Manufacturing challenges in large AMOLED foldable displays.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Foldable Display Evolution and Objectives

AMOLED (Active-Matrix Organic Light-Emitting Diode) technology has revolutionized the display industry, offering superior image quality, energy efficiency, and flexibility. The evolution of AMOLED displays has been marked by continuous improvements in manufacturing processes, materials, and design techniques. From small smartphone screens to large television panels, AMOLED technology has expanded its reach across various consumer electronics segments.

The concept of foldable displays emerged as a natural progression in the quest for more versatile and compact devices. AMOLED's inherent flexibility made it an ideal candidate for this application. The journey of foldable AMOLED displays began with prototypes and concept devices, gradually evolving into commercially viable products. Early challenges included issues with durability, visible creases, and limited folding cycles.

As the technology matured, manufacturers focused on addressing these challenges, leading to significant advancements in flexible substrate materials, thin-film encapsulation techniques, and robust folding mechanisms. The introduction of ultra-thin glass (UTG) as a cover material marked a significant milestone, offering improved scratch resistance and a more premium feel compared to plastic alternatives.

The primary objectives in the development of large AMOLED foldable displays include enhancing durability, minimizing the visible crease, increasing the number of folding cycles, and improving overall display performance. Manufacturers aim to create displays that can withstand hundreds of thousands of folds without degradation in image quality or structural integrity. Another key goal is to reduce the thickness of the display stack while maintaining or improving its robustness.

Achieving uniform brightness and color accuracy across the entire folding surface presents a unique challenge, especially at the folding area. Engineers are working on advanced pixel compensation techniques and optimized OLED materials to ensure consistent performance regardless of the display's folded state. Additionally, there is a focus on developing more efficient manufacturing processes to increase yield rates and reduce production costs, making foldable AMOLED displays more accessible to a broader market.

Looking ahead, the industry is exploring new form factors beyond the current inward and outward folding designs. Concepts such as rollable and stretchable displays are being researched, potentially opening up new applications and use cases. The ultimate objective is to create displays that can seamlessly adapt to various form factors while maintaining the high image quality and energy efficiency that AMOLED technology is known for.

The concept of foldable displays emerged as a natural progression in the quest for more versatile and compact devices. AMOLED's inherent flexibility made it an ideal candidate for this application. The journey of foldable AMOLED displays began with prototypes and concept devices, gradually evolving into commercially viable products. Early challenges included issues with durability, visible creases, and limited folding cycles.

As the technology matured, manufacturers focused on addressing these challenges, leading to significant advancements in flexible substrate materials, thin-film encapsulation techniques, and robust folding mechanisms. The introduction of ultra-thin glass (UTG) as a cover material marked a significant milestone, offering improved scratch resistance and a more premium feel compared to plastic alternatives.

The primary objectives in the development of large AMOLED foldable displays include enhancing durability, minimizing the visible crease, increasing the number of folding cycles, and improving overall display performance. Manufacturers aim to create displays that can withstand hundreds of thousands of folds without degradation in image quality or structural integrity. Another key goal is to reduce the thickness of the display stack while maintaining or improving its robustness.

Achieving uniform brightness and color accuracy across the entire folding surface presents a unique challenge, especially at the folding area. Engineers are working on advanced pixel compensation techniques and optimized OLED materials to ensure consistent performance regardless of the display's folded state. Additionally, there is a focus on developing more efficient manufacturing processes to increase yield rates and reduce production costs, making foldable AMOLED displays more accessible to a broader market.

Looking ahead, the industry is exploring new form factors beyond the current inward and outward folding designs. Concepts such as rollable and stretchable displays are being researched, potentially opening up new applications and use cases. The ultimate objective is to create displays that can seamlessly adapt to various form factors while maintaining the high image quality and energy efficiency that AMOLED technology is known for.

Market Demand for Large Foldable Screens

The market demand for large foldable screens has been steadily increasing in recent years, driven by consumer desire for more versatile and immersive mobile experiences. This trend is particularly evident in the smartphone and tablet sectors, where foldable displays offer a unique combination of portability and expanded screen real estate.

In the smartphone market, foldable devices have carved out a growing niche. Major manufacturers like Samsung, Huawei, and Motorola have introduced foldable models, catering to users who seek larger displays without compromising on pocket-friendliness. These devices typically unfold to provide tablet-like screen sizes, enhancing productivity and entertainment capabilities.

The tablet market has also shown interest in foldable technology, with potential for devices that can transform from compact tablets to laptop-sized screens. This versatility appeals to professionals and creatives who require larger displays for work but value portability.

Beyond mobile devices, there is emerging demand in other sectors. The automotive industry is exploring foldable displays for dashboard interfaces and entertainment systems, offering enhanced functionality and aesthetics. Similarly, the gaming industry sees potential in portable consoles with foldable screens, providing immersive gaming experiences on the go.

Consumer electronics retailers report growing interest in foldable devices, particularly among tech enthusiasts and early adopters. While initial adoption was limited due to high costs and durability concerns, improvements in technology and manufacturing processes are gradually addressing these issues, broadening market appeal.

Market research indicates that the foldable display market is poised for significant growth. Factors driving this growth include technological advancements, increasing consumer acceptance, and expanding applications across various industries. However, challenges remain, including high production costs, yield issues in manufacturing large AMOLED foldable displays, and the need for more robust folding mechanisms.

Despite these challenges, industry analysts project continued market expansion. The unique value proposition of foldable displays – combining compact form factors with large screen experiences – positions them as a potentially disruptive technology in the display market. As manufacturing processes improve and costs decrease, foldable displays are expected to penetrate more mainstream consumer segments, further driving demand and market growth.

In the smartphone market, foldable devices have carved out a growing niche. Major manufacturers like Samsung, Huawei, and Motorola have introduced foldable models, catering to users who seek larger displays without compromising on pocket-friendliness. These devices typically unfold to provide tablet-like screen sizes, enhancing productivity and entertainment capabilities.

The tablet market has also shown interest in foldable technology, with potential for devices that can transform from compact tablets to laptop-sized screens. This versatility appeals to professionals and creatives who require larger displays for work but value portability.

Beyond mobile devices, there is emerging demand in other sectors. The automotive industry is exploring foldable displays for dashboard interfaces and entertainment systems, offering enhanced functionality and aesthetics. Similarly, the gaming industry sees potential in portable consoles with foldable screens, providing immersive gaming experiences on the go.

Consumer electronics retailers report growing interest in foldable devices, particularly among tech enthusiasts and early adopters. While initial adoption was limited due to high costs and durability concerns, improvements in technology and manufacturing processes are gradually addressing these issues, broadening market appeal.

Market research indicates that the foldable display market is poised for significant growth. Factors driving this growth include technological advancements, increasing consumer acceptance, and expanding applications across various industries. However, challenges remain, including high production costs, yield issues in manufacturing large AMOLED foldable displays, and the need for more robust folding mechanisms.

Despite these challenges, industry analysts project continued market expansion. The unique value proposition of foldable displays – combining compact form factors with large screen experiences – positions them as a potentially disruptive technology in the display market. As manufacturing processes improve and costs decrease, foldable displays are expected to penetrate more mainstream consumer segments, further driving demand and market growth.

Technical Hurdles in AMOLED Foldable Production

The production of large AMOLED foldable displays presents several significant technical challenges that manufacturers must overcome. One of the primary hurdles is the development of flexible substrates that can withstand repeated folding and unfolding without degradation. Traditional glass substrates are not suitable for this application, necessitating the use of advanced materials such as polyimide films. These films must maintain their flexibility while also providing adequate protection for the delicate OLED components.

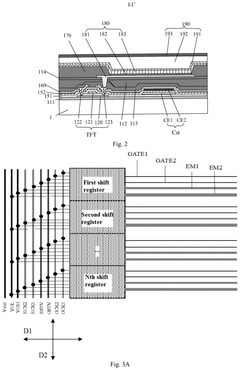

Another major challenge lies in the design and fabrication of the thin-film transistor (TFT) backplane. The TFT layer must be able to flex without losing its electrical properties or developing defects. This requires innovative approaches to materials science and circuit design, including the use of low-temperature polycrystalline silicon (LTPS) or oxide TFTs that can maintain performance under mechanical stress.

The OLED emissive layer itself poses unique difficulties in foldable displays. The organic materials used in OLEDs are sensitive to oxygen and moisture, which can lead to degradation and reduced lifespan. In foldable devices, the risk of environmental exposure is heightened due to the dynamic nature of the display. Manufacturers must develop advanced encapsulation techniques to protect the OLED materials, such as thin-film encapsulation (TFE) that can flex without compromising its barrier properties.

The folding mechanism introduces stress points that can lead to pixel defects and non-uniform brightness across the display. Engineers must design the display stack to distribute stress evenly and minimize localized strain. This often involves the use of neutral plane concepts and carefully engineered buffer layers to absorb mechanical stress.

Touch sensor integration presents another set of challenges. Traditional indium tin oxide (ITO) touch sensors are too brittle for foldable displays. Alternative materials like silver nanowires or metal mesh structures are being explored, but these must be optimized for transparency, conductivity, and flexibility simultaneously.

Lastly, the manufacturing process itself requires significant adaptation. The production of foldable displays demands extremely precise alignment and handling of ultra-thin materials. New equipment and processes must be developed to handle these delicate components without introducing defects. This includes specialized bonding techniques for flexible substrates and novel approaches to quality control that can detect issues unique to foldable displays.

Overcoming these technical hurdles requires a multidisciplinary approach, combining advances in materials science, electrical engineering, and manufacturing processes. As the industry continues to innovate, we can expect to see gradual improvements in the quality, durability, and production efficiency of large AMOLED foldable displays.

Another major challenge lies in the design and fabrication of the thin-film transistor (TFT) backplane. The TFT layer must be able to flex without losing its electrical properties or developing defects. This requires innovative approaches to materials science and circuit design, including the use of low-temperature polycrystalline silicon (LTPS) or oxide TFTs that can maintain performance under mechanical stress.

The OLED emissive layer itself poses unique difficulties in foldable displays. The organic materials used in OLEDs are sensitive to oxygen and moisture, which can lead to degradation and reduced lifespan. In foldable devices, the risk of environmental exposure is heightened due to the dynamic nature of the display. Manufacturers must develop advanced encapsulation techniques to protect the OLED materials, such as thin-film encapsulation (TFE) that can flex without compromising its barrier properties.

The folding mechanism introduces stress points that can lead to pixel defects and non-uniform brightness across the display. Engineers must design the display stack to distribute stress evenly and minimize localized strain. This often involves the use of neutral plane concepts and carefully engineered buffer layers to absorb mechanical stress.

Touch sensor integration presents another set of challenges. Traditional indium tin oxide (ITO) touch sensors are too brittle for foldable displays. Alternative materials like silver nanowires or metal mesh structures are being explored, but these must be optimized for transparency, conductivity, and flexibility simultaneously.

Lastly, the manufacturing process itself requires significant adaptation. The production of foldable displays demands extremely precise alignment and handling of ultra-thin materials. New equipment and processes must be developed to handle these delicate components without introducing defects. This includes specialized bonding techniques for flexible substrates and novel approaches to quality control that can detect issues unique to foldable displays.

Overcoming these technical hurdles requires a multidisciplinary approach, combining advances in materials science, electrical engineering, and manufacturing processes. As the industry continues to innovate, we can expect to see gradual improvements in the quality, durability, and production efficiency of large AMOLED foldable displays.

Current Manufacturing Techniques for Foldables

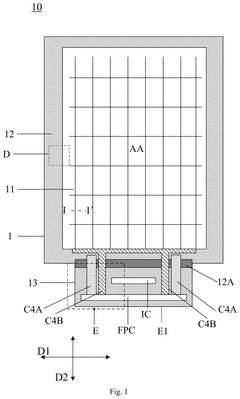

01 Flexible AMOLED display structure

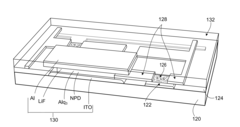

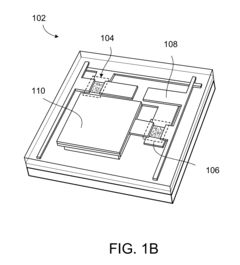

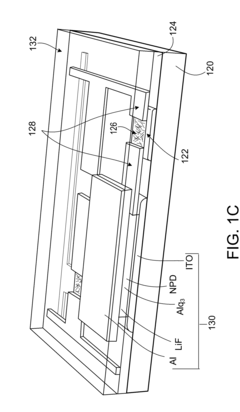

Foldable AMOLED displays incorporate flexible substrates and specialized layers to enable bending without damage. These structures often include a flexible OLED panel, a thin-film encapsulation layer, and a flexible cover window to protect the display while allowing folding.- Flexible AMOLED display structure: Foldable AMOLED displays incorporate flexible substrates and specialized layering techniques to enable bending without damage. This includes the use of thin-film transistors (TFTs) on flexible materials and protective layers to prevent stress-induced failures during folding and unfolding operations.

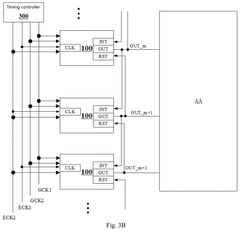

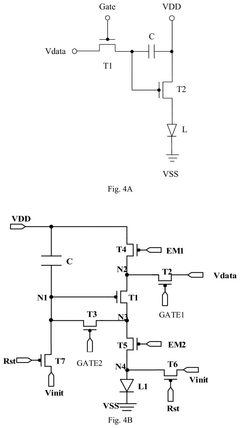

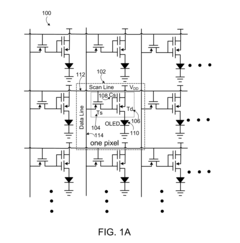

- Pixel circuit design for foldable displays: Advanced pixel circuit designs are crucial for maintaining image quality in foldable AMOLED displays. These circuits compensate for potential variations in electrical characteristics caused by bending and ensure uniform brightness and color across the folded and unfolded states of the display.

- Folding mechanism and hinge design: The folding mechanism and hinge design are critical components of foldable AMOLED displays. These elements must allow for smooth folding while protecting the display from damage and maintaining proper alignment. Advanced hinge designs can also incorporate features to reduce stress on the display during folding operations.

- Touch sensor integration in foldable displays: Integrating touch sensors into foldable AMOLED displays presents unique challenges. Specialized designs and materials are used to ensure touch functionality remains accurate and responsive across the entire display surface, even when folded. This may include the use of flexible touch sensors or novel integration techniques.

- Display driver optimization for foldable screens: Display drivers for foldable AMOLED screens require optimization to handle the unique requirements of these displays. This includes managing different display configurations in folded and unfolded states, adjusting refresh rates and power consumption, and ensuring seamless transitions between display modes.

02 Folding mechanism and hinge design

The folding mechanism and hinge design are crucial for AMOLED foldable displays. These components allow for smooth folding and unfolding while protecting the display from stress and damage. Advanced hinge designs may incorporate features to minimize creasing and extend the lifespan of the display.Expand Specific Solutions03 Display driver and control circuitry

Specialized display drivers and control circuitry are developed to manage the unique requirements of foldable AMOLED displays. These components handle image processing, refresh rates, and power management across different folding states and screen configurations.Expand Specific Solutions04 Touch sensing and user interface

Foldable AMOLED displays incorporate advanced touch sensing technologies to maintain responsiveness across different folding states. User interface designs are adapted to optimize the user experience for various form factors, including fully unfolded, partially folded, and folded configurations.Expand Specific Solutions05 Durability and reliability enhancements

To improve the longevity of foldable AMOLED displays, various techniques are employed to enhance durability and reliability. These may include specialized materials, stress-relief layers, and protective films to prevent damage from repeated folding and environmental factors.Expand Specific Solutions

Key AMOLED Foldable Display Manufacturers

The manufacturing of large AMOLED foldable displays is currently in a nascent stage, with the market poised for significant growth as consumer demand for flexible devices increases. The global foldable display market is projected to expand rapidly, driven by innovations in smartphone and tablet designs. Technologically, the field is still evolving, with companies like Samsung Electronics, BOE Technology, and LG Electronics leading the charge. These firms are investing heavily in R&D to overcome challenges such as durability, yield rates, and cost-effectiveness. While Samsung has a head start in commercialization, other players like China Star Optoelectronics and Everdisplay Optronics are quickly catching up, intensifying competition in this high-potential sector.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced manufacturing techniques for large AMOLED foldable displays, including their proprietary flexible OLED technology. They utilize a low-temperature polycrystalline oxide (LTPO) backplane technology, which allows for variable refresh rates and improved power efficiency[1]. BOE has also implemented an advanced vapor deposition process for organic materials, ensuring uniform layer thickness across large display areas[2]. To address the challenges of folding stress, they've developed a multi-layer buffer structure that enhances the flexibility and durability of the display[3]. BOE's production lines are equipped with high-precision laser cutting tools to achieve precise edge finishing for foldable displays, minimizing edge defects and improving yield rates[4].

Strengths: Advanced LTPO backplane technology, proprietary vapor deposition process, and multi-layer buffer structure for enhanced durability. Weaknesses: Relatively new to the foldable display market compared to some competitors, potentially leading to lower initial yield rates.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered large AMOLED foldable displays with their Ultra-Thin Glass (UTG) technology, which provides enhanced durability and a premium feel[5]. They employ a sophisticated multi-layer structure, including a polymer layer beneath the UTG for added flexibility. Samsung's manufacturing process involves advanced laser cutting techniques for precise panel shaping and a proprietary folding mechanism design that minimizes stress on the display when folded[6]. To address color shift and brightness uniformity issues in large foldable displays, Samsung has developed an AI-driven compensation algorithm that adjusts pixel values in real-time[7]. Their production lines feature highly automated processes and in-line quality control systems to maintain consistency across large display areas[8].

Strengths: Industry-leading UTG technology, advanced multi-layer structure, and AI-driven display optimization. Weaknesses: High production costs and potential supply chain dependencies for specialized materials.

Innovative Solutions in Foldable AMOLED Production

Display substrate, manufacturing method thereof, and display apparatus

PatentPendingUS20250022422A1

Innovation

- The display substrate design includes a bendable extension part with a conductive structure featuring a lower and upper part stacked perpendicular to the substrate, where the upper part acts as a protection layer, simplifying the manufacturing process by eliminating the need for additional protection layers and allowing for direct contact with the lower part, thereby reducing resistance and enhancing signal transmission.

Separated Carbon Nanotube-Based Active Matrix Organic Light-Emitting Diode Displays

PatentInactiveUS20140070169A1

Innovation

- The use of separated semiconducting nanotubes as the active channel material in transistors, with a network of nanotubes disposed over a functionalized gate dielectric layer, and integrated into a display control circuit to drive OLED pixels, enabling high on/off ratios and current density.

Supply Chain Dynamics for Foldable Components

The supply chain for foldable AMOLED displays is complex and dynamic, involving multiple specialized components and manufacturing processes. Key components include flexible substrates, thin-film transistors (TFTs), organic light-emitting materials, and protective layers. The production of these components requires advanced technologies and precision manufacturing capabilities, which are currently concentrated among a limited number of suppliers.

Flexible substrate production, a critical element in foldable displays, is dominated by a few key players such as Kolon Industries and SK IE Technology. These companies have invested heavily in developing ultra-thin polyimide films that can withstand repeated folding without degradation. The limited number of suppliers capable of producing high-quality flexible substrates at scale creates potential bottlenecks in the supply chain.

TFT production for foldable displays presents unique challenges, as traditional silicon-based TFTs are too rigid. Low-temperature polycrystalline silicon (LTPS) and oxide TFT technologies have emerged as viable alternatives, with companies like LG Display and Samsung Display leading the development. However, the yield rates for these advanced TFTs remain lower than those for conventional displays, impacting overall production capacity and costs.

The organic light-emitting materials used in AMOLED displays are supplied by specialized chemical companies such as Universal Display Corporation and Idemitsu Kosan. These materials are crucial for display performance and longevity, particularly in foldable devices where stress on the materials is heightened. The development and production of new, more durable OLED materials tailored for foldable displays is ongoing, with potential to reshape supplier relationships in the future.

Protective layers, including ultra-thin glass and advanced polymer films, are essential for safeguarding the delicate OLED components in foldable displays. Corning and Schott have made significant strides in ultra-thin glass technology, while companies like 3M and Sumitomo Chemical are advancing polymer-based solutions. The integration of these protective layers adds complexity to the manufacturing process and requires close collaboration between display manufacturers and material suppliers.

The geographical concentration of the foldable display supply chain in East Asia, particularly South Korea and China, introduces potential vulnerabilities to regional disruptions. Efforts to diversify the supply chain and establish production capabilities in other regions are underway but face significant technological and economic barriers.

As the demand for foldable displays grows, the supply chain is evolving to meet new challenges. Vertical integration strategies are being pursued by some major display manufacturers to secure key component supplies and reduce dependencies. Additionally, collaborative research and development efforts between display makers, material suppliers, and equipment manufacturers are intensifying to address technical challenges and improve production efficiencies across the supply chain.

Flexible substrate production, a critical element in foldable displays, is dominated by a few key players such as Kolon Industries and SK IE Technology. These companies have invested heavily in developing ultra-thin polyimide films that can withstand repeated folding without degradation. The limited number of suppliers capable of producing high-quality flexible substrates at scale creates potential bottlenecks in the supply chain.

TFT production for foldable displays presents unique challenges, as traditional silicon-based TFTs are too rigid. Low-temperature polycrystalline silicon (LTPS) and oxide TFT technologies have emerged as viable alternatives, with companies like LG Display and Samsung Display leading the development. However, the yield rates for these advanced TFTs remain lower than those for conventional displays, impacting overall production capacity and costs.

The organic light-emitting materials used in AMOLED displays are supplied by specialized chemical companies such as Universal Display Corporation and Idemitsu Kosan. These materials are crucial for display performance and longevity, particularly in foldable devices where stress on the materials is heightened. The development and production of new, more durable OLED materials tailored for foldable displays is ongoing, with potential to reshape supplier relationships in the future.

Protective layers, including ultra-thin glass and advanced polymer films, are essential for safeguarding the delicate OLED components in foldable displays. Corning and Schott have made significant strides in ultra-thin glass technology, while companies like 3M and Sumitomo Chemical are advancing polymer-based solutions. The integration of these protective layers adds complexity to the manufacturing process and requires close collaboration between display manufacturers and material suppliers.

The geographical concentration of the foldable display supply chain in East Asia, particularly South Korea and China, introduces potential vulnerabilities to regional disruptions. Efforts to diversify the supply chain and establish production capabilities in other regions are underway but face significant technological and economic barriers.

As the demand for foldable displays grows, the supply chain is evolving to meet new challenges. Vertical integration strategies are being pursued by some major display manufacturers to secure key component supplies and reduce dependencies. Additionally, collaborative research and development efforts between display makers, material suppliers, and equipment manufacturers are intensifying to address technical challenges and improve production efficiencies across the supply chain.

Environmental Impact of Foldable Display Production

The production of foldable displays, particularly large AMOLED foldable displays, presents significant environmental challenges that warrant careful consideration. The manufacturing process involves the use of various materials and chemicals, many of which have potential environmental impacts if not properly managed.

One of the primary concerns is the consumption of rare earth elements and precious metals required for the production of AMOLED displays. These materials are often mined in environmentally sensitive areas, leading to habitat destruction and potential contamination of local ecosystems. The extraction process itself is energy-intensive and can result in substantial greenhouse gas emissions.

The production of flexible substrates, a key component of foldable displays, often involves the use of plastics and polymers. These materials are typically derived from fossil fuels and are not biodegradable, contributing to long-term environmental pollution. Additionally, the chemical processes used to create these flexible substrates may generate hazardous waste that requires specialized disposal methods.

Water usage is another critical environmental factor in the production of foldable displays. The manufacturing process requires large volumes of ultra-pure water for cleaning and etching. This not only puts strain on local water resources but also generates wastewater that may contain trace amounts of chemicals and metals, necessitating extensive treatment before release.

Energy consumption during the production of foldable displays is substantial, contributing to the overall carbon footprint of the devices. The high-precision manufacturing processes, clean room environments, and specialized equipment all require significant amounts of electricity, often sourced from fossil fuel-based power plants.

The use of organic light-emitting materials in AMOLED displays introduces additional environmental concerns. While these materials offer superior display quality and energy efficiency, their production and disposal can pose risks if not properly managed. Some of these organic compounds may be toxic or have unknown long-term environmental effects.

As the demand for foldable displays grows, the industry faces increasing pressure to address these environmental challenges. Manufacturers are exploring more sustainable production methods, including the use of recycled materials, implementation of closed-loop water systems, and investment in renewable energy sources for their facilities. Additionally, research into bio-based and biodegradable materials for flexible substrates shows promise for reducing the environmental impact of foldable display production in the future.

One of the primary concerns is the consumption of rare earth elements and precious metals required for the production of AMOLED displays. These materials are often mined in environmentally sensitive areas, leading to habitat destruction and potential contamination of local ecosystems. The extraction process itself is energy-intensive and can result in substantial greenhouse gas emissions.

The production of flexible substrates, a key component of foldable displays, often involves the use of plastics and polymers. These materials are typically derived from fossil fuels and are not biodegradable, contributing to long-term environmental pollution. Additionally, the chemical processes used to create these flexible substrates may generate hazardous waste that requires specialized disposal methods.

Water usage is another critical environmental factor in the production of foldable displays. The manufacturing process requires large volumes of ultra-pure water for cleaning and etching. This not only puts strain on local water resources but also generates wastewater that may contain trace amounts of chemicals and metals, necessitating extensive treatment before release.

Energy consumption during the production of foldable displays is substantial, contributing to the overall carbon footprint of the devices. The high-precision manufacturing processes, clean room environments, and specialized equipment all require significant amounts of electricity, often sourced from fossil fuel-based power plants.

The use of organic light-emitting materials in AMOLED displays introduces additional environmental concerns. While these materials offer superior display quality and energy efficiency, their production and disposal can pose risks if not properly managed. Some of these organic compounds may be toxic or have unknown long-term environmental effects.

As the demand for foldable displays grows, the industry faces increasing pressure to address these environmental challenges. Manufacturers are exploring more sustainable production methods, including the use of recycled materials, implementation of closed-loop water systems, and investment in renewable energy sources for their facilities. Additionally, research into bio-based and biodegradable materials for flexible substrates shows promise for reducing the environmental impact of foldable display production in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!