Innovations to combat AMOLED degradation mechanisms.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Degradation Background and Objectives

Active-Matrix Organic Light-Emitting Diode (AMOLED) technology has revolutionized the display industry since its inception in the late 1980s. This advanced display technology offers superior image quality, energy efficiency, and flexibility compared to traditional LCD displays. However, AMOLED displays face a significant challenge in the form of degradation mechanisms that affect their long-term performance and lifespan.

AMOLED degradation is a complex phenomenon involving multiple factors, including chemical reactions, physical stress, and environmental influences. The primary degradation mechanisms include organic material decomposition, electrode oxidation, and charge carrier trapping. These processes lead to decreased luminance, color shift, and non-uniform aging across the display, ultimately impacting the user experience and device longevity.

The evolution of AMOLED technology has been marked by continuous efforts to mitigate these degradation issues. Early research focused on understanding the fundamental causes of degradation at the molecular level. This led to the development of more stable organic materials and improved device architectures. Subsequently, attention shifted towards optimizing device operation and implementing compensation techniques to counteract the effects of aging.

Current technological objectives in combating AMOLED degradation mechanisms are multifaceted. Researchers and industry players are striving to develop novel materials with enhanced stability and resistance to degradation factors. This includes the exploration of new emissive materials, charge transport layers, and encapsulation technologies. Additionally, there is a strong focus on advancing driving schemes and compensation algorithms to extend display lifetime and maintain image quality over time.

Another key objective is to improve the understanding of degradation mechanisms under various operating conditions and environmental factors. This involves developing more accurate models for predicting display aging and optimizing device performance based on usage patterns. Furthermore, there is a growing emphasis on developing in-situ monitoring techniques to detect and quantify degradation in real-time, enabling more effective compensation strategies.

The pursuit of innovations to combat AMOLED degradation mechanisms is driven by the increasing demand for high-performance, long-lasting displays in various applications. From smartphones and televisions to automotive displays and wearable devices, the need for durable AMOLED technology continues to grow. As such, addressing degradation issues is crucial not only for improving product quality but also for expanding the potential applications of AMOLED technology in emerging fields such as flexible and transparent electronics.

AMOLED degradation is a complex phenomenon involving multiple factors, including chemical reactions, physical stress, and environmental influences. The primary degradation mechanisms include organic material decomposition, electrode oxidation, and charge carrier trapping. These processes lead to decreased luminance, color shift, and non-uniform aging across the display, ultimately impacting the user experience and device longevity.

The evolution of AMOLED technology has been marked by continuous efforts to mitigate these degradation issues. Early research focused on understanding the fundamental causes of degradation at the molecular level. This led to the development of more stable organic materials and improved device architectures. Subsequently, attention shifted towards optimizing device operation and implementing compensation techniques to counteract the effects of aging.

Current technological objectives in combating AMOLED degradation mechanisms are multifaceted. Researchers and industry players are striving to develop novel materials with enhanced stability and resistance to degradation factors. This includes the exploration of new emissive materials, charge transport layers, and encapsulation technologies. Additionally, there is a strong focus on advancing driving schemes and compensation algorithms to extend display lifetime and maintain image quality over time.

Another key objective is to improve the understanding of degradation mechanisms under various operating conditions and environmental factors. This involves developing more accurate models for predicting display aging and optimizing device performance based on usage patterns. Furthermore, there is a growing emphasis on developing in-situ monitoring techniques to detect and quantify degradation in real-time, enabling more effective compensation strategies.

The pursuit of innovations to combat AMOLED degradation mechanisms is driven by the increasing demand for high-performance, long-lasting displays in various applications. From smartphones and televisions to automotive displays and wearable devices, the need for durable AMOLED technology continues to grow. As such, addressing degradation issues is crucial not only for improving product quality but also for expanding the potential applications of AMOLED technology in emerging fields such as flexible and transparent electronics.

Market Demand for Durable AMOLED Displays

The demand for durable AMOLED displays has been steadily increasing across various sectors, driven by the growing adoption of smartphones, smartwatches, televisions, and other electronic devices. As consumers become more reliant on these devices for both personal and professional use, the need for longer-lasting, high-quality displays has become paramount.

In the smartphone market, which represents the largest segment for AMOLED displays, durability is a key factor influencing consumer purchasing decisions. Users expect their devices to maintain vibrant colors and sharp images throughout the lifespan of their phones, typically 2-3 years. This expectation has put pressure on manufacturers to develop more resilient AMOLED technologies that can withstand prolonged use without significant degradation.

The automotive industry has also emerged as a significant driver of demand for durable AMOLED displays. As vehicles become more technologically advanced, incorporating larger and more sophisticated infotainment systems, the need for high-quality, long-lasting displays has increased. Automotive displays must endure harsh environmental conditions, including extreme temperatures and constant vibrations, making durability a critical factor.

The wearable technology market, particularly smartwatches, has shown a strong preference for AMOLED displays due to their energy efficiency and vibrant colors. However, the small form factor of these devices makes them more susceptible to wear and tear, creating a demand for displays that can maintain their quality over extended periods of use.

In the television sector, OLED TVs, which use AMOLED technology, have gained popularity for their superior picture quality. Consumers investing in premium OLED TVs expect these displays to maintain their performance for many years, driving the need for innovations that combat degradation and extend the lifespan of these expensive devices.

The commercial display market, including digital signage and public information systems, also requires durable AMOLED displays. These applications often involve continuous operation in various environmental conditions, necessitating displays that can maintain their brightness and color accuracy over extended periods.

As the Internet of Things (IoT) continues to expand, the demand for durable AMOLED displays in smart home devices, industrial control panels, and other connected gadgets is expected to grow. These applications often require displays that can operate reliably for years without maintenance or replacement.

The market's emphasis on sustainability and environmental responsibility has further intensified the focus on display durability. Consumers and businesses alike are seeking products with longer lifespans to reduce electronic waste and the frequency of device replacements, aligning with global efforts to minimize environmental impact.

In the smartphone market, which represents the largest segment for AMOLED displays, durability is a key factor influencing consumer purchasing decisions. Users expect their devices to maintain vibrant colors and sharp images throughout the lifespan of their phones, typically 2-3 years. This expectation has put pressure on manufacturers to develop more resilient AMOLED technologies that can withstand prolonged use without significant degradation.

The automotive industry has also emerged as a significant driver of demand for durable AMOLED displays. As vehicles become more technologically advanced, incorporating larger and more sophisticated infotainment systems, the need for high-quality, long-lasting displays has increased. Automotive displays must endure harsh environmental conditions, including extreme temperatures and constant vibrations, making durability a critical factor.

The wearable technology market, particularly smartwatches, has shown a strong preference for AMOLED displays due to their energy efficiency and vibrant colors. However, the small form factor of these devices makes them more susceptible to wear and tear, creating a demand for displays that can maintain their quality over extended periods of use.

In the television sector, OLED TVs, which use AMOLED technology, have gained popularity for their superior picture quality. Consumers investing in premium OLED TVs expect these displays to maintain their performance for many years, driving the need for innovations that combat degradation and extend the lifespan of these expensive devices.

The commercial display market, including digital signage and public information systems, also requires durable AMOLED displays. These applications often involve continuous operation in various environmental conditions, necessitating displays that can maintain their brightness and color accuracy over extended periods.

As the Internet of Things (IoT) continues to expand, the demand for durable AMOLED displays in smart home devices, industrial control panels, and other connected gadgets is expected to grow. These applications often require displays that can operate reliably for years without maintenance or replacement.

The market's emphasis on sustainability and environmental responsibility has further intensified the focus on display durability. Consumers and businesses alike are seeking products with longer lifespans to reduce electronic waste and the frequency of device replacements, aligning with global efforts to minimize environmental impact.

Current Challenges in AMOLED Longevity

AMOLED (Active-Matrix Organic Light-Emitting Diode) technology has revolutionized display systems, offering superior image quality, energy efficiency, and design flexibility. However, the longevity of AMOLED displays remains a significant challenge, with several degradation mechanisms impacting their performance over time.

One of the primary challenges is the differential aging of organic materials used in AMOLED displays. Different color subpixels degrade at varying rates, leading to color shift and reduced brightness uniformity across the display. This issue is particularly pronounced in blue OLEDs, which typically have shorter lifespans compared to red and green counterparts.

Another critical challenge is the susceptibility of AMOLED displays to moisture and oxygen. These environmental factors can cause oxidation of the organic materials, leading to the formation of non-emissive dark spots and reducing overall display performance. While encapsulation technologies have improved, achieving perfect protection remains elusive, especially for flexible AMOLED displays.

Thermal degradation is also a significant concern for AMOLED longevity. High operating temperatures can accelerate the breakdown of organic materials, reducing their efficiency and lifespan. This issue is exacerbated in high-brightness applications or when displays are used in challenging environmental conditions.

Electrical stress is another factor contributing to AMOLED degradation. Continuous operation at high current densities can lead to charge trapping and the formation of defects within the organic layers. This results in decreased luminous efficiency and potential pixel failure over time.

The phenomenon of image retention or burn-in presents a unique challenge for AMOLED displays. Static elements displayed for extended periods can cause uneven aging of pixels, leading to persistent ghost images. This is particularly problematic in applications with fixed UI elements or logos.

Manufacturing consistency and scalability also pose challenges to AMOLED longevity. Ensuring uniform deposition of organic materials across large areas and maintaining consistent performance between different production batches remain ongoing issues in the industry.

As AMOLED technology advances, new form factors such as foldable and rollable displays introduce additional longevity concerns. The mechanical stress associated with repeated folding or rolling can accelerate degradation at stress points, potentially leading to localized failures or non-uniform aging across the display surface.

Addressing these challenges requires a multifaceted approach, combining innovations in materials science, device architecture, and manufacturing processes. The development of more stable organic compounds, improved encapsulation techniques, and advanced compensation algorithms are all critical areas of research in the quest to enhance AMOLED longevity.

One of the primary challenges is the differential aging of organic materials used in AMOLED displays. Different color subpixels degrade at varying rates, leading to color shift and reduced brightness uniformity across the display. This issue is particularly pronounced in blue OLEDs, which typically have shorter lifespans compared to red and green counterparts.

Another critical challenge is the susceptibility of AMOLED displays to moisture and oxygen. These environmental factors can cause oxidation of the organic materials, leading to the formation of non-emissive dark spots and reducing overall display performance. While encapsulation technologies have improved, achieving perfect protection remains elusive, especially for flexible AMOLED displays.

Thermal degradation is also a significant concern for AMOLED longevity. High operating temperatures can accelerate the breakdown of organic materials, reducing their efficiency and lifespan. This issue is exacerbated in high-brightness applications or when displays are used in challenging environmental conditions.

Electrical stress is another factor contributing to AMOLED degradation. Continuous operation at high current densities can lead to charge trapping and the formation of defects within the organic layers. This results in decreased luminous efficiency and potential pixel failure over time.

The phenomenon of image retention or burn-in presents a unique challenge for AMOLED displays. Static elements displayed for extended periods can cause uneven aging of pixels, leading to persistent ghost images. This is particularly problematic in applications with fixed UI elements or logos.

Manufacturing consistency and scalability also pose challenges to AMOLED longevity. Ensuring uniform deposition of organic materials across large areas and maintaining consistent performance between different production batches remain ongoing issues in the industry.

As AMOLED technology advances, new form factors such as foldable and rollable displays introduce additional longevity concerns. The mechanical stress associated with repeated folding or rolling can accelerate degradation at stress points, potentially leading to localized failures or non-uniform aging across the display surface.

Addressing these challenges requires a multifaceted approach, combining innovations in materials science, device architecture, and manufacturing processes. The development of more stable organic compounds, improved encapsulation techniques, and advanced compensation algorithms are all critical areas of research in the quest to enhance AMOLED longevity.

Existing Anti-Degradation Technologies

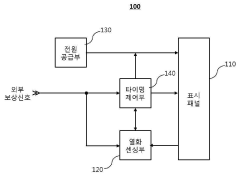

01 Compensation techniques for AMOLED degradation

Various compensation techniques are employed to address AMOLED display degradation. These methods involve adjusting pixel driving signals, implementing feedback mechanisms, and using sensor data to compensate for luminance and color shifts caused by aging. Such techniques help maintain image quality and extend the lifespan of AMOLED displays.- Compensation techniques for AMOLED degradation: Various compensation techniques are employed to address AMOLED display degradation. These methods involve adjusting pixel driving signals, implementing feedback mechanisms, and using advanced algorithms to compensate for luminance and color shifts caused by aging. Such techniques help maintain image quality and extend the lifespan of AMOLED displays.

- Structural improvements to reduce AMOLED degradation: Innovations in AMOLED display structure aim to mitigate degradation issues. These include novel pixel designs, improved organic layer compositions, and enhanced encapsulation techniques. Such structural improvements help to reduce the rate of degradation and increase the overall durability of AMOLED displays.

- Sensing and monitoring of AMOLED degradation: Advanced sensing and monitoring systems are developed to detect and measure AMOLED display degradation in real-time. These systems use various sensors and algorithms to track changes in pixel performance, allowing for timely adjustments and compensations to maintain display quality.

- Power management for AMOLED longevity: Power management techniques are implemented to extend the lifespan of AMOLED displays. These methods involve optimizing power distribution, implementing dynamic voltage scaling, and using intelligent brightness control algorithms to reduce stress on individual pixels and minimize degradation over time.

- Image processing to counteract AMOLED degradation effects: Advanced image processing algorithms are developed to counteract the visual effects of AMOLED display degradation. These techniques involve real-time adjustments to color, contrast, and brightness levels, as well as implementing sophisticated image enhancement algorithms to maintain perceived image quality despite underlying pixel degradation.

02 Pixel structure improvements for AMOLED longevity

Advancements in pixel structure design aim to enhance AMOLED display longevity. These improvements include optimized layouts, novel materials, and innovative fabrication techniques that reduce stress on organic light-emitting materials. Such enhancements contribute to slower degradation rates and more uniform aging across the display.Expand Specific Solutions03 Power management strategies to reduce AMOLED wear

Power management strategies are implemented to minimize AMOLED display wear. These include adaptive brightness control, selective pixel dimming, and intelligent power distribution techniques. By optimizing power consumption, these methods help reduce thermal stress and extend the overall lifespan of AMOLED displays.Expand Specific Solutions04 Sensing and monitoring systems for AMOLED degradation

Advanced sensing and monitoring systems are developed to track AMOLED display degradation in real-time. These systems utilize various sensors, including temperature, current, and optical sensors, to detect changes in display performance. The collected data is used to implement adaptive compensation and maintenance strategies, ensuring consistent display quality over time.Expand Specific Solutions05 Material innovations to combat AMOLED degradation

Research focuses on developing new materials to combat AMOLED display degradation. These innovations include more stable organic light-emitting compounds, improved encapsulation materials, and novel electrode designs. By enhancing the inherent stability of display components, these material advancements aim to significantly extend the lifespan of AMOLED displays.Expand Specific Solutions

Key Players in AMOLED Display Industry

The AMOLED degradation mitigation market is in a growth phase, with increasing demand for longer-lasting displays in smartphones, wearables, and other devices. The market size is expanding rapidly, driven by the widespread adoption of AMOLED technology. Technologically, solutions are evolving from basic compensation algorithms to more advanced pixel circuits and materials. Key players like Samsung Display, LG Display, and BOE are investing heavily in R&D to address this challenge. Emerging companies such as IGNIS Innovation are also making significant contributions with innovative approaches. While progress has been made, the technology is not yet fully mature, with ongoing research focused on novel materials, circuit designs, and AI-driven compensation techniques to further extend AMOLED lifespan and performance.

IGNIS Innovation, Inc.

Technical Solution: IGNIS Innovation has developed a suite of technologies specifically aimed at addressing AMOLED degradation. Their MaxLife™ technology uses advanced algorithms and in-pixel sensors to compensate for both short-term and long-term degradation effects[8]. They have also introduced a novel external compensation technique that allows for more accurate and frequent pixel adjustments without impacting display performance[9]. IGNIS's approach includes real-time monitoring of each pixel's voltage and current characteristics, enabling precise compensation for variations in threshold voltage and mobility[10].

Strengths: Specialized focus on AMOLED compensation, adaptable to various panel manufacturers. Weaknesses: Reliance on partnerships for implementation, potential licensing costs for display makers.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has made significant strides in combating AMOLED degradation through their advanced oxide backplane technology. They have developed high-mobility oxide TFTs that allow for lower driving voltages, reducing stress on OLED materials[11]. BOE has also implemented a proprietary compensation circuit design that adjusts for both voltage threshold shifts and mobility changes over time[12]. Additionally, they have introduced a new encapsulation technology that significantly reduces moisture and oxygen penetration, two major factors in OLED degradation[13].

Strengths: Large-scale production capabilities, integrated supply chain. Weaknesses: Relatively newer to OLED market compared to Korean competitors, still catching up in some advanced technologies.

Core Innovations in AMOLED Lifespan Extension

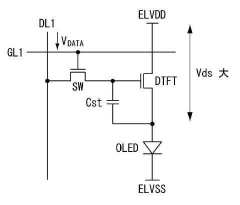

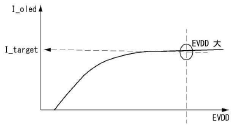

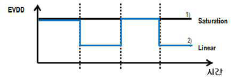

Organic light emitting diode display and operating method thereof

PatentActiveKR1020190034855A

Innovation

- An organic light emitting display device with a deterioration sensing unit and timing controller that continuously varies the high potential voltage based on the panel's deterioration state, optimizing power consumption and lifespan by adjusting the lower boundary value of the high potential voltage.

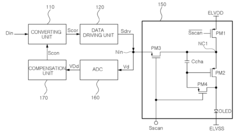

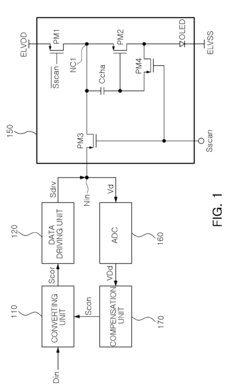

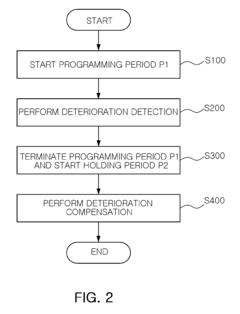

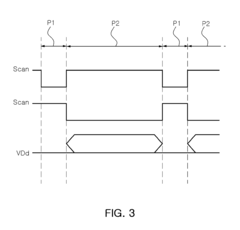

Active matrix organic light emitting diode display having deterioration detection function in programming period

PatentInactiveUS20120044271A1

Innovation

- An AMOLED display system that includes a data driving unit generating analog correction signals, a pixel unit with MOS transistors and a charging capacitor to charge and detect deterioration, and an analog-to-digital converter to rapidly detect deterioration during a programming period, allowing for rapid compensation through a compensation unit.

Environmental Impact of AMOLED Manufacturing

The manufacturing process of AMOLED displays has significant environmental implications that warrant careful consideration. The production of these advanced displays involves several stages, each with its own environmental impact. One of the primary concerns is the use of rare earth elements and precious metals in AMOLED manufacturing. These materials are often mined using environmentally destructive methods, leading to habitat destruction, soil erosion, and water pollution in mining regions.

The fabrication of AMOLED panels requires extensive use of chemicals, including solvents, acids, and various organic compounds. Many of these substances are toxic and pose potential risks to both human health and the environment if not properly managed. Proper disposal and treatment of chemical waste from AMOLED production facilities are crucial to prevent contamination of soil and water resources.

Energy consumption is another significant environmental factor in AMOLED manufacturing. The production process, particularly the deposition of organic layers and the creation of thin-film transistors, requires substantial amounts of electricity. This high energy demand often translates to increased carbon emissions, depending on the energy sources used by manufacturing facilities.

Water usage is also a concern in AMOLED production. Large volumes of ultra-pure water are needed for cleaning and processing, potentially straining local water resources in areas where manufacturing plants are located. The treatment and disposal of wastewater from these processes present additional environmental challenges.

The environmental impact extends to the end-of-life stage of AMOLED displays. As consumer electronics have relatively short lifespans, the disposal of devices containing AMOLED screens contributes to the growing problem of electronic waste. Recycling AMOLED displays is complex due to the mix of materials used, including organic compounds and various metals, making it challenging to recover and reuse components effectively.

To address these environmental concerns, the AMOLED industry is exploring more sustainable manufacturing practices. This includes developing more efficient production processes to reduce energy consumption, implementing closed-loop water systems to minimize water usage, and researching alternative materials that are more environmentally friendly. Additionally, efforts are being made to improve the recyclability of AMOLED displays and to establish more effective e-waste management systems.

As the demand for AMOLED displays continues to grow, balancing technological advancement with environmental responsibility becomes increasingly important. The industry must continue to innovate not only in display technology but also in sustainable manufacturing practices to mitigate the environmental impact of AMOLED production.

The fabrication of AMOLED panels requires extensive use of chemicals, including solvents, acids, and various organic compounds. Many of these substances are toxic and pose potential risks to both human health and the environment if not properly managed. Proper disposal and treatment of chemical waste from AMOLED production facilities are crucial to prevent contamination of soil and water resources.

Energy consumption is another significant environmental factor in AMOLED manufacturing. The production process, particularly the deposition of organic layers and the creation of thin-film transistors, requires substantial amounts of electricity. This high energy demand often translates to increased carbon emissions, depending on the energy sources used by manufacturing facilities.

Water usage is also a concern in AMOLED production. Large volumes of ultra-pure water are needed for cleaning and processing, potentially straining local water resources in areas where manufacturing plants are located. The treatment and disposal of wastewater from these processes present additional environmental challenges.

The environmental impact extends to the end-of-life stage of AMOLED displays. As consumer electronics have relatively short lifespans, the disposal of devices containing AMOLED screens contributes to the growing problem of electronic waste. Recycling AMOLED displays is complex due to the mix of materials used, including organic compounds and various metals, making it challenging to recover and reuse components effectively.

To address these environmental concerns, the AMOLED industry is exploring more sustainable manufacturing practices. This includes developing more efficient production processes to reduce energy consumption, implementing closed-loop water systems to minimize water usage, and researching alternative materials that are more environmentally friendly. Additionally, efforts are being made to improve the recyclability of AMOLED displays and to establish more effective e-waste management systems.

As the demand for AMOLED displays continues to grow, balancing technological advancement with environmental responsibility becomes increasingly important. The industry must continue to innovate not only in display technology but also in sustainable manufacturing practices to mitigate the environmental impact of AMOLED production.

Standardization of AMOLED Durability Testing

The standardization of AMOLED durability testing is crucial for ensuring consistent quality and performance across the industry. Currently, there is a lack of universally accepted standards for evaluating AMOLED display longevity, which has led to inconsistencies in reported lifespans and performance metrics among manufacturers.

To address this issue, several key areas require standardization. First, the definition of display lifetime needs to be clearly established. This includes determining the specific criteria for measuring brightness decay, color shift, and other degradation factors that signify the end of a display's useful life.

Secondly, standardized test conditions must be developed. These should encompass a range of environmental factors such as temperature, humidity, and ambient light exposure. Additionally, standardized usage patterns that simulate real-world scenarios need to be established, including varying brightness levels, on-screen content, and duty cycles.

The development of standardized measurement techniques is equally important. This involves specifying the equipment and methodologies for accurately assessing parameters like luminance, color gamut, and power consumption over time. Calibration procedures for testing equipment should also be standardized to ensure consistency across different testing facilities.

Furthermore, accelerated aging protocols need to be established and validated. These protocols aim to simulate long-term degradation in a shorter timeframe, allowing for more rapid assessment of display durability. However, care must be taken to ensure that accelerated tests accurately predict real-world performance.

Collaboration between industry leaders, research institutions, and standards organizations is essential for developing and implementing these standardized testing procedures. Organizations such as the International Electrotechnical Commission (IEC) and the Society for Information Display (SID) are well-positioned to lead these efforts.

By establishing standardized durability testing for AMOLED displays, manufacturers can provide more accurate and comparable lifespan estimates to consumers. This will not only improve transparency in the market but also drive innovation in display technologies as companies strive to meet and exceed these standardized benchmarks.

To address this issue, several key areas require standardization. First, the definition of display lifetime needs to be clearly established. This includes determining the specific criteria for measuring brightness decay, color shift, and other degradation factors that signify the end of a display's useful life.

Secondly, standardized test conditions must be developed. These should encompass a range of environmental factors such as temperature, humidity, and ambient light exposure. Additionally, standardized usage patterns that simulate real-world scenarios need to be established, including varying brightness levels, on-screen content, and duty cycles.

The development of standardized measurement techniques is equally important. This involves specifying the equipment and methodologies for accurately assessing parameters like luminance, color gamut, and power consumption over time. Calibration procedures for testing equipment should also be standardized to ensure consistency across different testing facilities.

Furthermore, accelerated aging protocols need to be established and validated. These protocols aim to simulate long-term degradation in a shorter timeframe, allowing for more rapid assessment of display durability. However, care must be taken to ensure that accelerated tests accurately predict real-world performance.

Collaboration between industry leaders, research institutions, and standards organizations is essential for developing and implementing these standardized testing procedures. Organizations such as the International Electrotechnical Commission (IEC) and the Society for Information Display (SID) are well-positioned to lead these efforts.

By establishing standardized durability testing for AMOLED displays, manufacturers can provide more accurate and comparable lifespan estimates to consumers. This will not only improve transparency in the market but also drive innovation in display technologies as companies strive to meet and exceed these standardized benchmarks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!