Breakthroughs in self-emissive AMOLED sensor technology.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Sensor Evolution

The evolution of AMOLED sensor technology has been marked by significant breakthroughs and continuous improvements over the past decade. Initially, AMOLED displays were primarily used for their superior visual quality and energy efficiency in smartphones and other consumer electronics. However, the integration of sensing capabilities into these displays has opened up new possibilities for user interaction and device functionality.

The first generation of AMOLED sensors focused on basic touch functionality, utilizing the display's inherent light-emitting properties to detect user input. This approach eliminated the need for a separate touch layer, reducing device thickness and manufacturing costs. As the technology progressed, researchers and engineers explored ways to enhance the sensing capabilities of AMOLED displays.

A major milestone in AMOLED sensor evolution was the development of in-display fingerprint sensors. This technology allowed for the seamless integration of biometric authentication directly into the display area, eliminating the need for separate fingerprint sensors and enabling full-screen designs. The initial implementations used optical sensing techniques, which were later improved with the introduction of ultrasonic sensing for enhanced accuracy and security.

Another significant advancement came with the integration of pressure-sensitive technology into AMOLED displays. This allowed devices to detect varying levels of force applied to the screen, enabling new forms of user interaction and input methods. The technology has since evolved to provide more precise pressure detection and haptic feedback, enhancing the user experience across various applications.

Recent years have seen the emergence of self-emissive AMOLED sensor technology, which represents a paradigm shift in display-based sensing. This innovation allows the display pixels themselves to act as both light emitters and sensors, enabling more sophisticated and versatile sensing capabilities. Self-emissive sensors can detect ambient light, proximity, and even heart rate, all without the need for additional hardware components.

The latest breakthroughs in self-emissive AMOLED sensor technology have focused on improving sensitivity, accuracy, and power efficiency. Researchers have developed new materials and pixel architectures that enhance the sensing capabilities while maintaining excellent display performance. These advancements have paved the way for applications in health monitoring, augmented reality, and advanced user authentication.

As AMOLED sensor technology continues to evolve, we can expect to see further integration of sensing capabilities into displays, blurring the lines between display and sensor technologies. Future developments may include enhanced multi-modal sensing, improved energy harvesting from ambient light, and even the ability to detect and analyze chemical compounds in the environment.

The first generation of AMOLED sensors focused on basic touch functionality, utilizing the display's inherent light-emitting properties to detect user input. This approach eliminated the need for a separate touch layer, reducing device thickness and manufacturing costs. As the technology progressed, researchers and engineers explored ways to enhance the sensing capabilities of AMOLED displays.

A major milestone in AMOLED sensor evolution was the development of in-display fingerprint sensors. This technology allowed for the seamless integration of biometric authentication directly into the display area, eliminating the need for separate fingerprint sensors and enabling full-screen designs. The initial implementations used optical sensing techniques, which were later improved with the introduction of ultrasonic sensing for enhanced accuracy and security.

Another significant advancement came with the integration of pressure-sensitive technology into AMOLED displays. This allowed devices to detect varying levels of force applied to the screen, enabling new forms of user interaction and input methods. The technology has since evolved to provide more precise pressure detection and haptic feedback, enhancing the user experience across various applications.

Recent years have seen the emergence of self-emissive AMOLED sensor technology, which represents a paradigm shift in display-based sensing. This innovation allows the display pixels themselves to act as both light emitters and sensors, enabling more sophisticated and versatile sensing capabilities. Self-emissive sensors can detect ambient light, proximity, and even heart rate, all without the need for additional hardware components.

The latest breakthroughs in self-emissive AMOLED sensor technology have focused on improving sensitivity, accuracy, and power efficiency. Researchers have developed new materials and pixel architectures that enhance the sensing capabilities while maintaining excellent display performance. These advancements have paved the way for applications in health monitoring, augmented reality, and advanced user authentication.

As AMOLED sensor technology continues to evolve, we can expect to see further integration of sensing capabilities into displays, blurring the lines between display and sensor technologies. Future developments may include enhanced multi-modal sensing, improved energy harvesting from ambient light, and even the ability to detect and analyze chemical compounds in the environment.

Market Demand Analysis

The market demand for self-emissive AMOLED sensor technology has been experiencing significant growth, driven by the increasing adoption of advanced display technologies in various consumer electronics and industrial applications. This innovative technology combines the benefits of AMOLED displays with integrated sensing capabilities, offering enhanced user experiences and enabling new functionalities in devices.

In the consumer electronics sector, smartphones and wearable devices are the primary drivers of market demand for self-emissive AMOLED sensors. The technology allows for thinner, more power-efficient devices with improved touch sensitivity and potential for in-display fingerprint recognition. As consumers increasingly seek devices with larger, edge-to-edge displays and seamless user interfaces, the demand for this technology is expected to surge.

The automotive industry represents another significant market for self-emissive AMOLED sensors. As vehicles become more technologically advanced and incorporate larger, more interactive displays, the need for high-quality, responsive touch interfaces grows. Self-emissive AMOLED sensors offer improved visibility in various lighting conditions and can be integrated into curved or irregularly shaped surfaces, making them ideal for modern vehicle interiors.

In the healthcare and medical devices sector, self-emissive AMOLED sensors are gaining traction due to their potential for creating flexible, wearable health monitoring devices. The technology's ability to combine display and sensing functions in a single, thin layer opens up new possibilities for non-invasive health tracking and diagnostics.

The industrial and commercial sectors are also showing increased interest in self-emissive AMOLED sensor technology. Applications in control panels, interactive kiosks, and industrial displays benefit from the technology's durability, energy efficiency, and enhanced touch responsiveness.

Market analysts project a compound annual growth rate (CAGR) for the self-emissive AMOLED sensor market to be in the double digits over the next five years. This growth is attributed to the expanding applications across various industries and the continuous improvements in manufacturing processes, which are gradually reducing production costs.

However, challenges remain in terms of production scalability and cost-effectiveness, particularly for larger display sizes. As these challenges are addressed, it is anticipated that the market demand will further accelerate, potentially disrupting traditional display and sensor technologies in numerous applications.

In the consumer electronics sector, smartphones and wearable devices are the primary drivers of market demand for self-emissive AMOLED sensors. The technology allows for thinner, more power-efficient devices with improved touch sensitivity and potential for in-display fingerprint recognition. As consumers increasingly seek devices with larger, edge-to-edge displays and seamless user interfaces, the demand for this technology is expected to surge.

The automotive industry represents another significant market for self-emissive AMOLED sensors. As vehicles become more technologically advanced and incorporate larger, more interactive displays, the need for high-quality, responsive touch interfaces grows. Self-emissive AMOLED sensors offer improved visibility in various lighting conditions and can be integrated into curved or irregularly shaped surfaces, making them ideal for modern vehicle interiors.

In the healthcare and medical devices sector, self-emissive AMOLED sensors are gaining traction due to their potential for creating flexible, wearable health monitoring devices. The technology's ability to combine display and sensing functions in a single, thin layer opens up new possibilities for non-invasive health tracking and diagnostics.

The industrial and commercial sectors are also showing increased interest in self-emissive AMOLED sensor technology. Applications in control panels, interactive kiosks, and industrial displays benefit from the technology's durability, energy efficiency, and enhanced touch responsiveness.

Market analysts project a compound annual growth rate (CAGR) for the self-emissive AMOLED sensor market to be in the double digits over the next five years. This growth is attributed to the expanding applications across various industries and the continuous improvements in manufacturing processes, which are gradually reducing production costs.

However, challenges remain in terms of production scalability and cost-effectiveness, particularly for larger display sizes. As these challenges are addressed, it is anticipated that the market demand will further accelerate, potentially disrupting traditional display and sensor technologies in numerous applications.

Technical Challenges

The development of self-emissive AMOLED sensor technology faces several significant technical challenges that researchers and engineers must overcome to achieve widespread adoption and improved performance.

One of the primary obstacles is the integration of sensing capabilities without compromising display quality. The incorporation of sensors within the AMOLED structure can potentially interfere with pixel performance, leading to reduced brightness, color accuracy, or resolution. Balancing the sensor functionality with optimal display characteristics requires innovative design solutions and advanced manufacturing techniques.

Another critical challenge lies in the power consumption of integrated sensors. AMOLED displays are known for their energy efficiency, but adding sensing capabilities can increase overall power draw. Developing low-power sensing technologies that can operate seamlessly within the AMOLED architecture is crucial for maintaining the energy advantages of these displays, especially in mobile and wearable devices where battery life is a key consideration.

Durability and longevity of self-emissive AMOLED sensors present another hurdle. The organic materials used in AMOLED displays are susceptible to degradation over time, and integrating sensors may exacerbate this issue. Ensuring that the sensor components do not accelerate the aging process of the display or compromise its lifespan is essential for the technology's long-term viability.

Uniformity and consistency across the display area pose significant challenges when incorporating sensing elements. Achieving uniform sensor performance across the entire screen while maintaining consistent display quality requires precise manufacturing processes and advanced calibration techniques. Any variations in sensor response or display output could lead to a suboptimal user experience.

The complexity of signal processing and data interpretation from integrated sensors adds another layer of technical difficulty. Distinguishing between intentional inputs and unintended interactions, as well as accurately interpreting various types of sensor data (e.g., touch, pressure, or biometric information) in real-time, demands sophisticated algorithms and processing capabilities.

Manufacturing scalability remains a significant challenge for self-emissive AMOLED sensor technology. The intricate processes required to produce these advanced displays with integrated sensing capabilities must be adaptable to large-scale production to be commercially viable. Developing cost-effective and reliable manufacturing methods that can maintain high yields at scale is crucial for widespread adoption.

Lastly, the challenge of cross-talk between display and sensor functions must be addressed. Ensuring that the operation of the display does not interfere with sensor readings, and vice versa, requires careful design considerations and advanced isolation techniques. Overcoming this challenge is essential for maintaining the accuracy and reliability of both the display and sensing functionalities in self-emissive AMOLED sensor technology.

One of the primary obstacles is the integration of sensing capabilities without compromising display quality. The incorporation of sensors within the AMOLED structure can potentially interfere with pixel performance, leading to reduced brightness, color accuracy, or resolution. Balancing the sensor functionality with optimal display characteristics requires innovative design solutions and advanced manufacturing techniques.

Another critical challenge lies in the power consumption of integrated sensors. AMOLED displays are known for their energy efficiency, but adding sensing capabilities can increase overall power draw. Developing low-power sensing technologies that can operate seamlessly within the AMOLED architecture is crucial for maintaining the energy advantages of these displays, especially in mobile and wearable devices where battery life is a key consideration.

Durability and longevity of self-emissive AMOLED sensors present another hurdle. The organic materials used in AMOLED displays are susceptible to degradation over time, and integrating sensors may exacerbate this issue. Ensuring that the sensor components do not accelerate the aging process of the display or compromise its lifespan is essential for the technology's long-term viability.

Uniformity and consistency across the display area pose significant challenges when incorporating sensing elements. Achieving uniform sensor performance across the entire screen while maintaining consistent display quality requires precise manufacturing processes and advanced calibration techniques. Any variations in sensor response or display output could lead to a suboptimal user experience.

The complexity of signal processing and data interpretation from integrated sensors adds another layer of technical difficulty. Distinguishing between intentional inputs and unintended interactions, as well as accurately interpreting various types of sensor data (e.g., touch, pressure, or biometric information) in real-time, demands sophisticated algorithms and processing capabilities.

Manufacturing scalability remains a significant challenge for self-emissive AMOLED sensor technology. The intricate processes required to produce these advanced displays with integrated sensing capabilities must be adaptable to large-scale production to be commercially viable. Developing cost-effective and reliable manufacturing methods that can maintain high yields at scale is crucial for widespread adoption.

Lastly, the challenge of cross-talk between display and sensor functions must be addressed. Ensuring that the operation of the display does not interfere with sensor readings, and vice versa, requires careful design considerations and advanced isolation techniques. Overcoming this challenge is essential for maintaining the accuracy and reliability of both the display and sensing functionalities in self-emissive AMOLED sensor technology.

Current Solutions

01 Self-emissive AMOLED display technology

Self-emissive AMOLED (Active-Matrix Organic Light-Emitting Diode) technology is used in displays where each pixel emits its own light. This results in high contrast ratios, vibrant colors, and energy efficiency. The technology is widely applied in smartphones, televisions, and other electronic devices.- Self-emissive AMOLED display technology: Self-emissive AMOLED displays use organic light-emitting diodes to produce light, offering advantages such as high contrast ratios, wide color gamut, and fast response times. These displays are commonly used in smartphones, tablets, and other electronic devices.

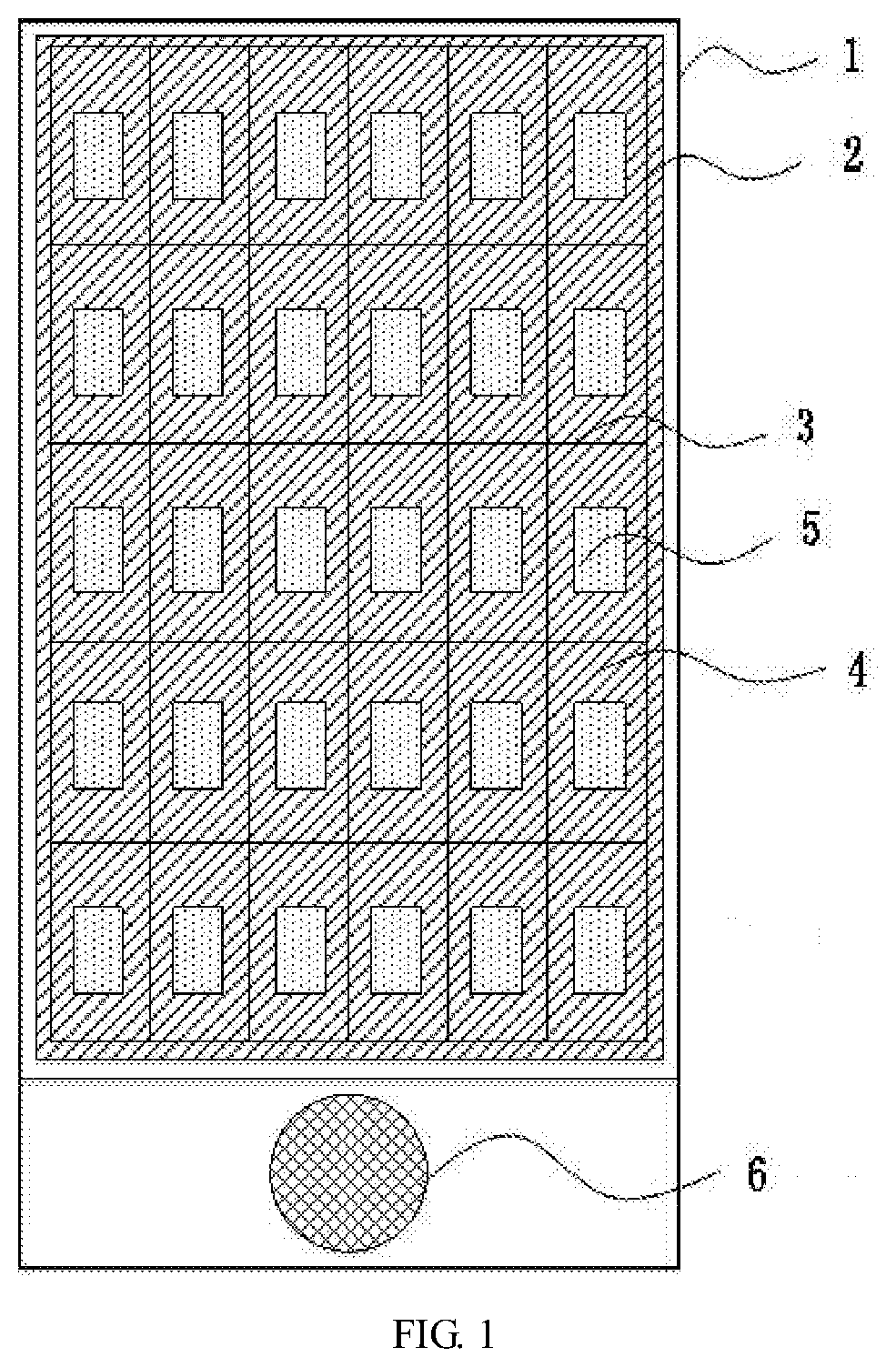

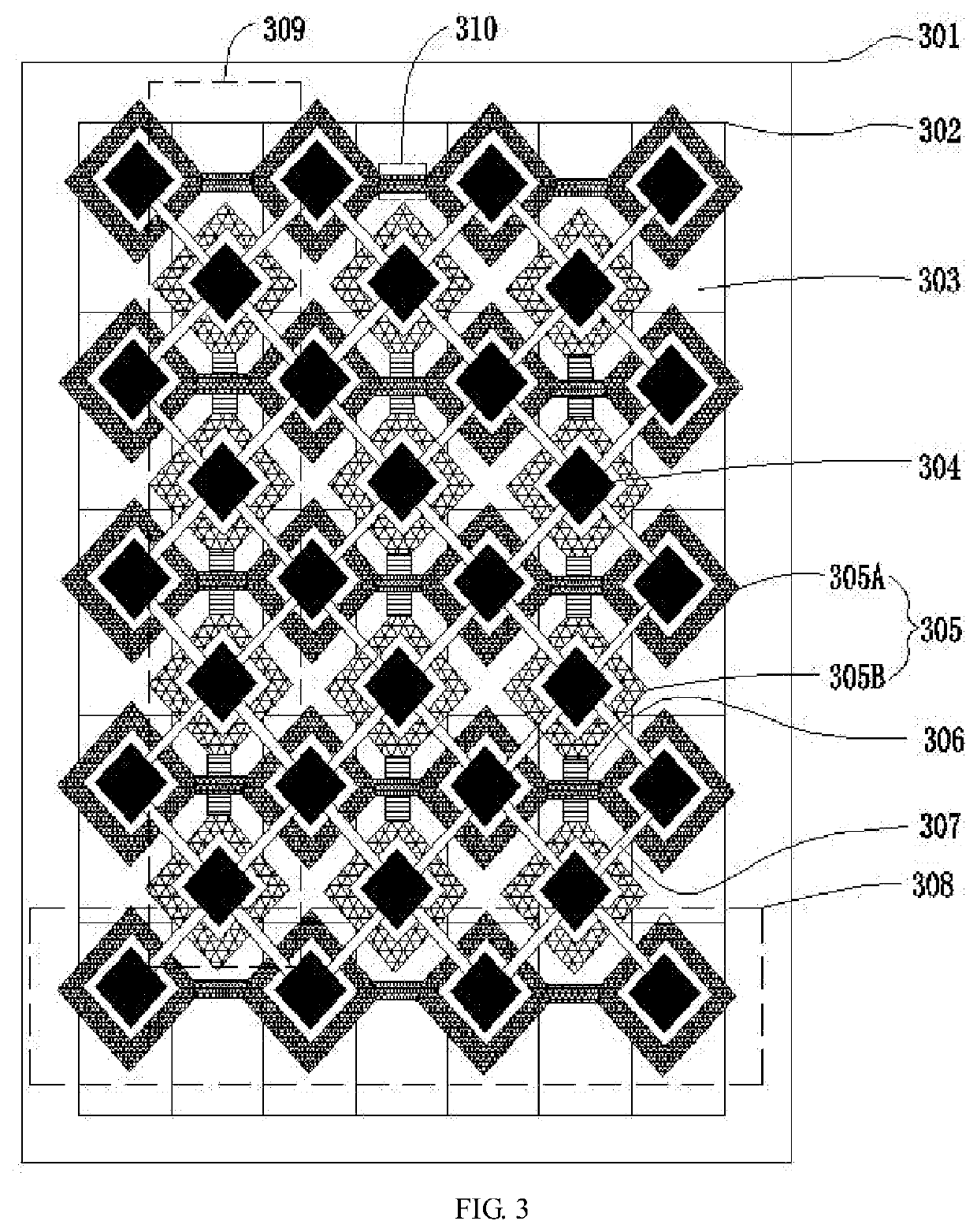

- Integration of sensors in AMOLED displays: Sensors can be integrated into AMOLED displays to enhance functionality. These sensors may include touch sensors, fingerprint sensors, or ambient light sensors, allowing for improved user interaction and device performance.

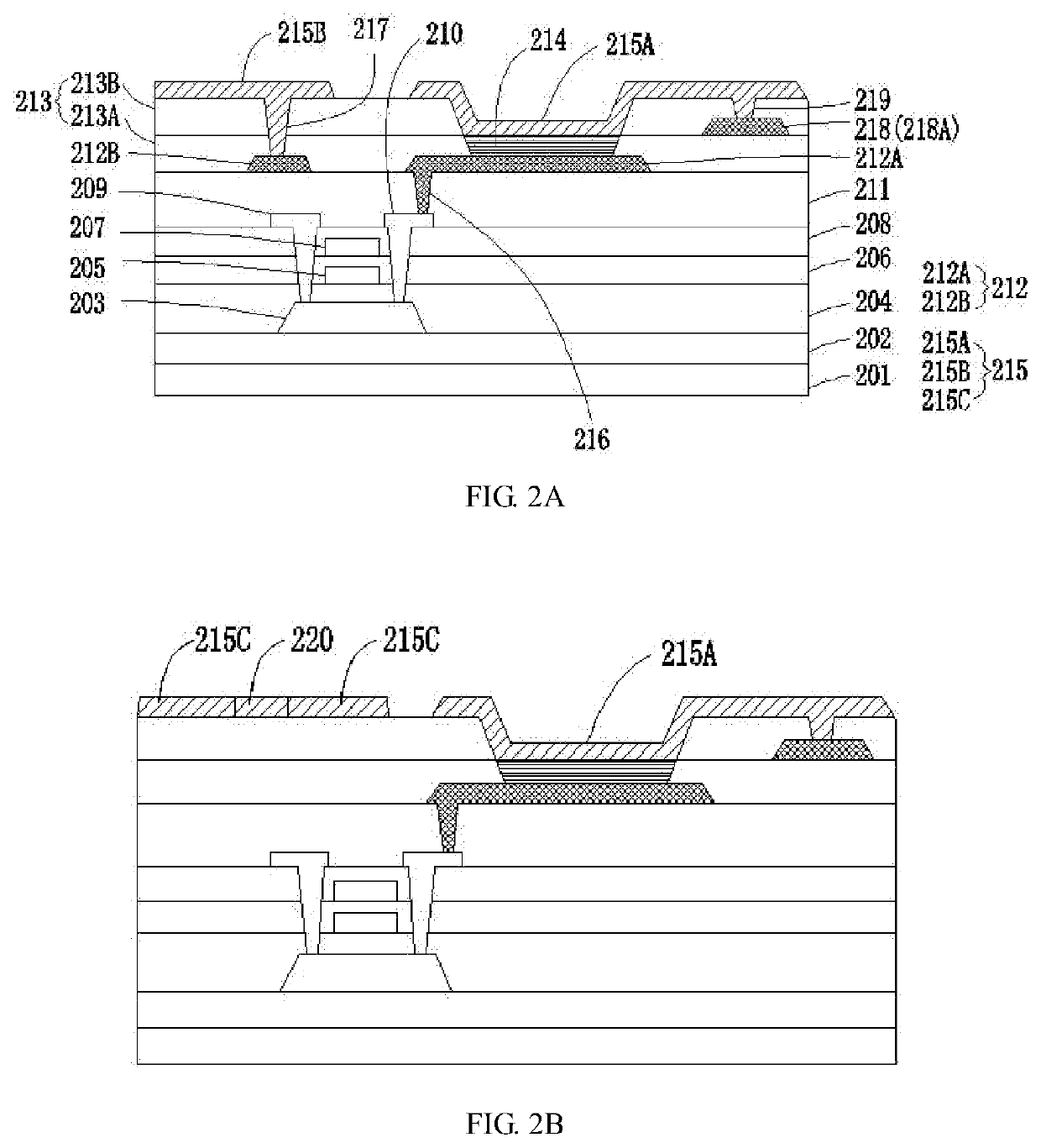

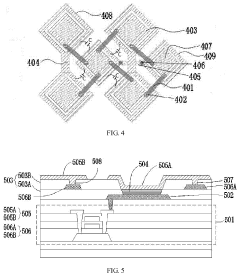

- Pixel structure and driving methods for AMOLED displays: Advanced pixel structures and driving methods are developed to improve the performance of AMOLED displays. These innovations can enhance image quality, reduce power consumption, and increase the lifespan of the display.

- Manufacturing processes for AMOLED displays: Various manufacturing processes are employed to produce AMOLED displays, including deposition techniques, patterning methods, and encapsulation processes. These processes aim to improve yield, reduce costs, and enhance the overall quality of the displays.

- AMOLED display applications and device integration: AMOLED displays are integrated into various devices and applications, including smartphones, wearables, and automotive displays. The self-emissive nature of these displays allows for flexible and curved form factors, enabling new design possibilities.

02 Integration of sensors in AMOLED displays

Sensors can be integrated directly into AMOLED displays, allowing for functionalities such as touch sensing, fingerprint recognition, and ambient light detection. This integration can lead to thinner device profiles and improved user interaction without compromising display quality.Expand Specific Solutions03 Pixel structure and driving methods

Advanced pixel structures and driving methods are developed to enhance the performance of self-emissive AMOLED displays. These improvements focus on increasing brightness, reducing power consumption, and extending the lifespan of OLED materials.Expand Specific Solutions04 Manufacturing processes for AMOLED sensors

Specialized manufacturing processes are employed to produce self-emissive AMOLED sensors. These processes involve precise deposition of organic materials, encapsulation techniques to protect against moisture and oxygen, and integration of thin-film transistors for active matrix control.Expand Specific Solutions05 Applications of self-emissive AMOLED sensors

Self-emissive AMOLED sensors find applications in various fields beyond traditional displays. These include wearable devices, automotive displays, virtual and augmented reality systems, and medical imaging equipment, where high-quality visual output and integrated sensing capabilities are crucial.Expand Specific Solutions

Industry Leaders

The self-emissive AMOLED sensor technology market is in a growth phase, with increasing demand driven by advancements in display technology and consumer electronics. Major players like Samsung Display, LG Display, and BOE Technology are leading the competition, investing heavily in R&D to improve AMOLED performance and production efficiency. The market size is expanding rapidly, fueled by adoption in smartphones, wearables, and automotive displays. Technological maturity varies among companies, with Samsung and LG holding more advanced capabilities, while Chinese firms like BOE and CSOT are rapidly catching up, narrowing the gap in both quality and production capacity.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has made significant progress in self-emissive AMOLED sensor technology, particularly in the realm of flexible displays. They have developed a stretchable AMOLED display that can be elongated by up to 20% while maintaining full functionality[7]. BOE's AMOLED sensors incorporate advanced touch integration, with reports suggesting a 30% improvement in touch sensitivity compared to traditional implementations[8]. The company has also focused on enhancing the lifespan of their AMOLED displays, with recent advancements reportedly extending the operational life by up to 30% through improved materials and manufacturing processes[9].

Strengths: Leadership in flexible display technology, improved touch sensitivity, extended display lifespan. Weaknesses: Catching up to Korean competitors in some areas of AMOLED technology, potential yield challenges with cutting-edge products.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has made significant breakthroughs in self-emissive AMOLED sensor technology. They have developed an advanced OLED display with integrated touch and fingerprint sensing capabilities[1]. This technology eliminates the need for separate touch and fingerprint sensors, reducing device thickness and complexity. Samsung's AMOLED sensors utilize a unique pixel structure that allows for both light emission and sensing, enabling features like under-display fingerprint recognition and improved touch responsiveness[2]. The company has also made strides in enhancing the energy efficiency of their AMOLED displays, with reports suggesting up to 30% reduction in power consumption compared to previous generations[3].

Strengths: Industry-leading AMOLED technology, integrated sensing capabilities, reduced device complexity. Weaknesses: Higher production costs, potential yield issues with advanced manufacturing processes.

Key Innovations

Amoled double-side display

PatentActiveUS20200219957A1

Innovation

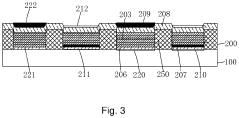

- An AMOLED double-sided display design featuring a substrate with alternating top-emitting and bottom-emitting OLED units, where the anode of top-emitting units is thicker and reflective, and the cathode of bottom-emitting units is thicker and light-transmissive, allowing for single IC control and eliminating mirrored images.

Active matrix organic light emitting diode (amoled) display panel

PatentInactiveUS20210343972A1

Innovation

- The integration of sensing electrodes into the AMOLED display panel allows for underscreen fingerprint identification, utilizing a patterned cathode layer with insulated first and second electrode rows and conductive bridges to form capacitors for fingerprint recognition, thereby embedding fingerprint identification within the screen and increasing the display area ratio.

Manufacturing Processes

The manufacturing processes for self-emissive AMOLED sensor technology have undergone significant advancements in recent years. These processes are crucial for the production of high-quality, efficient, and cost-effective sensors that can be integrated into various devices.

One of the key manufacturing processes involves the deposition of organic materials onto a substrate. This is typically achieved through thermal evaporation under vacuum conditions. The process requires precise control of temperature and deposition rates to ensure uniform layer thickness and optimal performance. Recent breakthroughs in this area include the development of advanced evaporation sources that allow for more accurate and consistent material deposition.

Another critical aspect of the manufacturing process is the patterning of the OLED layers. Traditionally, fine metal masks (FMM) have been used for this purpose. However, innovations in laser-induced thermal imaging (LITI) and inkjet printing technologies have opened up new possibilities for more precise and efficient patterning. These methods offer improved resolution and reduced material waste compared to traditional techniques.

The encapsulation of AMOLED sensors is a crucial step in the manufacturing process to protect the organic materials from moisture and oxygen. Thin-film encapsulation (TFE) has emerged as a promising technique, allowing for thinner and more flexible devices. Recent breakthroughs in atomic layer deposition (ALD) have further improved the quality and reliability of encapsulation layers.

Integration of the sensing elements into the AMOLED structure presents unique manufacturing challenges. Advanced techniques such as in-cell touch integration and on-cell fingerprint sensors have been developed to address these challenges. These methods require precise alignment and careful consideration of the impact on the OLED stack performance.

Quality control and testing are integral parts of the manufacturing process. Innovations in automated optical inspection (AOI) systems and electrical testing methods have significantly improved the detection of defects and ensure consistent performance across produced sensors. Machine learning algorithms are increasingly being employed to enhance the accuracy and efficiency of these quality control processes.

Scaling up production while maintaining quality and yield remains a significant challenge in AMOLED sensor manufacturing. Recent advancements in roll-to-roll processing and large-area deposition techniques show promise for increasing production volumes and reducing costs. These methods are particularly relevant for flexible and foldable AMOLED sensors, which require specialized manufacturing approaches.

One of the key manufacturing processes involves the deposition of organic materials onto a substrate. This is typically achieved through thermal evaporation under vacuum conditions. The process requires precise control of temperature and deposition rates to ensure uniform layer thickness and optimal performance. Recent breakthroughs in this area include the development of advanced evaporation sources that allow for more accurate and consistent material deposition.

Another critical aspect of the manufacturing process is the patterning of the OLED layers. Traditionally, fine metal masks (FMM) have been used for this purpose. However, innovations in laser-induced thermal imaging (LITI) and inkjet printing technologies have opened up new possibilities for more precise and efficient patterning. These methods offer improved resolution and reduced material waste compared to traditional techniques.

The encapsulation of AMOLED sensors is a crucial step in the manufacturing process to protect the organic materials from moisture and oxygen. Thin-film encapsulation (TFE) has emerged as a promising technique, allowing for thinner and more flexible devices. Recent breakthroughs in atomic layer deposition (ALD) have further improved the quality and reliability of encapsulation layers.

Integration of the sensing elements into the AMOLED structure presents unique manufacturing challenges. Advanced techniques such as in-cell touch integration and on-cell fingerprint sensors have been developed to address these challenges. These methods require precise alignment and careful consideration of the impact on the OLED stack performance.

Quality control and testing are integral parts of the manufacturing process. Innovations in automated optical inspection (AOI) systems and electrical testing methods have significantly improved the detection of defects and ensure consistent performance across produced sensors. Machine learning algorithms are increasingly being employed to enhance the accuracy and efficiency of these quality control processes.

Scaling up production while maintaining quality and yield remains a significant challenge in AMOLED sensor manufacturing. Recent advancements in roll-to-roll processing and large-area deposition techniques show promise for increasing production volumes and reducing costs. These methods are particularly relevant for flexible and foldable AMOLED sensors, which require specialized manufacturing approaches.

Energy Efficiency

Energy efficiency is a critical aspect of self-emissive AMOLED sensor technology, as it directly impacts device performance, battery life, and overall user experience. Recent breakthroughs in this area have focused on optimizing power consumption while maintaining or enhancing sensor functionality.

One significant advancement is the development of low-power AMOLED displays with integrated sensors. These displays utilize pixel-level sensing capabilities, allowing for touch and biometric sensing without the need for additional layers or components. By integrating sensing functions directly into the display, power consumption is reduced, as fewer separate components are required to operate.

Another key innovation is the implementation of adaptive refresh rates in AMOLED sensors. This technology dynamically adjusts the display's refresh rate based on the content being shown and the level of user interaction. For instance, when displaying static content or during periods of inactivity, the refresh rate can be lowered to conserve energy. Conversely, when high responsiveness is required, such as during touch interactions or displaying fast-moving content, the refresh rate can be increased.

Improvements in OLED materials have also contributed to enhanced energy efficiency. New emissive materials with higher quantum efficiency have been developed, allowing for brighter displays at lower power levels. Additionally, advancements in OLED stack designs have led to reduced voltage requirements, further decreasing power consumption.

The integration of artificial intelligence and machine learning algorithms has enabled more sophisticated power management in AMOLED sensor systems. These algorithms can predict user behavior and optimize display settings accordingly, balancing power consumption with performance requirements in real-time.

Furthermore, breakthroughs in circuit design have resulted in more efficient driver ICs for AMOLED displays with integrated sensors. These new designs minimize power loss during signal processing and data transmission, contributing to overall energy savings.

Lastly, the development of ultra-low-power modes for AMOLED sensors has significantly extended battery life in devices. These modes allow certain sensing functions to remain active while consuming minimal power, enabling features such as always-on displays and gesture recognition without significantly impacting battery performance.

One significant advancement is the development of low-power AMOLED displays with integrated sensors. These displays utilize pixel-level sensing capabilities, allowing for touch and biometric sensing without the need for additional layers or components. By integrating sensing functions directly into the display, power consumption is reduced, as fewer separate components are required to operate.

Another key innovation is the implementation of adaptive refresh rates in AMOLED sensors. This technology dynamically adjusts the display's refresh rate based on the content being shown and the level of user interaction. For instance, when displaying static content or during periods of inactivity, the refresh rate can be lowered to conserve energy. Conversely, when high responsiveness is required, such as during touch interactions or displaying fast-moving content, the refresh rate can be increased.

Improvements in OLED materials have also contributed to enhanced energy efficiency. New emissive materials with higher quantum efficiency have been developed, allowing for brighter displays at lower power levels. Additionally, advancements in OLED stack designs have led to reduced voltage requirements, further decreasing power consumption.

The integration of artificial intelligence and machine learning algorithms has enabled more sophisticated power management in AMOLED sensor systems. These algorithms can predict user behavior and optimize display settings accordingly, balancing power consumption with performance requirements in real-time.

Furthermore, breakthroughs in circuit design have resulted in more efficient driver ICs for AMOLED displays with integrated sensors. These new designs minimize power loss during signal processing and data transmission, contributing to overall energy savings.

Lastly, the development of ultra-low-power modes for AMOLED sensors has significantly extended battery life in devices. These modes allow certain sensing functions to remain active while consuming minimal power, enabling features such as always-on displays and gesture recognition without significantly impacting battery performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!