How nanotube technology advances AMOLED displays?

JUL 17, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanotube AMOLED Evolution

The evolution of nanotube technology in AMOLED displays represents a significant leap forward in display technology. Carbon nanotubes (CNTs) have emerged as a promising material for advancing AMOLED performance due to their unique electrical and mechanical properties. The journey of integrating nanotubes into AMOLED displays began in the early 2000s when researchers first explored the potential of CNTs as electron emitters in field emission displays.

As AMOLED technology gained traction, the focus shifted towards using nanotubes to enhance the performance of thin-film transistors (TFTs) that drive individual pixels. The high mobility and current-carrying capacity of CNTs made them an attractive alternative to traditional amorphous silicon or low-temperature polycrystalline silicon TFTs. This led to the development of CNT-based TFTs with improved electron mobility and stability, enabling faster switching speeds and better control over pixel illumination.

The next major milestone came with the introduction of CNT-based transparent conductive films (TCFs) as potential replacements for indium tin oxide (ITO) in AMOLED displays. CNT-TCFs offered advantages such as flexibility, improved durability, and potentially lower production costs. This development paved the way for more robust and flexible AMOLED displays, opening up new form factors and applications.

In recent years, the integration of CNTs into the emissive layers of AMOLED displays has been a focus of research. Scientists have explored the use of semiconducting single-walled carbon nanotubes (SWCNTs) as light-emitting materials, leveraging their tunable bandgap to produce a wide range of colors. This approach promises to enhance color purity and efficiency in AMOLED displays.

The latest advancements in nanotube AMOLED technology involve the development of hybrid structures that combine CNTs with other nanomaterials such as quantum dots or perovskites. These hybrid systems aim to leverage the strengths of multiple materials to achieve superior display performance, including higher brightness, improved color gamut, and increased energy efficiency.

Looking ahead, the evolution of nanotube technology in AMOLED displays is expected to continue with a focus on scalable manufacturing processes, further improvements in efficiency and color quality, and the development of novel device architectures that fully exploit the unique properties of CNTs. As research progresses, we may see the emergence of entirely new display paradigms that push the boundaries of what is possible with AMOLED technology.

As AMOLED technology gained traction, the focus shifted towards using nanotubes to enhance the performance of thin-film transistors (TFTs) that drive individual pixels. The high mobility and current-carrying capacity of CNTs made them an attractive alternative to traditional amorphous silicon or low-temperature polycrystalline silicon TFTs. This led to the development of CNT-based TFTs with improved electron mobility and stability, enabling faster switching speeds and better control over pixel illumination.

The next major milestone came with the introduction of CNT-based transparent conductive films (TCFs) as potential replacements for indium tin oxide (ITO) in AMOLED displays. CNT-TCFs offered advantages such as flexibility, improved durability, and potentially lower production costs. This development paved the way for more robust and flexible AMOLED displays, opening up new form factors and applications.

In recent years, the integration of CNTs into the emissive layers of AMOLED displays has been a focus of research. Scientists have explored the use of semiconducting single-walled carbon nanotubes (SWCNTs) as light-emitting materials, leveraging their tunable bandgap to produce a wide range of colors. This approach promises to enhance color purity and efficiency in AMOLED displays.

The latest advancements in nanotube AMOLED technology involve the development of hybrid structures that combine CNTs with other nanomaterials such as quantum dots or perovskites. These hybrid systems aim to leverage the strengths of multiple materials to achieve superior display performance, including higher brightness, improved color gamut, and increased energy efficiency.

Looking ahead, the evolution of nanotube technology in AMOLED displays is expected to continue with a focus on scalable manufacturing processes, further improvements in efficiency and color quality, and the development of novel device architectures that fully exploit the unique properties of CNTs. As research progresses, we may see the emergence of entirely new display paradigms that push the boundaries of what is possible with AMOLED technology.

AMOLED Market Dynamics

The AMOLED display market has experienced significant growth in recent years, driven by increasing demand for high-quality displays in smartphones, televisions, and other electronic devices. This market segment has shown remarkable resilience and adaptability, with manufacturers continuously innovating to meet consumer expectations for improved visual experiences.

The global AMOLED market size was valued at approximately $25 billion in 2020 and is projected to reach over $50 billion by 2026, with a compound annual growth rate (CAGR) of around 13% during this period. This growth is primarily attributed to the rising adoption of AMOLED displays in smartphones, which account for the largest share of the market. The smartphone industry's shift towards larger screens and higher resolutions has further fueled the demand for AMOLED technology.

In addition to smartphones, the AMOLED market is expanding into other sectors such as televisions, smartwatches, and automotive displays. The automotive industry, in particular, is showing increased interest in AMOLED technology for infotainment systems and digital dashboards, driven by the trend towards connected and autonomous vehicles.

The market dynamics are also influenced by technological advancements, with manufacturers investing heavily in research and development to improve AMOLED performance and reduce production costs. Key areas of focus include enhancing color accuracy, increasing brightness levels, and extending the lifespan of AMOLED displays.

Competition in the AMOLED market is intense, with several major players vying for market share. Samsung Display holds a dominant position, particularly in the smartphone segment, while LG Display has made significant strides in large-format AMOLED panels for televisions. Other notable manufacturers include BOE Technology, Visionox, and AU Optronics.

The integration of nanotube technology in AMOLED displays represents a significant development in this market. Carbon nanotubes offer potential improvements in display performance, including enhanced electron mobility, increased transparency, and improved flexibility. These properties could lead to thinner, more energy-efficient displays with better color reproduction and contrast ratios.

As the AMOLED market continues to evolve, several trends are shaping its future. These include the development of foldable and rollable displays, the integration of under-display cameras, and the pursuit of higher refresh rates for improved motion handling. The ongoing research into quantum dot AMOLED (QD-AMOLED) technology also promises to deliver wider color gamuts and increased brightness levels.

The global AMOLED market size was valued at approximately $25 billion in 2020 and is projected to reach over $50 billion by 2026, with a compound annual growth rate (CAGR) of around 13% during this period. This growth is primarily attributed to the rising adoption of AMOLED displays in smartphones, which account for the largest share of the market. The smartphone industry's shift towards larger screens and higher resolutions has further fueled the demand for AMOLED technology.

In addition to smartphones, the AMOLED market is expanding into other sectors such as televisions, smartwatches, and automotive displays. The automotive industry, in particular, is showing increased interest in AMOLED technology for infotainment systems and digital dashboards, driven by the trend towards connected and autonomous vehicles.

The market dynamics are also influenced by technological advancements, with manufacturers investing heavily in research and development to improve AMOLED performance and reduce production costs. Key areas of focus include enhancing color accuracy, increasing brightness levels, and extending the lifespan of AMOLED displays.

Competition in the AMOLED market is intense, with several major players vying for market share. Samsung Display holds a dominant position, particularly in the smartphone segment, while LG Display has made significant strides in large-format AMOLED panels for televisions. Other notable manufacturers include BOE Technology, Visionox, and AU Optronics.

The integration of nanotube technology in AMOLED displays represents a significant development in this market. Carbon nanotubes offer potential improvements in display performance, including enhanced electron mobility, increased transparency, and improved flexibility. These properties could lead to thinner, more energy-efficient displays with better color reproduction and contrast ratios.

As the AMOLED market continues to evolve, several trends are shaping its future. These include the development of foldable and rollable displays, the integration of under-display cameras, and the pursuit of higher refresh rates for improved motion handling. The ongoing research into quantum dot AMOLED (QD-AMOLED) technology also promises to deliver wider color gamuts and increased brightness levels.

Nanotube Challenges in AMOLED

The integration of nanotube technology into AMOLED displays presents several significant challenges that researchers and manufacturers must overcome. One of the primary obstacles is the precise control and manipulation of nanotubes at the molecular level. The extremely small size of nanotubes, typically measuring just a few nanometers in diameter, makes it difficult to position and align them accurately within the display structure.

Another major challenge lies in the production of high-quality, uniform nanotubes at scale. Current manufacturing processes often result in a mixture of nanotubes with varying properties, including different lengths, diameters, and chiralities. This lack of consistency can lead to inconsistent performance across the display, affecting image quality and device reliability.

The integration of nanotubes into existing AMOLED manufacturing processes also poses significant hurdles. Traditional AMOLED fabrication techniques may not be directly compatible with nanotube incorporation, necessitating the development of new manufacturing methods and equipment. This adaptation process can be both time-consuming and costly, potentially slowing down the adoption of nanotube-enhanced AMOLED technology.

Ensuring the long-term stability and durability of nanotube-based components in AMOLED displays is another critical challenge. Nanotubes must maintain their electrical and optical properties over the lifetime of the display, withstanding factors such as heat, humidity, and mechanical stress. Developing robust encapsulation techniques and protective layers to shield the nanotubes from environmental factors is essential for the commercial viability of this technology.

The electrical properties of nanotubes can also present challenges in AMOLED applications. While nanotubes offer excellent conductivity, controlling their semiconducting behavior and achieving consistent performance across large areas of the display remains difficult. Researchers must develop methods to selectively grow or sort nanotubes with specific electronic properties to optimize their performance in different display components.

Furthermore, the potential health and environmental impacts of nanotube technology in consumer electronics raise concerns. The long-term effects of nanotube exposure and the environmental implications of nanotube-based devices at the end of their lifecycle are not yet fully understood. Addressing these safety and sustainability issues is crucial for widespread adoption and regulatory approval of nanotube-enhanced AMOLED displays.

Another major challenge lies in the production of high-quality, uniform nanotubes at scale. Current manufacturing processes often result in a mixture of nanotubes with varying properties, including different lengths, diameters, and chiralities. This lack of consistency can lead to inconsistent performance across the display, affecting image quality and device reliability.

The integration of nanotubes into existing AMOLED manufacturing processes also poses significant hurdles. Traditional AMOLED fabrication techniques may not be directly compatible with nanotube incorporation, necessitating the development of new manufacturing methods and equipment. This adaptation process can be both time-consuming and costly, potentially slowing down the adoption of nanotube-enhanced AMOLED technology.

Ensuring the long-term stability and durability of nanotube-based components in AMOLED displays is another critical challenge. Nanotubes must maintain their electrical and optical properties over the lifetime of the display, withstanding factors such as heat, humidity, and mechanical stress. Developing robust encapsulation techniques and protective layers to shield the nanotubes from environmental factors is essential for the commercial viability of this technology.

The electrical properties of nanotubes can also present challenges in AMOLED applications. While nanotubes offer excellent conductivity, controlling their semiconducting behavior and achieving consistent performance across large areas of the display remains difficult. Researchers must develop methods to selectively grow or sort nanotubes with specific electronic properties to optimize their performance in different display components.

Furthermore, the potential health and environmental impacts of nanotube technology in consumer electronics raise concerns. The long-term effects of nanotube exposure and the environmental implications of nanotube-based devices at the end of their lifecycle are not yet fully understood. Addressing these safety and sustainability issues is crucial for widespread adoption and regulatory approval of nanotube-enhanced AMOLED displays.

Current Nanotube Solutions

01 Carbon nanotube-based electrodes for AMOLED displays

Carbon nanotubes are utilized as electrodes in AMOLED displays, offering improved conductivity and transparency. This technology enhances the overall performance of the display, including brightness, contrast, and energy efficiency. The use of carbon nanotubes also allows for the development of flexible and stretchable AMOLED displays.- Carbon nanotube-based electrodes for AMOLED displays: Carbon nanotubes are utilized as electrodes in AMOLED displays, offering improved conductivity and transparency. This technology enhances the overall performance of the display, including brightness, contrast, and energy efficiency. The use of carbon nanotubes also allows for the development of flexible and stretchable AMOLED displays.

- Nanotube-based thin-film transistors for AMOLED displays: Thin-film transistors incorporating carbon nanotubes are used in AMOLED displays to control pixel switching. These transistors offer improved electron mobility, faster response times, and better stability compared to traditional silicon-based transistors. The integration of nanotube-based transistors enables the production of high-performance, large-area AMOLED displays.

- Nanotube-enhanced light-emitting layers in AMOLED displays: Carbon nanotubes are incorporated into the light-emitting layers of AMOLED displays to improve their efficiency and color purity. The nanotubes can act as electron transport materials or as dopants to enhance the performance of organic light-emitting materials. This technology results in displays with better color reproduction and longer lifespans.

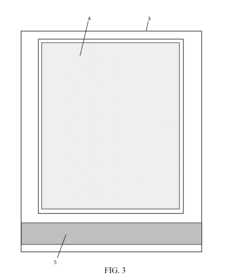

- Nanotube-based touch sensors integrated with AMOLED displays: Carbon nanotube networks are used to create transparent touch sensors that can be integrated directly into AMOLED displays. This technology allows for the development of thinner and more responsive touch-enabled displays, eliminating the need for separate touch panels. The result is improved touch sensitivity and reduced overall device thickness.

- Nanotube-enhanced color filters for AMOLED displays: Carbon nanotubes are incorporated into color filters used in AMOLED displays to improve color purity and contrast. The nanotubes can act as light-absorbing materials or as structural elements to enhance the optical properties of the color filters. This technology results in displays with more vibrant colors and improved viewing angles.

02 Nanotube-based thin-film transistors for AMOLED displays

Thin-film transistors incorporating carbon nanotubes are used in AMOLED displays to improve pixel switching and current control. This technology enables higher resolution, faster response times, and better color accuracy in displays. The use of nanotube-based transistors also contributes to reduced power consumption and improved device longevity.Expand Specific Solutions03 Nanotube-enhanced light-emitting layers in AMOLED displays

Carbon nanotubes are integrated into the light-emitting layers of AMOLED displays to enhance luminescence efficiency and color purity. This technology improves the overall display quality, including brightness, contrast, and color gamut. The use of nanotubes in light-emitting layers also contributes to increased display lifespan and reduced power consumption.Expand Specific Solutions04 Nanotube-based touch sensors integrated with AMOLED displays

Carbon nanotubes are used to create transparent and flexible touch sensors that can be integrated with AMOLED displays. This technology enables the development of more responsive and accurate touch interfaces while maintaining the display's visual quality. The use of nanotube-based touch sensors also allows for the creation of curved or foldable AMOLED devices.Expand Specific Solutions05 Nanotube-enhanced color filters for AMOLED displays

Carbon nanotubes are incorporated into color filters used in AMOLED displays to improve color purity and efficiency. This technology enhances the overall display quality by providing more vibrant and accurate colors. The use of nanotube-enhanced color filters also contributes to reduced power consumption and improved display brightness.Expand Specific Solutions

Key AMOLED Manufacturers

The nanotube technology in AMOLED displays is in a nascent stage of development, with significant potential for market growth. The global AMOLED display market is expanding rapidly, driven by increasing demand for high-quality displays in smartphones, TVs, and wearables. Companies like BOE Technology, LG Display, and TCL China Star Optoelectronics are at the forefront of this technology, investing heavily in research and development. While the technology is still evolving, these major players are making strides in improving display performance, energy efficiency, and flexibility. The competitive landscape is intense, with both established display manufacturers and innovative startups vying for market share in this promising field.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced nanotube-based AMOLED displays, utilizing carbon nanotubes (CNTs) as the electron emission source in their display technology. Their approach involves creating a network of CNTs on the cathode, which emits electrons when an electric field is applied. These electrons then excite phosphors on the anode, producing light. BOE's nanotube AMOLED technology offers improved electron emission efficiency and uniformity compared to traditional OLED displays[1][3]. The company has also focused on enhancing the stability and longevity of CNT-based displays by developing specialized encapsulation techniques and optimizing the CNT growth process[2].

Strengths: Higher electron emission efficiency, improved display uniformity, and potential for flexible displays. Weaknesses: Challenges in mass production scalability and potential higher initial manufacturing costs.

LG Display Co., Ltd.

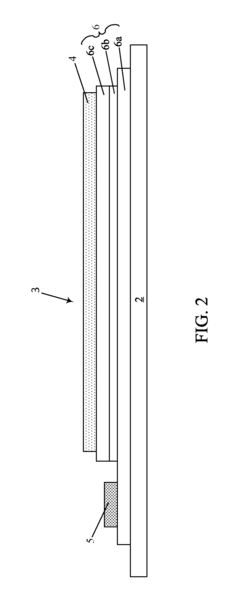

Technical Solution: LG Display has incorporated carbon nanotube technology into their AMOLED displays to enhance performance and efficiency. Their approach involves using CNTs as a transparent conductive layer, replacing traditional indium tin oxide (ITO). This results in improved conductivity and flexibility of the display[4]. LG has also explored using CNTs in the electron transport layer of AMOLED devices, leading to better charge mobility and reduced power consumption[5]. Additionally, the company has developed a proprietary method for aligning CNTs in specific patterns to optimize light emission and color accuracy in their displays[6].

Strengths: Enhanced flexibility, improved conductivity, and reduced power consumption. Weaknesses: Potential challenges in ensuring consistent CNT quality and integration with existing manufacturing processes.

Nanotube AMOLED Innovations

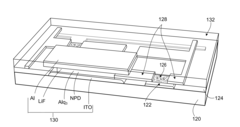

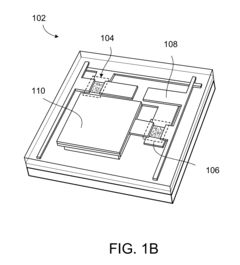

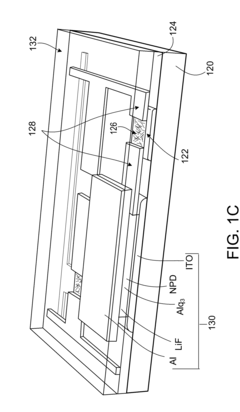

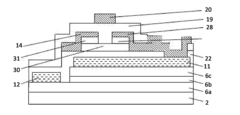

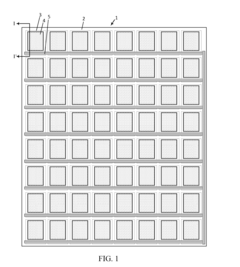

Separated Carbon Nanotube-Based Active Matrix Organic Light-Emitting Diode Displays

PatentInactiveUS20140070169A1

Innovation

- The use of separated semiconducting nanotubes as the active channel material in transistors, with a network of nanotubes disposed over a functionalized gate dielectric layer, and integrated into a display control circuit to drive OLED pixels, enabling high on/off ratios and current density.

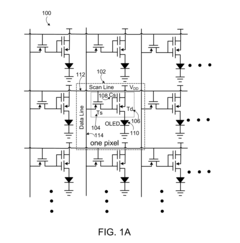

Active matrix light emitting diodes display module with carbon nanotubes control circuits and methods of fabrication

PatentActiveUS20160329378A1

Innovation

- Integration of single-walled carbon nanotubes (SWCNT) control circuits with light-emitting diode pixels using crystalline semiconductors, featuring N and P electrodes, SWCNT switching transistors, driving transistors, and charge storage capacitors, which are fabricated using a method involving forming a common source layer, insulation, SWCNT thin film, source/drain layers, and dielectric layers to enable efficient voltage application and light emission.

Environmental Impact

The integration of nanotube technology in AMOLED displays presents both environmental challenges and opportunities. Carbon nanotubes (CNTs) used in these displays offer potential improvements in energy efficiency, which could lead to reduced power consumption and longer device lifespans. This efficiency gain may result in decreased electronic waste and lower overall environmental impact throughout the product lifecycle.

However, the production of carbon nanotubes raises concerns about resource consumption and potential environmental contamination. The synthesis of CNTs often involves energy-intensive processes and the use of potentially hazardous chemicals. Proper handling and disposal of these materials are crucial to prevent environmental pollution. Additionally, the long-term effects of nanoparticles on ecosystems and human health are not yet fully understood, necessitating ongoing research and careful monitoring.

The durability and flexibility of CNT-enhanced AMOLED displays may contribute to the development of more robust and longer-lasting devices. This could potentially reduce the frequency of device replacements, thereby decreasing electronic waste generation. However, the complex nature of these advanced displays may pose challenges for recycling and end-of-life management, requiring the development of specialized recycling processes to recover and reuse valuable materials.

The adoption of nanotube technology in AMOLED displays also has implications for supply chain sustainability. The sourcing of raw materials for CNT production, such as graphite, may lead to increased mining activities and associated environmental impacts. Balancing the benefits of improved display performance against these potential environmental costs is a key consideration for manufacturers and policymakers.

As the technology matures, there is potential for more environmentally friendly production methods and materials to be developed. Research into green synthesis techniques for CNTs and the use of bio-based precursors could mitigate some of the environmental concerns associated with their production. Furthermore, advancements in nanomaterial design may lead to more efficient and less resource-intensive manufacturing processes, aligning with broader sustainability goals in the electronics industry.

However, the production of carbon nanotubes raises concerns about resource consumption and potential environmental contamination. The synthesis of CNTs often involves energy-intensive processes and the use of potentially hazardous chemicals. Proper handling and disposal of these materials are crucial to prevent environmental pollution. Additionally, the long-term effects of nanoparticles on ecosystems and human health are not yet fully understood, necessitating ongoing research and careful monitoring.

The durability and flexibility of CNT-enhanced AMOLED displays may contribute to the development of more robust and longer-lasting devices. This could potentially reduce the frequency of device replacements, thereby decreasing electronic waste generation. However, the complex nature of these advanced displays may pose challenges for recycling and end-of-life management, requiring the development of specialized recycling processes to recover and reuse valuable materials.

The adoption of nanotube technology in AMOLED displays also has implications for supply chain sustainability. The sourcing of raw materials for CNT production, such as graphite, may lead to increased mining activities and associated environmental impacts. Balancing the benefits of improved display performance against these potential environmental costs is a key consideration for manufacturers and policymakers.

As the technology matures, there is potential for more environmentally friendly production methods and materials to be developed. Research into green synthesis techniques for CNTs and the use of bio-based precursors could mitigate some of the environmental concerns associated with their production. Furthermore, advancements in nanomaterial design may lead to more efficient and less resource-intensive manufacturing processes, aligning with broader sustainability goals in the electronics industry.

Nanotube Display Standards

Nanotube display standards are crucial for ensuring consistency and quality in the implementation of carbon nanotube technology in AMOLED displays. These standards encompass various aspects of nanotube-based display manufacturing, performance metrics, and quality control measures.

The primary focus of nanotube display standards is on the structural and electrical properties of carbon nanotubes used in display fabrication. Specifications typically include nanotube length, diameter, chirality, and purity levels. These parameters directly influence the performance characteristics of AMOLED displays, such as brightness, contrast ratio, and power efficiency.

Standards also address the integration of carbon nanotubes into display components, particularly in the creation of transparent conductive films. Guidelines for nanotube dispersion, deposition techniques, and post-processing methods are essential to achieve uniform and stable nanotube networks. These standards ensure reproducibility and scalability in manufacturing processes.

Performance benchmarks form another critical aspect of nanotube display standards. These include metrics for transparency, conductivity, and flexibility of nanotube-based electrodes. Standardized testing procedures are established to evaluate these properties, allowing for consistent comparison across different manufacturers and technologies.

Durability and reliability standards are particularly important for AMOLED displays utilizing nanotube technology. These standards define acceptable levels of performance degradation over time, resistance to environmental factors, and overall lifespan expectations. Accelerated aging tests and stress simulations are standardized to assess long-term stability and reliability.

Environmental and safety considerations are also addressed in nanotube display standards. Guidelines for handling and disposal of nanomaterials, as well as potential health and environmental impacts, are outlined to ensure responsible manufacturing practices.

Interoperability standards play a crucial role in the broader adoption of nanotube-based AMOLED displays. These standards define protocols for interfacing nanotube displays with existing display drivers and control systems, ensuring compatibility with a wide range of electronic devices.

As nanotube technology in AMOLED displays continues to evolve, standards organizations work closely with industry leaders and research institutions to update and refine these standards. This ongoing collaboration ensures that nanotube display standards remain relevant and supportive of technological advancements in the field.

The primary focus of nanotube display standards is on the structural and electrical properties of carbon nanotubes used in display fabrication. Specifications typically include nanotube length, diameter, chirality, and purity levels. These parameters directly influence the performance characteristics of AMOLED displays, such as brightness, contrast ratio, and power efficiency.

Standards also address the integration of carbon nanotubes into display components, particularly in the creation of transparent conductive films. Guidelines for nanotube dispersion, deposition techniques, and post-processing methods are essential to achieve uniform and stable nanotube networks. These standards ensure reproducibility and scalability in manufacturing processes.

Performance benchmarks form another critical aspect of nanotube display standards. These include metrics for transparency, conductivity, and flexibility of nanotube-based electrodes. Standardized testing procedures are established to evaluate these properties, allowing for consistent comparison across different manufacturers and technologies.

Durability and reliability standards are particularly important for AMOLED displays utilizing nanotube technology. These standards define acceptable levels of performance degradation over time, resistance to environmental factors, and overall lifespan expectations. Accelerated aging tests and stress simulations are standardized to assess long-term stability and reliability.

Environmental and safety considerations are also addressed in nanotube display standards. Guidelines for handling and disposal of nanomaterials, as well as potential health and environmental impacts, are outlined to ensure responsible manufacturing practices.

Interoperability standards play a crucial role in the broader adoption of nanotube-based AMOLED displays. These standards define protocols for interfacing nanotube displays with existing display drivers and control systems, ensuring compatibility with a wide range of electronic devices.

As nanotube technology in AMOLED displays continues to evolve, standards organizations work closely with industry leaders and research institutions to update and refine these standards. This ongoing collaboration ensures that nanotube display standards remain relevant and supportive of technological advancements in the field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!