that can offer more immersive and interactive experiences. This trend is likely to accelerate with the development of foldable and flexible display technologies, which open up new possibilities for integrating tactile feedback into various form factors.

The automotive industry is another sector showing significant interest in this technology. As vehicles become more autonomous and infotainment systems more sophisticated, there is a growing need for intuitive, tactile interfaces that can enhance driver and passenger experiences while minimizing distractions. This includes applications in dashboard controls, navigation systems, and entertainment interfaces.

As the Internet of Things (IoT) continues to expand, there is an emerging demand for tactile interfaces in smart home devices and industrial control systems. These interfaces could provide more intuitive ways to interact with connected devices, potentially improving accessibility for users with visual impairments or in situations where visual attention is limited.

Tactile Display Challenges

The development of tactile AMOLED surfaces for virtual interactions faces several significant challenges that researchers and engineers must overcome. One of the primary obstacles is achieving high-resolution tactile feedback on a pixel-level scale. Current technologies struggle to provide precise haptic sensations that match the visual resolution of AMOLED displays, limiting the realism of virtual interactions.

Another major challenge lies in integrating tactile actuators without compromising the display's visual quality or flexibility. AMOLED screens are known for their thinness and ability to be curved or folded, but adding tactile components can increase bulk and reduce flexibility. Balancing these competing requirements demands innovative materials and design solutions.

Power consumption presents a further hurdle in tactile AMOLED development. Haptic feedback mechanisms often require substantial energy, which can drain battery life in mobile devices. Engineers must develop energy-efficient actuation methods that can operate within the power constraints of portable electronics while still delivering convincing tactile sensations.

Durability and longevity of tactile surfaces pose additional challenges. Repeated physical interactions can lead to wear and tear, potentially degrading both the tactile and visual performance over time. Creating robust tactile elements that can withstand millions of touch cycles without failure is crucial for commercial viability.

Latency is another critical issue in tactile display systems. To create a seamless and immersive experience, the tactile response must be perfectly synchronized with visual and auditory cues. Minimizing the delay between user input and haptic output requires advanced signal processing and fast-acting actuators.

Scalability and manufacturing complexity also present significant obstacles. Producing tactile AMOLED displays at scale requires developing new fabrication processes that can integrate haptic components efficiently and cost-effectively. This may involve adapting existing AMOLED production lines or creating entirely new manufacturing techniques.

Lastly, achieving a wide range of tactile sensations remains a formidable challenge. Replicating the diverse textures, pressures, and vibrations encountered in the real world demands sophisticated haptic rendering algorithms and versatile actuation technologies. Creating a universal tactile display capable of simulating any surface or interaction is still a distant goal that researchers are actively pursuing.

Another major challenge lies in integrating tactile actuators without compromising the display's visual quality or flexibility. AMOLED screens are known for their thinness and ability to be curved or folded, but adding tactile components can increase bulk and reduce flexibility. Balancing these competing requirements demands innovative materials and design solutions.

Power consumption presents a further hurdle in tactile AMOLED development. Haptic feedback mechanisms often require substantial energy, which can drain battery life in mobile devices. Engineers must develop energy-efficient actuation methods that can operate within the power constraints of portable electronics while still delivering convincing tactile sensations.

Durability and longevity of tactile surfaces pose additional challenges. Repeated physical interactions can lead to wear and tear, potentially degrading both the tactile and visual performance over time. Creating robust tactile elements that can withstand millions of touch cycles without failure is crucial for commercial viability.

Latency is another critical issue in tactile display systems. To create a seamless and immersive experience, the tactile response must be perfectly synchronized with visual and auditory cues. Minimizing the delay between user input and haptic output requires advanced signal processing and fast-acting actuators.

Scalability and manufacturing complexity also present significant obstacles. Producing tactile AMOLED displays at scale requires developing new fabrication processes that can integrate haptic components efficiently and cost-effectively. This may involve adapting existing AMOLED production lines or creating entirely new manufacturing techniques.

Lastly, achieving a wide range of tactile sensations remains a formidable challenge. Replicating the diverse textures, pressures, and vibrations encountered in the real world demands sophisticated haptic rendering algorithms and versatile actuation technologies. Creating a universal tactile display capable of simulating any surface or interaction is still a distant goal that researchers are actively pursuing.

Current Tactile Solutions

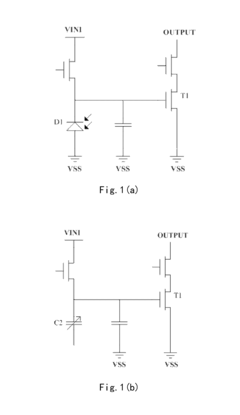

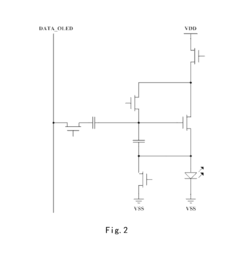

01 Haptic feedback mechanisms for AMOLED displays

Integration of haptic feedback systems with AMOLED displays to provide tactile sensations. These mechanisms can include actuators, vibration motors, or piezoelectric elements that generate localized vibrations or movements in response to touch inputs, enhancing user interaction with the display surface.- Tactile feedback mechanisms for AMOLED displays: Various mechanisms are employed to provide tactile feedback on AMOLED surfaces. These include the use of piezoelectric actuators, electrostatic forces, or mechanical vibrations to create a sense of touch or texture on the otherwise smooth display surface. This technology enhances user interaction by simulating physical buttons or textures on touchscreens.

- Integration of haptic feedback with AMOLED displays: Haptic feedback systems are integrated with AMOLED displays to provide a more immersive user experience. These systems can generate localized vibrations or forces in response to touch inputs, enhancing the tactile sensation and improving user interaction with the display. The integration often involves placing actuators beneath or around the display panel.

- Pressure-sensitive AMOLED touchscreens: Pressure-sensitive technology is incorporated into AMOLED touchscreens to detect varying levels of touch pressure. This allows for more nuanced input and can be used to trigger different actions or provide graduated tactile feedback based on the applied pressure. The technology often uses force sensors integrated with the display panel.

- Texture simulation on AMOLED surfaces: Advanced techniques are developed to simulate various textures on smooth AMOLED surfaces. These methods use a combination of visual cues, micro-vibrations, and electrostatic forces to create the illusion of different surface textures. This technology enhances the tactile experience and can be used for virtual buttons, sliders, or other interface elements.

- Flexible AMOLED displays with tactile feedback: Flexible AMOLED displays are combined with tactile feedback mechanisms to create bendable or foldable devices with enhanced user interaction. These displays can provide haptic feedback even when deformed, using specially designed actuators or by leveraging the inherent properties of flexible materials. This technology is particularly relevant for wearable devices and foldable smartphones.

02 Tactile surface textures on AMOLED screens

Development of techniques to create variable surface textures on AMOLED displays. This can involve using electroactive polymers, microfluidic systems, or shape-memory materials to dynamically alter the screen's surface, providing tactile feedback and simulating different textures.Expand Specific Solutions03 Force-sensitive AMOLED displays

Implementation of force-sensing technology in AMOLED displays to detect varying levels of touch pressure. This allows for more nuanced interactions and can be combined with haptic feedback to provide a more immersive tactile experience.Expand Specific Solutions04 Electrostatic feedback for AMOLED touchscreens

Utilization of electrostatic forces to create tactile sensations on AMOLED touchscreens. This technology can generate friction or texture effects by modulating the electrostatic field between the user's finger and the screen surface, providing a unique form of tactile feedback.Expand Specific Solutions05 Integration of tactile elements with AMOLED display structure

Innovative approaches to incorporate tactile elements directly into the layered structure of AMOLED displays. This can include embedding micro-actuators, using flexible OLED substrates, or integrating tactile pixels alongside display pixels to create a seamless tactile-visual interface.Expand Specific Solutions

Key Tactile AMOLED Players

The development of tactile AMOLED surfaces for virtual interactions is in its early stages, with the market showing significant growth potential. This emerging technology is at the intersection of display innovation and haptic feedback, attracting interest from major players in the electronics and display industries. Companies like Samsung Electronics, BOE Technology Group, and Tianma Microelectronics are likely to be at the forefront, leveraging their expertise in AMOLED display manufacturing. The market is expected to expand rapidly as virtual and augmented reality applications become more prevalent. However, the technology's maturity is still evolving, with ongoing research and development efforts focused on enhancing tactile sensation and integration with existing display technologies.

BOE Technology Group Co., Ltd.

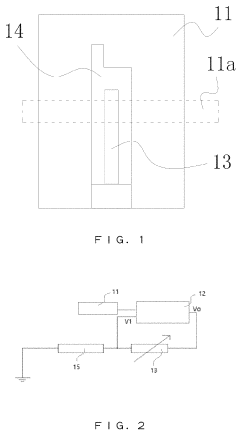

Technical Solution: BOE has developed a tactile AMOLED surface technology that integrates pressure-sensitive sensors directly into the display panel. This innovation allows for precise touch detection and force sensing across the entire screen surface. The company's approach utilizes a matrix of micro-capacitive sensors embedded within the OLED layers, enabling multi-point pressure detection with high resolution[1]. BOE's tactile AMOLED surfaces can distinguish between different levels of touch pressure, allowing for more nuanced and intuitive user interactions. The technology also incorporates haptic feedback mechanisms, providing users with tactile responses that simulate the feel of physical buttons or textures[2]. This advanced tactile display system is designed to enhance virtual interactions in various applications, including smartphones, automotive interfaces, and immersive VR/AR experiences.

Strengths: Industry-leading AMOLED manufacturing capabilities, advanced sensor integration, and wide application potential. Weaknesses: High production costs and potential durability concerns for long-term use.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered the development of tactile AMOLED surfaces with their proprietary "S-Force Touch" technology. This system integrates force-sensitive sensors beneath the AMOLED display, allowing for pressure-sensitive input across the entire screen. Samsung's approach uses a combination of capacitive and resistive sensing methods to achieve high accuracy and low latency in touch detection[3]. The company has also developed advanced haptic feedback systems that work in tandem with the tactile surface, providing localized vibrations that simulate various textures and button presses[4]. Samsung's tactile AMOLED technology incorporates machine learning algorithms to improve touch recognition and adapt to user behavior over time. This adaptive system enhances the precision of virtual interactions, making it particularly suitable for applications in mobile devices, gaming, and professional design tools.

Strengths: Extensive R&D resources, established market presence, and integration with a wide ecosystem of devices. Weaknesses: Proprietary technology may limit adoption by other manufacturers.

Tactile AMOLED Innovations

Active matrix organic light emitting diode pixel unit circuit and display panel

PatentActiveUS9530354B2

Innovation

- An active matrix organic light emitting diode pixel unit circuit is designed with specific modules such as a light emitting module, driving module, threshold compensation module, light emitting control module, touch sensing module, and sensing signal output module, utilizing common data lines and control signals to integrate the TSP in Cell circuit, including additional TFTs and capacitors, while optimizing circuit components and signal operations.

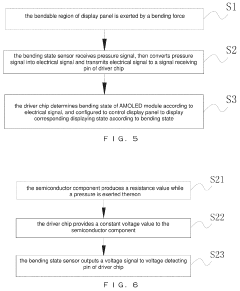

Active-matrix organic light emitting diode module operable in bendable states and displaying method thereof

PatentActiveUS20190355299A1

Innovation

- An AMOLED module with a bending state sensor and driver chip, where the sensor receives pressure signals and converts them into electrical signals to directly control the display panel's state, reducing the reliance on the main control chip for determining and processing bending states.

Human-Computer Interaction

The development of tactile AMOLED surfaces for virtual interactions represents a significant advancement in human-computer interaction (HCI). This technology aims to bridge the gap between the digital and physical worlds by providing users with a more immersive and intuitive interface experience. By integrating tactile feedback into AMOLED displays, users can perceive texture, pressure, and other haptic sensations when interacting with virtual objects on the screen.

The evolution of this technology builds upon existing touchscreen capabilities, adding a new dimension of sensory feedback. Traditional touchscreens rely primarily on visual and auditory cues, but tactile AMOLED surfaces introduce a third sensory channel, enhancing the overall user experience. This advancement has the potential to revolutionize various applications, from mobile devices and gaming to virtual reality and remote operation systems.

One of the key challenges in developing tactile AMOLED surfaces lies in creating a seamless integration of haptic actuators with the display technology. Engineers must overcome issues such as maintaining display quality while incorporating tactile elements, minimizing power consumption, and ensuring durability under repeated use. Additionally, the development of sophisticated algorithms to translate virtual textures and forces into accurate haptic sensations is crucial for creating realistic and responsive interactions.

The potential applications for tactile AMOLED surfaces in HCI are vast. In the realm of mobile devices, users could experience enhanced typing feedback, more intuitive navigation, and improved accessibility features for visually impaired individuals. For gaming and virtual reality, tactile surfaces could provide a more immersive experience by allowing users to feel virtual objects and environments. In professional settings, such as medical training or industrial design, tactile feedback could enable more precise and realistic simulations.

As research in this field progresses, we can expect to see advancements in materials science, actuator technology, and haptic rendering algorithms. The integration of machine learning and AI could lead to more adaptive and personalized tactile experiences. Furthermore, the development of standardized protocols for haptic information transmission will be essential for widespread adoption and interoperability across different devices and platforms.

The evolution of this technology builds upon existing touchscreen capabilities, adding a new dimension of sensory feedback. Traditional touchscreens rely primarily on visual and auditory cues, but tactile AMOLED surfaces introduce a third sensory channel, enhancing the overall user experience. This advancement has the potential to revolutionize various applications, from mobile devices and gaming to virtual reality and remote operation systems.

One of the key challenges in developing tactile AMOLED surfaces lies in creating a seamless integration of haptic actuators with the display technology. Engineers must overcome issues such as maintaining display quality while incorporating tactile elements, minimizing power consumption, and ensuring durability under repeated use. Additionally, the development of sophisticated algorithms to translate virtual textures and forces into accurate haptic sensations is crucial for creating realistic and responsive interactions.

The potential applications for tactile AMOLED surfaces in HCI are vast. In the realm of mobile devices, users could experience enhanced typing feedback, more intuitive navigation, and improved accessibility features for visually impaired individuals. For gaming and virtual reality, tactile surfaces could provide a more immersive experience by allowing users to feel virtual objects and environments. In professional settings, such as medical training or industrial design, tactile feedback could enable more precise and realistic simulations.

As research in this field progresses, we can expect to see advancements in materials science, actuator technology, and haptic rendering algorithms. The integration of machine learning and AI could lead to more adaptive and personalized tactile experiences. Furthermore, the development of standardized protocols for haptic information transmission will be essential for widespread adoption and interoperability across different devices and platforms.

Tactile Feedback Standards

The development of tactile AMOLED surfaces for virtual interactions necessitates the establishment of comprehensive tactile feedback standards to ensure consistency, quality, and interoperability across devices and applications. These standards play a crucial role in defining the parameters and specifications for tactile sensations, enabling a more immersive and realistic user experience.

One of the primary aspects of tactile feedback standards is the definition of haptic signal characteristics. This includes specifying the frequency range, amplitude, and duration of tactile sensations. For AMOLED surfaces, these standards typically encompass a frequency range of 50-500 Hz, with varying amplitudes to simulate different textures and sensations. The duration of tactile feedback is also standardized, ranging from brief pulses of 10-50 milliseconds for button clicks to longer durations of up to 500 milliseconds for more complex interactions.

Tactile feedback standards also address the spatial resolution of haptic sensations on AMOLED surfaces. This involves defining the minimum distance between two distinct tactile points that can be perceived by users. Current standards typically aim for a spatial resolution of 1-5 mm, depending on the specific application and target user group. Higher resolutions allow for more detailed and nuanced tactile experiences, particularly important for applications such as virtual braille or fine texture simulation.

Another critical aspect of these standards is the definition of tactile patterns and effects. This includes standardized representations of common interactions such as button presses, swipes, and scrolling gestures. These patterns are typically described using a combination of amplitude, frequency, and temporal characteristics, allowing developers to create consistent tactile experiences across different devices and platforms.

Latency is a crucial factor in tactile feedback, and standards define acceptable ranges for response times between user input and tactile output. For virtual interactions on AMOLED surfaces, the standard typically specifies a maximum latency of 20-30 milliseconds to maintain a sense of immediacy and realism. This low latency is particularly important for applications requiring precise timing, such as virtual musical instruments or gaming interfaces.

Tactile feedback standards also address the issue of power consumption and efficiency. Given the energy constraints of mobile devices, these standards define acceptable ranges for power usage during tactile feedback generation. This often involves specifying maximum current draw and duty cycles for haptic actuators, ensuring that tactile feedback enhances the user experience without significantly impacting battery life.

Interoperability is a key consideration in tactile feedback standards, ensuring that haptic effects can be consistently reproduced across different devices and platforms. This involves standardizing the format and encoding of haptic data, allowing for seamless integration and portability of tactile content. Common file formats and APIs for haptic effects are defined, enabling developers to create once and deploy across multiple devices.

One of the primary aspects of tactile feedback standards is the definition of haptic signal characteristics. This includes specifying the frequency range, amplitude, and duration of tactile sensations. For AMOLED surfaces, these standards typically encompass a frequency range of 50-500 Hz, with varying amplitudes to simulate different textures and sensations. The duration of tactile feedback is also standardized, ranging from brief pulses of 10-50 milliseconds for button clicks to longer durations of up to 500 milliseconds for more complex interactions.

Tactile feedback standards also address the spatial resolution of haptic sensations on AMOLED surfaces. This involves defining the minimum distance between two distinct tactile points that can be perceived by users. Current standards typically aim for a spatial resolution of 1-5 mm, depending on the specific application and target user group. Higher resolutions allow for more detailed and nuanced tactile experiences, particularly important for applications such as virtual braille or fine texture simulation.

Another critical aspect of these standards is the definition of tactile patterns and effects. This includes standardized representations of common interactions such as button presses, swipes, and scrolling gestures. These patterns are typically described using a combination of amplitude, frequency, and temporal characteristics, allowing developers to create consistent tactile experiences across different devices and platforms.

Latency is a crucial factor in tactile feedback, and standards define acceptable ranges for response times between user input and tactile output. For virtual interactions on AMOLED surfaces, the standard typically specifies a maximum latency of 20-30 milliseconds to maintain a sense of immediacy and realism. This low latency is particularly important for applications requiring precise timing, such as virtual musical instruments or gaming interfaces.

Tactile feedback standards also address the issue of power consumption and efficiency. Given the energy constraints of mobile devices, these standards define acceptable ranges for power usage during tactile feedback generation. This often involves specifying maximum current draw and duty cycles for haptic actuators, ensuring that tactile feedback enhances the user experience without significantly impacting battery life.

Interoperability is a key consideration in tactile feedback standards, ensuring that haptic effects can be consistently reproduced across different devices and platforms. This involves standardizing the format and encoding of haptic data, allowing for seamless integration and portability of tactile content. Common file formats and APIs for haptic effects are defined, enabling developers to create once and deploy across multiple devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!